suspension INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 369 of 2395

SBR686C

Precautions

PRECAUTIONSNBAX0001IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

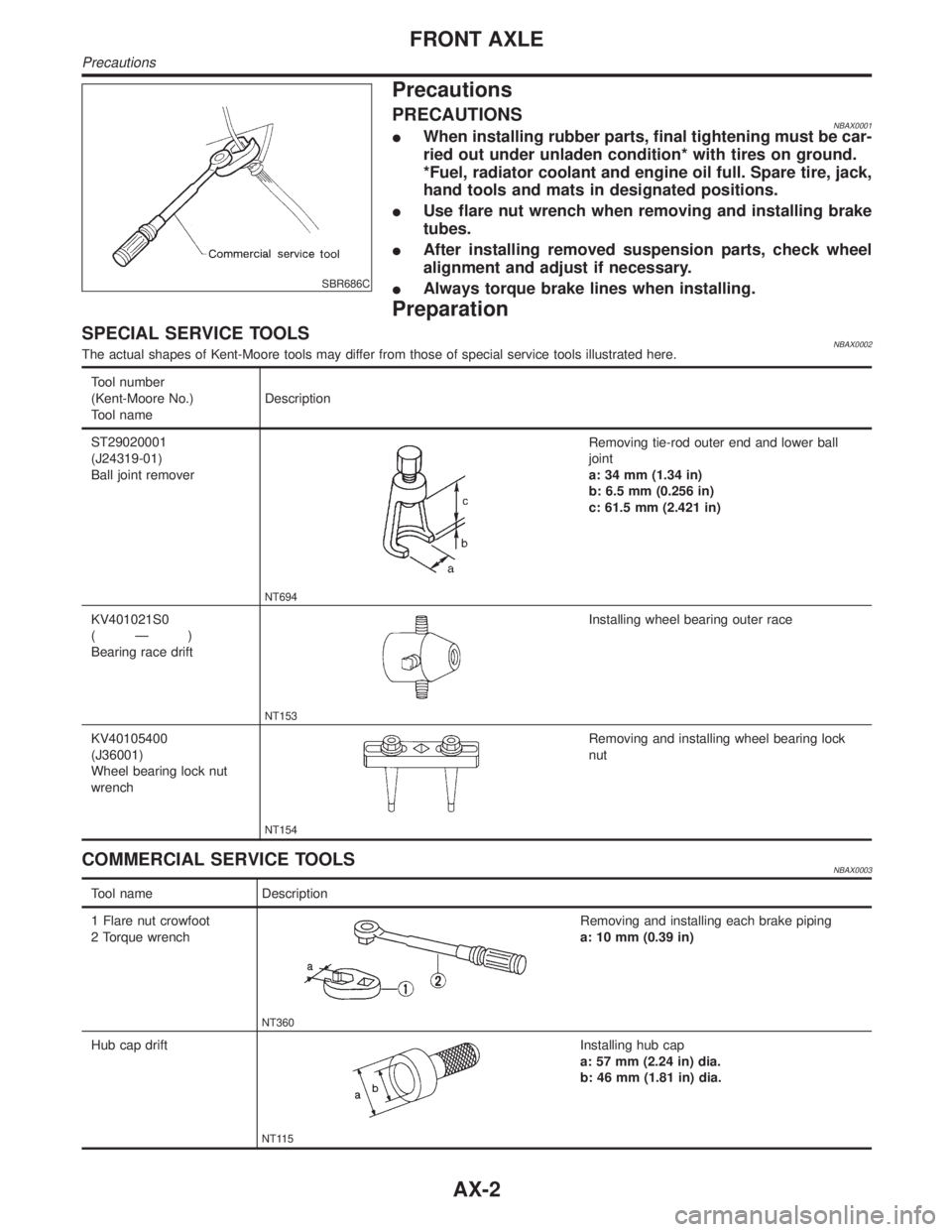

SPECIAL SERVICE TOOLSNBAX0002The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST29020001

(J24319-01)

Ball joint remover

NT694

Removing tie-rod outer end and lower ball

joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV401021S0

(Ð)

Bearing race drift

NT153

Installing wheel bearing outer race

KV40105400

(J36001)

Wheel bearing lock nut

wrench

NT154

Removing and installing wheel bearing lock

nut

COMMERCIAL SERVICE TOOLSNBAX0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Hub cap drift

NT115

Installing hub cap

a: 57 mm (2.24 in) dia.

b: 46 mm (1.81 in) dia.

