boot INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 372 of 2395

SMA580A

10. Measure starting force ªAº at wheel hub bolt.

SFA830

11. Install lock washer by tightening the lock nut within 15 to 30

degrees.

12. Turn wheel hub several times in both directions to seat wheel

bearing correctly.

13. Measure starting force ªBº at wheel hub bolt. Refer to proce-

dure 10.

14. Wheel bearing preload ªCº can be calculated as shown below.

C=BþA

Wheel bearing preload ªCº:

7.06 - 20.99 N (0.72 - 2.14 kg, 1.59 - 4.72 lb)

15. If wheel bearing preload ªCº is outside specifications, remove

lock washer. Tighten or loosen lock nut within±15 degrees

(Refer to step 11 above). Install lock washer, then repeat steps

12, 13 and 14.

16. Repeat above procedures until correct axial end play and

wheel bearing preload are obtained.

17. Install drive flange and wheel hub cap.

SFA901

DRIVE SHAFTNBAX0006ICheck boot and drive shaft for cracks, wear, damage and

grease leakage.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

On-vehicle Service (Cont'd)

AX-5

Page 378 of 2395

SFA236

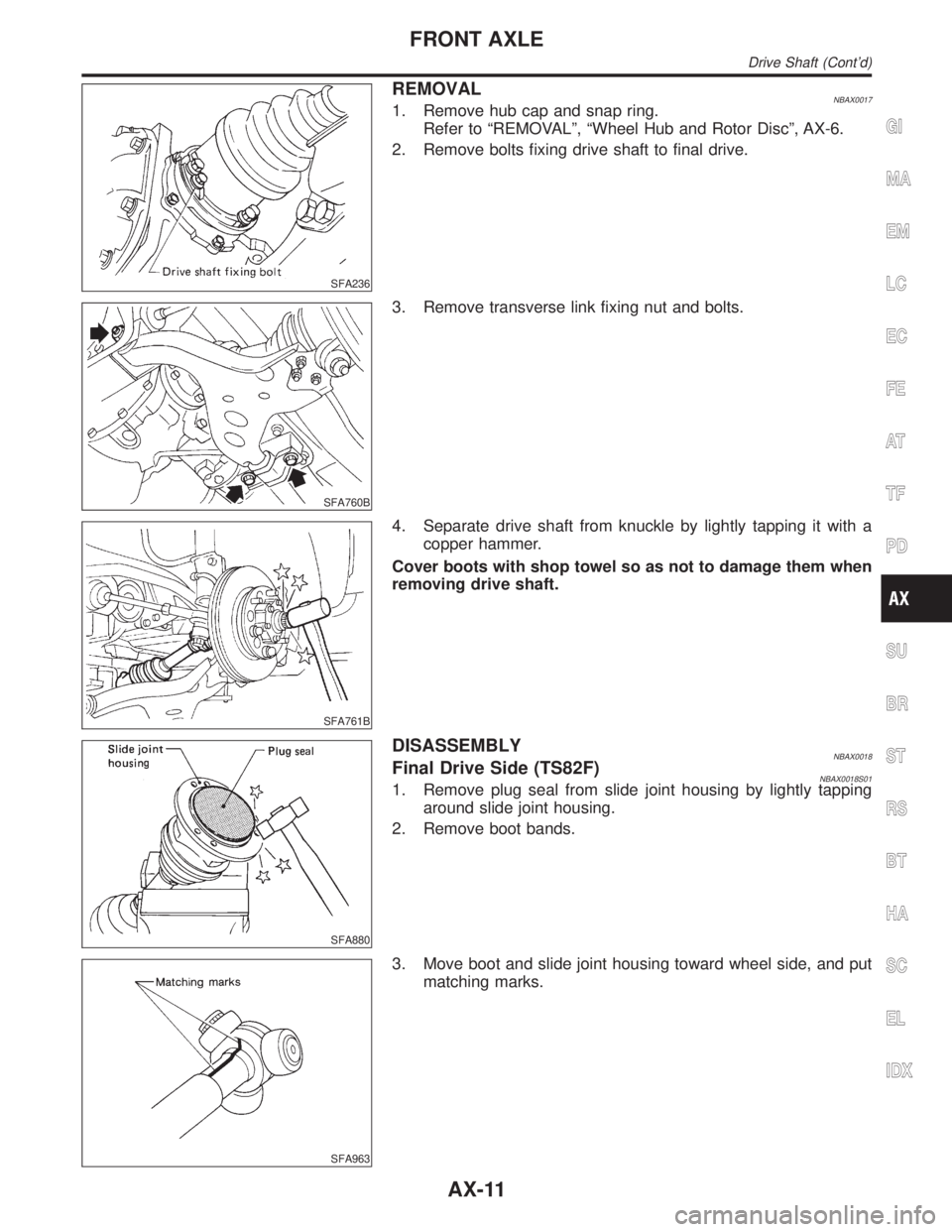

REMOVALNBAX00171. Remove hub cap and snap ring.

Refer to ªREMOVALº, ªWheel Hub and Rotor Discº, AX-6.

2. Remove bolts fixing drive shaft to final drive.

SFA760B

3. Remove transverse link fixing nut and bolts.

SFA761B

4. Separate drive shaft from knuckle by lightly tapping it with a

copper hammer.

Cover boots with shop towel so as not to damage them when

removing drive shaft.

SFA880

DISASSEMBLYNBAX0018Final Drive Side (TS82F)NBAX0018S011. Remove plug seal from slide joint housing by lightly tapping

around slide joint housing.

2. Remove boot bands.

SFA963

3. Move boot and slide joint housing toward wheel side, and put

matching marks.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Drive Shaft (Cont'd)

AX-11

Page 379 of 2395

SFA964

4. Remove snap ring.

SFA392

5. Detach spider assembly with press.

