check transmission fluid INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 6 of 2395

AUTOMATIC TRANSMISSION

SECTION

AT

CONTENTS

TROUBLE DIAGNOSIS - INDEX....................................4

Alphabetical & P No. Index for DTC ...........................4

PRECAUTIONS...............................................................6

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²......................................................6

Precautions for On Board Diagnostic (OBD)

System of A/T and Engine...........................................6

Precautions ..................................................................6

Service Notice or Precautions .....................................8

Wiring Diagrams and Trouble Diagnosis .....................9

PREPARATION.............................................................10

Special Service Tools ................................................10

OVERALL SYSTEM......................................................12

A/T Electrical Parts Location .....................................12

Circuit Diagram ..........................................................13

Cross-sectional View .................................................14

Hydraulic Control Circuit ............................................15

Shift Mechanism ........................................................16

Control System ..........................................................25

Control Mechanism ....................................................26

Control Valve .............................................................31

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................33

Introduction ................................................................33

OBD-II Function for A/T System ................................33

One or Two Trip Detection Logic of OBD-II ..............33

OBD-II Diagnostic Trouble Code (DTC) ....................33

Malfunction Indicator Lamp (MIL) ..............................37

CONSULT-II ...............................................................37

Diagnostic Procedure Without CONSULT-II ..............46

TROUBLE DIAGNOSIS - INTRODUCTION..................53

Introduction ................................................................53

Work Flow ..................................................................57

TROUBLE DIAGNOSIS - BASIC INSPECTION...........59

A/T Fluid Check .........................................................59

Stall Test ....................................................................59

Line Pressure Test .....................................................62

Road Test...................................................................63TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................81

Symptom Chart ..........................................................81

TCM Terminals and Reference Value........................92

TROUBLE DIAGNOSIS FOR POWER SUPPLY..........96

Wiring Diagram - AT - MAIN ......................................96

Diagnostic Procedure ................................................97

DTC P0705 PARK/NEUTRAL POSITION SWITCH.....99

Description .................................................................99

Wiring Diagram - AT - PNP/SW...............................101

Diagnostic Procedure ..............................................102

Component Inspection .............................................103

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT.......................................................................105

Description ...............................................................105

Wiring Diagram - AT - FTS ......................................107

Diagnostic Procedure ..............................................108

Component Inspection ............................................. 110

DTC P0720 VEHICLE SPEED SENSOR.A/T

(REVOLUTION SENSOR)........................................... 111

Description ............................................................... 111

Wiring Diagram - AT - VSSA/T ................................ 113

Diagnostic Procedure .............................................. 114

Component Inspection ............................................. 115

DTC P0725 ENGINE SPEED SIGNAL....................... 116

Description ............................................................... 116

Wiring Diagram - AT - ENGSS ................................ 117

Diagnostic Procedure .............................................. 118

DTC P0731 IMPROPER SHIFTING TO 1ST GEAR

POSITION....................................................................120

Description ...............................................................120

Wiring Diagram - AT - 1ST ......................................123

Diagnostic Procedure ..............................................124

Component Inspection .............................................125

DTC P0732 IMPROPER SHIFTING TO 2ND GEAR

POSITION....................................................................126

Description ...............................................................126

Wiring Diagram - AT - 2ND......................................129

Diagnostic Procedure ..............................................130

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 13 of 2395

IBefore assembly, apply a coat of recommended ATF to all

parts. Apply petroleum jelly to protect O-rings and seals, or

hold bearings and washers in place during assembly. Do not

use grease.

IExtreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

IReplace ATF cooler if excessive foreign material is found in oil

pan or clogging strainer. Refer to ªATF COOLER SERVICEº,

AT-9.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is

drained. Old A/T fluid will remain in torque converter and ATF

cooling system.

Always follow the procedures when changing A/T fluid. Refer

to MA-21, ªChanging A/T Fluidº.

Service Notice or PrecautionsNBAT0004FAIL-SAFENBAT0004S01The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of ª1º, ª2º or ªDº. The

customer may complain of sluggish or poor acceleration.

When the ignition key is turned ªONº following Fail-Safe operation, O/D OFF indicator lamp blinks for about

8 seconds. (For ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, refer to AT-46.)

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

ªOFFº for 5 seconds, then ªONº.

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the ªWORK FLOWº (Refer to AT-57).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICENBAT0004S04The torque converter should be replaced under any of the following conditions:

IExternal leaks in the hub weld area.

IConverter hub is scored or damaged.

IConverter pilot is broken, damaged or fits poorly into crankshaft.