FRONT AXLE

Precautions

AX-2

Page 370 of 2395

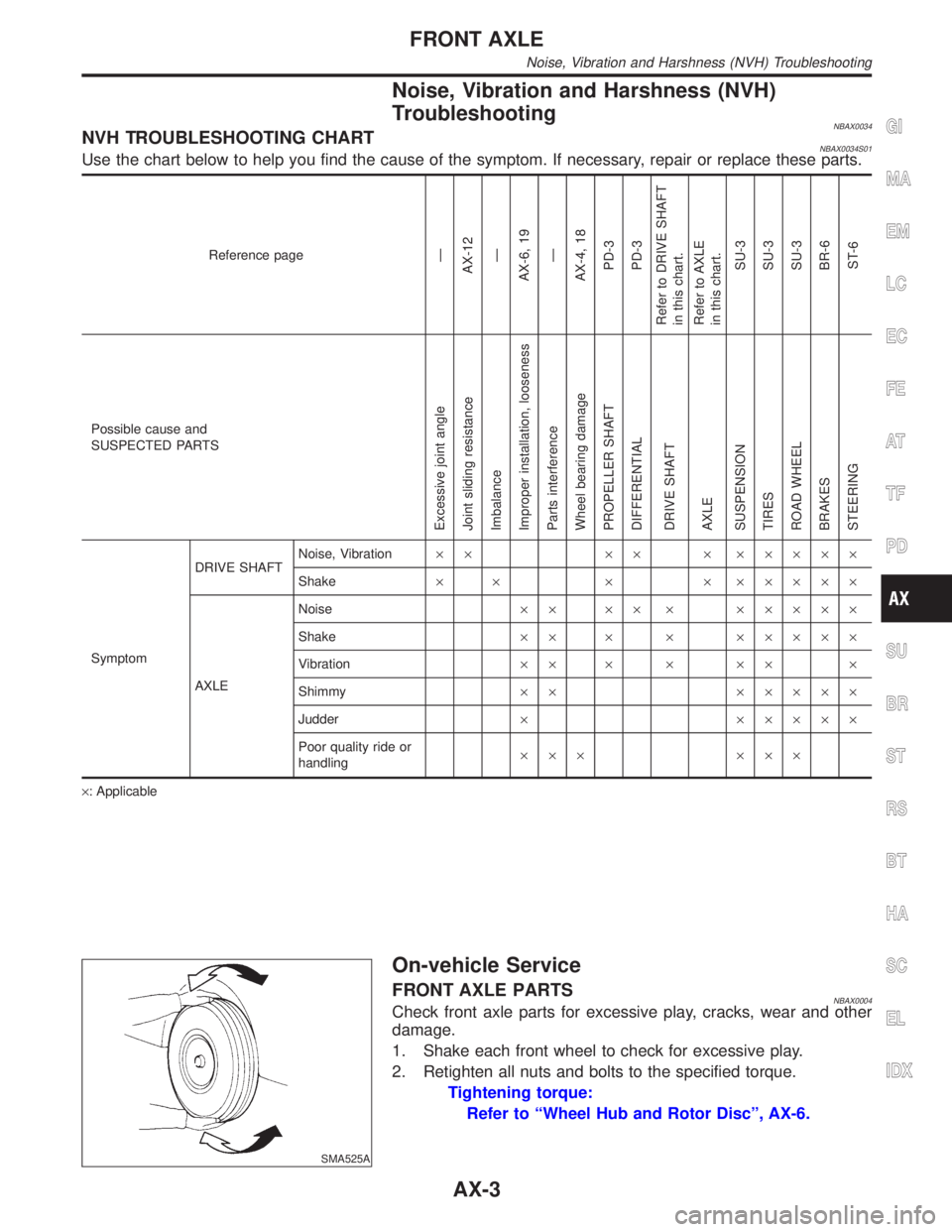

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBAX0034NVH TROUBLESHOOTING CHARTNBAX0034S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

AX-12

Ð

AX-6, 19

Ð

AX-4, 18

PD-3

PD-3

Refer to DRIVE SHAFT

in this chart.

Refer to AXLE

in this chart.

SU-3

SU-3

SU-3

BR-6

ST-6

Possible cause and

SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

Wheel bearing damage

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomDRIVE SHAFTNoise, Vibration´´ ´´ ´ ´´´´´

Shake´ ´ ´ ´ ´´´´´

AXLENoise´´ ´´ ´ ´´´´´

Shake´´ ´ ´ ´´´´´

Vibration´´ ´ ´ ´´ ´

Shimmy´´ ´´´´´

Judder´ ´´´´´

Poor quality ride or

handling´´´ ´´´

´: Applicable

SMA525A

On-vehicle Service

FRONT AXLE PARTSNBAX0004Check front axle parts for excessive play, cracks, wear and other

damage.

