P0505 INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 540 of 2395

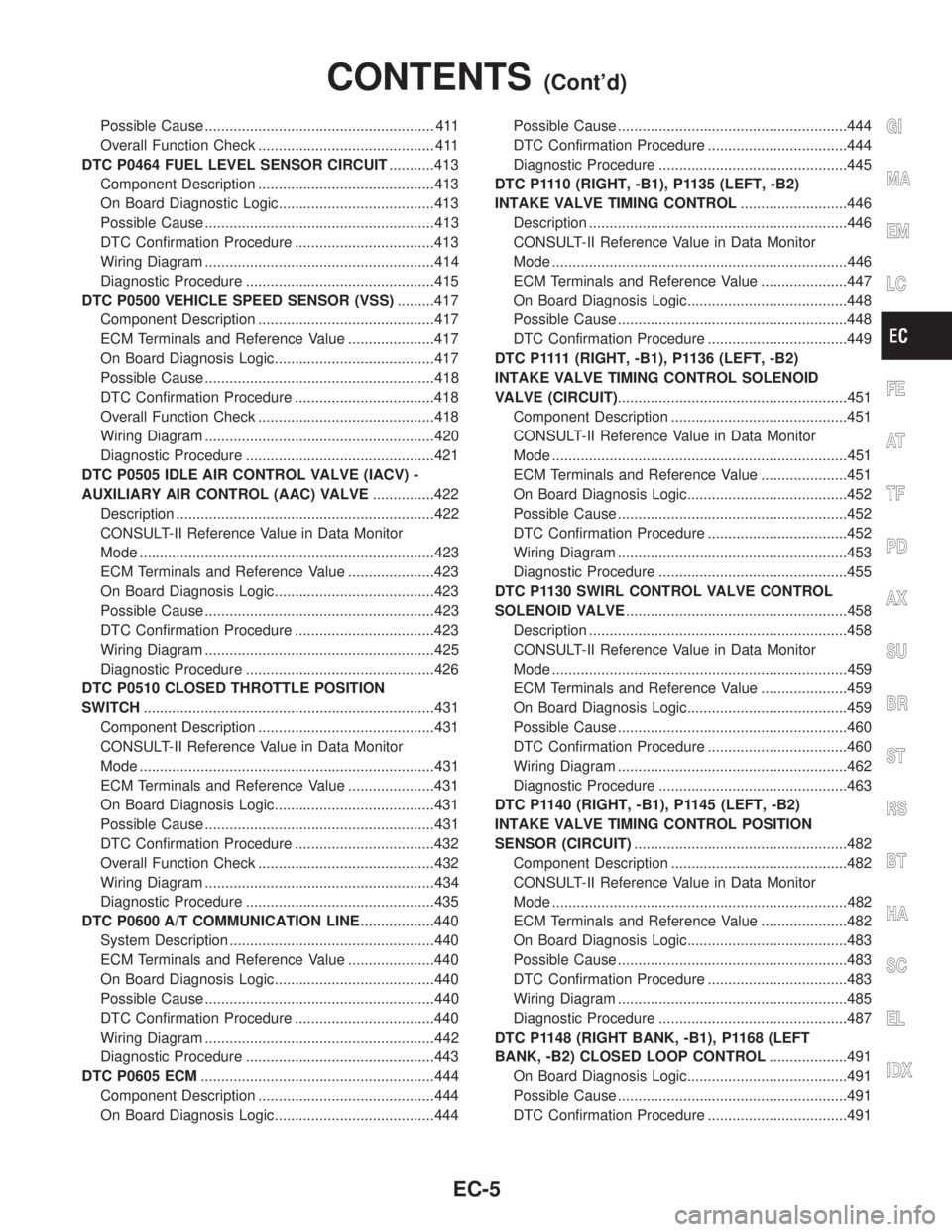

Possible Cause ........................................................ 411

Overall Function Check ........................................... 411

DTC P0464 FUEL LEVEL SENSOR CIRCUIT...........413

Component Description ...........................................413

On Board Diagnostic Logic......................................413

Possible Cause ........................................................413

DTC Confirmation Procedure ..................................413

Wiring Diagram ........................................................414

Diagnostic Procedure ..............................................415

DTC P0500 VEHICLE SPEED SENSOR (VSS).........417

Component Description ...........................................417

ECM Terminals and Reference Value .....................417

On Board Diagnosis Logic.......................................417

Possible Cause ........................................................418

DTC Confirmation Procedure ..................................418

Overall Function Check ...........................................418

Wiring Diagram ........................................................420

Diagnostic Procedure ..............................................421

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............422

Description ...............................................................422

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................423

ECM Terminals and Reference Value .....................423

On Board Diagnosis Logic.......................................423

Possible Cause ........................................................423

DTC Confirmation Procedure ..................................423

Wiring Diagram ........................................................425

Diagnostic Procedure ..............................................426

DTC P0510 CLOSED THROTTLE POSITION

SWITCH.......................................................................431

Component Description ...........................................431

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................431

ECM Terminals and Reference Value .....................431

On Board Diagnosis Logic.......................................431

Possible Cause ........................................................431

DTC Confirmation Procedure ..................................432

Overall Function Check ...........................................432

Wiring Diagram ........................................................434

Diagnostic Procedure ..............................................435

DTC P0600 A/T COMMUNICATION LINE..................440

System Description ..................................................440

ECM Terminals and Reference Value .....................440

On Board Diagnosis Logic.......................................440

Possible Cause ........................................................440

DTC Confirmation Procedure ..................................440

Wiring Diagram ........................................................442

Diagnostic Procedure ..............................................443

DTC P0605 ECM.........................................................444

