wheel bolt torque INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 283 of 2395

SAT801C

12. Support A/T and transfer assembly with a jack.

13. Remove rear engine mounting member from body and A/T

assembly. Tighten rear engine mounting member to the speci-

fied torque. Refer to EM-59, ªRear Engine Mountingº.

14. Remove bolts securing A/T assembly to engine.

ISecure torque converter to prevent it from dropping.

ISecure A/T assembly to a jack.

15. Lower A/T assembly with transfer.

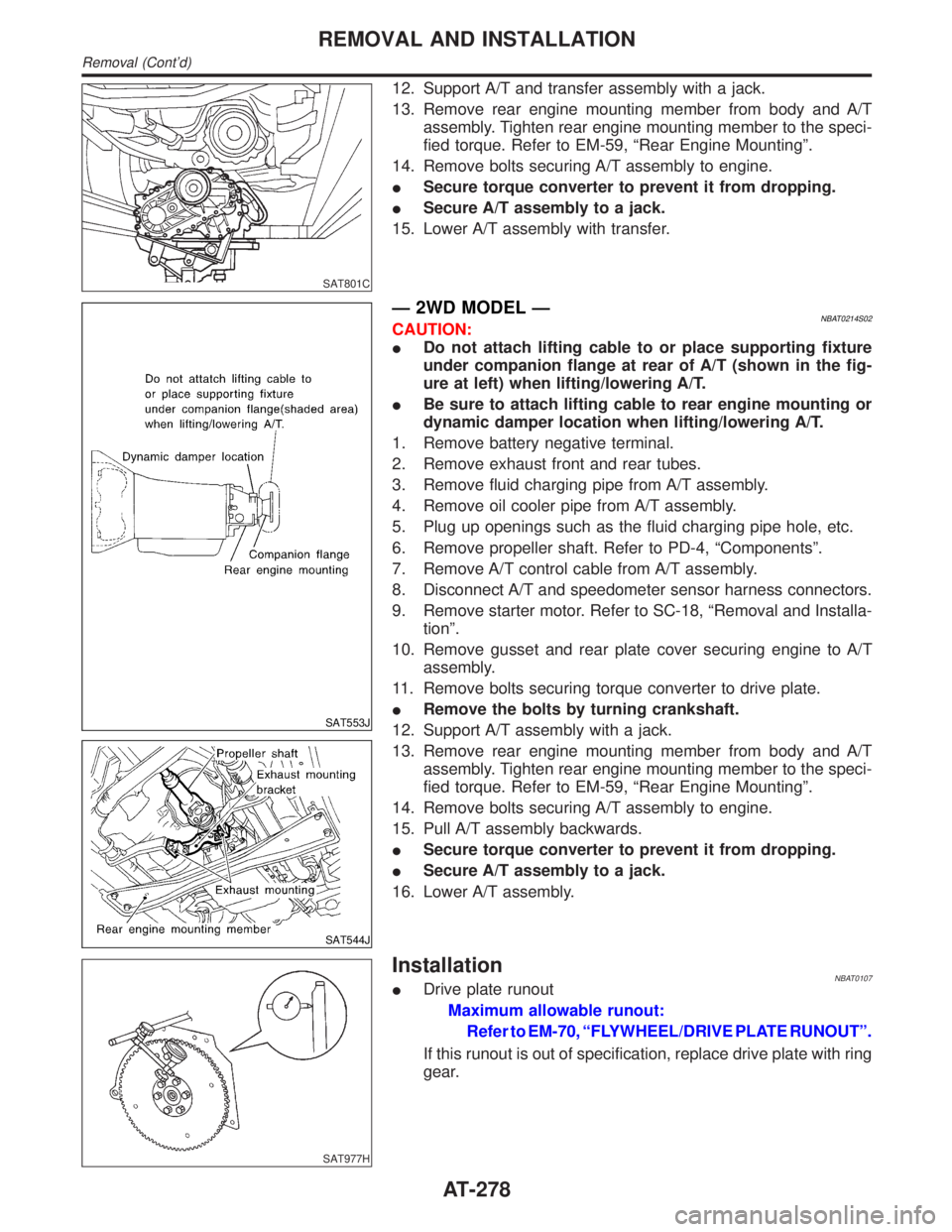

SAT553J

SAT544J

Ð 2WD MODEL ÐNBAT0214S02CAUTION:

IDo not attach lifting cable to or place supporting fixture

under companion flange at rear of A/T (shown in the fig-

ure at left) when lifting/lowering A/T.

IBe sure to attach lifting cable to rear engine mounting or

dynamic damper location when lifting/lowering A/T.

1. Remove battery negative terminal.

2. Remove exhaust front and rear tubes.

3. Remove fluid charging pipe from A/T assembly.

4. Remove oil cooler pipe from A/T assembly.

5. Plug up openings such as the fluid charging pipe hole, etc.

6. Remove propeller shaft. Refer to PD-4, ªComponentsº.

7. Remove A/T control cable from A/T assembly.

8. Disconnect A/T and speedometer sensor harness connectors.

9. Remove starter motor. Refer to SC-18, ªRemoval and Installa-

tionº.

10. Remove gusset and rear plate cover securing engine to A/T

assembly.

11. Remove bolts securing torque converter to drive plate.

IRemove the bolts by turning crankshaft.

12. Support A/T assembly with a jack.

13. Remove rear engine mounting member from body and A/T

assembly. Tighten rear engine mounting member to the speci-

fied torque. Refer to EM-59, ªRear Engine Mountingº.

14. Remove bolts securing A/T assembly to engine.

15. Pull A/T assembly backwards.

ISecure torque converter to prevent it from dropping.

ISecure A/T assembly to a jack.