1. Shake each front wheel to check for excessive play.

2. Retighten all nuts and bolts to the specified torque.

Tightening torque:

Refer to ªWheel Hub and Rotor Discº, AX-6.

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Noise, Vibration and Harshness (NVH) Troubleshooting

AX-3

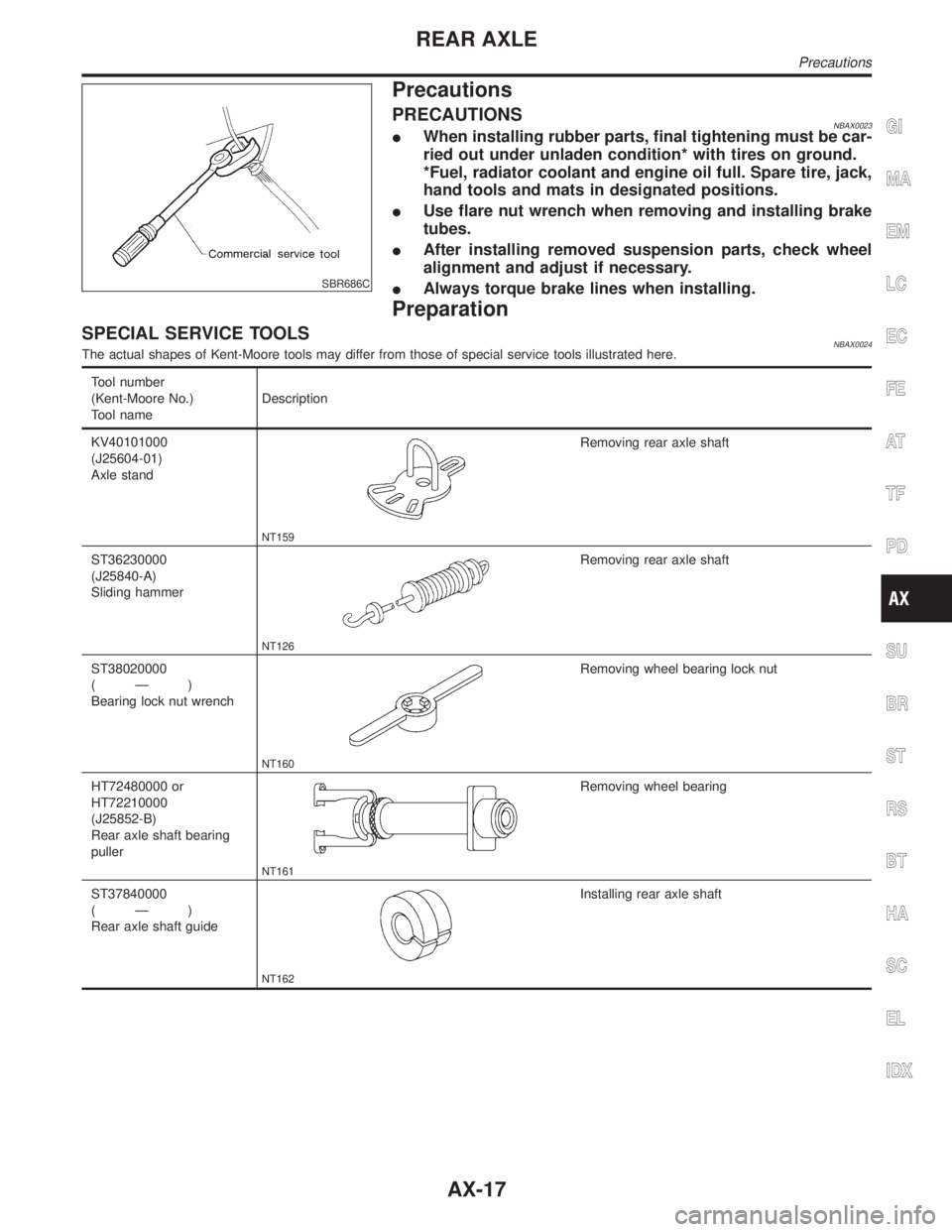

Page 384 of 2395

SBR686C

Precautions

PRECAUTIONSNBAX0023IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNBAX0024The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

KV40101000

(J25604-01)

Axle stand

NT159

Removing rear axle shaft

ST36230000

(J25840-A)

Sliding hammer

NT126

Removing rear axle shaft

ST38020000

(Ð)