ISteel particles are found after flushing the cooler and cooler lines.

IPump is damaged or steel particles are found in the converter.

IVehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

IConverter is contaminated with engine coolant containing antifreeze.

IInternal failure of stator roller clutch.

IHeavy clutch debris due to overheating (blue converter).

ISteel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged Ð indicates that lining material came from converter.

The torque converter should not be replaced if:

IThe fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

PRECAUTIONS

Precautions (Cont'd)

AT-8

Page 64 of 2395

A/T Fluid CheckNBAT0021FLUID LEAKAGE CHECKNBAT0021S011. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

SAT638A

FLUID CONDITION CHECKNBAT0021S02

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pinkWater contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECKNBAT0021S03Refer to MA-21, ªChecking A/T Fluidº.

SAT647B

Stall TestNBAT0022STALL TEST PROCEDURENBAT0022S011. Check A/T fluid and engine oil levels. If necessary, add fluid

and oil.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

SAT513G

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

IIt is good practice to put a mark on point of specified

engine rpm on indicator.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

A/T Fluid Check

AT-59

Page 126 of 2395

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0039S01CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITIONS:

Always drive vehicle on a level road to improve the accuracy of

test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª1ST GR FNCTN P0731º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 10 to 20 km/h (6 to 12 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

ICheck that ªGEARº shows ª2º after releasing pedal.

5) Depress accelerator pedal to WOT (more than 7.0/8 of

ªTHROTTLE POSIº) quickly from a speed of 10 to 20 km/h (6

to 12 MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or

ªCOMPLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-124.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to the

following step.

ICheck that ªGEARº shows ª1º when depressing accelera-

tor pedal to WOT.

IIf ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAG RESULTSº for ªENGINEº. In case

a 1st trip DTC other than P0731 is shown, refer to appli-

cable ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1,2,3,4

No malfunction exists 1,2,3,4

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0731 IMPROPER SHIFTING TO 1ST GEAR POSITION

Description (Cont'd)

AT-121

Page 132 of 2395

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0042S01CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITIONS:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª2ND GR FNCTN P0732º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 25 to 30 km/h (16 to 19 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

ICheck that ªGEARº shows ª3º or ª4º after releasing pedal.

5) Depress accelerator pedal to WOT (more than 7.0/8 of

ªTHROTTLE POSIº) quickly from a speed of 25 to 30 km/h (16

to 19 MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or

ªCOMPLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-130.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

ICheck that ªGEARº shows ª2º when depressing accelera-

tor pedal to WOT.

IIf ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAG RESULTSº for ªENGINEº. In case

a 1st trip DTC other than P0732 is shown, refer to appli-

cable ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1,2,3,4

No malfunction exists 1,2,3,4

Malfunction for P0732 exists. 4,3,3,4

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0732 IMPROPER SHIFTING TO 2ND GEAR POSITION

Description (Cont'd)

AT-127

Page 138 of 2395

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0045S01CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITIONS:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª3RD GR FNCTN P0733º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 35 to 45 km/h (22 to 28 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 1.0/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

ICheck that ªGEARº shows ª4º after releasing pedal.

5) Depress accelerator pedal steadily with 3.5/8 - 4.5/8 of

ªTHROTTLE POSIº from a speed of 35 to 45 km/h (22 to 28

MPH) until ªTESTINGº changes to ªSTOP VEHICLEº or ªCOM-

PLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-136.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

ICheck that ªGEARº shows ª3º when depressing accelera-

tor pedal with 3.5/8 - 4.5/8 of ªTHROTTLE POSIº.

IIf ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAG RESULTSº for ªENGINEº. In case

a 1st trip DTC other than P0733 is shown, refer to appli-

cable ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern

when screen is changed to 1,2,3,4

No malfunction exists. 1,2,3,4

Malfunction for P0733 exists. 1,1,4,4

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0733 IMPROPER SHIFTING TO 3RD GEAR POSITION

Description (Cont'd)

AT-133

Page 145 of 2395

SAT014K

SAT971J

SAT021J

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NBAT0048S01CAUTION:

IAlways drive vehicle at a safe speed.

IBe careful not to rev engine into the red zone on the

tachometer.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

TESTING CONDITIONS:

Always drive vehicle on a level road to improve the accuracy

of test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Start engine and select ªDATA MONITORº mode for ªA/Tº with

CONSULT-II.

2) Make sure that output voltage of A/T fluid temperature sensor

is within the range below.

