Power steering pump INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 542 of 2395

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................585

ECM Terminals and Reference Value .....................585

On Board Diagnosis Logic.......................................586

Possible Cause ........................................................586

DTC Confirmation Procedure ..................................586

Wiring Diagram ........................................................587

Diagnostic Procedure ..............................................588

DTC P1491 VACUUM CUT VALVE BYPASS

VALVE..........................................................................591

Description ...............................................................591

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................591

ECM Terminals and Reference Value .....................591

On Board Diagnosis Logic.......................................592

Possible Cause ........................................................592

DTC Confirmation Procedure ..................................592

Overall Function Check ...........................................593

Wiring Diagram ........................................................594

Diagnostic Procedure ..............................................595

DTC P1605 A/T DIAGNOSIS COMMUNICATION

LINE.............................................................................603

Component Description ...........................................603

On Board Diagnosis Logic.......................................603

Possible Cause ........................................................603

DTC Confirmation Procedure ..................................603

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................604

Component Description ...........................................604

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................604

ECM Terminals and Reference Value .....................604

On Board Diagnosis Logic.......................................604

Possible Cause ........................................................604

DTC Confirmation Procedure ..................................605

Overall Function Check ...........................................606

Wiring Diagram ........................................................607

Diagnostic Procedure ..............................................608

VARIABLE INDUCTION AIR CONTROL SYSTEM

(VIAS)...........................................................................610

Description ...............................................................610

ECM Terminals and Reference Value ..................... 611

Wiring Diagram ........................................................612

Diagnostic Procedure ..............................................613

INJECTOR...................................................................616

Component Description ...........................................616

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................616

ECM Terminals and Reference Value .....................616

Wiring Diagram ........................................................617Diagnostic Procedure ..............................................618

START SIGNAL...........................................................621

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................621

ECM Terminals and Reference Value .....................621

Wiring Diagram ........................................................622

Diagnostic Procedure ..............................................623

FUEL PUMP.................................................................625

System Description ..................................................625

Component Description ...........................................625

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................625

ECM Terminals and Reference Value .....................626

Wiring Diagram ........................................................627

Diagnostic Procedure ..............................................628

POWER STEERING OIL PRESSURE SWITCH.........634

Component Description ...........................................634

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................634

ECM Terminals and Reference Value .....................634

Wiring Diagram ........................................................635

Diagnostic Procedure ..............................................636

REFRIGERANT PRESSURE SENSOR......................639

Description ...............................................................639

ECM Terminals and Reference Value .....................639

Wiring Diagram ........................................................640

Diagnostic Procedure ..............................................641

ELECTRICAL LOAD SIGNAL.....................................643

ECM Terminals and Reference Value .....................643

Wiring Diagram ........................................................644

Diagnostic Procedure ..............................................645

MIL & DATA LINK CONNECTORS............................648

Wiring Diagram ........................................................648

SERVICE DATA AND SPECIFICATIONS (SDS).......649

Fuel Pressure Regulator..........................................649

Idle Speed and Ignition Timing ................................649

Mass Air Flow Sensor..............................................649

Engine Coolant Temperature Sensor ......................649

Heated Oxygen Sensor 1 Heater (Front) ................649

Fuel Pump ...............................................................649

IACV-AAC Valve ......................................................649

Injector .....................................................................649

Resistor ....................................................................649

Throttle Position Sensor ..........................................650

Calculated Load Value.............................................650

Intake Air Temperature Sensor ................................650

Heated Oxygen Sensor 2 Heater (Rear).................650

Crankshaft Position Sensor (REF) ..........................650

Fuel Tank Temperature Sensor ...............................650

Camshaft Position Sensor (PHASE) .......................650GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

