turn signal INFINITI QX56 2004 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2004, Model line: QX56, Model: INFINITI QX56 2004Pages: 3371, PDF Size: 78.5 MB

Page 3005 of 3371

SE-56

AUTOMATIC DRIVE POSITIONER

Revision: August 20072004 QX56

2. CHECK SLIDING MOTOR SENSOR CIRCUIT HARNESS CONTINUITY

1. Disconnect driver seat control unit connector and sliding motor LH connector.

2. Check continuity between driver seat control unit connector P2

terminals 16, 24, 31 and sliding motor P4 terminals 1, 2, 3.

3. Check continuity between driver seat control unit P2 terminals

16, 24, 31 and ground.

OK or NG

OK >> Replace sliding motor.

NG >> Repair or replace harness.

Reclining Sensor Circuit InspectionEIS002YR

1. CHECK FUNCTION

With CONSULT-II

Check operation with “RECLN PULSE” on the DATA MONITOR to make sure the pulse changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector and

ground, with oscilloscope.

OK or NG

OK >> Reclining sensor circuit is OK.

NG >> GO TO 2.16 (W) - 3 (W) : Continuity should exist.

24 (Y/G) - 2 (Y/G) : Continuity should exist.

31 (L/Y) - 1 (L/Y) : Continuity should exist.

16 (W) - Ground : Continuity should not exist.

24 (Y/G) - Ground : Continuity should not exist.

31 (L/Y) - Ground : Continuity should not exist.

LIIA0706E

Monitor item [POERATION or UNIT] Contents

RECLN PULSE —The seat reclining position (pulse) judged

from the reclining sensor is displayed

PIIA4558E

ConnectorTe r m i n a l s

(Wire color)

Condition Signal

(+) (–)

P2 9 (L/R) GroundReclining

motor

operation

PIIA4559E

PIIA3278E

Page 3006 of 3371

AUTOMATIC DRIVE POSITIONER

SE-57

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: August 20072004 QX56

2. CHECK RECLINING MOTOR SENSOR CIRCUIT HARNESS CONTINUITY

1. Disconnect driver seat control unit and reclining motor LH.

2. Check continuity between driver seat control unit connector P2

terminals 9, 31 and reclining motor LH connector P5 terminals 1,

2.

3. Check continuity between driver seat control unit connector P2

terminals 9, 31 and ground.

OK or NG

OK >> Replace reclining motor.

NG >> Repair or replace harness.

Lifting Sensor (Front) Circuit InspectionEIS002YS

1. CHECK FUNCTION

With CONSULT-II

Check operation with “LIFT FR PULSE” on the DATA MONITOR to make sure the pulse changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector and

ground, with oscilloscope.

OK or NG

OK >> Front lifting sensor is OK.

NG >> GO TO 2.9 (L/R) - 1 (L/R) : Continuity should exist.

31 (L/Y) - 2 (L/Y) : Continuity should exist.

9 (L/R) - Ground : Continuity should not exist.

31 (L/Y) - Ground : Continuity should not exist.

LIIA0707E

Monitor item [OPERATION or UNIT] Contents

LIFT FR PULSE —The front lifting position (pulse) judged

from the lifting sensor (front) is dis-

played

PIIA4558E

ConnectorTe r m i n a l s

(Wire color)

Condition Signal

(+) (–)

P2 25 (LG) GroundLifting

motor

(front)

operation

PIIA4561E

PIIA3278E

Page 3007 of 3371

SE-58

AUTOMATIC DRIVE POSITIONER

Revision: August 20072004 QX56

2. CHECK FRONT LIFTING MOTOR SENSOR CIRCUIT HARNESS CONTINUITY

1. Disconnect driver seat control unit and lifting motor (front).

2. Check continuity between driver seat control unit connector P2 terminals 16, 25, 31 and lifting motor

(front) connector P6 terminals 1, 2, 3.

3. Check continuity between driver seat control unit connector P2

terminals 16, 25, 31 and ground.

OK or NG

OK >> Replace lifting motor (front).

NG >> Repair or replace harness.

Lifting Sensor (Rear) Circuit InspectionEIS002YT

1. CHECK FUNCTION

With CONSULT-II

Check operation with “LIFT RR PULSE” on the DATA MONITOR to make sure pulse changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector and

ground, with oscilloscope.