Bearing lock nut wrench

NT160

Removing wheel bearing lock nut

HT72480000 or

HT72210000

(J25852-B)

Rear axle shaft bearing

puller

NT161

Removing wheel bearing

ST37840000

(Ð)

Rear axle shaft guide

NT162

Installing rear axle shaft

GI

MA

EM

LC

EC

FE

AT

TF

PD

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REAR AXLE

Precautions

AX-17

Page 395 of 2395

NBBR0085

NVH Troubleshooting ChartNBBR0085S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

BR-22, 28

BR-22, 28

BR-26

BR-22

Ð

Ð

BR-24, 28

Ð

Ð

Ð

BR-25

BR-28

PD-3

PD-3

AX-3

AX-3

SU-3

SU-3

SU-3

ST-6

Possible cause and

SUSPECTED PARTS

Linings or pads - damaged

Linings or pads - uneven wear

Return spring damaged

Shims damaged

Rotor or drum imbalance

Rotor or drum damage

Rotor or drum runout

Rotor or drum deformation

Rotor or drum deflection

Rotor or drum rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

STEERING

Symptom BRAKENoise´´´´ ´´´´´´´´

Shake´ ´ ´´´´´´

Shimmy, Judder´´´´´´´´ ´´´´´

´: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

BR-6

Page 1658 of 2395

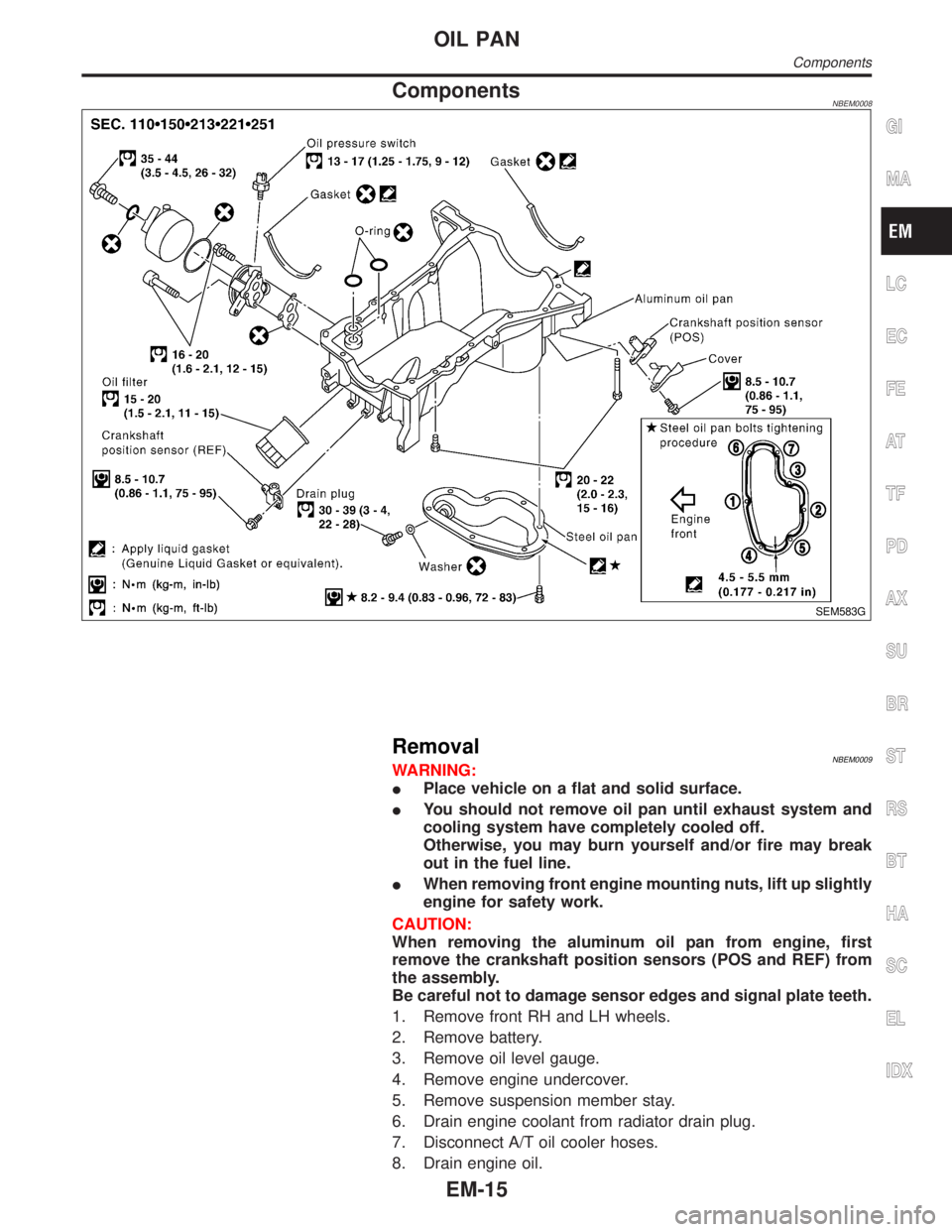

ComponentsNBEM0008

SEM583G

RemovalNBEM0009WARNING:

IPlace vehicle on a flat and solid surface.

