engine oil INFINITI QX4 2001 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1052 of 2395

SEF977Y

Component DescriptionNBEC0292The crankshaft position sensor (POS) is located on the oil pan

facing the gear teeth (cogs) of the signal plate (flywheel). It detects

the crankshaft position signal (1É signal).

The sensor consists of a permanent magnet, core and coil.

When engine is running, the gap between the sensor and the gear

teeth (cogs) will periodically change. Permeability near the sensor

also changes.

Due to the permeability change, the magnetic flux near the core is

changed. Therefore, the voltage signal generated in the coil is

changed.

The ECM receives the voltage signal and detects the crankshaft

position signal (1É signal).

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0581Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPS´RPM (POS)ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

ENG SPEED

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1336 CRANKSHAFT POSITION SENSOR (CKPS) (POS) (COG)

Component Description

EC-517

Page 1146 of 2395

SEF018Z

COMPONENT DESCRIPTIONNBEC0596S02Power ValveNBEC0596S0201The power valve is installed in intake manifold collector and used

to control the suction passage of the variable induction air control

system. It is set in the fully closed or fully opened position by the

power valve actuator operated by the vacuum stored in the surge

tank. The vacuum in the surge tank is controlled by the VIAS con-

trol solenoid valve.

SEF019Z

VIAS Control Solenoid ValveNBEC0596S0202The VIAS control solenoid valve cuts the intake manifold vacuum

signal for power valve control. It responds to ON/OFF signals from

the ECM. When the solenoid is off, the vacuum signal from the

intake manifold is cut. When the ECM sends an ON signal the coil

pulls the plunger downward and feeds the vacuum signal to the

power valve actuator.

ECM Terminals and Reference ValueNBEC0684Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

16 Y/GVIAS control solenoid

valve[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IEngine speed is above 5,000 rpm.0 - 1.0V

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

VARIABLE INDUCTION AIR CONTROL SYSTEM (VIAS)

Description (Cont'd)

EC-611

Page 1151 of 2395

SEF375Z

Component DescriptionNBEC0383The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the injector circuit, the coil in the injector is

energized. The energized coil pulls the needle valve back and

allows fuel to flow through the injector into the intake manifold. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the injector remains open. The

ECM controls the injection pulse duration based on engine fuel

needs.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0384Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

INJ PULSE-B2

INJ PULSE-B1IEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 2.4 - 3.2 msec

2,000 rpm 1.9 - 2.8 msec

B/FUEL SCHDL dittoIdle 2.0 - 3.2 msec

2,000 rpm 1.4 - 2.6 msec

ECM Terminals and Reference ValueNBEC0685Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

101

102

103

104

105

107R/B

L/W

R/W

PU/R

R/Y

R/LInjector No. 1

Injector No. 5

Injector No. 2

Injector No. 6

Injector No. 3

Injector No. 4[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

INJECTOR

Component Description

EC-616

Page 1169 of 2395

SEF028Z

Component DescriptionNBEC0398The power steering oil pressure switch is attached to the power

steering high-pressure tube and detects a power steering load.

When a power steering load is detected, it signals the ECM. The

ECM adjusts the IACV-AAC valve to increase the idle speed and

adjust for the increased load.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0399Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

PW/ST SIGNALIEngine: After warming up, idle

the engineSteering wheel in neutral position

(forward direction)OFF

The steering wheel is fully turned. ON

ECM Terminals and Reference ValueNBEC0687Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

47 R/BPower steering oil

pressure switch[Engine is running]

ISteering wheel is being turned.0 - 1.0V

[Engine is running]

ISteering wheel is not being turned.Approximately 5V

POWER STEERING OIL PRESSURE SWITCH

Component Description

EC-634

Page 1171 of 2395

Diagnostic ProcedureNBEC0402

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Check ªPW/ST SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF228Y

OK or NG

OK©INSPECTION END

NG©GO TO 4.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Start engine.

2. Check voltage between ECM terminal 47 and ground under the following conditions.

SEF363X

OK or NG

OK©INSPECTION END

NG©GO TO 4.

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure

EC-636

Page 1172 of 2395

4 CHECK POWER STEERING OIL PRESSURE SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect power steering oil pressure switch harness connector.