Component Description ...........................................444

On Board Diagnosis Logic.......................................444Possible Cause ........................................................444

DTC Confirmation Procedure ..................................444

Diagnostic Procedure ..............................................445

DTC P1110 (RIGHT, -B1), P1135 (LEFT, -B2)

INTAKE VALVE TIMING CONTROL..........................446

Description ...............................................................446

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................446

ECM Terminals and Reference Value .....................447

On Board Diagnosis Logic.......................................448

Possible Cause ........................................................448

DTC Confirmation Procedure ..................................449

D T C P 1111(RIGHT, -B1), P1136 (LEFT, -B2)

INTAKE VALVE TIMING CONTROL SOLENOID

VALVE (CIRCUIT)........................................................451

Component Description ...........................................451

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................451

ECM Terminals and Reference Value .....................451

On Board Diagnosis Logic.......................................452

Possible Cause ........................................................452

DTC Confirmation Procedure ..................................452

Wiring Diagram ........................................................453

Diagnostic Procedure ..............................................455

DTC P1130 SWIRL CONTROL VALVE CONTROL

SOLENOID VALVE......................................................458

Description ...............................................................458

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................459

ECM Terminals and Reference Value .....................459

On Board Diagnosis Logic.......................................459

Possible Cause ........................................................460

DTC Confirmation Procedure ..................................460

Wiring Diagram ........................................................462

Diagnostic Procedure ..............................................463

DTC P1140 (RIGHT, -B1), P1145 (LEFT, -B2)

INTAKE VALVE TIMING CONTROL POSITION

SENSOR (CIRCUIT)....................................................482

Component Description ...........................................482

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................482

ECM Terminals and Reference Value .....................482

On Board Diagnosis Logic.......................................483

Possible Cause ........................................................483

DTC Confirmation Procedure ..................................483

Wiring Diagram ........................................................485

Diagnostic Procedure ..............................................487

DTC P1148 (RIGHT BANK, -B1), P1168 (LEFT

BANK, -B2) CLOSED LOOP CONTROL...................491

On Board Diagnosis Logic.......................................491

Possible Cause ........................................................491

DTC Confirmation Procedure ..................................491GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

