engine oil INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 869 of 2395

SEF977Y

Component DescriptionNBEC0191The crankshaft position sensor (POS) is located on the oil pan

facing the gear teeth (cogs) of the signal plate (flywheel). It detects

the crankshaft position signal (1É signal).

The sensor consists of a permanent magnet, core and coil.

When engine is running, the gap between the sensor and the gear

teeth (cogs) will periodically change. Permeability near the sensor

also changes.

Due to the permeability change, the magnetic flux near the core is

changed. Therefore, the voltage signal generated in the coil is

changed.

The ECM receives the voltage signal and detects the crankshaft

position signal (1É signal).

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0492Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPS´RPM (POS)ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

DTC P0335 CRANKSHAFT POSITION SENSOR (CKPS) (POS)

Component Description

EC-334

Page 877 of 2395

SEF252P

Component DescriptionNBEC0197The camshaft position sensor (PHASE) is located on the engine

front cover facing the camshaft sprocket. It detects the cylinder No.

signal.

The sensor consists of a permanent magnet, core and coil.

When engine is running, the gap between the sensor and the

camshaft sprocket will periodically change. Permeability near the

sensor also changes.

Due to the permeability change, the magnetic flux near the core is

changed. Therefore, the voltage signal generated in the coil is

changed.

The ECM receives the voltage signal and detects the cylinder No.

signal.

ECM Terminals and Reference ValueNBEC0665Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

66

76L

LCamshaft position sen-

sor (PHASE)[Engine is running]

IWarm-up condition

IIdle speedApproximately 4.2VH

(AC voltage)

SEF582X

H: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

On Board Diagnosis LogicNBEC0199Malfunction is detected when

(Malfunction A)the cylinder No. signal is not sent to ECM for the

first few seconds during engine cranking,

(Malfunction B)the cylinder No. signal is not sent to ECM during

engine running,

(Malfunction C)the cylinder No. signal is not in the normal pattern

during engine running.

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS) (PHASE)

Component Description

EC-342

Page 886 of 2395

6 CHECK IGNITION SPARK

1. Turn ignition switch ªOFFº.

2. Disconnect ignition coil assembly from rocker cover.

3. Connect a known good spark plug to the ignition coil assembly.

4. Place end of spark plug against a suitable ground and crank engine.

5. Check for spark.

SEF575Q

OK or NG

OK©GO TO 7.

NG©Check ignition coil with power transistor and their circuit. Refer to EC-499.

7 CHECK INJECTOR

1. Turn ignition switch ªOFFº.

2. Remove injector assembly.

Refer to EC-41.

Keep fuel hose and all injectors connected to injector gallery.

3. Disconnect all ignition coil harness connectors.

4. Turn ignition switch ªONº.

Make sure fuel does not drip from injector.

OK or NG

OK (Does not drip.)©GO TO 8.

NG (Drips.)©Replace the injector(s) from which fuel is dripping.

8 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

Trouble is fixed.©INSPECTION END

Trouble is not fixed.©Replace warm-up three way catalyst.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0420 (RIGHT BANK, -B1), P0430 (LEFT BANK, -B2) THREE WAY

CATALYST FUNCTION

Diagnostic Procedure (Cont'd)

EC-351

Page 957 of 2395

DescriptionNBEC0249SYSTEM DESCRIPTIONNBEC0249S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed (POS signal)

Idle air

controlIACV-AAC valve Crankshaft position sensor (REF) Engine speed (REF signal)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Park/neutral position (PNP) switch Park/neutral position

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Battery Battery voltage

Vehicle speed sensor Vehicle speed

Ambient air temperature switch Ambient air temperature

Intake air temperature sensor Intake air temperature

Absolute pressure sensor Ambient barometic pressure

This system automatically controls engine idle speed to a specified

level. Idle speed is controlled through fine adjustment of the

amount of air which by-passes the throttle valve via IACV-AAC

valve. The IACV-AAC valve changes the opening of the air by-pass

passage to control the amount of auxiliary air. This valve is actu-

ated by a step motor built into the valve, which moves the valve in

the axial direction in steps corresponding to the ECM output sig-

nals. One step of IACV-AAC valve movement causes the respec-

tive opening of the air by-pass passage. (i.e. when the step

advances, the opening is enlarged.) The opening of the valve is

varied to allow for optimum control of the engine idling speed. The

crankshaft position sensor (POS) detects the actual engine speed

and sends a signal to the ECM. The ECM then controls the step

position of the IACV-AAC valve so that engine speed coincides with

the target value memorized in ECM. The target engine speed is the

lowest speed at which the engine can operate steadily. The opti-

mum value stored in the ECM is determined by takig into consid-

eration various engine conditions, such as during warm up,

deceleration, and engine load (air conditioner, power steering and

cooling fan operation).