SEF028Z

3. Check harness continuity between power steering oil pressure switch terminal 2 and engine ground. Refer to Wiring

Diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to power in harness or connectors.

5 CHECK POWER STEERING OIL PRESSURE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 47 and power steering oil pressure switch terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK POWER STEERING OIL PRESSURE SWITCH

1. Disconnect power steering oil pressure switch harness connector then start engine.

2. Check continuity between power steering oil pressure switch terminals 1 and 2 under the following conditions.

SEF364X

OK or NG

OK©GO TO 7.

NG©Replace power steering oil pressure switch.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure (Cont'd)

EC-637

Page 1259 of 2395

SEL350X

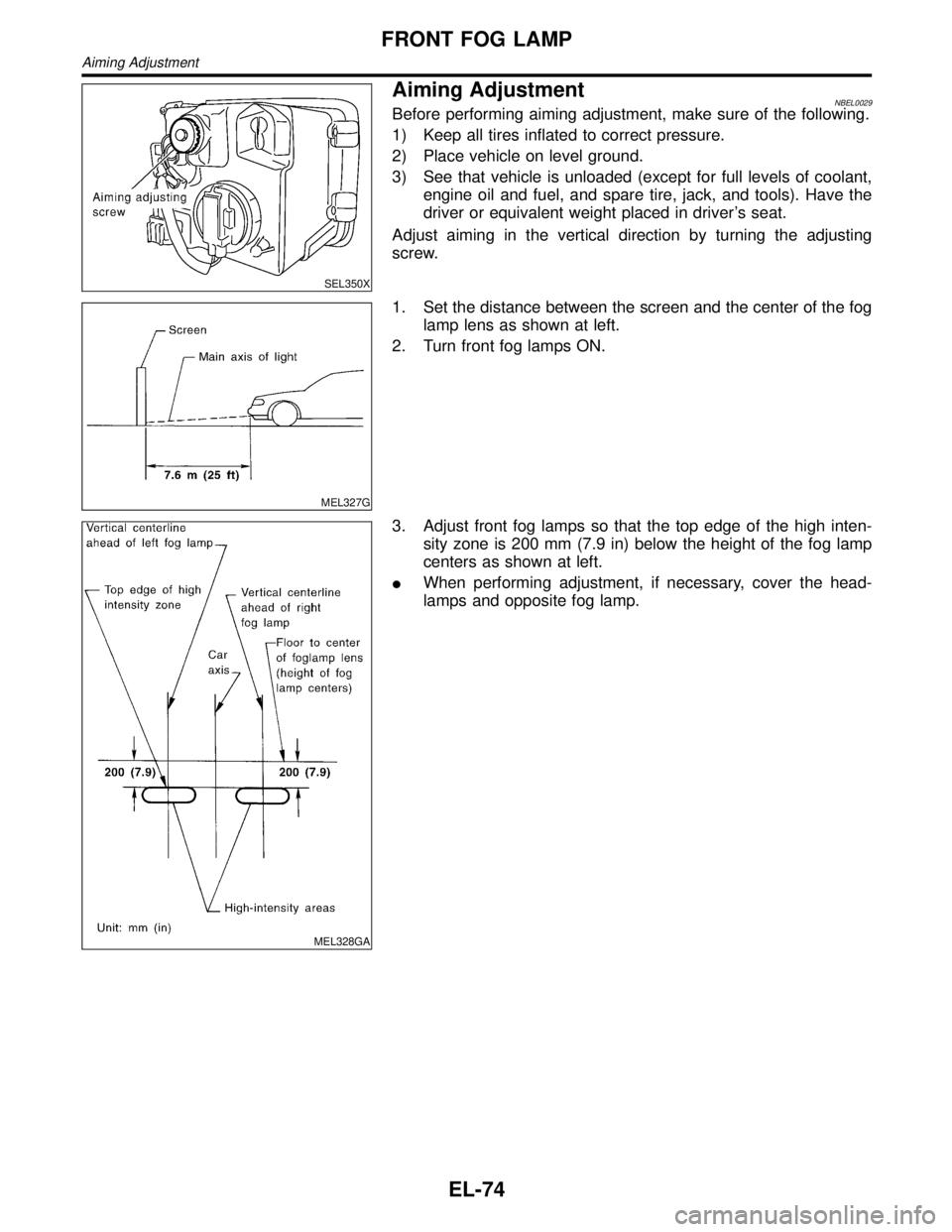

Aiming AdjustmentNBEL0029Before performing aiming adjustment, make sure of the following.