SFA799

6. Draw out boot.

Cover drive shaft serration with tape so as not to damage the

boot.

SFA455

Wheel Side (ZF100)NBAX0018S02CAUTION:

The joint on the wheel side cannot be disassembled.

IBefore separating joint assembly, put matching marks on drive

shaft and joint assembly.

ISeparate joint assembly with suitable tool.

Be careful not to damage threads on drive shaft.

IRemove boot bands.

INSPECTIONNBAX0019Thoroughly clean all parts in cleaning solvent, and dry with com-

pressed air. Check parts for evidence of deformation and other

damage.

Drive ShaftNBAX0019S01Replace drive shaft if it is twisted or cracked.

BootNBAX0019S02Check boot for fatigue, cracks, and wear. Replace boot with new

boot bands.

FRONT AXLE

Drive Shaft (Cont'd)

AX-12

Page 380 of 2395

Joint Assembly (Final drive side)NBAX0019S03IReplace any parts of double offset joint which show signs of

scorching, rust, wear or excessive play.

ICheck serration for deformation. Replace if necessary.

ICheck slide joint housing for any damage. Replace if neces-

sary.

Joint Assembly (Wheel side)NBAX0019S04Replace joint assembly if it is deformed or damaged.

ASSEMBLYNBAX0020IAfter drive shaft has been assembled, ensure that it

moves smoothly over its entire range without binding.

IUse NISSAN GENUINE GREASE or equivalent after every

overhaul.

SFA800

Final Drive Side (TS82F)NBAX0020S011. Install new small boot band, boot and side joint housing to

drive shaft.

Cover drive shaft serration with tape so as not to damage boot

during installation.

SFA397

2. Install spider assembly securely, ensuring marks are properly

aligned.

IPress-fit with spider assembly serration chamfer facing

shaft.

3. Install new snap ring.

SFA460BA

4. Pack with grease.

Specified amount of grease:

95 - 105 g (3.35 - 3.70 oz)

5. Make sure that boot is properly installed on the drive shaft

groove. Set boot so that it does not swell and deform when its

length is ªL

1º.