16. Lower A/T assembly.

SAT977H

InstallationNBAT0107IDrive plate runout

Maximum allowable runout:

Refer to EM-70, ªFLYWHEEL/DRIVE PLATE RUNOUTº.

If this runout is out of specification, replace drive plate with ring

gear.

REMOVAL AND INSTALLATION

Removal (Cont'd)

AT-278

Page 370 of 2395

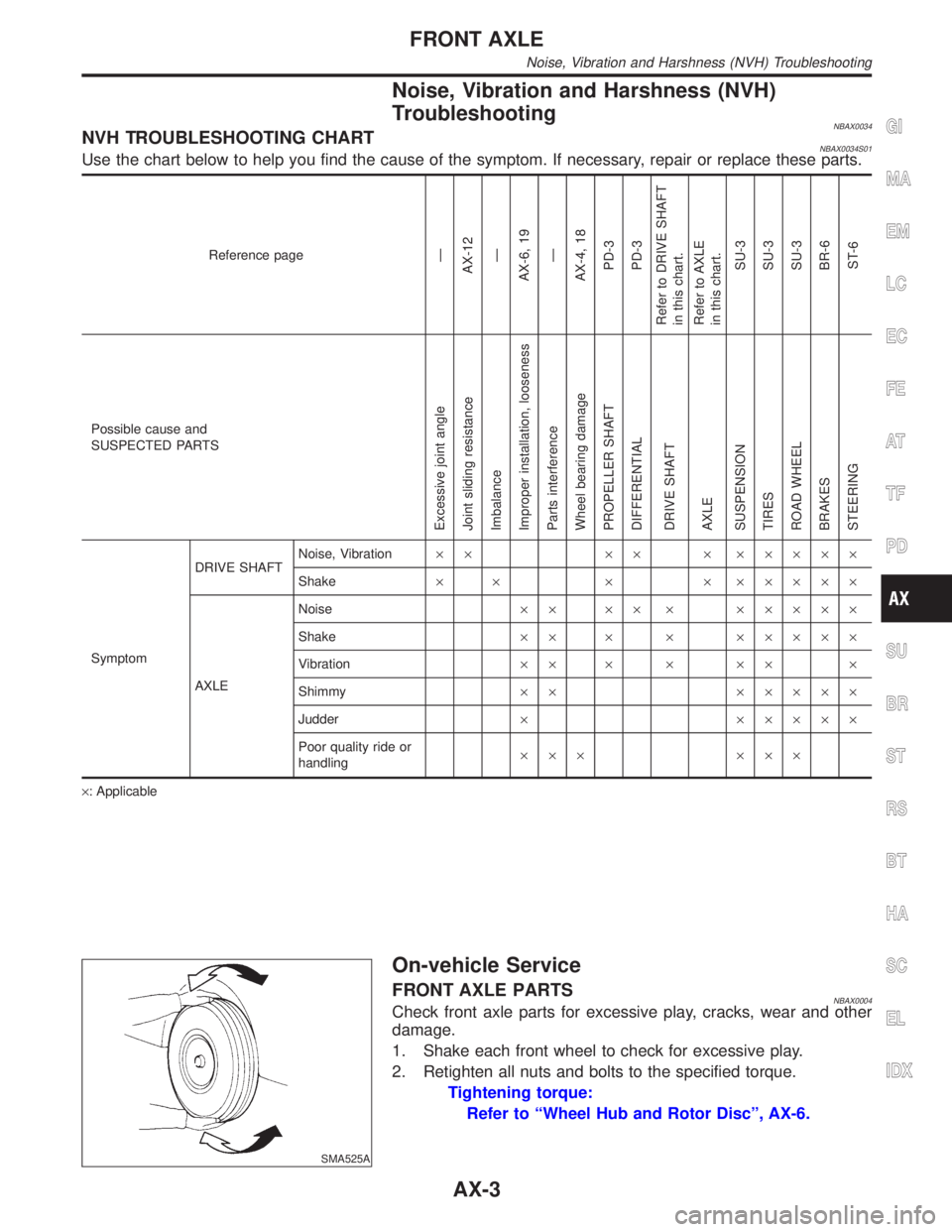

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBAX0034NVH TROUBLESHOOTING CHARTNBAX0034S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

AX-12

Ð

AX-6, 19

Ð

AX-4, 18

PD-3

PD-3

Refer to DRIVE SHAFT

in this chart.

Refer to AXLE

in this chart.

SU-3

SU-3

SU-3

BR-6

ST-6

Possible cause and

SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration´´ ´´ ´ ´´´´´

Shake´ ´ ´ ´ ´´´´´

AXLENoise´´ ´´ ´ ´´´´´

Shake´´ ´ ´ ´´´´´

Vibration´´ ´ ´ ´´ ´

Shimmy´´ ´´´´´

Judder´ ´´´´´

Poor quality ride or

handling´´´ ´´´

´: Applicable

SMA525A

On-vehicle Service

FRONT AXLE PARTSNBAX0004Check front axle parts for excessive play, cracks, wear and other

damage.