1) Keep all tires inflated to correct pressure.

2) Place vehicle on level ground.

3) See that vehicle is unloaded (except for full levels of coolant,

engine oil and fuel, and spare tire, jack, and tools). Have the

driver or equivalent weight placed in driver's seat.

Adjust aiming in the vertical direction by turning the adjusting

screw.

MEL327G

1. Set the distance between the screen and the center of the fog

lamp lens as shown at left.

2. Turn front fog lamps ON.

MEL328GA

3. Adjust front fog lamps so that the top edge of the high inten-

sity zone is 200 mm (7.9 in) below the height of the fog lamp

centers as shown at left.

IWhen performing adjustment, if necessary, cover the head-

lamps and opposite fog lamp.

FRONT FOG LAMP

Aiming Adjustment

EL-74

Page 1307 of 2395

SEL062WA

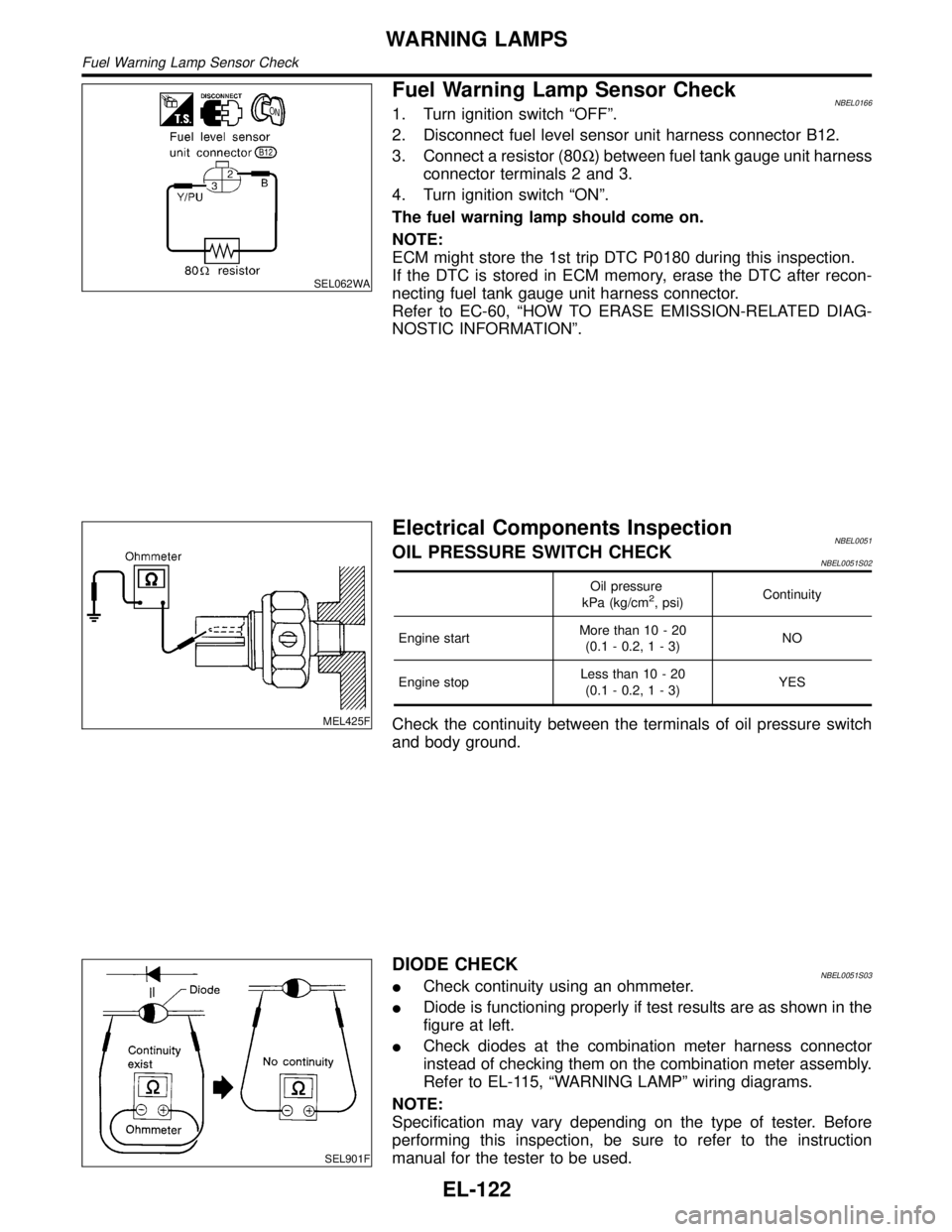

Fuel Warning Lamp Sensor CheckNBEL01661. Turn ignition switch ªOFFº.

2. Disconnect fuel level sensor unit harness connector B12.

3. Connect a resistor (80W) between fuel tank gauge unit harness

connector terminals 2 and 3.

4. Turn ignition switch ªONº.

The fuel warning lamp should come on.

NOTE:

ECM might store the 1st trip DTC P0180 during this inspection.

If the DTC is stored in ECM memory, erase the DTC after recon-

necting fuel tank gauge unit harness connector.

Refer to EC-60, ªHOW TO ERASE EMISSION-RELATED DIAG-

NOSTIC INFORMATIONº.

MEL425F

Electrical Components InspectionNBEL0051OIL PRESSURE SWITCH CHECKNBEL0051S02

Oil pressure

kPa (kg/cm2, psi)Continuity

Engine startMore than 10 - 20

(0.1-0.2,1-3)NO

Engine stopLess than 10 - 20

(0.1-0.2,1-3)YES

Check the continuity between the terminals of oil pressure switch

and body ground.

SEL901F

DIODE CHECKNBEL0051S03ICheck continuity using an ohmmeter.

IDiode is functioning properly if test results are as shown in the

figure at left.