EC-5

Page 544 of 2395

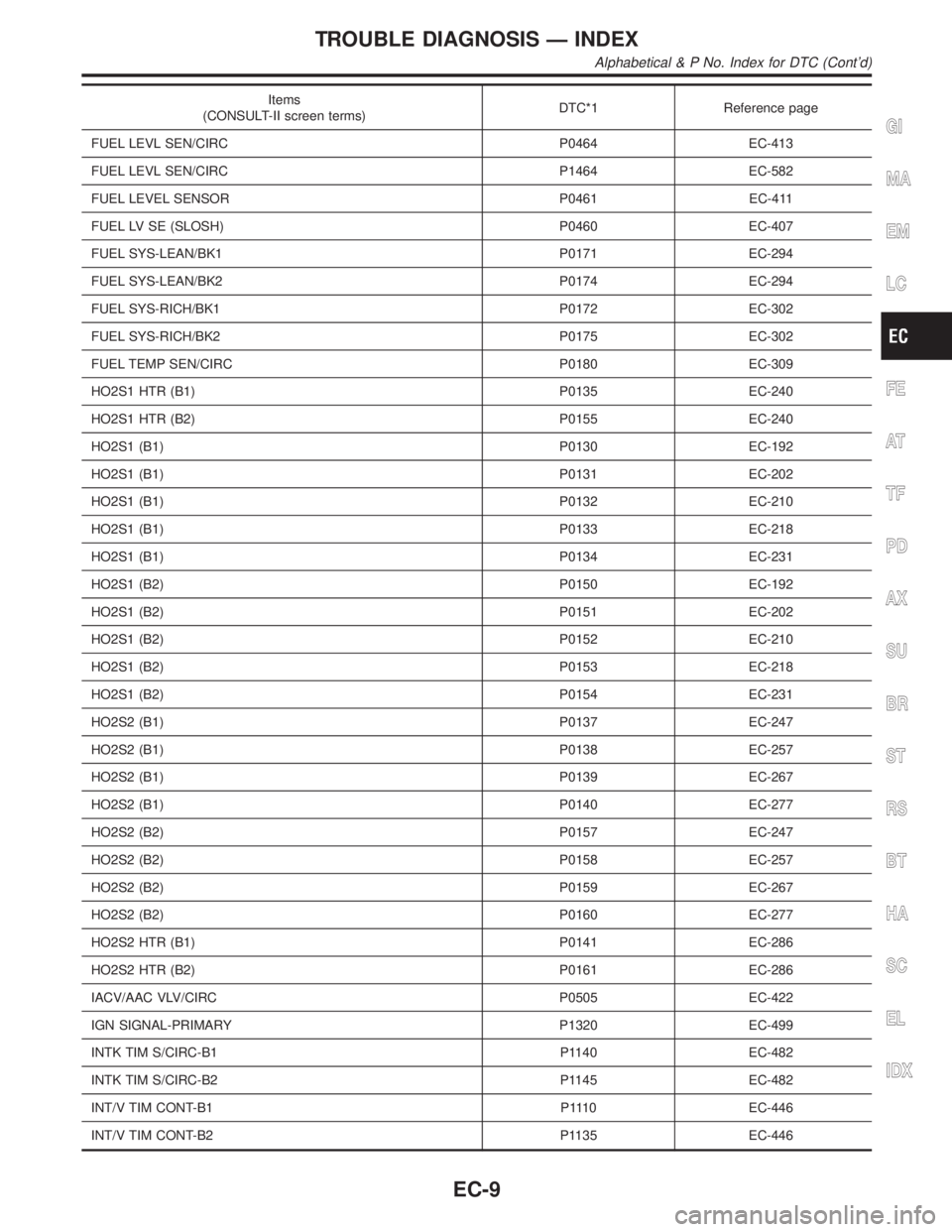

Items

(CONSULT-II screen terms)DTC*1 Reference page

FUEL LEVL SEN/CIRC P0464 EC-413

FUEL LEVL SEN/CIRC P1464 EC-582

FUEL LEVEL SENSOR P0461 EC-411

FUEL LV SE (SLOSH) P0460 EC-407

FUEL SYS-LEAN/BK1 P0171 EC-294

FUEL SYS-LEAN/BK2 P0174 EC-294

FUEL SYS-RICH/BK1 P0172 EC-302

FUEL SYS-RICH/BK2 P0175 EC-302

FUEL TEMP SEN/CIRC P0180 EC-309

HO2S1 HTR (B1) P0135 EC-240

HO2S1 HTR (B2) P0155 EC-240

HO2S1 (B1) P0130 EC-192

HO2S1 (B1) P0131 EC-202

HO2S1 (B1) P0132 EC-210

HO2S1 (B1) P0133 EC-218

HO2S1 (B1) P0134 EC-231

HO2S1 (B2) P0150 EC-192

HO2S1 (B2) P0151 EC-202

HO2S1 (B2) P0152 EC-210

HO2S1 (B2) P0153 EC-218

HO2S1 (B2) P0154 EC-231

HO2S2 (B1) P0137 EC-247

HO2S2 (B1) P0138 EC-257

HO2S2 (B1) P0139 EC-267

HO2S2 (B1) P0140 EC-277

HO2S2 (B2) P0157 EC-247

HO2S2 (B2) P0158 EC-257

HO2S2 (B2) P0159 EC-267

HO2S2 (B2) P0160 EC-277

HO2S2 HTR (B1) P0141 EC-286

HO2S2 HTR (B2) P0161 EC-286

IACV/AAC VLV/CIRC P0505 EC-422

IGN SIGNAL-PRIMARY P1320 EC-499

INTK TIM S/CIRC-B1 P1140 EC-482

INTK TIM S/CIRC-B2 P1145 EC-482

INT/V TIM CONT-B1 P1110 EC-446

INT/V TIM CONT-B2 P1135 EC-446

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC (Cont'd)