1. Shake each front wheel to check for excessive play.

2. Retighten all nuts and bolts to the specified torque.

Tightening torque:

Refer to ªWheel Hub and Rotor Discº, AX-6.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-3

Page 382 of 2395

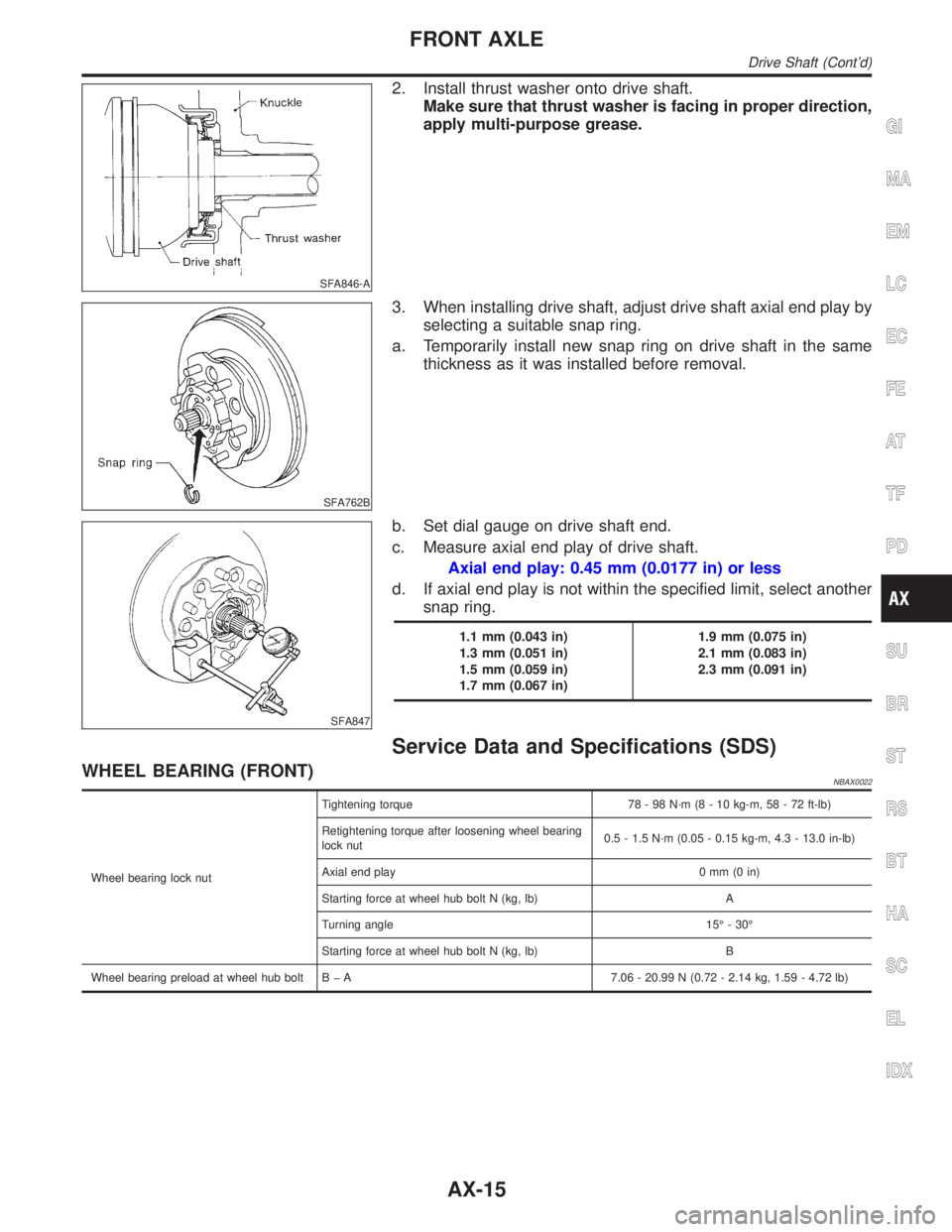

SFA846-A

2. Install thrust washer onto drive shaft.

Make sure that thrust washer is facing in proper direction,

apply multi-purpose grease.

SFA762B

3. When installing drive shaft, adjust drive shaft axial end play by

selecting a suitable snap ring.

a. Temporarily install new snap ring on drive shaft in the same

thickness as it was installed before removal.

SFA847

b. Set dial gauge on drive shaft end.

c. Measure axial end play of drive shaft.

Axial end play: 0.45 mm (0.0177 in) or less

d. If axial end play is not within the specified limit, select another

snap ring.

1.1 mm (0.043 in)

1.3 mm (0.051 in)

1.5 mm (0.059 in)

1.7 mm (0.067 in)1.9 mm (0.075 in)

2.1 mm (0.083 in)

2.3 mm (0.091 in)

Service Data and Specifications (SDS)

WHEEL BEARING (FRONT)NBAX0022

Wheel bearing lock nutTightening torque 78 - 98 N´m (8 - 10 kg-m, 58 - 72 ft-lb)

Retightening torque after loosening wheel bearing

lock nut0.5 - 1.5 N´m (0.05 - 0.15 kg-m, 4.3 - 13.0 in-lb)

Axial end play 0 mm (0 in)

Starting force at wheel hub bolt N (kg, lb) A

Turning angle 15É - 30É

Starting force at wheel hub bolt N (kg, lb) B

Wheel bearing preload at wheel hub bolt B þ A 7.06 - 20.99 N (0.72 - 2.14 kg, 1.59 - 4.72 lb)

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Drive Shaft (Cont'd)

AX-15

Page 385 of 2395

COMMERCIAL SERVICE TOOLSNBAX0025

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Rear axle oil seal drift

NT163

Installing oil seal

a: 74 mm (2.91 in) dia.

b: 68 mm (2.68 in) dia.

c: 10 mm (0.39 in)

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBAX0035Refer to ªNoise, Vibration and Harshness (NVH) Troubleshootingº,

ªFRONT AXLEº, AX-3.