FLUID TEMP SEN: 0.4 - 1.5V

If out of range, drive the vehicle to decrease the voltage (warm

up the fluid) or stop engine to increase the voltage (cool down

the fluid).

3) Select ª4TH GR FNCTN P0734º of ªDTC WORK SUPPORTº

mode for ªA/Tº with CONSULT-II and touch ªSTARTº.

4) Accelerate vehicle to 55 to 65 km/h (34 to 40 MPH) under the

following condition and release the accelerator pedal com-

pletely.

THROTTLE POSI: Less than 5.5/8 (at all times during step

4)

Selector lever: D position (OD ªONº)

ICheck that ªGEARº shows ª3º after releasing pedal.

5) Depress accelerator pedal steadily with 1.0/8 - 2.0/8 of

ªTHROTTLE POSIº from a speed of 55 to 65 km/h (34 to 40

MPH) until ªTESTINGº has turned to ªSTOP VEHICLEº or

ªCOMPLETEDº. (It will take approximately 3 seconds.)

If the check result NG appears on CONSULT-II screen, go to

ªDIAGNOSTIC PROCEDUREº, AT-143.

If ªSTOP VEHICLEº appears on CONSULT-II screen, go to

following step.

ICheck that ªGEARº shows ª4º when depressing accelera-

tor pedal with 1.0/8 - 2.0/8 of ªTHROTTLE POSIº.

IIf ªTESTINGº does not appear on CONSULT-II for a long

time, select ªSELF-DIAG RESULTSº for ªENGINEº. In case

a 1st trip DTC other than P0734 is shown, refer to appli-

cable ªTROUBLE DIAGNOSIS FOR DTCº.

6) Stop vehicle.

7) Follow the instruction displayed. (Check for normal shifting

referring to the table below.)

Vehicle conditionGear on actual transmission shift pattern when

screen is changed to 1,2,3,4

No malfunction exists 1,2,3,4

Malfunction for P0734 exists. 1,2,2,1

DTC P0734 IMPROPER SHIFTING TO 4TH GEAR POSITION

Description (Cont'd)