Length ªL

1º: 95 - 97 mm (3.74 - 3.82 in)

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Drive Shaft (Cont'd)

AX-13

Page 381 of 2395

SFA443B

6. Lock new larger boot band securely with a suitable tool, then

lock new smaller boot band.

7. Install new plug seal to slide joint housing by lightly tapping it.

Apply sealant to mating surface of plug seal.

SFA800

Wheel Side (ZF100)NBAX0020S021. Install new small boot band and boot on drive shaft.

Cover drive shaft serration with tape so as not to damage boot

during installation.

SFA884

2. Set joint assembly onto drive shaft by lightly tapping it.

Install joint assembly securely, ensuring marks which were

made during disassembly are properly aligned.

SFA473BA

3. Pack drive shaft with specified amount of grease.

Specified amount of grease:

135 - 145 g (4.76 - 5.11 oz)

4. Make sure that boot is properly installed on the drive shaft

groove. Set boot so that it does not swell and deform when its

length is ªL

2º.

Length ªL

2º: 96 - 98 mm (3.78 - 3.86 in)

5. Lock new larger boot band securely with a suitable tool.

6. Lock new smaller boot band.

SFA887

INSTALLATIONNBAX00211. Apply multi-purpose grease.

FRONT AXLE

Drive Shaft (Cont'd)

AX-14

Page 383 of 2395

DRIVE SHAFT=NBAX0033

Drive shaft joint typeFinal drive sideTS82F

Wheel sideZF100

Fixed joint axial end play limit 1 mm (0.04 in)

Diameter Wheel side (D

1)29.0 mm (1.142 in)

GreaseQualityNissan genuine grease or equivalent

Specified amount of greaseFinal drive side 95 - 105 g (3.35 - 3.70 oz)

Wheel side 135 - 145 g (4.76 - 5.11 oz)

Drive shaft axial end play0.45 mm (0.0177 in) or less

Boot lengthFinal drive side (L

1) 95 - 97 mm (3.74 - 3.82 in)

Wheel side (L

2) 96 - 98 mm (3.78 - 3.86 in)

SAX001

Drive Shaft End Snap RingNBAX0033S01

Thickness mm (in) Part No. Thickness mm (in) Part No.

1.1 (0.043)

1.3 (0.051)

1.5 (0.059)

1.7 (0.067)39253-88G10

39253-88G11

39253-88G12

39253-88G131.9 (0.075)

2.1 (0.083)

2.3 (0.091)39253-88G14

39253-88G15

39253-88G16

FRONT AXLE

Service Data and Specifications (SDS) (Cont'd)