ICheck diodes at the combination meter harness connector

instead of checking them on the combination meter assembly.

Refer to EL-115, ªWARNING LAMPº wiring diagrams.

NOTE:

Specification may vary depending on the type of tester. Before

performing this inspection, be sure to refer to the instruction

manual for the tester to be used.

WARNING LAMPS

Fuel Warning Lamp Sensor Check

EL-122

Page 1351 of 2395

Trouble DiagnosesNBEL0082AUDIO UNITNBEL0082S01

Symptom Possible causes Repair order

Audio unit inoperative (no

digital display and no

sound from speakers).1. 10A fuse

2. Poor audio unit case ground

3. Audio unit1. Check 10A fuse [No. 10, located in fuse block (J/B)].

Turn ignition switch ON and verify that battery posi-

tive voltage is present at terminal 10 of audio unit.

2. Check audio unit case ground.

3. Remove audio unit for repair.

Audio unit presets are lost

when ignition switch is

turned OFF.1. 15A fuse

2. Audio unit1. Check 15A fuse [No. 4, located in fuse block (J/B)]

and verify that battery positive voltage is present at

terminal 6 of audio unit.

2. Remove audio unit for repair.

AM stations are weak or

noisy (FM stations OK).1. Antenna

2. Poor audio unit ground

3. Audio unit1. Check antenna.

2. Check audio unit ground.

3. Remove audio unit for repair.

FM stations are weak or

noisy (AM stations OK).1. Window antenna

2. Audio unit1. Check window antenna.

2. Remove audio unit for repair.

Audio unit generates noise

in AM and FM modes with

engine running.1. Poor audio unit ground

2. Loose or missing ground bonding

straps

3. Ignition condenser or rear window

defogger noise suppressor condenser

4. Alternator

5. Ignition coil or secondary wiring

6. Audio unit1. Check audio unit ground.

2. Check ground bonding straps.

3. Replace ignition condenser or rear window defogger

noise suppressor condenser.