EC-7

Page 562 of 2395

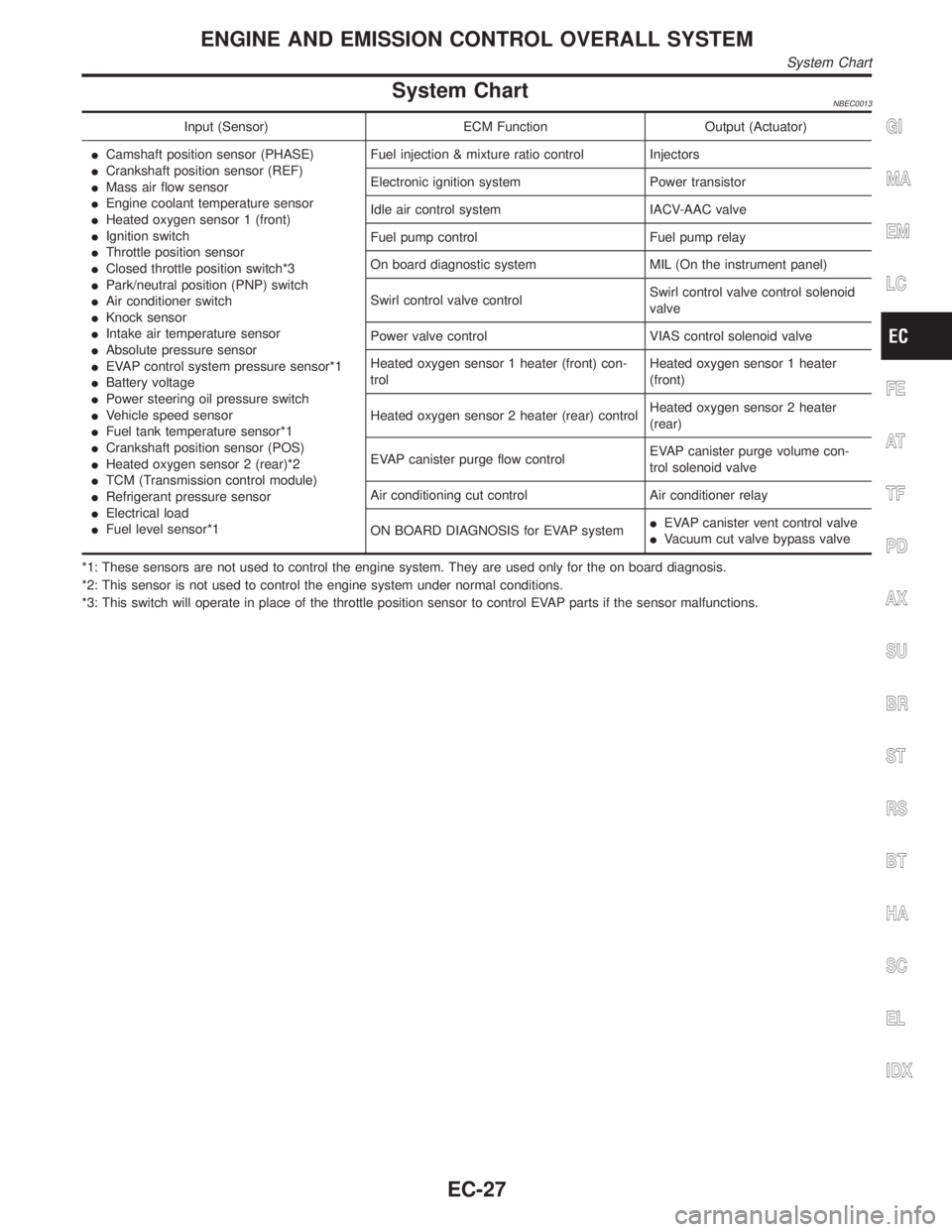

System ChartNBEC0013

Input (Sensor) ECM Function Output (Actuator)

ICamshaft position sensor (PHASE)

ICrankshaft position sensor (REF)

IMass air flow sensor

IEngine coolant temperature sensor

IHeated oxygen sensor 1 (front)

IIgnition switch

IThrottle position sensor

IClosed throttle position switch*3

IPark/neutral position (PNP) switch

IAir conditioner switch

IKnock sensor

IIntake air temperature sensor

IAbsolute pressure sensor

IEVAP control system pressure sensor*1

IBattery voltage

IPower steering oil pressure switch

IVehicle speed sensor

IFuel tank temperature sensor*1

ICrankshaft position sensor (POS)

IHeated oxygen sensor 2 (rear)*2

ITCM (Transmission control module)

IRefrigerant pressure sensor

IElectrical load

IFuel level sensor*1Fuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Fuel pump control Fuel pump relay

On board diagnostic system MIL (On the instrument panel)

Swirl control valve controlSwirl control valve control solenoid

valve

Power valve control VIAS control solenoid valve

Heated oxygen sensor 1 heater (front) con-

trolHeated oxygen sensor 1 heater

(front)

Heated oxygen sensor 2 heater (rear) controlHeated oxygen sensor 2 heater

(rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Air conditioning cut control Air conditioner relay

ON BOARD DIAGNOSIS for EVAP systemIEVAP canister vent control valve

IVacuum cut valve bypass valve

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: This sensor is not used to control the engine system under normal conditions.