IYou should not remove oil pan until exhaust system and

cooling system have completely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in the fuel line.

IWhen removing front engine mounting nuts, lift up slightly

engine for safety work.

CAUTION:

When removing the aluminum oil pan from engine, first

remove the crankshaft position sensors (POS and REF) from

the assembly.

Be careful not to damage sensor edges and signal plate teeth.

1. Remove front RH and LH wheels.

2. Remove battery.

3. Remove oil level gauge.

4. Remove engine undercover.

5. Remove suspension member stay.

6. Drain engine coolant from radiator drain plug.

7. Disconnect A/T oil cooler hoses.

8. Drain engine oil.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL PAN

Components

EM-15

Page 1659 of 2395

9. Remove the crankshaft position sensors (REF and POS).

10. Remove drive belts and idler pulley with bracket.

11. Remove power steering oil pump, then put it aside holding with

a suitable wire.

12. Remove alternator.

SEM605G

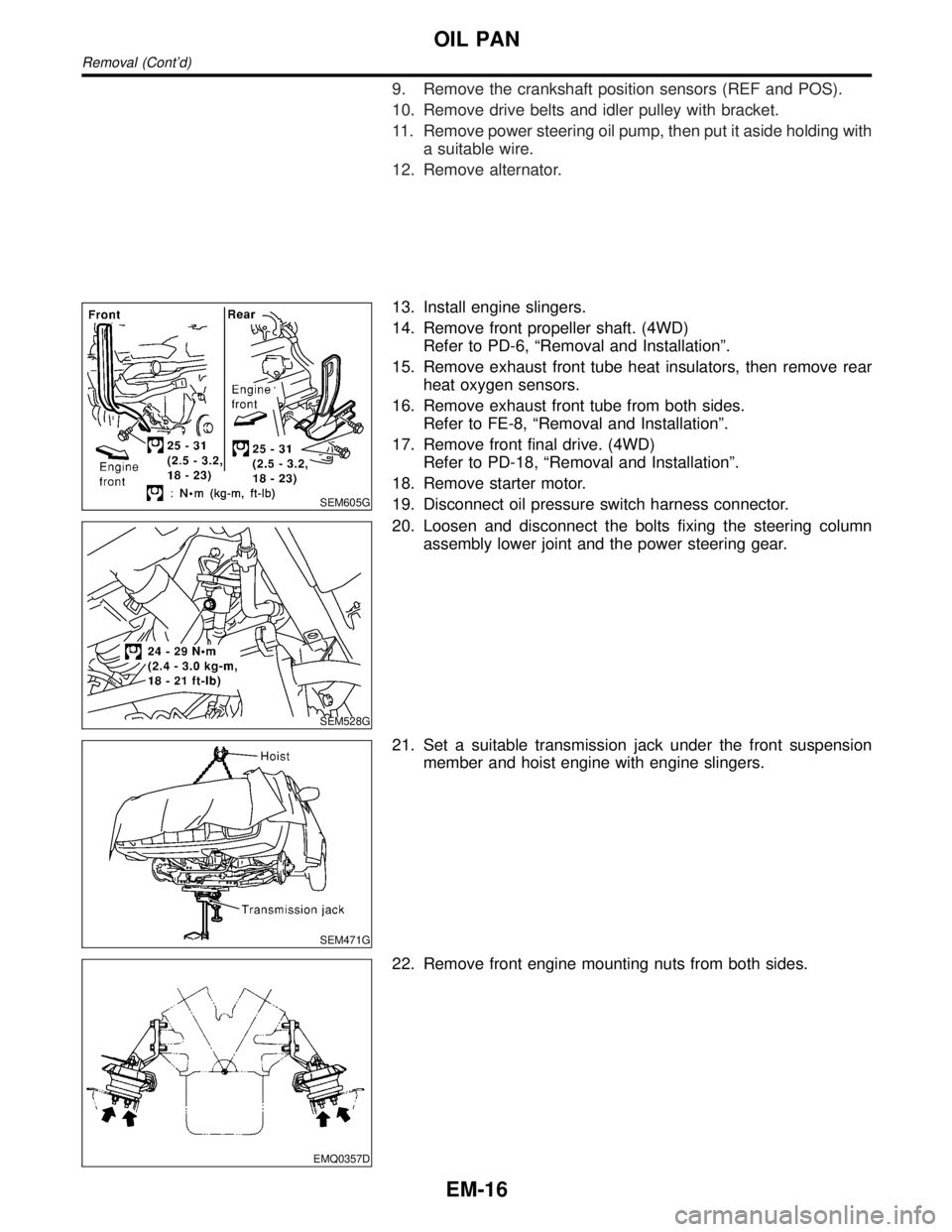

13. Install engine slingers.

14. Remove front propeller shaft. (4WD)

Refer to PD-6, ªRemoval and Installationº.

15. Remove exhaust front tube heat insulators, then remove rear

heat oxygen sensors.

16. Remove exhaust front tube from both sides.

Refer to FE-8, ªRemoval and Installationº.

17. Remove front final drive. (4WD)

Refer to PD-18, ªRemoval and Installationº.

18. Remove starter motor.

19. Disconnect oil pressure switch harness connector.

SEM528G

20. Loosen and disconnect the bolts fixing the steering column

assembly lower joint and the power steering gear.

SEM471G

21. Set a suitable transmission jack under the front suspension

member and hoist engine with engine slingers.

EMQ0357D

22. Remove front engine mounting nuts from both sides.

OIL PAN

Removal (Cont'd)

EM-16

Page 1660 of 2395

SEM529G

SEM530G

23. Remove front suspension member bolts.

24. Lower the transmission jack carefully to secure clearance

between the oil pan and suspension member.