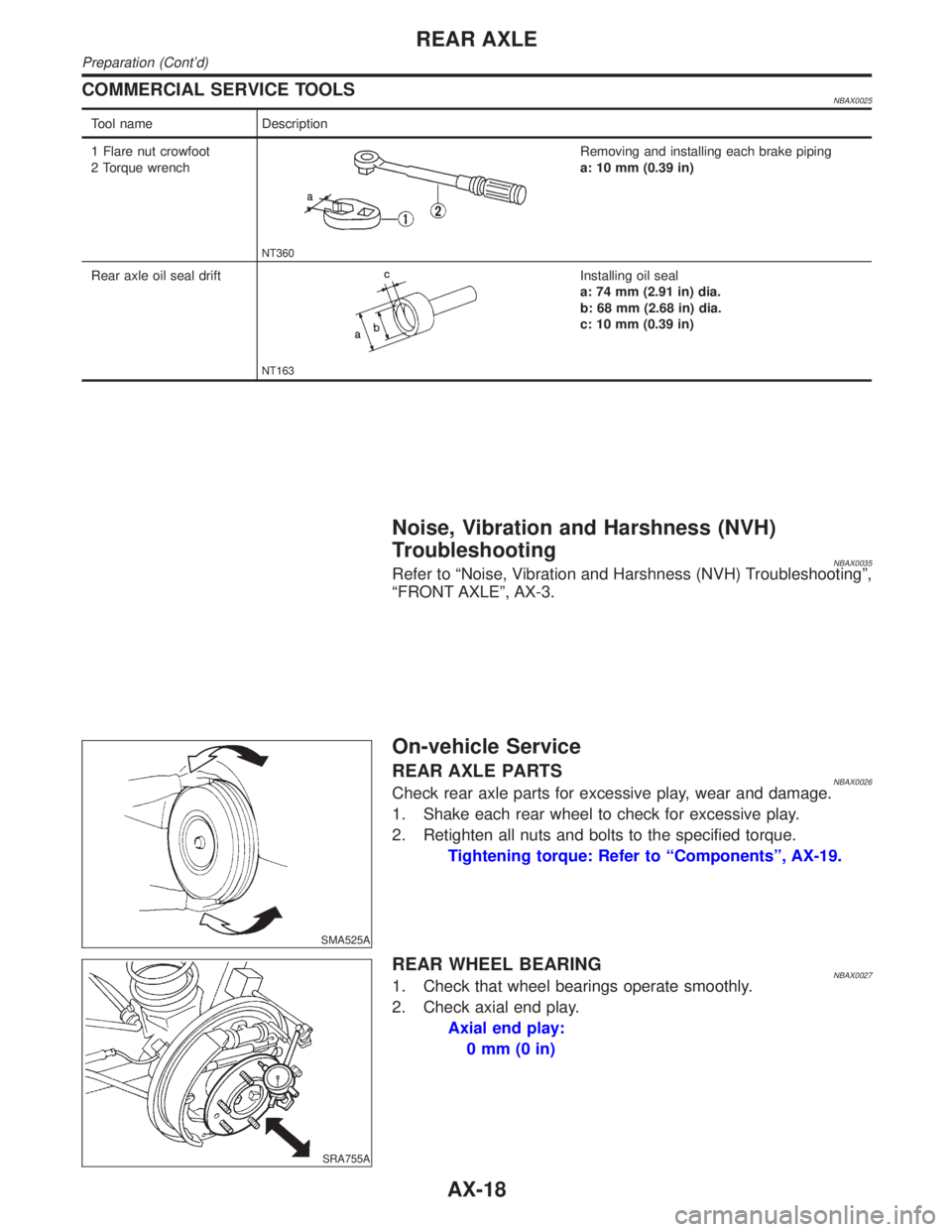

SMA525A

On-vehicle Service

REAR AXLE PARTSNBAX0026Check rear axle parts for excessive play, wear and damage.

1. Shake each rear wheel to check for excessive play.

2. Retighten all nuts and bolts to the specified torque.

Tightening torque: Refer to ªComponentsº, AX-19.

SRA755A

REAR WHEEL BEARINGNBAX00271. Check that wheel bearings operate smoothly.

2. Check axial end play.

Axial end play:

0mm(0in)

REAR AXLE

Preparation (Cont'd)