*3: This switch will operate in place of the throttle position sensor to control EVAP parts if the sensor malfunctions.GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

System Chart

EC-27

Page 1407 of 2395

System DescriptionNBEL0216Refer to Owner's Manual for ASCD operating instructions.

POWER SUPPLY AND GROUNDNBEL0216S01Power is supplied at all times:

Ithrough 10A fuse [No. 14, located in the fuse block (J/B)]

Ito the stop lamp switch terminal 1, and

Ithrough 7.5A fuse (No. 52, located in fuse and fusible link box)

Ito the horn relay terminals 1 and 3.

When ignition switch is in the ON or START position, power is supplied:

Ithrough 7.5A fuse [No. 11, located in the fuse block (J/B)]

Ito ASCD brake switch terminal 1 and

Ito ASCD control unit terminal 5,

Ithrough 10A fuse [No. 18, located in the fuse block (J/B)]

Ito park/neutral position relay terminal 1,

Ithrough 10A fuse [No. 8, located in the fuse block (J/B)]

Ito combination meter terminal 66, and

When park/neutral position switch is in the P or N position, ground is supplied:

Ito park/neutral position relay terminal 2

Ithrough park/neutral position switch and body grounds B55 and B75.

When ASCD main switch is depressed (ON), ground is supplied:

Ito ASCD control unit terminal 9

Ifrom ASCD steering switch terminal 4

Ito ASCD steering switch terminal 5

Ithrough body grounds M4, M66 and M147

then ASCD control unit holds CRUISE condition and illuminates CRUISE indicator.

Ground is supplied:

Ifrom ASCD control unit terminal 15

Ito combination meter terminal 46.

OPERATIONNBEL0216S02Set OperationNBEL0216S0201To activate the ASCD, all following conditions must exist.

IGround supply to ASCD control unit terminal 9 (Main switch is in ON position.)

IPower supply to ASCD control unit terminal 8 (Brake pedal is released and A/T selector lever is in other

than P and N position.)

IVehicle speed is between 40 km/h (25 MPH) and 144 km/h (89 MPH). (Signal from combination meter)

When the SET/COAST switch is depressed, power is supplied:

Ifrom ASCD steering switch terminal 2

Ito ASCD control unit terminal 11.

And then ASCD pump is activated to control throttle wire and ASCD control unit supply ground

Ito combination meter terminals 51 to illuminate SET indicator.

A/T Overdrive Control during Cruise Control DrivingNBEL0216S0202When the vehicle speed is approximately 3 km/h (2 MPH) below set speed, a signal is sent

Ifrom ASCD control unit terminal 10

Ito TCM (transmission control module) terminal 24.

When this occurs, the TCM (transmission control module) cancels overdrive.

After vehicle speed is approximately 1 km/h (1 MPH) below set speed, overdrive is reactivated.

ASCD Shifting ControlNBEL0216S0203During ASCD cruise, ASCD control unit controls A/T shifting to avoid uncomfortable shifting.

This is used to control the signals below.

IThrottle position sensor from ECM

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System Description

EL-222

Page 1408 of 2395

IA/T shift solenoid valve A

Coast OperationNBEL0216S0204When the SET/COAST switch is depressed during cruise control driving, ASCD actuator returns the throttle

cable to decrease vehicle set speed until the switch is released. And then ASCD will keep the new set speed.

Accel OperationNBEL0216S0205When the RESUME/ACCEL switch is depressed, power is supplied

Ifrom ASCD steering switch terminal 3

Ito ASCD control unit terminal 24.

If the RESUME/ACCEL switch is depressed during cruise control driving, ASCD actuator pulls the throttle cable

to increase the vehicle speed until the switch is released or vehicle speed is reached to maximum controlled

speed by the system. And then ASCD will keep the new set speed.

Cancel OperationNBEL0216S0206When any of following condition exists, cruise operation will be canceled.

ICANCEL switch is depressed. (Power supply to ASCD control unit terminals 11 and 24)

IBrake pedal is depressed. (Power supply to ASCD control unit terminal 23 from stop lamp switch)

IBrake pedal is depressed or A/T selector lever is shifted to P or N position. (Power supply to ASCD con-

trol unit terminal 8 is interrupted.)

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operation will be canceled and vehicle

speed memory will be erased.

Resume OperationNBEL0216S0207When the RESUME/ACCEL switch is depressed after cancel operation other than depressing MAIN switch is

performed, vehicle speed will return to last set speed. To resume vehicle set speed, vehicle condition must

meet following conditions.

IBrake pedal is released.

IA/T selector lever is in other than P and N position.

IVehicle speed is between 40 km/h (25 MPH) and 144 km/h (89 MPH).