AX-16

Page 411 of 2395

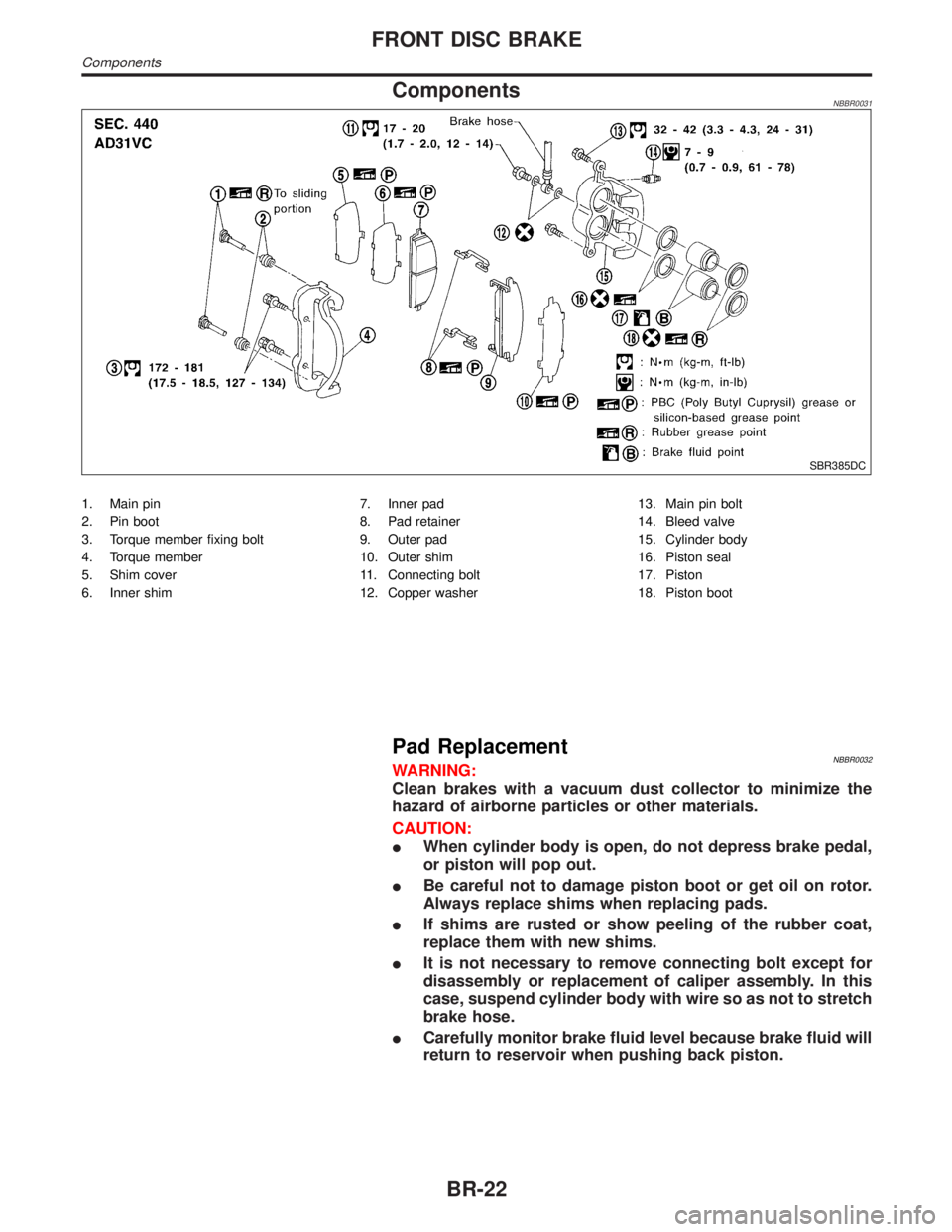

ComponentsNBBR0031

SBR385DC

1. Main pin

2. Pin boot

3. Torque member fixing bolt

4. Torque member

5. Shim cover

6. Inner shim7. Inner pad

8. Pad retainer

9. Outer pad

10. Outer shim

11. Connecting bolt

12. Copper washer13. Main pin bolt

14. Bleed valve

15. Cylinder body

16. Piston seal

17. Piston

18. Piston boot

Pad ReplacementNBBR0032WARNING:

Clean brakes with a vacuum dust collector to minimize the

hazard of airborne particles or other materials.

CAUTION:

IWhen cylinder body is open, do not depress brake pedal,

or piston will pop out.

IBe careful not to damage piston boot or get oil on rotor.

Always replace shims when replacing pads.

IIf shims are rusted or show peeling of the rubber coat,

replace them with new shims.

IIt is not necessary to remove connecting bolt except for

disassembly or replacement of caliper assembly. In this

case, suspend cylinder body with wire so as not to stretch

brake hose.

ICarefully monitor brake fluid level because brake fluid will

return to reservoir when pushing back piston.