AT-140

Page 284 of 2395

SAT017B

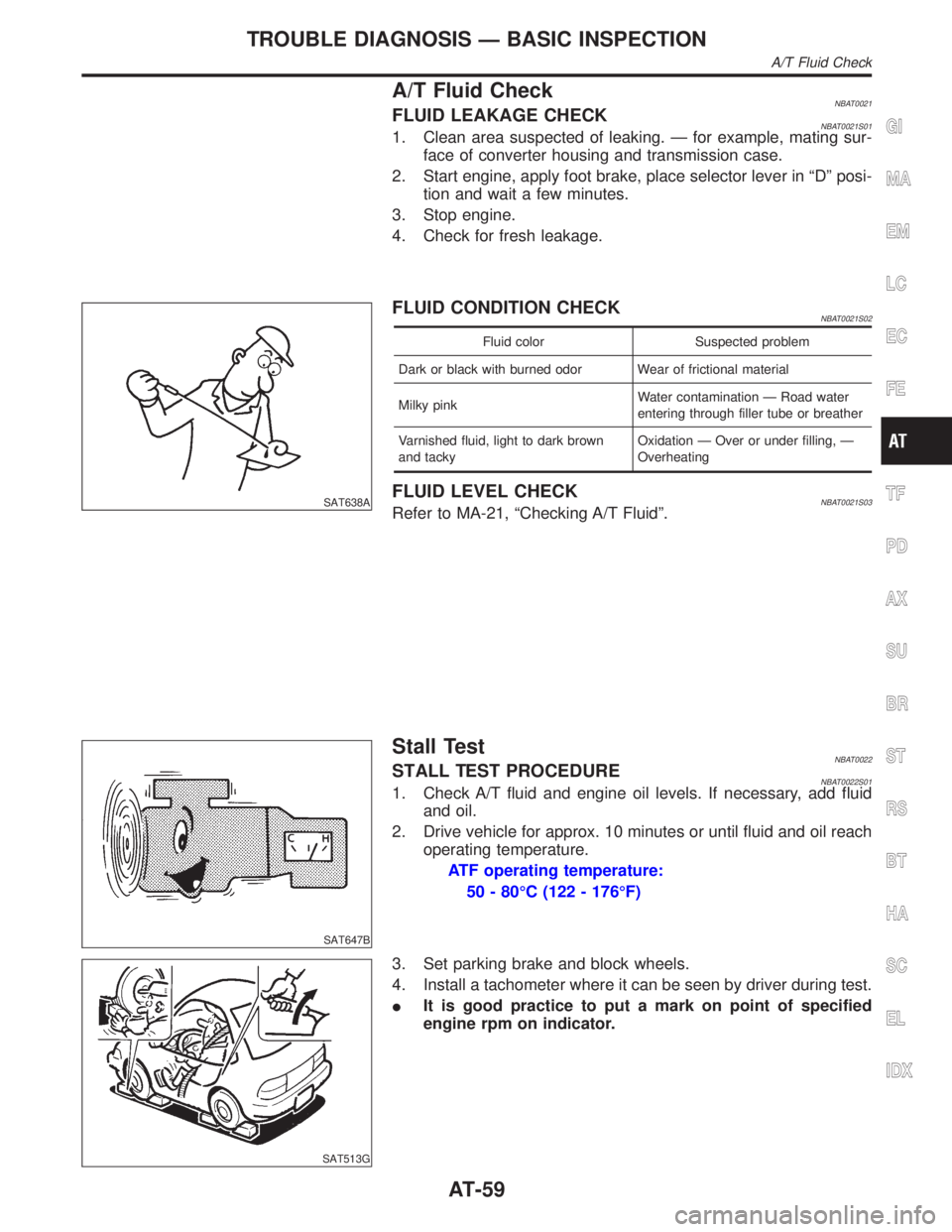

IWhen connecting torque converter to transmission, measure

distance ªAº to be certain that they are correctly assembled.

Distance ªAº:

25.0 mm (0.984 in) or more

SAT148K

IInstall converter to drive plate.

IAfter converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission

rotates freely without binding.

SAT149K

ITighten bolts securing transmission.

Bolt No.Tightening torque

N´m (kg-m, ft-lb)Bolt length ªº

mm (in)

1 70 - 80 (7.1 - 8.2, 52 - 59) 65 (2.56)

2 70 - 80 (7.1 - 8.2, 52 - 59) 55 (2.17)

3 29 - 39 (3.0 - 4.0, 22 - 29) 40 (1.57)

IReinstall any part removed.

SAT638A

ICheck fluid level in transmission.

IMove selector lever through all positions to be sure that trans-

mission operates correctly.

With parking brake applied, rotate engine at idling. Move selec-

tor lever through ªNº to ªDº, to ª2º, to ª1º and to ªRº positions.

A slight shock should be felt by hand gripping selector each

time transmission is shifted.

IPerform road test. Refer to ªROAD TESTº, AT-63.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REMOVAL AND INSTALLATION

Installation (Cont'd)