ASCD PUMP OPERATIONNBEL0216S03The ASCD pump consists of a vacuum motor, an air valve and a release valve. When the ASCD activates,

power is supplied

Ifrom terminal 12 of ASCD control unit

Ito ASCD pump terminal 1.

Ground is supplied to vacuum motor, air valve and release valve from ASCD control unit depending on the

operated condition as shown in the below table.

The pump is connected to ASCD actuator by vacuum hose. When the ASCD pump is activated, the ASCD

pump vacuum the diaphragm of ASCD actuator to control throttle cable.

Air valve (*1) Release valve (*1) Vacuum motorActuator inner pres-

sure

ASCD not operating Open Open Stopped Atmosphere

ASCD operatingReleasing throttle

cableOpen Closed Stopped Vacuum

Holding throttle

positionClosed Closed Stopped Vacuum (*2)

Pulling throttle cable Closed Closed Operated Vacuum

*1: When power and ground is supplied, valve is closed.

*2: Set position held.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System Description (Cont'd)

EL-223

Page 1415 of 2395

Trouble DiagnosesNBEL0218SYMPTOM CHARTNBEL0218S01

PROCEDURE Diagnostic procedure

REFERENCE PAGE (EL- ) 231 232 233 234 235 235 237

SYMPTOM

FAIL-SAFE SYSTEM CHECK

POWER SUPPLY AND GROUND CIRCUIT CHECK

ASCD BRAKE/STOP LAMP SWITCH CHECK

ASCD STEERING SWITCH CHECK

VEHICLE SPEED SENSOR CHECK

ASCD PUMP CIRCUIT CHECK

ASCD ACTUATOR/PUMP CHECK

ASCD cannot be set. (ªCRUISEº indica-

tor lamp does not ON.)XXH3

ASCD cannot be set. (ªSETº indicator

lamp does not blink.)XXX

ASCD cannot be set. (ªSETº indicator

lamp blinks.H1)X XXXX

Vehicle speed does not decrease after

SET/COAST switch has been pressed.XX

Vehicle speed does not return to the set

speed after RESUME/ACCEL switch has

been pressed.H2XX

Vehicle speed does not increase after

RESUME/ACCEL switch has been

pressed.XX

System is not released after CANCEL

switch (steering) has been pressed.XX

Large difference between set speed and

actual vehicle speed.XXX

Deceleration is greatest immediately

after ASCD has been set.XXX

H1: It indicates that system is in fail-safe. After completing diagnostic procedures, perform ªFAIL-SAFE SYSTEM CHECKº (EL-231) to

verify repairs.

H2: If vehicle speed is greater than 40 km/h (25 MPH) after system has been released, pressing RESUME/ACCEL switch returns vehicle

speed to the set speed previously achieved. However, doing so when the ASCD main switch is turned to ªOFFº, vehicle speed will not

return to the set speed since the memory is canceled.

H3: Check only main switch built-in steering switch.