EC-9

Page 547 of 2395

DTC*1Items

(CONSULT-II screen terms)Reference page

P0217 ENG OVER TEMP EC-314

P0300 MULTI CYL MISFIRE EC-320

P0301 CYL 1 MISFIRE EC-320

P0302 CYL 2 MISFIRE EC-320

P0303 CYL 3 MISFIRE EC-320

P0304 CYL 4 MISFIRE EC-320

P0305 CYL 5 MISFIRE EC-320

P0306 CYL 6 MISFIRE EC-320

P0325*2 KNOCK SEN/CIRC-B1 EC-328

P0335 CPS/CIRCUIT (POS) EC-334

P0340 CAM PS/CIRC (PHS) EC-342

P0420 TW CATALYST SYS-B1 EC-347

P0430 TW CATALYST SYS-B2 EC-347

P0440 EVAP SMALL LEAK EC-352

P0443 PURG VOLUME CONT/V EC-367

P0446 VENT CONTROL VALVE EC-374

P0450 EVAP SYS PRES SEN EC-381

P0455 EVAP GROSS LEAK EC-394

P0460 FUEL LV SE (SLOSH) EC-407

P0461 FUEL LEVEL SENSOR EC-411

P0464 FUEL LEVL SEN/CIRC EC-413

P0500 VEH SPEED SEN/CIRC*4 EC-417

P0505 IACV/AAC VLV/CIRC EC-422

P0510 CLOSED TP SW/CIRC EC-431

P0600*2 A/T COMM LINE EC-440

P0605 ECMEC-444

P0705 PNP SW/CIRC AT-111

P0710 ATF TEMP SEN/CIRC AT-116

P0720 VEH SPD SEN/CIR A/T*4 AT-124

P0725 ENGINE SPEED SIG AT-130

P0731 A/T 1ST GR FNCTN AT-136

P0732 A/T 2ND GR FNCTN AT-143

P0733 A/T 3RD GR FNCTN AT-151

P0734 A/T 4TH GR FNCTN AT-157

P0740 TCC SOLENOID/CIRC AT-165

P0744 A/T TCC S/V FNCTN AT-170

P0745 L/PRESS SOL/CIRC AT-174

TROUBLE DIAGNOSIS Ð INDEX

Alphabetical & P No. Index for DTC (Cont'd)

EC-12

Page 606 of 2395

Items

(CONSULT-II screen terms)DTC*1 SRT codeTest value/ Test

limit

(GST only)1st trip DTC*1 Reference page

KNOCK SEN/CIRC-B1 P0325 Ð Ð Ð EC-328

CPS/CIRCUIT (POS) P0335 Ð Ð X EC-334

CAM PS/CIRC (PHS) P0340 Ð Ð X EC-342

TW CATALYST SYS-B1 P0420 X X X*2 EC-347

TW CATALYST SYS-B2 P0430 X X X*2 EC-347

EVAP SMALL LEAK P0440 X X X*2 EC-352

PURG VOLUME CONT/V P0443 Ð Ð X EC-367

VENT CONTROL VALVE P0446 Ð Ð X EC-374

EVAP SYS PRES SEN P0450 Ð Ð X EC-381

EVAP GROSS LEAK P0455 X X X*2 EC-394

FUEL LV SE (SLOSH) P0460 Ð Ð X EC-407

FUEL LEVEL SENSOR P0461 Ð Ð X EC-411

FUEL LEVEL SEN/CIRC P0464 Ð Ð X EC-413

VEH SPEED SEN/CIRC P0500 Ð Ð X EC-417

IACV/AAC VLV/CIRC P0505 Ð Ð X EC-422

CLOSED TP SW/CIRC P0510 Ð Ð X EC-431

A/T COMM LINE P0600 Ð Ð Ð EC-440

ECM P0605 Ð Ð X EC-444

PNP SW/CIRC P0705 Ð Ð X AT-111

ATF TEMP SEN/CIRC P0710 Ð Ð X AT-116

VEH SPD SEN/CIR AT P0720 Ð Ð X AT-124

ENGINE SPEED SIG P0725 Ð Ð X AT-130

A/T 1ST GR FNCTN P0731 Ð Ð X AT-136

A/T 2ND GR FNCTN P0732 Ð Ð X AT-143

A/T 3RD GR FNCTN P0733 Ð Ð X AT-151

A/T 4TH GR FNCTN P0734 Ð Ð X AT-157

TCC SOLENOID/CIRC P0740 Ð Ð X AT-165

A/T TCC S/V FNCTN P0744 Ð Ð X AT-170

L/PRESS SOL/CIRC P0745 Ð Ð X AT-174

SFT SOL A/CIRC P0750 Ð Ð X AT-180

SFT SOL B/CIRC P0755 Ð Ð X AT-189

INT/V TIM CONT-B1 P1110 Ð Ð X EC-446

INT/V TIM V/CIR-B1 P1111 Ð Ð XEC-451

SWIRL CONT SOL/V P1130 Ð Ð X EC-458

INT/V TIM CONT-B2 P1135 Ð Ð X EC-446

INT/V TIM V/CIR-B2 P1136 Ð Ð X EC-451

INTK TIM S/CIRC-B1 P1140 Ð Ð X EC-482

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Emission-related Diagnostic Information (Cont'd)