AT-279

Page 359 of 2395

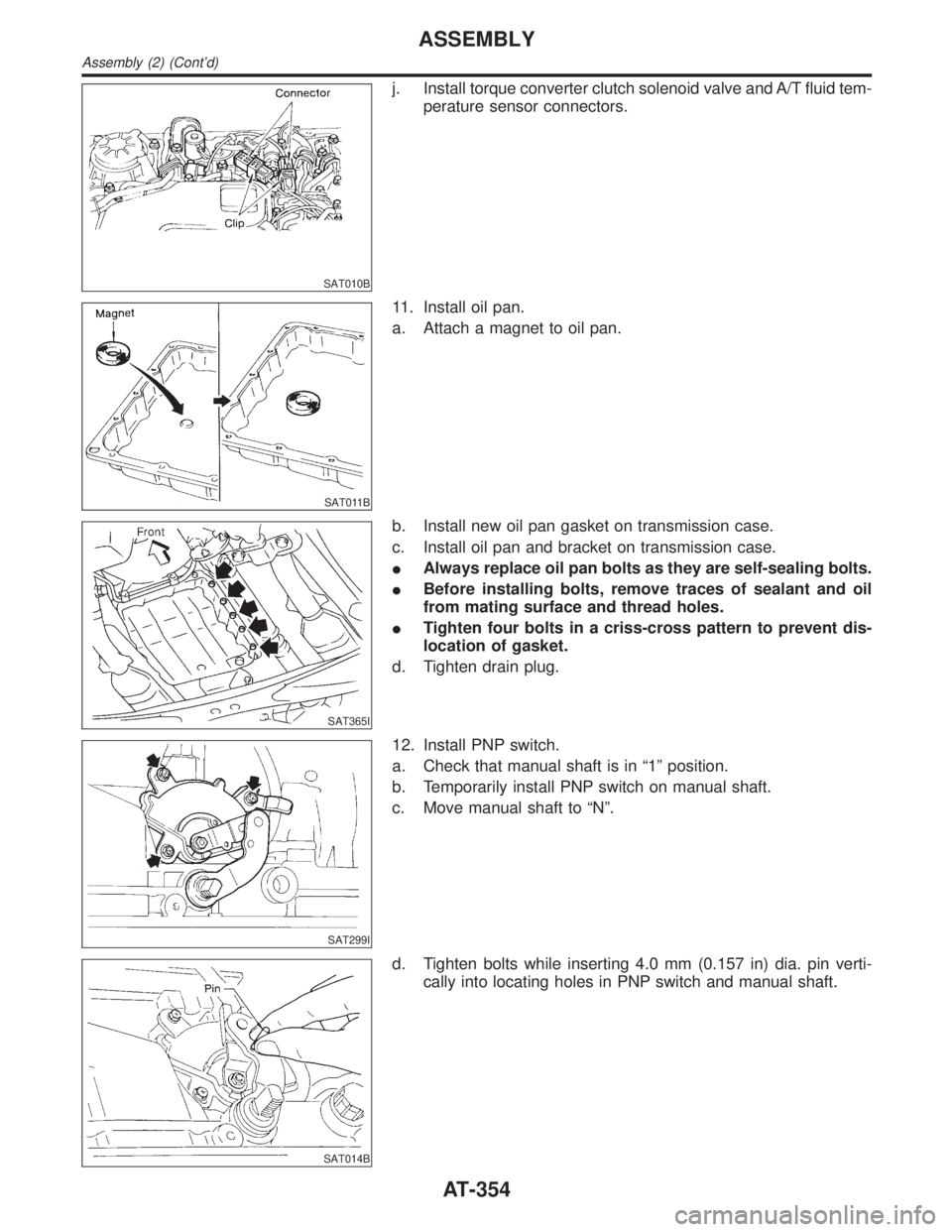

SAT010B

j. Install torque converter clutch solenoid valve and A/T fluid tem-

perature sensor connectors.

SAT011B

11. Install oil pan.

a. Attach a magnet to oil pan.

SAT365I

b. Install new oil pan gasket on transmission case.

c. Install oil pan and bracket on transmission case.

IAlways replace oil pan bolts as they are self-sealing bolts.

IBefore installing bolts, remove traces of sealant and oil

from mating surface and thread holes.

ITighten four bolts in a criss-cross pattern to prevent dis-

location of gasket.

d. Tighten drain plug.

SAT299I

12. Install PNP switch.

a. Check that manual shaft is in ª1º position.

b. Temporarily install PNP switch on manual shaft.

c. Move manual shaft to ªNº.

SAT014B

d. Tighten bolts while inserting 4.0 mm (0.157 in) dia. pin verti-

cally into locating holes in PNP switch and manual shaft.

ASSEMBLY

Assembly (2) (Cont'd)