AX-18

Page 389 of 2395

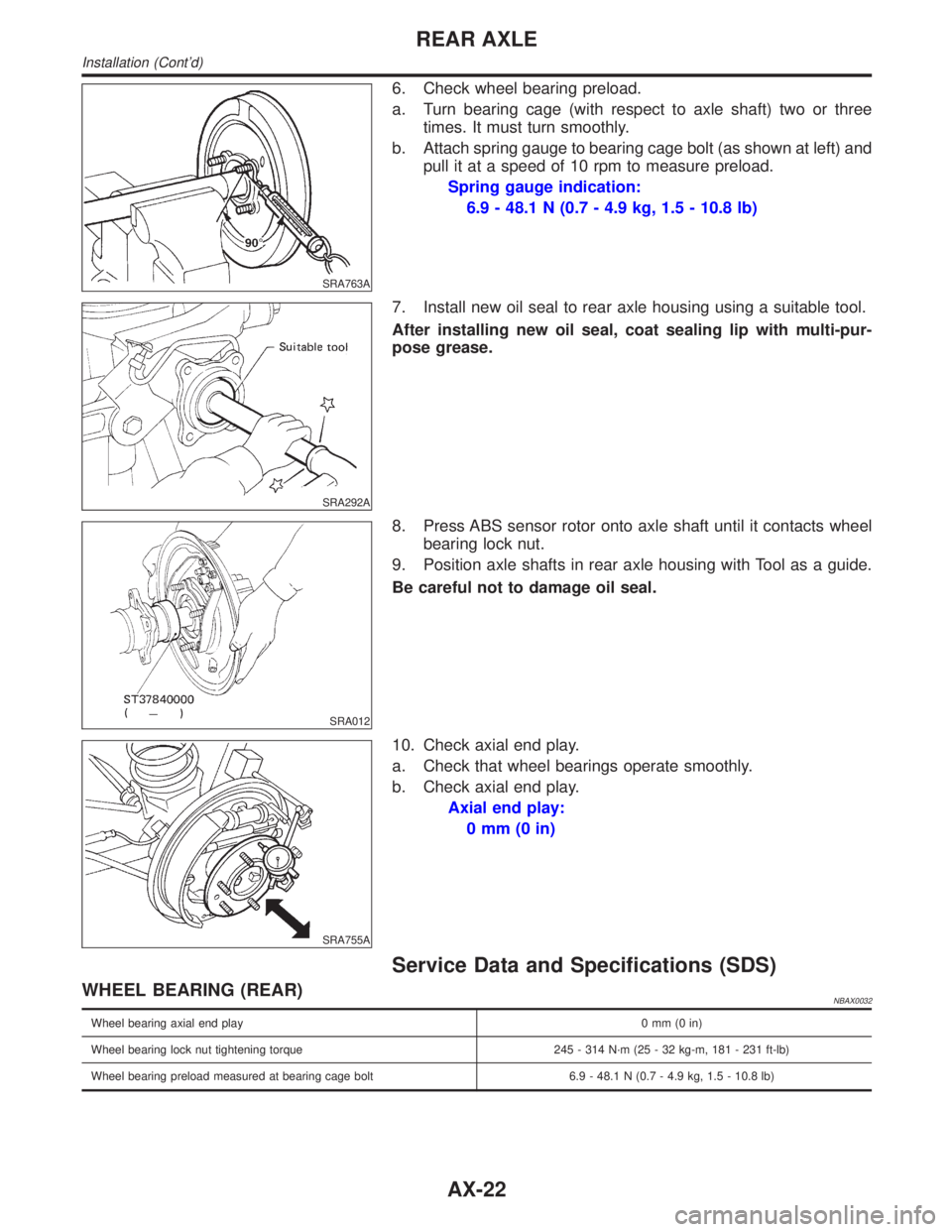

SRA763A

6. Check wheel bearing preload.

a. Turn bearing cage (with respect to axle shaft) two or three

times. It must turn smoothly.

b. Attach spring gauge to bearing cage bolt (as shown at left) and

pull it at a speed of 10 rpm to measure preload.

Spring gauge indication:

6.9 - 48.1 N (0.7 - 4.9 kg, 1.5 - 10.8 lb)

SRA292A

7. Install new oil seal to rear axle housing using a suitable tool.

After installing new oil seal, coat sealing lip with multi-pur-

pose grease.

SRA012

8. Press ABS sensor rotor onto axle shaft until it contacts wheel

bearing lock nut.

9. Position axle shafts in rear axle housing with Tool as a guide.

Be careful not to damage oil seal.

SRA755A

10. Check axial end play.

a. Check that wheel bearings operate smoothly.

b. Check axial end play.

Axial end play:

0mm(0in)

Service Data and Specifications (SDS)

WHEEL BEARING (REAR)NBAX0032

Wheel bearing axial end play0mm(0in)

Wheel bearing lock nut tightening torque 245 - 314 N´m (25 - 32 kg-m, 181 - 231 ft-lb)

Wheel bearing preload measured at bearing cage bolt 6.9 - 48.1 N (0.7 - 4.9 kg, 1.5 - 10.8 lb)

REAR AXLE

Installation (Cont'd)