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Trouble Diagnoses

EL-230

Page 1659 of 2395

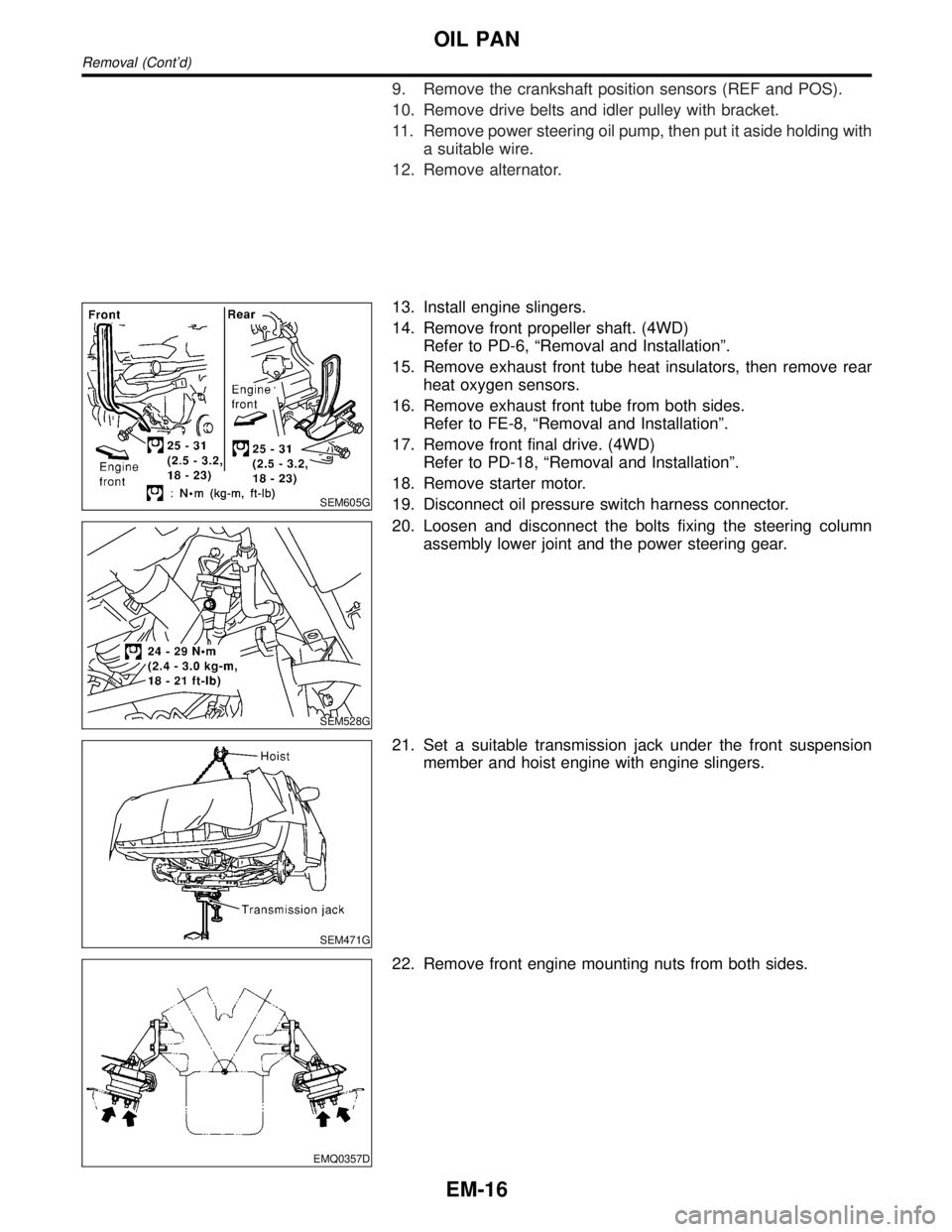

9. Remove the crankshaft position sensors (REF and POS).

10. Remove drive belts and idler pulley with bracket.

11. Remove power steering oil pump, then put it aside holding with

a suitable wire.

12. Remove alternator.

SEM605G

13. Install engine slingers.

14. Remove front propeller shaft. (4WD)

Refer to PD-6, ªRemoval and Installationº.

15. Remove exhaust front tube heat insulators, then remove rear

heat oxygen sensors.

16. Remove exhaust front tube from both sides.

Refer to FE-8, ªRemoval and Installationº.

17. Remove front final drive. (4WD)

Refer to PD-18, ªRemoval and Installationº.

18. Remove starter motor.

19. Disconnect oil pressure switch harness connector.

SEM528G

20. Loosen and disconnect the bolts fixing the steering column

assembly lower joint and the power steering gear.

SEM471G

21. Set a suitable transmission jack under the front suspension

member and hoist engine with engine slingers.

EMQ0357D

22. Remove front engine mounting nuts from both sides.

OIL PAN

Removal (Cont'd)

EM-16

Page 1666 of 2395

CAUTION:

IAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

IWhen installing camshafts, chain tensioners, oil seals, or

other sliding parts, lubricate contacting surfaces with new

engine oil.

IApply new engine oil to bolt threads and seat surfaces

when installing camshaft sprockets and crankshaft pulley.

IBefore disconnecting fuel hose, release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

IBe careful not to damage sensor edges.

IDo not spill engine coolant on drive belts.

RemovalNBEM00121. Release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

2. Remove battery.

3. Remove radiator.

Refer to LC-19, ªREMOVAL AND INSTALLATIONº.

4. Drain engine oil.

5. Remove drive belts and idler pulley with brackets.

6. Remove cooling fan with bracket.

7. Remove engine cover.

8. Remove air duct with air cleaner case, collector, blow-by hose,

vacuum hoses, fuel hoses, water hoses, wires, harnesses,

connectors and so on.

9. Remove the air compressor, and tie it down using rope or the

like to keep it from interfering.

10. Remove the power steering oil pump and reservoir tank. Tie

them down using rope or the like to keep them from interfer-

ing.