OK or NG

OK >> Rear lifting sensor circuit is OK.

NG >> GO TO 2.16 (W) - 3 (W) : Continuity should exist.

25 (LG) - 2 (LG) : Continuity should exist.

31 (L/Y) - 1 (L/Y) : Continuity should exist.

16 (W) - Ground : Continuity should not exist.

25 (LG) - Ground : Continuity should not exist.

31 (L/Y) - Ground : Continuity should not exist.

LIIA0708E

Monitor item [OPERATION or UNIT]

LIFT RR PULSE —The rear lifting position (pulse) judged from

the lifting sensor (rear) is displayed.

PIIA4558E

ConnectorTe r m i n a l s

(Wire color)

Condition Signal

(+) (–)

P2 10 (W) GroundLifting

motor

(rear)

operation

PIIA4563E

PIIA3278E

Page 3008 of 3371

AUTOMATIC DRIVE POSITIONER

SE-59

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: August 20072004 QX56

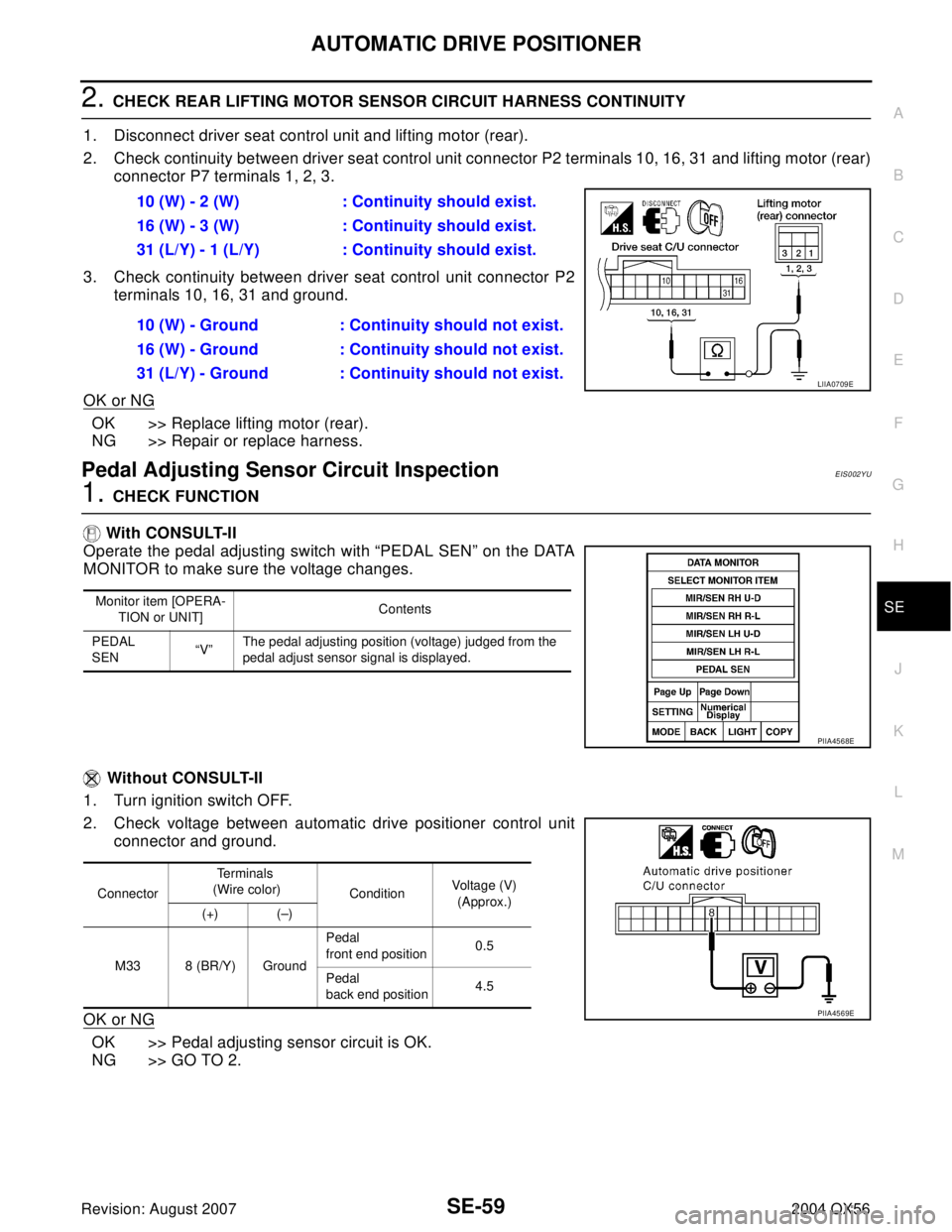

2. CHECK REAR LIFTING MOTOR SENSOR CIRCUIT HARNESS CONTINUITY

1. Disconnect driver seat control unit and lifting motor (rear).

2. Check continuity between driver seat control unit connector P2 terminals 10, 16, 31 and lifting motor (rear)

connector P7 terminals 1, 2, 3.

3. Check continuity between driver seat control unit connector P2

terminals 10, 16, 31 and ground.

OK or NG

OK >> Replace lifting motor (rear).

NG >> Repair or replace harness.

Pedal Adjusting Sensor Circuit InspectionEIS002YU

1. CHECK FUNCTION

With CONSULT-II

Operate the pedal adjusting switch with “PEDAL SEN” on the DATA

MONITOR to make sure the voltage changes.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between automatic drive positioner control unit

connector and ground.

OK or NG

OK >> Pedal adjusting sensor circuit is OK.

NG >> GO TO 2.10 (W) - 2 (W) : Continuity should exist.

16 (W) - 3 (W) : Continuity should exist.

31 (L/Y) - 1 (L/Y) : Continuity should exist.

10 (W) - Ground : Continuity should not exist.

16 (W) - Ground : Continuity should not exist.

31 (L/Y) - Ground : Continuity should not exist.

LIIA0709E

Monitor item [OPERA-

TION or UNIT]Contents

PEDAL

SEN“V”The pedal adjusting position (voltage) judged from the