4. Check alternator.

5. Check ignition coil and secondary wiring.

6. Remove audio unit for repair.

Audio unit generates noise

in AM and FM modes with

accessories on (switch

pops and motor noise).1. Poor audio unit ground

2. Antenna

3. Accessory ground

4. Faulty accessory1. Check audio unit ground.

2. Check antenna.

3. Check accessory ground.

4. Replace accessory.

Audio unit controls are

operational, but no sound

is heard from any speaker.1. 15A fuse

2. Audio unit output

3. Audio unit1. Check 15A fuse [No. 4, located in fuse block (J/B)].

Verify battery positive voltage is present at terminal 3

of audio amp. relay.

2. Check audio unit output voltage (Terminal 12).

3. Remove audio unit for repair.

All front speakers are inop-

erative.1. Audio amp. relay

2. Audio amp. relay ground

3. Amp. ON signal1. Check audio amp. relay.

2. Check audio amp. relay ground (Terminal 2).

3. Turn ignition switch ACC and audio unit ON. Verify

battery positive voltage is present at terminal 1 of

audio amp. relay.

Individual front speaker is

noisy or inoperative.1. Speaker ground

2. Power supply

3. Audio unit output

4. Speaker1. Check speaker ground (Terminal 5).

2. Check power supply for speaker (Terminal 4).

3. Check audio unit output voltage for speaker.

4. Replace speaker.

Both rear speakers are

inoperative.1. Poor rear speaker amp. ground

2. Power supply

3. Amp. ON signal

4. Rear speaker amp.1. Check rear speaker amp. ground circuit.

2. Check power supply for rear speaker amp. (Terminal

11).

3. Turn ignition switch ACC and audio unit ON. Verify

battery positive voltage is present at terminal 9 of

rear speaker amp.

4. Remove rear speaker amp. for repair.

Individual rear speaker is

noisy or inoperative.1. Speaker

2. Audio unit/amp. output

3. Speaker circuit

4. Audio unit1. Check speaker.

2. Check audio unit/amp. output.

3. Check wires for open or short between audio unit/

amp. and speakers.