AX-22

Page 1745 of 2395

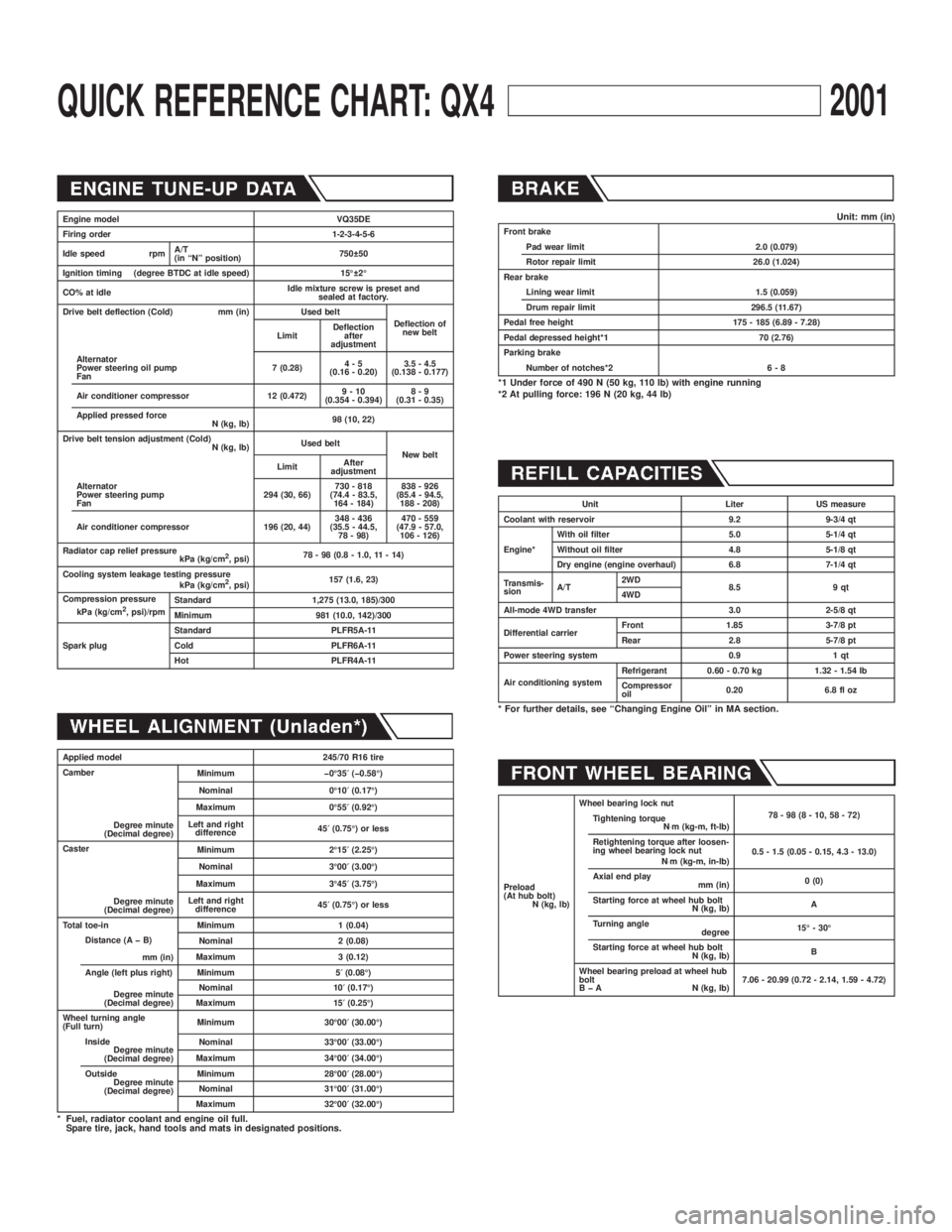

QUICK REFERENCE CHART: QX42001

Engine model VQ35DE

Firing order 1-2-3-4-5-6

Idle speed rpmA/T

(in ªNº position)750 50

Ignition timing (degree BTDC at idle speed) 15É 2É

CO% at idleIdle mixture screw is preset and

sealed at factory.

Drive belt deflection (Cold) mm (in) Used belt

Deflection of

new belt

LimitDeflection

after

adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4-5

(0.16 - 0.20)3.5 - 4.5

(0.138 - 0.177)

Air conditioner compressor 12 (0.472)9-10

(0.354 - 0.394)8-9

(0.31 - 0.35)

Applied pressed force

N (kg, lb)98 (10, 22)

Drive belt tension adjustment (Cold)

N (kg, lb)Used belt

New belt

LimitAfter

adjustment

Alternator

Power steering pump

Fan294 (30, 66)730 - 818

(74.4 - 83.5,

164 - 184)838 - 926

(85.4 - 94.5,

188 - 208)

Air conditioner compressor 196 (20, 44)348 - 436

(35.5 - 44.5,

78 - 98)470 - 559

(47.9 - 57.0,

106 - 126)

Radiator cap relief pressure

kPa (kg/cm

2, psi)78 - 98 (0.8 - 1.0, 11 - 14)

Cooling system leakage testing pressure

kPa (kg/cm

2, psi)157 (1.6, 23)

Compression pressure

kPa (kg/cm

2, psi)/rpmStandard 1,275 (13.0, 185)/300

Minimum 981 (10.0, 142)/300

Spark plugStandard PLFR5A-11

Cold PLFR6A-11

Hot PLFR4A-11

Applied model 245/70 R16 tire

Camber

Degree minute

(Decimal degree)Minimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right

difference45¢(0.75É) or less

Caster

Degree minute

(Decimal degree)Minimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right

difference45¢(0.75É) or less

Total toe-in Minimum 1 (0.04)

Distance (A þ B)

mm (in)Nominal 2 (0.08)

Maximum 3 (0.12)

Angle (left plus right)

Degree minute

(Decimal degree)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle

(Full turn)Minimum 30É00¢(30.00É)

Inside

Degree minute

(Decimal degree)Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

Outside

Degree minute

(Decimal degree)Minimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

* Fuel, radiator coolant and engine oil full.

Spare tire, jack, hand tools and mats in designated positions.

Unit: mm (in)Front brake

Pad wear limit 2.0 (0.079)

Rotor repair limit 26.0 (1.024)

Rear brake

Lining wear limit 1.5 (0.059)

Drum repair limit 296.5 (11.67)

Pedal free height 175 - 185 (6.89 - 7.28)

Pedal depressed height*1 70 (2.76)

Parking brake

Number of notches*2 6 - 8

*1 Under force of 490 N (50 kg, 110 lb) with engine running

*2 At pulling force: 196 N (20 kg, 44 lb)

Unit Liter US measure

Coolant with reservoir 9.2 9-3/4 qt

Engine*With oil filter 5.0 5-1/4 qt

Without oil filter 4.8 5-1/8 qt

Dry engine (engine overhaul) 6.8 7-1/4 qt

Transmis-

sionA/T2WD

8.5 9 qt

4WD

All-mode 4WD transfer 3.0 2-5/8 qt

Differential carrierFront 1.85 3-7/8 pt

Rear 2.8 5-7/8 pt

Power steering system 0.9 1 qt

Air conditioning systemRefrigerant 0.60 - 0.70 kg 1.32 - 1.54 lb

Compressor

oil0.20 6.8 fl oz

* For further details, see ªChanging Engine Oilº in MA section.