25. Remove A/T oil cooler tube.

26. Remove water hose and tube.

SEM469G

27. Remove the four engine-to-transmission bolts.

SEM463G

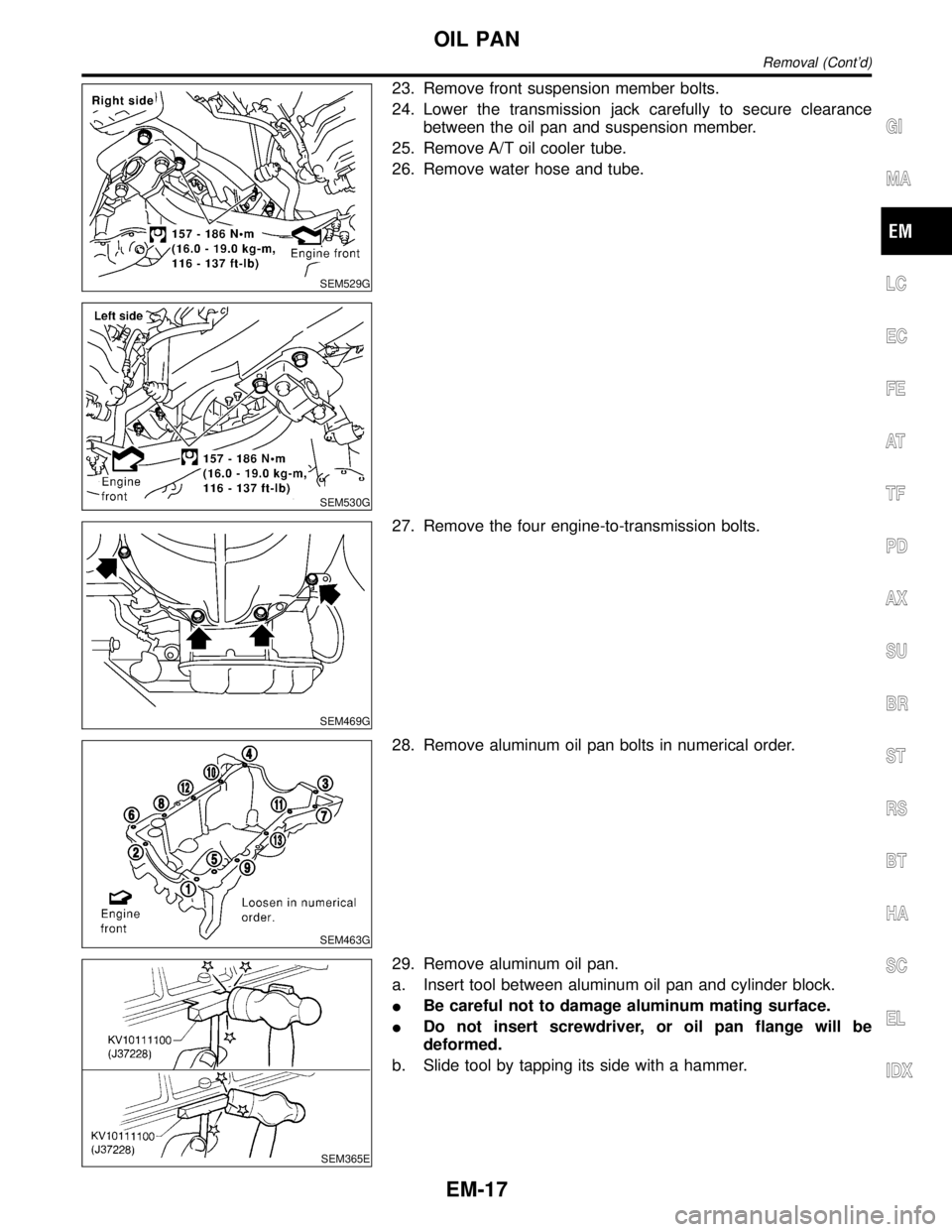

28. Remove aluminum oil pan bolts in numerical order.

SEM365E

29. Remove aluminum oil pan.

a. Insert tool between aluminum oil pan and cylinder block.

IBe careful not to damage aluminum mating surface.

IDo not insert screwdriver, or oil pan flange will be

deformed.

b. Slide tool by tapping its side with a hammer.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL PAN

Removal (Cont'd)