SEF765P

COMPONENT DESCRIPTIONNBEC0249S02IACV-AAC ValveNBEC0249S0201The IACV-AAC valve is operated by a step motor for centralized

control of auxiliary air supply. This motor has four winding phases

and is actuated by the output signals of ECM which turns ON and

OFF two windings each in seqeunce. Each time the IACV-AAC

valve opens or closes to change tha auxiliary air quantity, the ECM

sends a pulse signal to the step motor. When no change in the

auxiliary air quantity is needed, the ECM does not issue the pulse

signal. A certain voltage signal is issued so that the valve remains

at that particular opening.

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Description

EC-422

Page 986 of 2395

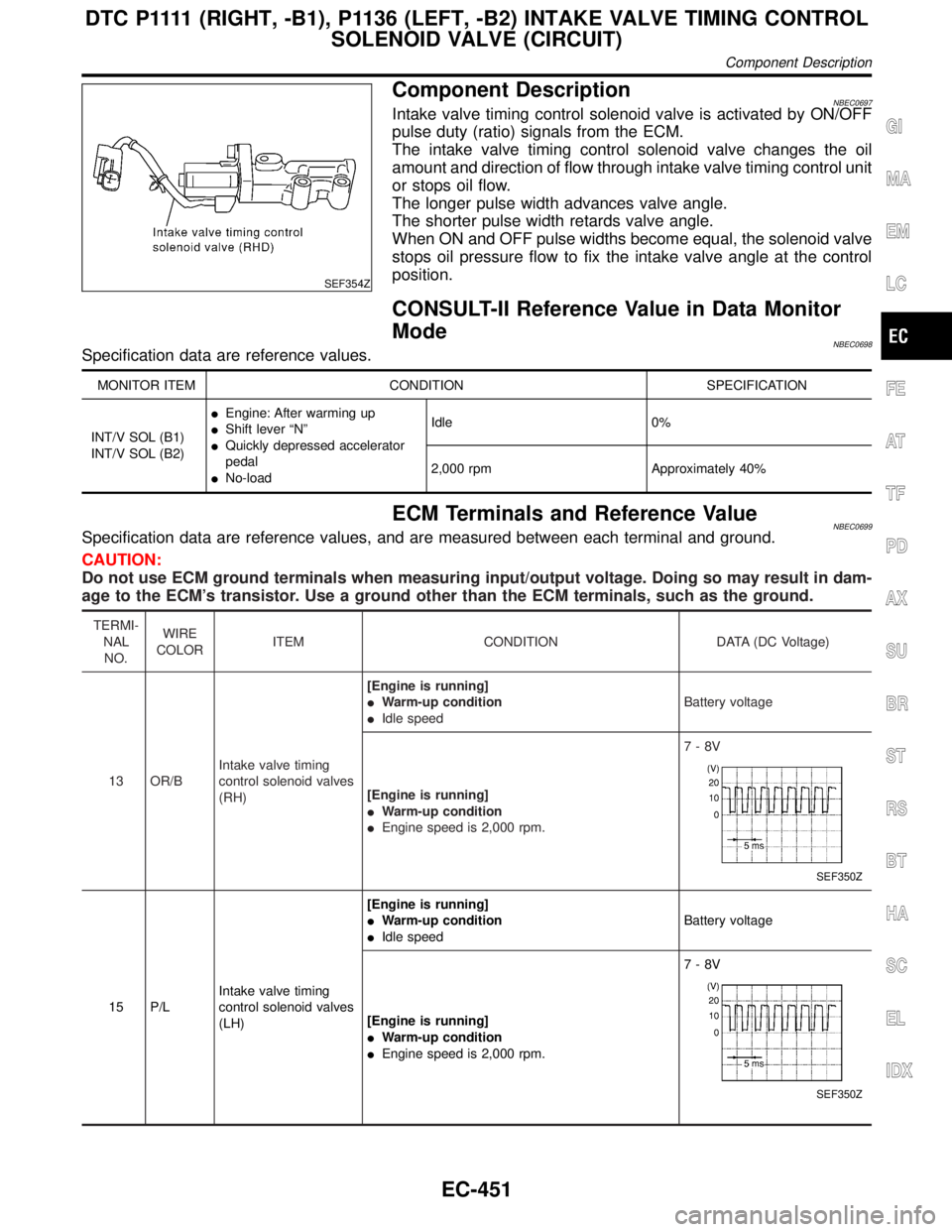

SEF354Z

Component DescriptionNBEC0697Intake valve timing control solenoid valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil

amount and direction of flow through intake valve timing control unit

or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the intake valve angle at the control

position.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0698Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

INT/V SOL (B1)

INT/V SOL (B2)IEngine: After warming up

IShift lever ªNº

IQuickly depressed accelerator

pedal

INo-loadIdle 0%

2,000 rpm Approximately 40%

ECM Terminals and Reference ValueNBEC0699Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than the ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

13 OR/BIntake valve timing

control solenoid valves

(RH)[Engine is running]

IWarm-up condition

IIdle speedBattery voltage

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpm.7-8V

SEF350Z

15 P/LIntake valve timing

control solenoid valves

(LH)[Engine is running]

IWarm-up condition

IIdle speedBattery voltage

[Engine is running]

IWarm-up condition

IEngine speed is 2,000 rpm.7-8V

SEF350Z

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

D T C P 1111(RIGHT, -B1), P1136 (LEFT, -B2) INTAKE VALVE TIMING CONTROL

SOLENOID VALVE (CIRCUIT)

Component Description

EC-451

Page 1034 of 2395

Component DescriptionNBEC0286IGNITION COIL & POWER TRANSISTORNBEC0286S01The ignition signal from the ECM is sent to and amplified by the power transistor. The power transistor turns

on and off the ignition coil primary circuit. This on-off operation induces the proper high voltage in the coil

secondary circuit.