EC-71

Page 651 of 2395

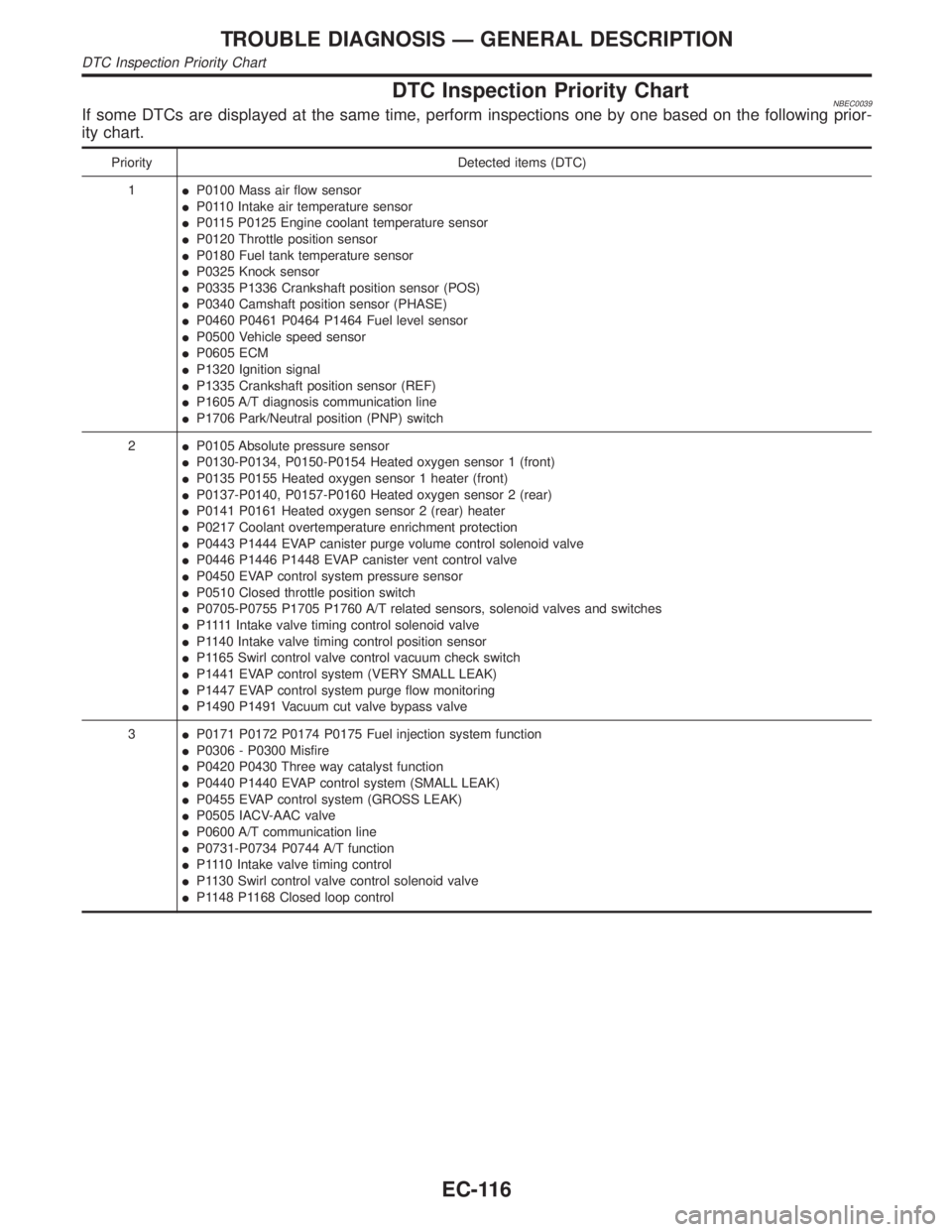

DTC Inspection Priority ChartNBEC0039If some DTCs are displayed at the same time, perform inspections one by one based on the following prior-

ity chart.

Priority Detected items (DTC)

1IP0100 Mass air flow sensor

IP0110 Intake air temperature sensor

IP0115 P0125 Engine coolant temperature sensor

IP0120 Throttle position sensor

IP0180 Fuel tank temperature sensor

IP0325 Knock sensor

IP0335 P1336 Crankshaft position sensor (POS)

IP0340 Camshaft position sensor (PHASE)

IP0460 P0461 P0464 P1464 Fuel level sensor

IP0500 Vehicle speed sensor

IP0605 ECM

IP1320 Ignition signal

IP1335 Crankshaft position sensor (REF)

IP1605 A/T diagnosis communication line

IP1706 Park/Neutral position (PNP) switch

2IP0105 Absolute pressure sensor

IP0130-P0134, P0150-P0154 Heated oxygen sensor 1 (front)

IP0135 P0155 Heated oxygen sensor 1 heater (front)

IP0137-P0140, P0157-P0160 Heated oxygen sensor 2 (rear)