Preload

(At hub bolt)

N (kg, lb)Wheel bearing lock nut

78-98(8-10,58-72)

Tightening torque

N×m (kg-m, ft-lb)

Retightening torque after loosen-

ing wheel bearing lock nut

N×m (kg-m, in-lb)0.5 - 1.5 (0.05 - 0.15, 4.3 - 13.0)

Axial end play

mm (in)0 (0)

Starting force at wheel hub bolt

N (kg, lb)A

Turning angle

degree15É - 30É

Starting force at wheel hub bolt

N (kg, lb)B

Wheel bearing preload at wheel hub

bolt

B þ A N (kg, lb)7.06 - 20.99 (0.72 - 2.14, 1.59 - 4.72)

Page 1747 of 2395

Wheels & Tires ..........................................................44

LIFTING POINTS AND TOW TRUCK TOWING...........45

Screw Jack ................................................................45

Garage Jack and Safety Stand .................................46

2-pole Lift ...................................................................47

Tow Truck Towing ......................................................472WD MODELS.........................................................48

4WD MODELS.........................................................48

VEHICLE RECOVERY..............................................49

TIGHTENING TORQUE OF STANDARD BOLTS........50

SAE J1930 TERMINOLOGY LIST................................51

SAE J1930 Terminology List .....................................51

CONTENTS(Cont'd)

GI-2

Page 1967 of 2395

S/VCSW - Wiring diagram ...........................EC-493

Swirl control valve control solenoid

valve .........................................................EC-458

Swirl control valve control vacuum

check switch .............................................EC-493

SWL/V - Wiring diagram ..............................EC-458

Symbols and abbreviations .............................GI-10

Symptom matrix chart...................................EC-118

System readiness test (SRT) code ................EC-61

T

2-4WD shift solenoid valve............................TF-111

Tachometer .....................................................EL-94

Tail lamp ..........................................................EL-61

TAIL/L - Wiring diagram ..................................EL-63

TCM circuit diagram ........................................AT-13

TCM inspection table ......................................AT-92

TFTS - Wiring diagram .................................EC-311

THEFT - Wiring diagram ...............................EL-300

Theft warning system....................................EL-294

Thermometer .................................................EL-110

Thermostat ......................................................LC-16

Three way catalyst function (Left bank) .......EC-347

Three way catalyst function (Right

bank) .........................................................EC-347

Three way catalyst precautions.........................GI-6

Throttle bodies ...............................................EM-12

Throttle position sensor (TPS) .....................EC-174

Throttle position sensor adjustment .............EC-101

Throttle position switch ...........EC-431, AT-184, 264

Tie-rod .............................................................ST-21

Tie-rod ball joints.............................................ST-21

Tightening torque of standard bolts.................GI-50

Timing chain ...................................................EM-20

Tire rotation ....................................................MA-24

Tire size ...........................................................GI-44

TLID - Wiring diagram ..................................EL-179

Tooth contact (front final drive 4WD) .............PD-29

Tooth contact diff. ...........................................PD-56

Torque converter installation .........................AT-278

Torque convertor clutch solenoid

valve ..................................................AT-152, 161

Tow truck towing ..............................................GI-47

Towing point.....................................................GI-49

TP/SW - Wiring diagram ..............................EC-434

TPS - Wiring diagram...................................EC-180

Transfer control unit inspection table..............TF-55

Transfer dropping resistor .............................TF-112

Transfer fluid replacement (Part time

4WD model) ...............................................MA-22

Transfer fluid temperature sensor .................TF-111

Transfer motor ...............................................TF-117

Transfer motor relay ......................................TF-113

Transfer serial number ....................................GI-43

TRANSMT - Wiring diagram .........................EL-325

Tread-FR&RR (Dimensions)............................GI-43

Trim .................................................................BT-28

Trouble diagnoses ...........................................GI-34

Trunk lid opener, electric...............................EL-178Turbine revolution sensor..............................AT-202

TURN - Wiring diagram ..................................EL-77

Turn signal lamp .............................................EL-75

Two trip detection logic ..................................EC-59

Two-pole lift .....................................................GI-47

U

Under body .....................................................BT-60

V

Vacuum cut valve ...........................................EC-32

Vacuum cut valve bypass valve.....EC-32, 585, 591

Vacuum hose (brake system).........................BR-21

Vacuum hose drawing (Engine control) .........EC-26

Valve clearance ..............................................EM-52

Valve guide.....................................................EM-43

Valve seat.......................................................EM-45

Valve spring....................................................EM-46

Vehicle identification number...........................GI-42

Vehicle recovery (freeing a stuck

vehicle) .........................................................GI-49

Vehicle speed sensor (VSS) ........................EC-417

VENT/V - Wiring diagram ............EC-376, 555, 576

Ventilation air filter ........................................HA-159

VIAS .............................................................EC-610

VIAS - Wiring diagram .................................EC-610

Viscosity number (SAE) .................................MA-12

VSS - Wiring diagram ..................................EC-420

W

Wait detection switch ....................................TF-112

WARN - Wiring diagram................................EL-115

Warning chime ..............................................EL-125

Warning lamps ..............................................EL-114

Washer, front .................................................EL-136

Washer, rear..................................................EL-141

Water pump ....................................................LC-12

Water temperature gauge ...............................EL-94

Weatherstrip - See Exterior ............................BT-35

Wheel balance ...............................................MA-24

Wheel bearing (front)........................................AX-4

Wheel bearing (rear) ......................................AX-18

Wheel hub (front)..............................................AX-6

Wheel sensors (ABS)...............................BR-56, 80

Wheel size .......................................................GI-44

Wheelarch height .............................................SU-5

Wheelbase (Dimensions) ................................GI-43

Wide open & closed throttle position

switch ........................................................EC-174

Width (Dimensions) .........................................GI-43

WINDOW - Wiring diagram ..........................EL-245

Window, door ..................................................BT-18

Window, rear side ...........................................BT-55

Window, side - See Rear side window ...........BT-55

ALPHABETICAL INDEX

IDX-8

Page 2197 of 2395

SST847C

InstallationNBST00221. Set wheels in the straight-ahead position.

2. Install transfer gear assembly.

3. Install column lower joint while aligning groove with protrusions

on the steering gear rear cover cap.

4. Tighten bolt while aligning groove on steering gear. Before

tightening bolt, ensure it is inserted correctly.

SST848C

5. When attaching steering column upper and lower joint to trans-

fer gear, it must be positioned as shown in figure at left.

SST707CA

InspectionNBST0024Do not disassemble steering transfer gear assembly.