FRONT DISC BRAKE

Components

BR-22

Page 413 of 2395

SBR085A

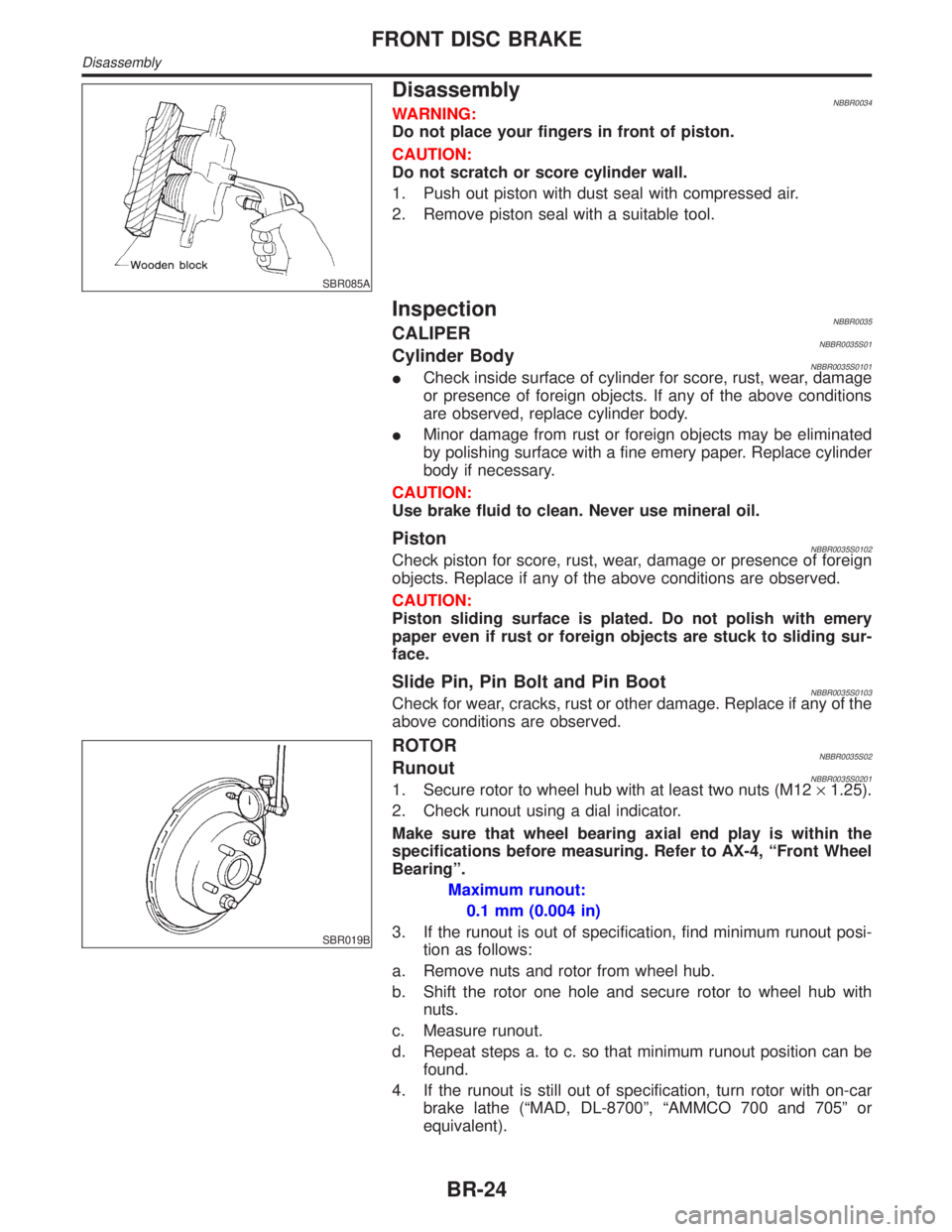

DisassemblyNBBR0034WARNING:

Do not place your fingers in front of piston.

CAUTION:

Do not scratch or score cylinder wall.

1. Push out piston with dust seal with compressed air.

2. Remove piston seal with a suitable tool.

InspectionNBBR0035CALIPERNBBR0035S01Cylinder BodyNBBR0035S0101ICheck inside surface of cylinder for score, rust, wear, damage

or presence of foreign objects. If any of the above conditions

are observed, replace cylinder body.

IMinor damage from rust or foreign objects may be eliminated

by polishing surface with a fine emery paper. Replace cylinder

body if necessary.