IP0141 P0161 Heated oxygen sensor 2 (rear) heater

IP0217 Coolant overtemperature enrichment protection

IP0443 P1444 EVAP canister purge volume control solenoid valve

IP0446 P1446 P1448 EVAP canister vent control valve

IP0450 EVAP control system pressure sensor

IP0510 Closed throttle position switch

IP0705-P0755 P1705 P1760 A/T related sensors, solenoid valves and switches

IP 1111Intake valve timing control solenoid valve

IP1140 Intake valve timing control position sensor

IP1165 Swirl control valve control vacuum check switch

IP1441 EVAP control system (VERY SMALL LEAK)

IP1447 EVAP control system purge flow monitoring

IP1490 P1491 Vacuum cut valve bypass valve

3IP0171 P0172 P0174 P0175 Fuel injection system function

IP0306 - P0300 Misfire

IP0420 P0430 Three way catalyst function

IP0440 P1440 EVAP control system (SMALL LEAK)

IP0455 EVAP control system (GROSS LEAK)

IP0505 IACV-AAC valve

IP0600 A/T communication line

IP0731-P0734 P0744 A/T function

IP1110 Intake valve timing control

IP1130 Swirl control valve control solenoid valve

IP1148 P1168 Closed loop control

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

DTC Inspection Priority Chart

EC-116

Page 957 of 2395

DescriptionNBEC0249SYSTEM DESCRIPTIONNBEC0249S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed (POS signal)

Idle air

controlIACV-AAC valve Crankshaft position sensor (REF) Engine speed (REF signal)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Park/neutral position (PNP) switch Park/neutral position

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Battery Battery voltage

Vehicle speed sensor Vehicle speed

Ambient air temperature switch Ambient air temperature

Intake air temperature sensor Intake air temperature

Absolute pressure sensor Ambient barometic pressure

This system automatically controls engine idle speed to a specified

level. Idle speed is controlled through fine adjustment of the

amount of air which by-passes the throttle valve via IACV-AAC

valve. The IACV-AAC valve changes the opening of the air by-pass

passage to control the amount of auxiliary air. This valve is actu-

ated by a step motor built into the valve, which moves the valve in

the axial direction in steps corresponding to the ECM output sig-

nals. One step of IACV-AAC valve movement causes the respec-

tive opening of the air by-pass passage. (i.e. when the step

advances, the opening is enlarged.) The opening of the valve is

varied to allow for optimum control of the engine idling speed. The

crankshaft position sensor (POS) detects the actual engine speed

and sends a signal to the ECM. The ECM then controls the step

position of the IACV-AAC valve so that engine speed coincides with

the target value memorized in ECM. The target engine speed is the

lowest speed at which the engine can operate steadily. The opti-

mum value stored in the ECM is determined by takig into consid-

eration various engine conditions, such as during warm up,

deceleration, and engine load (air conditioner, power steering and

cooling fan operation).

SEF765P

COMPONENT DESCRIPTIONNBEC0249S02IACV-AAC ValveNBEC0249S0201The IACV-AAC valve is operated by a step motor for centralized

control of auxiliary air supply. This motor has four winding phases

and is actuated by the output signals of ECM which turns ON and

OFF two windings each in seqeunce. Each time the IACV-AAC

valve opens or closes to change tha auxiliary air quantity, the ECM

sends a pulse signal to the step motor. When no change in the

auxiliary air quantity is needed, the ECM does not issue the pulse

signal. A certain voltage signal is issued so that the valve remains

at that particular opening.