ICheck that steering transfer gear assembly operates smoothly.

Also check for grease leakage, deformation and damage.

Replace steering transfer gear assembly if necessary.

ICheck rotating torque at input shaft in 360É and in both direc-

tions.

Rotating torque:

0.25 - 0.69 N´m (2.5 - 7.0 kg-cm, 2.2 - 6.1 in-lb)

If rotating torque is out of specification, replace steering trans-

fer gear assembly.

STEERING TRANSFER GEAR

Installation

ST-16

Page 2200 of 2395

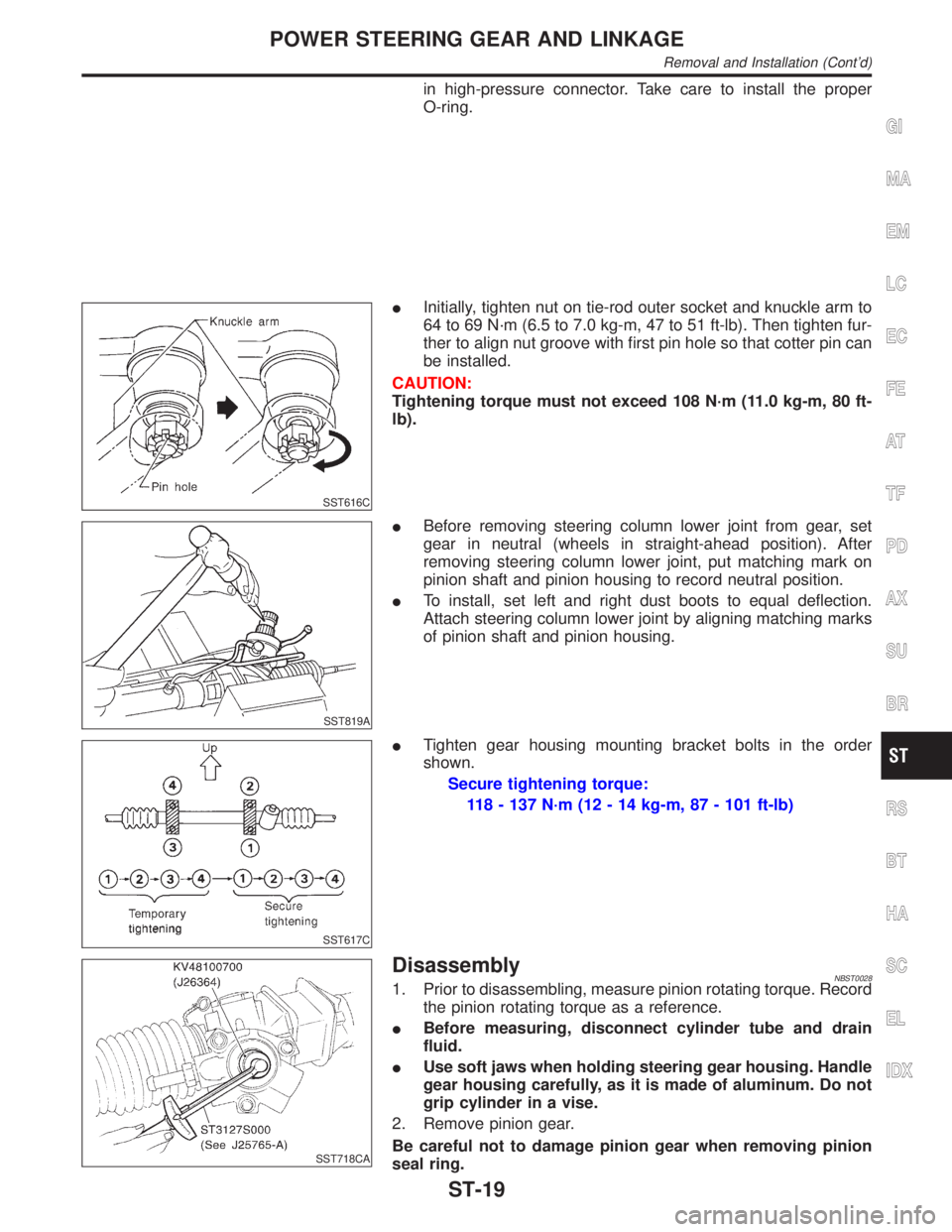

in high-pressure connector. Take care to install the proper

O-ring.

SST616C

IInitially, tighten nut on tie-rod outer socket and knuckle arm to

64 to 69 N´m (6.5 to 7.0 kg-m, 47 to 51 ft-lb). Then tighten fur-

ther to align nut groove with first pin hole so that cotter pin can

be installed.

CAUTION:

Tightening torque must not exceed 108 N´m (11.0 kg-m, 80 ft-

lb).

SST819A

IBefore removing steering column lower joint from gear, set

gear in neutral (wheels in straight-ahead position). After

removing steering column lower joint, put matching mark on

pinion shaft and pinion housing to record neutral position.

ITo install, set left and right dust boots to equal deflection.

Attach steering column lower joint by aligning matching marks

of pinion shaft and pinion housing.

SST617C

ITighten gear housing mounting bracket bolts in the order

shown.

Secure tightening torque:

118 - 137 N´m (12 - 14 kg-m, 87 - 101 ft-lb)

SST718CA

DisassemblyNBST00281. Prior to disassembling, measure pinion rotating torque. Record

the pinion rotating torque as a reference.

IBefore measuring, disconnect cylinder tube and drain

fluid.

IUse soft jaws when holding steering gear housing. Handle

gear housing carefully, as it is made of aluminum. Do not

grip cylinder in a vise.

2. Remove pinion gear.

Be careful not to damage pinion gear when removing pinion

seal ring.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Removal and Installation (Cont'd)

ST-19