SEF975Y

ECM Terminals and Reference ValueNBEC0675Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

21

22

23

30

31

32Y/R

G/R

L/R

GY

PU/W

GY/RIgnition signal No. 1

Ignition signal No. 2

Ignition signal No. 3

Ignition signal No. 4

Ignition signal No. 5

Ignition signal No. 6[Engine is running]

IWarm-up condition

IIdle speed0 - 0.2VH

SEF399T

[Engine is running]

IWarm-up condition

IEngine speed is 2,500 rpm.0.1 - 0.3VH

SEF645T

H: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

On Board Diagnosis LogicNBEC0288Malfunction is detected when the ignition signal in the primary cir-

cuit is not sent to ECM during engine cranking or running.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1320 IGNITION SIGNAL

Component Description

EC-499

Page 1035 of 2395

Possible CauseNBEC0572IHarness or connectors (The ignition primary circuit is open or

shorted.)

IPower transistor unit built into ignition coil

ICondenser

ICrankshaft position sensor (REF)

ICrankshaft position sensor (REF) circuit

SEF058Y

DTC Confirmation ProcedureNBEC0289NOTE:

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

IIf DTC P1320 is displayed with DTC P0335, P0340, P1335

or P1336, perform trouble diagnosis for DTC P0335,

P0340, P1335 or P1336 first. Refer to EC-334, EC-342,

EC-510 or EC-517.

WITH CONSULT-IINBEC0289S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine. (If engine does not run, turn ignition switch to

ªSTARTº for at least 5 seconds.)

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-504.

WITH GSTNBEC0289S02Follow the procedure ªWITH CONSULT-IIº above.

DTC P1320 IGNITION SIGNAL

Possible Cause

EC-500

Page 1039 of 2395

Diagnostic ProcedureNBEC0291

1 CHECK ENGINE START

Turn ignition switch ªOFFº, and restart engine.

Is engine running?

YesorNo

Yes (With CONSULT-II)©GO TO 2.

Yes (Without CONSULT-

II)©GO TO 12.

No©GO TO 3.

2 SEARCH FOR MALFUNCTIONING CIRCUIT

With CONSULT-II

1. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

2. Search for circuit which does not produce a momentary engine speed drop.

SEF190Y

©GO TO 12.

3 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

2. Check voltage between ECM terminals 110, 112 and ground with CONSULT-II or tester.

SEF366X

OK or NG

OK©GO TO 4.

NG©Go to TROUBLE DIAGNOSIS FOR POWER SUPPLY, EC-142.

DTC P1320 IGNITION SIGNAL

Diagnostic Procedure

EC-504

Page 1043 of 2395

12 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-V

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect ignition coil harness connector.

SEF975Y

4. Turn ignition switch ON.

5. Check voltage between ignition coil terminal 3 and ground with CONSULT-II or tester.

SEF370X

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 DETECT MALFUNCTIONING PART

Check the harness for open or short between ignition coil and harness connector F22.

©Repair or replace harness or connectors.

14 CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between ignition coil terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 15.

NG©Repair open circuit or short to power in harness or connectors.

DTC P1320 IGNITION SIGNAL

Diagnostic Procedure (Cont'd)

EC-508

Page 1045 of 2395

SEF253P

Component DescriptionNBEC0573The crankshaft position sensor (REF) is located on the oil pan

(upper) facing the crankshaft pulley. It detects the TDC (Top Dead

Center) signal (120É signal).

The sensor consists of a permanent magnet, core and coil.

When engine is running, the gap between the sensor and the

crankshaft pulley will periodically change. Permeability near the

sensor also changes.

Due to the permeability change, the magnetic flux near the core is

changed. Therefore, the voltage signal generated in the coil is

changed.

The ECM receives the voltage signal and detects the TDC signal

(120É signal).

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0574Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPS´RPM (POS)ITachometer: Connect

IRun engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

ENG SPEED

ECM Terminals and Reference ValueNBEC0676Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

65

75LG

LGCrankshaft position

sensor (REF)[Engine is running]

IWarm-up condition

IIdle speedApproximately 2.3VH

(AC voltage)

SEF581X

H: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

DTC P1335 CRANKSHAFT POSITION SENSOR (CKPS) (REF)

Component Description

EC-510