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Description

EC-422

Page 958 of 2395

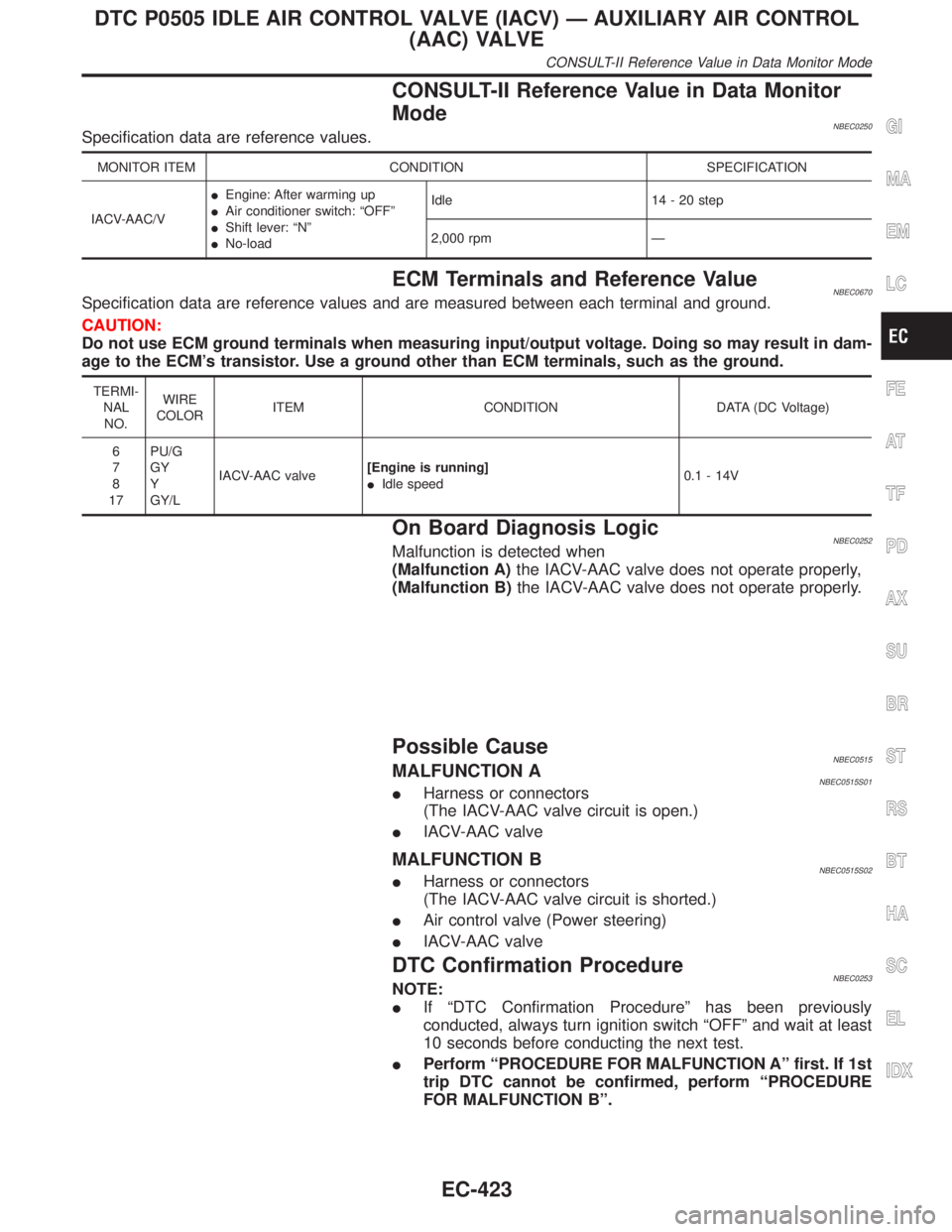

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0250Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

IACV-AAC/VIEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 14 - 20 step

2,000 rpm Ð

ECM Terminals and Reference ValueNBEC0670Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

6

7

8

17PU/G

GY

Y

GY/LIACV-AAC valve[Engine is running]

IIdle speed0.1 - 14V

On Board Diagnosis LogicNBEC0252Malfunction is detected when

(Malfunction A)the IACV-AAC valve does not operate properly,

(Malfunction B)the IACV-AAC valve does not operate properly.

Possible CauseNBEC0515MALFUNCTION ANBEC0515S01IHarness or connectors

(The IACV-AAC valve circuit is open.)

IIACV-AAC valve

MALFUNCTION BNBEC0515S02IHarness or connectors

(The IACV-AAC valve circuit is shorted.)

IAir control valve (Power steering)

IIACV-AAC valve

DTC Confirmation ProcedureNBEC0253NOTE:

IIf ªDTC Confirmation Procedureº has been previously

conducted, always turn ignition switch ªOFFº and wait at least

10 seconds before conducting the next test.

IPerform ªPROCEDURE FOR MALFUNCTION Aº first. If 1st

trip DTC cannot be confirmed, perform ªPROCEDURE

FOR MALFUNCTION Bº.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

CONSULT-II Reference Value in Data Monitor Mode

EC-423

Page 959 of 2395

SEF058Y

PROCEDURE FOR MALFUNCTION ANBEC0253S01TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V with ignition switch ªONº.

With CONSULT-IINBEC0253S01011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 10 seconds.

3) Perform ªIdle Air Volume Learningº (see EC-57).

4) Turn ignition switch ªOFFº and wait at least 10 seconds.

5) Turn ignition switch ªONº.

6) Select ªDATA MONITORº mode with CONSULT-II.

7) Start engine and let it idle.

8) Keep engine speed at 2,500 rpm for three seconds, then let it

idle for three seconds.

Do not rev engine to more than 3,000 rpm.

9) Perform step 4 once more.

10) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-426.

With GSTNBEC0253S0102Follow the procedure ªWith CONSULT-IIº above.

SEF174Y

PROCEDURE FOR MALFUNCTION BNBEC0253S02TESTING CONDITION:

IBefore performing the following procedure, confirm that

battery voltage is more than 11V at idle.

IAlways perform the test at a temperature above þ10ÉC

(14ÉF).

With CONSULT-IINBEC0253S02011) Open engine hood.

2) Start engine and warm it up to normal operating temperature.

3) Turn ignition switch ªOFFº and wait at least 10 seconds.

4) Perform ªIdle Air Volume Learningº (see EC-57).