4. Remove audio unit for repair.

AUDIO

Trouble Diagnoses

EL-166

Page 1642 of 2395

NBEL0145

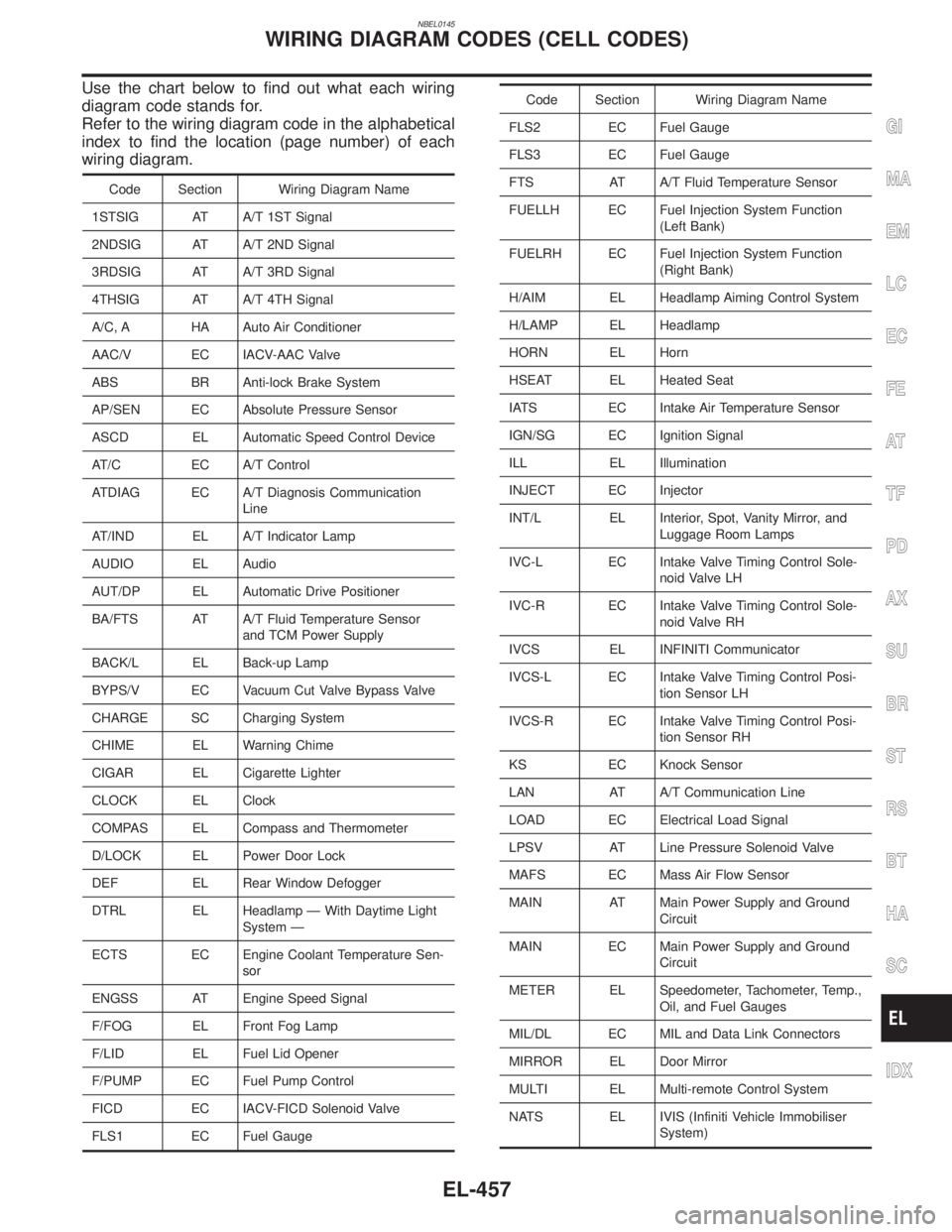

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

1STSIG AT A/T 1ST Signal

2NDSIG AT A/T 2ND Signal

3RDSIG AT A/T 3RD Signal

4THSIG AT A/T 4TH Signal

A/C, A HA Auto Air Conditioner

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

AP/SEN EC Absolute Pressure Sensor

ASCD EL Automatic Speed Control Device

AT/C EC A/T Control

ATDIAG EC A/T Diagnosis Communication

Line

AT/IND EL A/T Indicator Lamp

AUDIO EL Audio

AUT/DP EL Automatic Drive Positioner

BA/FTS AT A/T Fluid Temperature Sensor

and TCM Power Supply

BACK/L EL Back-up Lamp

BYPS/V EC Vacuum Cut Valve Bypass Valve

CHARGE SC Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CLOCK EL Clock

COMPAS EL Compass and Thermometer

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DTRL EL Headlamp Ð With Daytime Light

System Ð

ECTS EC Engine Coolant Temperature Sen-

sor

ENGSS AT Engine Speed Signal

F/FOG EL Front Fog Lamp

F/LID EL Fuel Lid Opener

F/PUMP EC Fuel Pump Control

FICD EC IACV-FICD Solenoid Valve

FLS1 EC Fuel Gauge

Code Section Wiring Diagram Name

FLS2 EC Fuel Gauge

FLS3 EC Fuel Gauge

FTS AT A/T Fluid Temperature Sensor

FUELLH EC Fuel Injection System Function

(Left Bank)

FUELRH EC Fuel Injection System Function

(Right Bank)

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HORN EL Horn

HSEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Interior, Spot, Vanity Mirror, and

Luggage Room Lamps

IVC-L EC Intake Valve Timing Control Sole-

noid Valve LH

IVC-R EC Intake Valve Timing Control Sole-

noid Valve RH

IVCS EL INFINITI Communicator

IVCS-L EC Intake Valve Timing Control Posi-

tion Sensor LH

IVCS-R EC Intake Valve Timing Control Posi-

tion Sensor RH

KS EC Knock Sensor

LAN AT A/T Communication Line

LOAD EC Electrical Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground

Circuit

MAIN EC Main Power Supply and Ground

Circuit

METER EL Speedometer, Tachometer, Temp.,

Oil, and Fuel Gauges

MIL/DL EC MIL and Data Link Connectors

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL IVIS (Infiniti Vehicle Immobiliser

System)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

WIRING DIAGRAM CODES (CELL CODES)

EL-457