CAUTION:

Use brake fluid to clean. Never use mineral oil.

PistonNBBR0035S0102Check piston for score, rust, wear, damage or presence of foreign

objects. Replace if any of the above conditions are observed.

CAUTION:

Piston sliding surface is plated. Do not polish with emery

paper even if rust or foreign objects are stuck to sliding sur-

face.

Slide Pin, Pin Bolt and Pin BootNBBR0035S0103Check for wear, cracks, rust or other damage. Replace if any of the

above conditions are observed.

SBR019B

ROTORNBBR0035S02RunoutNBBR0035S02011. Secure rotor to wheel hub with at least two nuts (M12´1.25).

2. Check runout using a dial indicator.

Make sure that wheel bearing axial end play is within the

specifications before measuring. Refer to AX-4, ªFront Wheel

Bearingº.

Maximum runout:

0.1 mm (0.004 in)

3. If the runout is out of specification, find minimum runout posi-

tion as follows:

a. Remove nuts and rotor from wheel hub.

b. Shift the rotor one hole and secure rotor to wheel hub with

nuts.

c. Measure runout.

d. Repeat steps a. to c. so that minimum runout position can be

found.

4. If the runout is still out of specification, turn rotor with on-car

brake lathe (ªMAD, DL-8700º, ªAMMCO 700 and 705º or

equivalent).

FRONT DISC BRAKE

Disassembly

BR-24

Page 414 of 2395

SBR020B

ThicknessNBBR0035S0202Thickness variation (At least 8 positions):

Maximum 0.015 mm (0.0006 in)

If thickness variation exceeds the specification, turn rotor with on-

car brake lathe.

Rotor repair limit:

26.0 mm (1.024 in)

SBR574

AssemblyNBBR00361. Insert piston seal into groove on cylinder body.

2. With piston boot fitted to piston, insert piston boot into groove

on cylinder body and install piston.

3. Properly secure piston boot

SBR387D

InstallationNBBR0037CAUTION:

IRefill with new brake fluid ªDOT 3º.

INever reuse drained brake fluid.

1. Install caliper assembly.

2. Install brake hose to caliper securely.

3. Install all parts and secure all bolts.

4. Bleed air. Refer to ªBleeding Brake Systemº, BR-8.

Brake Burnishing ProcedureNBBR0086When experiencing soft brake pedal feel at very low mileage, or

after replacing the rotor, burnish the brake pad contact surfaces

according to the following procedures.

CAUTION:

Only perform this procedure under safe road and traffic con-

ditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31

MPH).

2. Use medium brake pedal/foot effort to bring the vehicle to a

complete stop from 50 km/h (31 MPH). Adjust brake pedal/foot

pressure such that vehicle stopping time equals 3 to 5 sec-

onds.

3. To cool the brake system, drive the vehicle at 50 km/h (31

MPH) for 1 minute without stopping.

4. Repeat steps 1 to 3 10 times or more to complete the burnish-

ing procedure.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

ST

RS

BT

HA

SC

EL

IDX

FRONT DISC BRAKE

Inspection (Cont'd)