11. Remove alternator.

12. Remove the following.

IVacuum gallery

IWater bypass pipe

IBrackets

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Components (Cont'd)

EM-23

Page 1702 of 2395

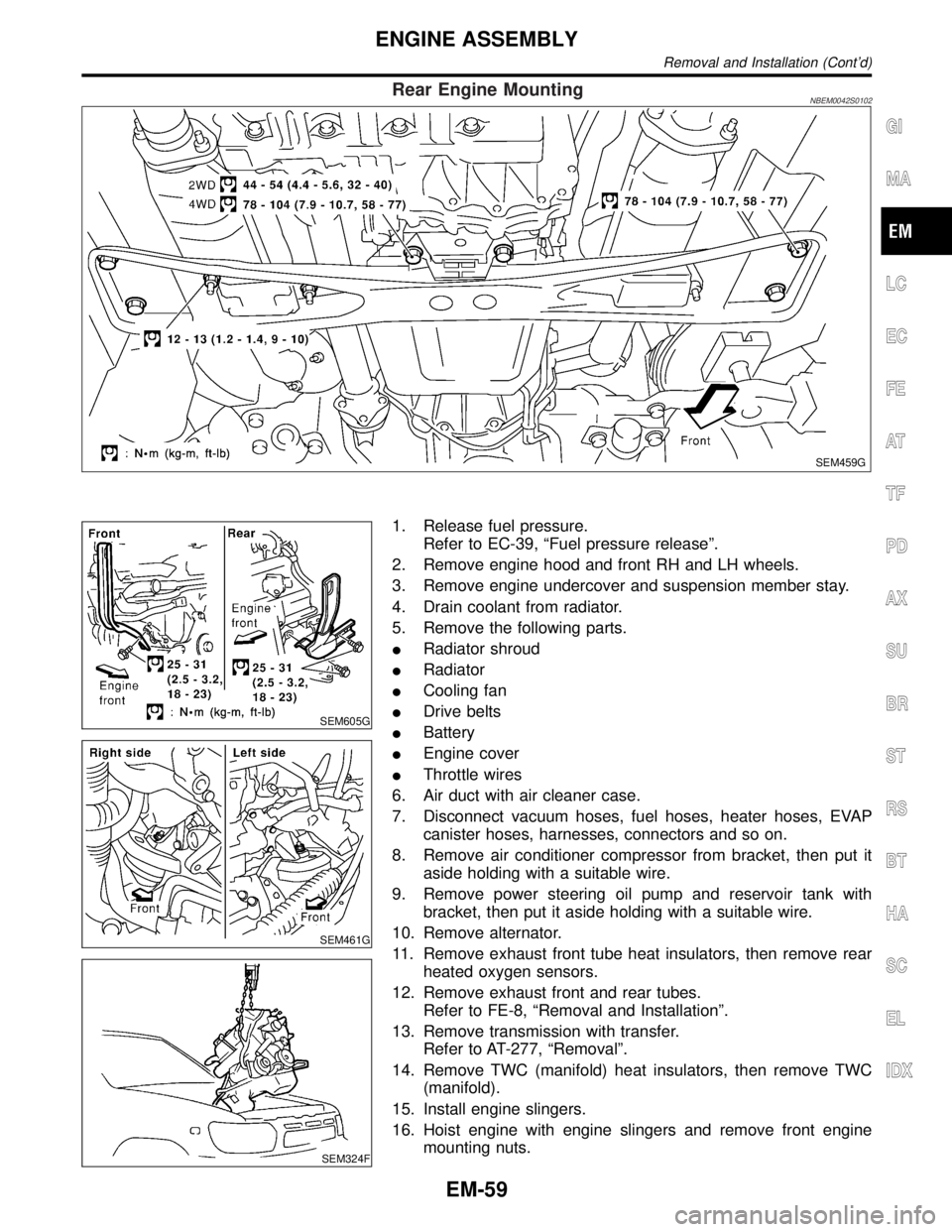

Rear Engine MountingNBEM0042S0102

SEM459G

SEM605G

SEM461G

SEM324F

1. Release fuel pressure.

Refer to EC-39, ªFuel pressure releaseº.

2. Remove engine hood and front RH and LH wheels.

3. Remove engine undercover and suspension member stay.

4. Drain coolant from radiator.

5. Remove the following parts.

IRadiator shroud

IRadiator

ICooling fan

IDrive belts

IBattery

IEngine cover

IThrottle wires

6. Air duct with air cleaner case.

7. Disconnect vacuum hoses, fuel hoses, heater hoses, EVAP

canister hoses, harnesses, connectors and so on.

8. Remove air conditioner compressor from bracket, then put it

aside holding with a suitable wire.

9. Remove power steering oil pump and reservoir tank with

bracket, then put it aside holding with a suitable wire.