pedal adjust sensor signal is displayed.

PIIA4568E

ConnectorTe r m i n a l s

(Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

M33 8 (BR/Y) GroundPedal

front end position0.5

Pedal

back end position4.5

PIIA4569E

Page 3016 of 3371

AUTOMATIC DRIVE POSITIONER

SE-67

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: August 20072004 QX56

3. CHECK SLIDING SWITCH

Check continuity between power seat switch LH as follows.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace power seat switch LH.

Reclining Switch InspectionEIS002YY

1. CHECK FUNCTION

With CONSULT-II

With “RECLN SW-FR, RECLN SW-RR” on the DATA MONITOR,

operate the reclining switch to check ON/OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between driver seat control unit connector and

ground.

OK or NG

OK >> Reclining switch circuit is OK.

NG >> GO TO 2.

Terminal

Condition Continuity

(+) (–)

7

3Sliding switch ON (BACKWARD operation) Yes

Other than above No

1Sliding switch ON (FORWARD operation) Yes

Other than above No

LIIA1126E

Monitor item [OPERA-

TION or UNIT]Contents

RECLN SW

–FR“ON/

OFF”ON/OFF status judged from the reclining switch (FR)

signal is displayed.

RECLN SW

–RR“ON/

OFF”ON/OFF status judged from the reclining switch (RR)

signal is displayed.

PIIA0313E

ConnectorTe r m i n a l s

(Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

P212 (O/B)

GroundReclining switch ON

(BACKWARD oper-

ation)0

Other than above Battery voltage

27 (G/B)Reclining switch ON

(FORWARD opera-

tion)0

Other than above Battery voltage

PIIA4580E

Page 3018 of 3371

AUTOMATIC DRIVE POSITIONER

SE-69

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: August 20072004 QX56

Lifting Switch (Front) Circuit InspectionEIS002YZ

1. CHECK FUNCTION

With CONSULT-II

With “LIFT FR SW-UP, LIFT FR SW-DN” on the DATA MONITOR,

operate the lifting switch (front) to check ON/OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between driver seat control unit connector and

ground.

OK or NG

OK >> Lifting switch (front) circuit is OK.

NG >> GO TO 2.