BR-25

Page 415 of 2395

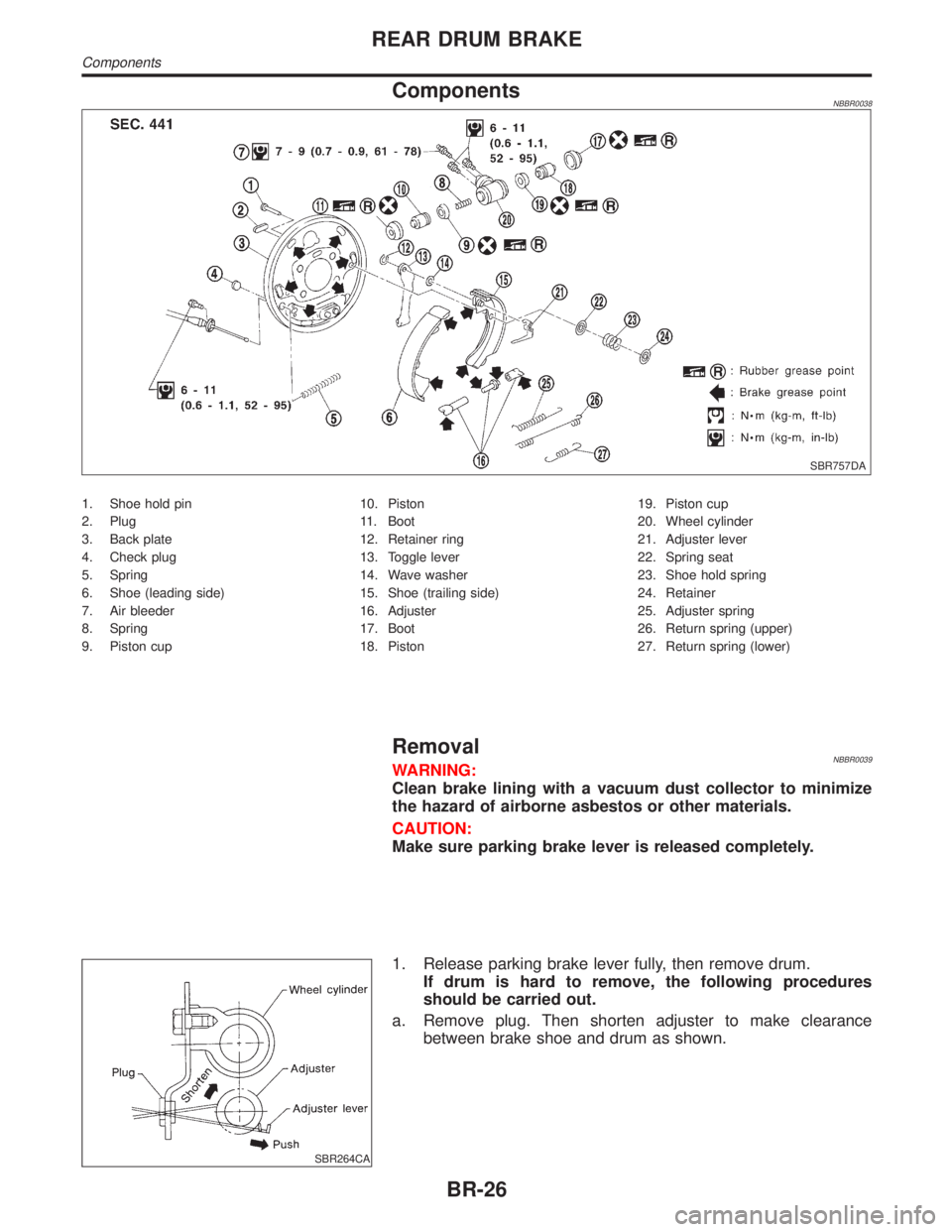

ComponentsNBBR0038

SBR757DA

1. Shoe hold pin

2. Plug

3. Back plate

4. Check plug

5. Spring

6. Shoe (leading side)

7. Air bleeder

8. Spring

9. Piston cup10. Piston

11. Boot

12. Retainer ring

13. Toggle lever

14. Wave washer

15. Shoe (trailing side)

16. Adjuster

17. Boot

18. Piston19. Piston cup

20. Wheel cylinder

21. Adjuster lever

22. Spring seat

23. Shoe hold spring

24. Retainer

25. Adjuster spring

26. Return spring (upper)

27. Return spring (lower)

RemovalNBBR0039WARNING:

Clean brake lining with a vacuum dust collector to minimize

the hazard of airborne asbestos or other materials.

CAUTION:

Make sure parking brake lever is released completely.

SBR264CA

1. Release parking brake lever fully, then remove drum.

If drum is hard to remove, the following procedures

should be carried out.

a. Remove plug. Then shorten adjuster to make clearance

between brake shoe and drum as shown.

REAR DRUM BRAKE

Components

BR-26