EM-17

Page 1669 of 2395

SEM419G

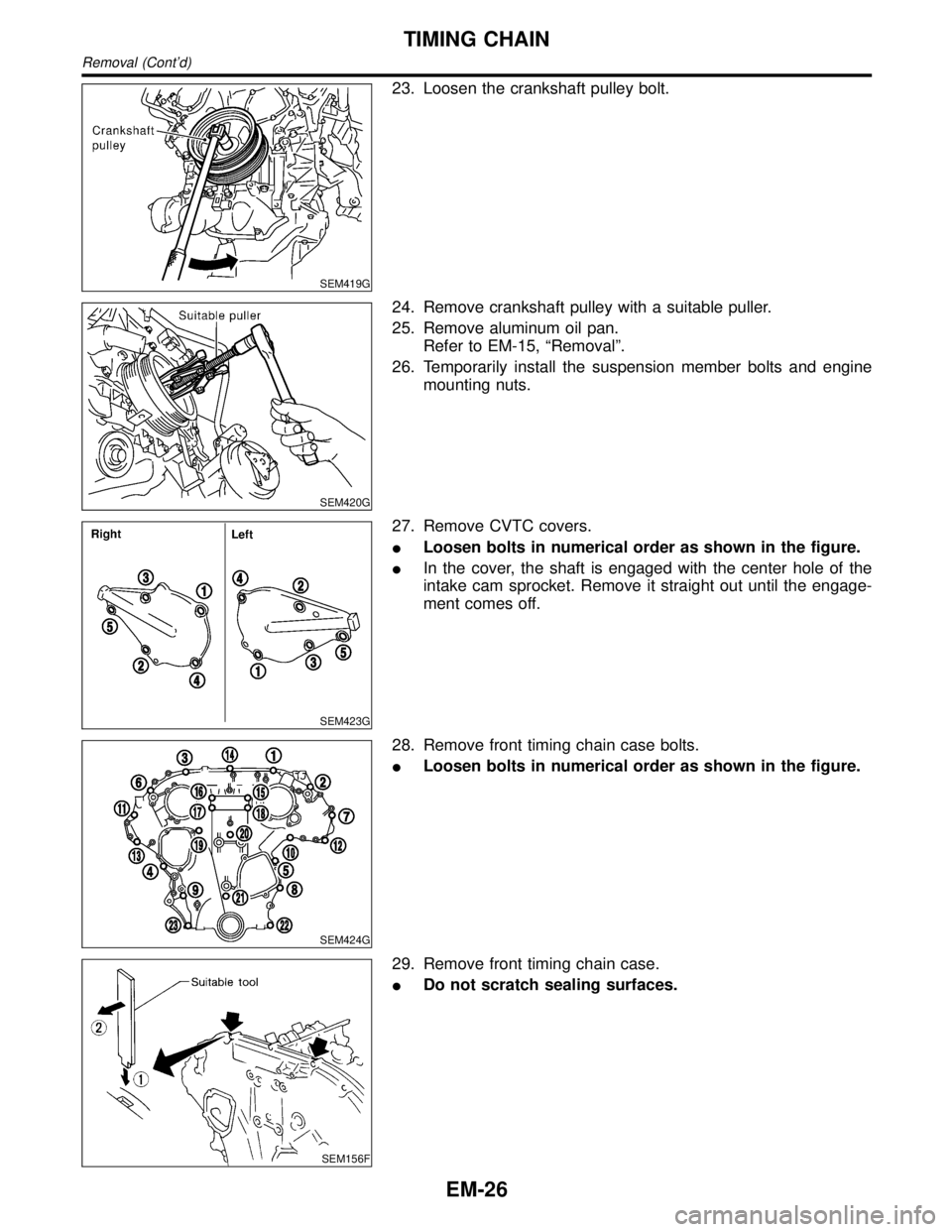

23. Loosen the crankshaft pulley bolt.

SEM420G

24. Remove crankshaft pulley with a suitable puller.

25. Remove aluminum oil pan.

Refer to EM-15, ªRemovalº.

26. Temporarily install the suspension member bolts and engine

mounting nuts.

SEM423G

27. Remove CVTC covers.

ILoosen bolts in numerical order as shown in the figure.

IIn the cover, the shaft is engaged with the center hole of the

intake cam sprocket. Remove it straight out until the engage-

ment comes off.

SEM424G

28. Remove front timing chain case bolts.

ILoosen bolts in numerical order as shown in the figure.

SEM156F

29. Remove front timing chain case.

IDo not scratch sealing surfaces.

TIMING CHAIN

Removal (Cont'd)

EM-26

Page 1676 of 2395

SEM439G

SEM440G

17. Install RH and LH rocker covers.

Rocker cover tightening procedure:

ITighten in numerical order as shown in the figure.

a. Tighten bolts 1 to 10 in that order to 6.9 to 8.8 N´m (0.7 to 0.9

kg-m, 61 to 78 in-lb).

b. Then tighten bolts 1 to 10 as indicated in figure to 6.9 to 8.8

N´m (0.7 to 0.9 kg-m, 61 to 78 in-lb).

18. Hang engine using the right and left side engine slingers with

a suitable hoist.

19. Set a suitable transmission jack under the suspension mem-

ber.

20. Remove right and left side engine mounting nuts.

21. Remove right and left side suspension member bolts.

22. Install aluminum oil pan. Refer to EM-18, ªInstallationº.

23. Set ring gear stopper using the mounting bolt hole.

IBe careful not to damage the signal plate teeth.

SEM417G

24. Install crankshaft pulley to crankshaft.

IAlign pointer with TDC mark on crankshaft pulley.

SEM531G

25. Install crankshaft pulley bolt.