5) Turn ignition switch ªOFFº and wait at least 10 seconds.

6) Turn ignition switch ªONº again and select ªDATA MONITORº

mode with CONSULT-II

7) Start engine and run it for at least 1 minute at idle speed.

8) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-426.

With GSTNBEC0253S0202Follow the procedure ªWith CONSULT-IIº above.

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

DTC Confirmation Procedure (Cont'd)

EC-424

Page 960 of 2395

Wiring DiagramNBEC0254

MEC966C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Wiring Diagram

EC-425

Page 961 of 2395

Diagnostic ProcedureNBEC0255

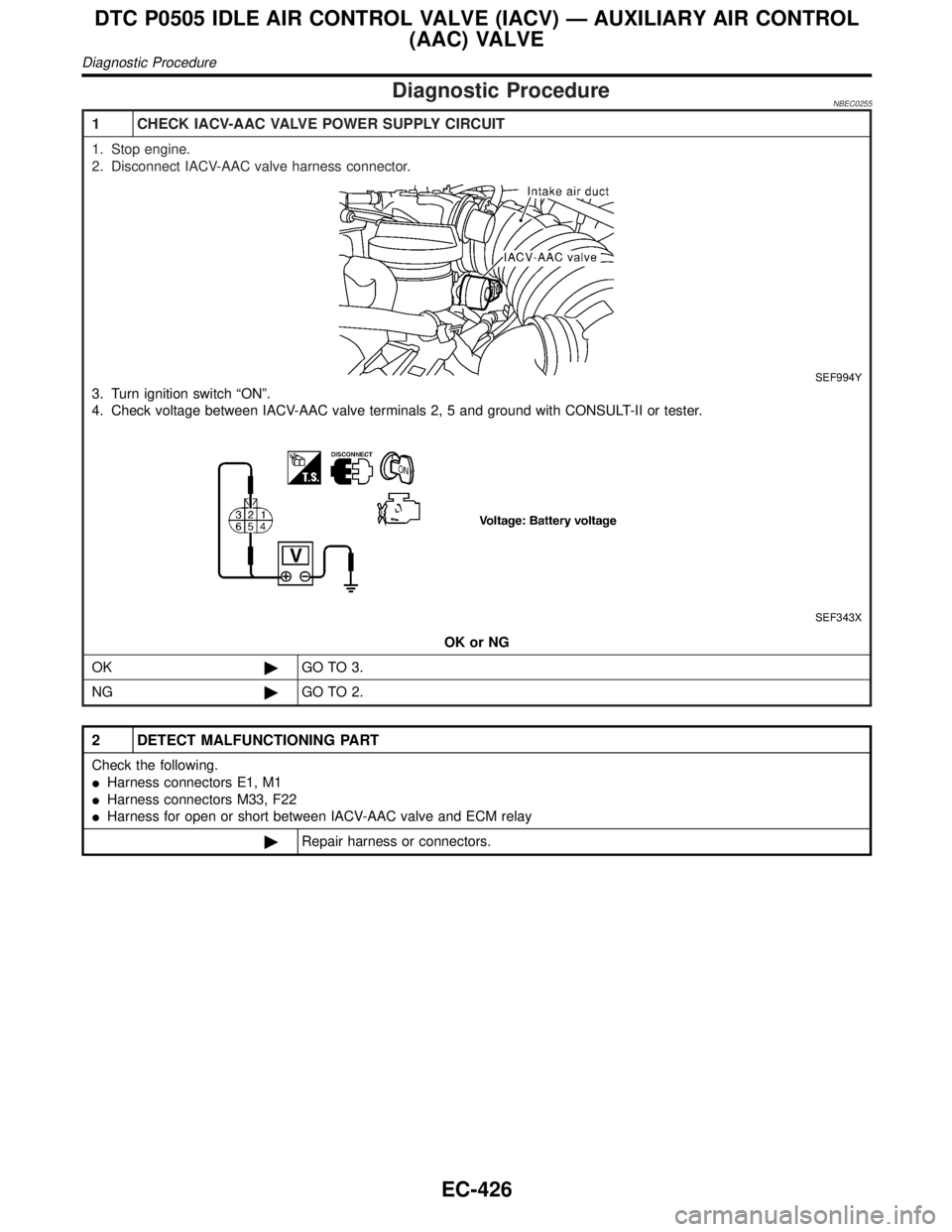

1 CHECK IACV-AAC VALVE POWER SUPPLY CIRCUIT

1. Stop engine.

2. Disconnect IACV-AAC valve harness connector.

SEF994Y

3. Turn ignition switch ªONº.

4. Check voltage between IACV-AAC valve terminals 2, 5 and ground with CONSULT-II or tester.

SEF343X

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1

IHarness connectors M33, F22

IHarness for open or short between IACV-AAC valve and ECM relay

©Repair harness or connectors.

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Diagnostic Procedure

EC-426