2. CHECK LIFTING SWITCH (FRONT) CIRCUIT HARNESS CONTINUITY

1. Disconnect driver seat control unit and power seat switch LH.

2. Check continuity between driver seat control unit connector P2

terminals 13, 28 and power seat switch LH connector P2 termi-

nals 5, 6.

3. Check continuity between driver seat control unit connector P2

terminals 13, 28 and ground

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

Monitor item [OPERA-

TION or UNIT]Contents

LIFT FR SW–

DN"ON/

OFF"ON / OFF status judged from the FR lifter switch

(DOWN) signal is displayed.

LIFT RR SW–

UP"ON/

OFF"ON / OFF status judged from the RR lifter switch (UP)

signal is displayed.

PIIA0323E

ConnectorTe r m i n a l s

(Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

P213 (L/B)

GroundLifting switch (front) ON

(DOWN operation)0

Other than above Battery voltage

28 (Y/B)Lifting switch (front) ON

(UP operation)0

Other than above Battery voltage

PIIA4583E

13 (L/B) - 5 (L/B) : Continuity should exist.

28 (Y/B) - 6 (Y/B) : Continuity should exist.

13 (L/B) - Ground : Continuity should not exist.

28 (Y/B) - Ground : Continuity should not exist.

LIIA1129E

Page 3019 of 3371

SE-70

AUTOMATIC DRIVE POSITIONER

Revision: August 20072004 QX56

3. CHECK LIFTING SWITCH (FRONT)

Check continuity between power seat switch LH as follows.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace power seat switch LH.

Lifting Switch (Rear) Circuit InspectionEIS002Z0

1. CHECK FUNCTION

With CONSULT-II

With “LIFT RR SW-UP, LIFT RR SW-DN” on the DATA MONITOR,

operate the rear lifting switch to check ON/OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between driver seat control unit connector and

ground.

OK or NG

OK >> Rear lifting switch circuit is OK.

NG >> GO TO 2.

Te r m i n a l s

Condition Continuity

(+) (–)

5

3Lifting switch (front) ON

(DOWN operation)Ye s

Other than above No

6Lifting switch (front) ON (UP operation) Yes

Other than above No

LIIA1130E

Monitor item [OPERATION or

UNIT]Contents

LIFT RR SW–UP “ON/OFF”Operation (ON)/open (OFF) status judged

from the RR lifter switch (UP) signal is dis-

played.

LIFT RR SW–DN “ON/OFF”Operation (ON)/open (OFF) status judged

from the RR lifter switch (DOWN) signal is

displayed.

PIIA0323E

ConnectorTe r m i n a l s

(Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

P214 (G/W)

GroundRear lifting switch ON

(DOWN operation)0

Other than above Battery voltage

29 (R/W)Rear lifting switch ON

(UP operation)0

Other than above Battery voltage

PIIA4586E

Page 3021 of 3371

SE-72

AUTOMATIC DRIVE POSITIONER

Revision: August 20072004 QX56

Pedal Adjusting Switch Circuit InspectionEIS002Z2

1. CHECK FUNCTION

With CONSULT-II

With “PEDAL SW-FR, PEDAL SW-RR” on the DATA MONITOR,

operate the pedal adjusting switch to check ON/OFF operation.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Check voltage between driver seat control unit connector and

ground.

OK or NG

OK >> Pedal adjusting switch circuit is OK.

NG >> GO TO 2.

2. CHECK PEDAL ADJUSTING SWITCH CIRCUIT HARNESS CONTINUITY

1. Disconnect driver seat control unit and pedal adjusting switch.

2. Check continuity between driver seat control unit connector P2

terminals 15, 30 and pedal adjusting switch connector M96 ter-

minals 2, 3.

3. Check continuity between driver seat control unit connector P2

terminals 15, 30 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

Monitor item [OPERATION or

UNIT]Contents

PEDAL SW–FR “ON/OFF”Operation (ON)/open (OFF) status

judged from the pedal adjusting switch

(FR) signal is displayed.

PEDAL SW–RR “ON/OFF”Operation (ON)/open (OFF) status

judged from the pedal adjusting switch

(RR) signal is displayed.

PIIA4590E

ConnectorTe r m i n a l s

(Wire color)

ConditionVoltage (V)

(Approx.)