10. Remove alternator.

11. Remove exhaust front tube heat insulators, then remove rear

heated oxygen sensors.

12. Remove exhaust front and rear tubes.

Refer to FE-8, ªRemoval and Installationº.

13. Remove transmission with transfer.

Refer to AT-277, ªRemovalº.

14. Remove TWC (manifold) heat insulators, then remove TWC

(manifold).

15. Install engine slingers.

16. Hoist engine with engine slingers and remove front engine

mounting nuts.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE ASSEMBLY

Removal and Installation (Cont'd)

EM-59

Page 1745 of 2395

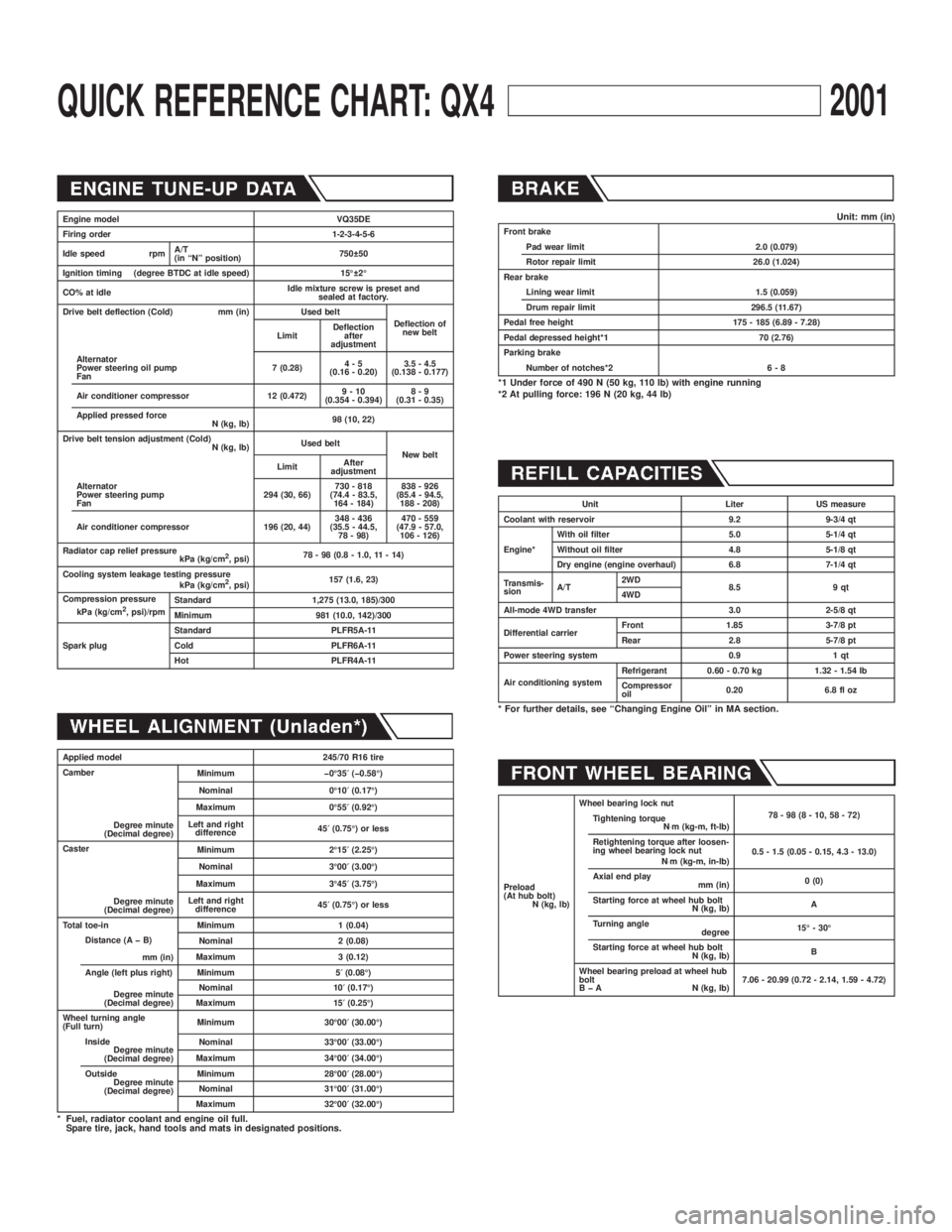

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)