AT-354

Page 592 of 2395

SEF452Y

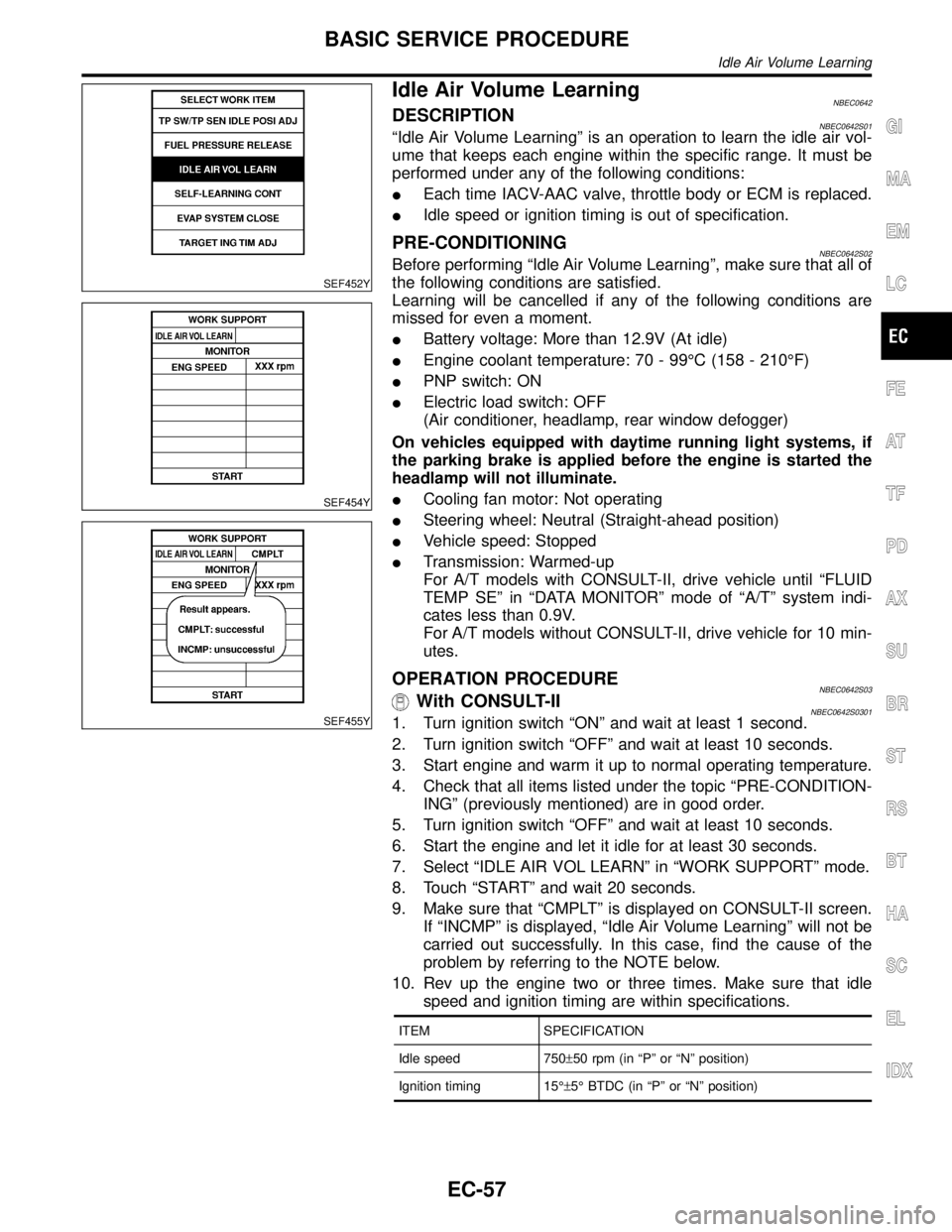

Idle Air Volume LearningNBEC0642

SEF454Y

SEF455Y

DESCRIPTIONNBEC0642S01ªIdle Air Volume Learningº is an operation to learn the idle air vol-

ume that keeps each engine within the specific range. It must be

performed under any of the following conditions:

IEach time IACV-AAC valve, throttle body or ECM is replaced.

IIdle speed or ignition timing is out of specification.

PRE-CONDITIONINGNBEC0642S02Before performing ªIdle Air Volume Learningº, make sure that all of

the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are

missed for even a moment.

IBattery voltage: More than 12.9V (At idle)

IEngine coolant temperature: 70 - 99ÉC (158 - 210ÉF)

IPNP switch: ON

IElectric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime running light systems, if

the parking brake is applied before the engine is started the

headlamp will not illuminate.

ICooling fan motor: Not operating

ISteering wheel: Neutral (Straight-ahead position)

IVehicle speed: Stopped

ITransmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until ªFLUID

TEMP SEº in ªDATA MONITORº mode of ªA/Tº system indi-

cates less than 0.9V.

For A/T models without CONSULT-II, drive vehicle for 10 min-

utes.

OPERATION PROCEDURENBEC0642S03With CONSULT-IINBEC0642S03011. Turn ignition switch ªONº and wait at least 1 second.

2. Turn ignition switch ªOFFº and wait at least 10 seconds.

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic ªPRE-CONDITION-

INGº (previously mentioned) are in good order.

5. Turn ignition switch ªOFFº and wait at least 10 seconds.

6. Start the engine and let it idle for at least 30 seconds.

7. Select ªIDLE AIR VOL LEARNº in ªWORK SUPPORTº mode.

8. Touch ªSTARTº and wait 20 seconds.

9. Make sure that ªCMPLTº is displayed on CONSULT-II screen.

If ªINCMPº is displayed, ªIdle Air Volume Learningº will not be

carried out successfully. In this case, find the cause of the

problem by referring to the NOTE below.

10. Rev up the engine two or three times. Make sure that idle

speed and ignition timing are within specifications.

ITEM SPECIFICATION

Idle speed 750±50 rpm (in ªPº or ªNº position)

Ignition timing 15ɱ5É BTDC (in ªPº or ªNº position)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

BASIC SERVICE PROCEDURE

Idle Air Volume Learning

EC-57