ILubricate thread and seat surface of the bolt with new

engine oil.

a. Tighten to 39 to 49 N´m (4.0 to 5.0 kg-m, 29 to 36 ft-lb).

b. Put a paint mark on the crankshaft pulley.

SEM963E

c. Again tighten by turning 60É to 66É, about the angle from one

hexagon bolt head corner to another.

26. Install camshaft position sensor (PHASE), crankshaft position

sensors (REF)/(POS) and CVTC sensors.

27. Reinstall removed parts in the reverse order of removal.

IWhen installing fuel tube and intake manifold collectors, refer

to EM-12, ªTIGHTENING PROCEDURESº.

IAfter starting engine, keep idling for three minutes. Then

rev engine up to 3,000 rpm under no load to purge air from

the high-pressure chamber of the chain tensioners. The

engine may produce a rattling noise. This indicates that

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Installation (Cont'd)

EM-33

Page 1679 of 2395

SEM828E

7. Apply engine oil to new valve oil seal and install it with Tool.

SEM715A

OIL SEAL INSTALLATION DIRECTIONNBEM0015S02IInstall new oil seal in the direction shown in the figure.

FRONT OIL SEALNBEM0015S031. Remove the following parts:

IEngine undercover

ISuspension member stay

IDrive belts

ICrankshaft position sensor (REF)

Be careful not to damage sensor edge.

ICrankshaft pulley

IRadiator

ICooling fan

SEM829E

2. Remove front oil seal using a suitable tool.

Be careful not to scratch front cover.

3. Apply engine oil to new oil seal and install it using a suitable

tool.

SEM830E

REAR OIL SEALNBEM0015S041. Remove transmission. Refer to AT-277, ªRemovalº.

2. Remove drive plate.

3. Remove oil pan. Refer to EM-15.

4. Remove rear oil seal retainer.

OIL SEAL

Replacement (Cont'd)

EM-36