Page 1965 of 2395

LSV (Load sensing valve) ..............................BR-12

Lubricant (R134a) A/C..................................HA-146

Lubricants .......................................................MA-11

Lubrication circuit (engine) ...............................LC-3

Lubrication-locks, hinges and hood

latches ........................................................MA-27

Luggage room lamp ........................................EL-88

M

MAFS - Wiring diagram................................EC-154

Magnet clutch .......................................HA-104, 150

MAIN - Wiring diagram.................................EC-142

Main oil pump (Transfer)...............................TF-131

Mainshaft (Transfer) ......................................TF-125

Maintenance (engine) ....................................MA-13

MAJOR OVERHALL......................................AT-281

Major overhaul (Transfer) .............................TF-120

Malfunction indicator lamp (MIL) ....................EC-74

Mass air flow sensor (MAFS) .......................EC-150

Master cylinder (brake) ..................................BR-16

Meter ...............................................................EL-94

METER - Wiring diagram................................EL-99

MIL & Data link connectors circuit ...............EC-648

MIL/DL - Wiring diagram ..............................EC-648

MIRROR - Wiring diagram............................EL-177

Mirror defogger .............................................EL-151

Mirror, door......................................................BT-56

Mirror, out side ................................................BT-56

Misfire ...........................................................EC-320

Mode door control linkage adjustment ...........HA-81

Mode door motor ............................................HA-75

Model variation ................................................GI-41

Molding - See Exterior ....................................BT-35

MULTI - Wiring diagram ................................EL-274

Multi-remote control system..........................EL-270

Multiplex communication ..............................HA-142

Multiport fuel injection (MFI) system ..............EC-28

Multiport fuel injection precautions ....................GI-6

N

NATS (Nissan anti-theft system)...................EL-328

NATS (Nissan anti-theft system)

precautions ....................................................GI-3

NATS - Wiring diagram .................................EL-330

NAVI - wiring diagram ...................................EL-394

Navigation System ........................................EL-385

Neutral-4LO switch ........................................TF-112

NVH troubleshooting (AX) ..........................AX-3, 18

NVH troubleshooting (BR)................................BR-6

NVH troubleshooting (PD)................................PD-3

NVH troubleshooting (ST).................................ST-6

NVH troubleshooting (SU) .........................SU-3, 15O

Oil change (capacity) .....................................MA-11

Oil filter (Transfer) .........................................TF-118

Oil pan (engine) .............................................EM-15

Oil pressure (engine) ........................................LC-4

Oil pump (A/T) ...............................................AT-297

Oil pump (engine) .............................................LC-5

Oil pump regulator valve (engine) ....................LC-6

Oil seal replacement (engine)........................EM-35

Oil seal replacement (front final drive

4WD) ...........................................................PD-15

Oil seal replacement (front of final

drive) ...........................................................PD-40

On board diagnostic system ..........................EC-59

Out side mirror ................................................BT-56

Overdrive control switch ................................AT-263

Overrun clutch ...............................................AT-320

Overrun clutch solenoid valve .......................AT-189

P

P/ANT - Wiring diagram ................................EL-170

Park/Neutral position switch .........................EC-604

Park/neutral position switch (A/T) .........AT-103, 263

Parking brake control .....................................BR-30

Parking lamp ...................................................EL-61

PCV (positive crankcase ventilation) .............EC-38

PGC/V - Wiring diagram ......................EC-370, 544

PHASE - Wiring diagram .............................EC-342

Pinion bearing preload diff. ............................PD-25

Pinion gear height diff. .............................PD-25, 53

Piston assembly .............................................EM-71

Piston pin inspection ......................................EM-63

Piston ring inspection.....................................EM-64

Piston to bore clearance ................................EM-66

Planetary carrier (Transfer) ...........................TF-134

PNP/SW - Wiring diagram ...........................EC-607

POS - Wiring diagram ..................................EC-517

POWER - Wiring diagram...............................EL-10

Power antenna ..............................................EL-169

Power door lock ............................................EL-254

Power door mirror .........................................EL-177

Power seat ....................................................EL-181

Power steering fluid level .....................MA-27, ST-8

Power steering gear........................................ST-17

Power steering hydraulic pressure .................ST-10

Power steering oil pressure switch ..............EC-634

Power steering oil pump .................................ST-27

Power steering system bleeding.......................ST-9

Power supply routing ........................................EL-9

Power transistor & ignition coil.....................EC-499

Power window ...............................................EL-241

PRE/SE - Wiring diagram ............................EC-384

Precations for Leak detection dye ...................HA-3

Precautions (General) .......................................GI-5

Pressure test (A/T) ..........................................AT-62

Propeller shaft ..................................................PD-3

ALPHABETICAL INDEX

IDX-6