(+) (–)

P215 (L)

GroundPedal adjusting switch

ON (BACKWARD oper-

ation)0

Other than above Battery voltage

30 (R)Pedal adjusting switch

ON (FORWARD opera-

tion)0

Other than above Battery voltage

PIIA4591E

15 (L) - 2 (L/Y) : Continuity should exist.

30 (R) - 3 (R) : Continuity should exist.

15 (L) - Ground : Continuity should not exist.

30 (R) - Ground : Continuity should not exist.

LIIA0726E

Page 3023 of 3371

SE-74

AUTOMATIC DRIVE POSITIONER

Revision: August 20072004 QX56

Door Mirror Switch (Changeover Switch) Circuit CheckEIS002Z3

1. CHECK FUNCTION

With CONSULT–II

Check the operation on “MIR CHNG SW – R” or “MIR CHNG SW–

L" in the DATA MONITOR.

Without CONSULT–II

1. Turn ignition switch to ACC.

2. Check voltage between automatic drive positioner control unit

connector and ground.

OK

orNG

OK >> Door mirror switch (changeover switch) is OK.

NG >> GO TO 2.

2. CHECK DOOR MIRROR SWITCH CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and door mirror switch .

3. Check continuity between automatic drive positioner control unit

connector M33 terminals 2, 18 and door mirror switch connector

D10 terminals 5, 6.

4. Check continuity between automatic drive positioner control unit

connector M33 terminals 2, 18 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

Monitor item [OPERATION

or UNIT]Contents

MIR CHNG S

W–R“ON/OFF”ON/OFF status judged from the door mirror switch

(switching to RIGHT) signal is displayed.

MIR CHNG S

W–L“ON/OFF”ON/OFF status judged from the door mirror switch

(switching to LEFT) signal is displayed.

PIIA0191E

ConnectorTerminals (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (-)

M332 (LG)

GroundChangeover switch

RIGHT position0

Other than above 5

18 (BR/W)Changeover switch

LEFT position0

Other than above 5

PIIA4767E

2 (LG) - 5 (LG) : Continuity should exist.

18 (BR/W) - 6 (BR/W) : Continuity should exist.

2 (LG) - Ground : Continuity should not exist.

18 (BR/W) - Ground : Continuity should not exist.

LIIA1011E

Page 3024 of 3371

AUTOMATIC DRIVE POSITIONER

SE-75

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: August 20072004 QX56

3. CHECK DOOR MIRROR SWITCH (CHANGEOVER SWITCH)

Check continuity between door mirror switch as follows.

OK or NG

OK >> Check the condition of the harness and the connector.

NG >> Replace door mirror switch.

Door Mirror Switch (Mirror Switch) Circuit CheckEIS002Z4

1. CHECK DOOR MIRROR SWITCH (MIRROR SWITCH) SIGNAL

With CONSULT–II

Check the operation on “MIR CON SW–UP/DN” and

“MIR CON SW–RH/LH” in the DATA MONITOR.

Without CONSULT–II

1. Turn ignition switch to ACC.

2. Check voltage between automatic drive positioner control unit

connector and ground.

OK or NG

OK >> Door mirror switch (mirror switch) circuit is OK.

NG >> GO TO 2.

Te r m i n a l s

Condition Continuity

(+) (–)

5

7Changeover switch RIGHT position Yes

Other than above No

6Changeover switch LEFT position Yes

Other than above No

LIIA1488E

Monitor item [OPERATION

or UNIT]Contents

MIR CON SW

–UP“ON/OFF”ON/OFF status judged from the door mirror switch

(UP) signal is displayed.

MIR CON SW

–DN“ON/OFF”ON/OFF status judged from the door mirror switch

(DOWN) signal is displayed.

MIR CON SW

–RH“ON/OFF”ON/OFF status judged from the door mirror switch

(RIGHT) signal is displayed.

MIR CON SW

–LH“ON/OFF”ON/OFF status judged from the door mirror switch

(LEFT) signal is displayed.

PIIA0199E

ConnectorTerminals (Wire color)

ConditionVoltage (V)

(Approx.)

(+) (-)

M333 (Y/B)

GroundMirror switch UP operation 0

Other than above 5

4 (V/W)Mirror switch LEFT operation 0

Other than above 5

19 (SB)Mirror switch DOWN operation 0

Other than above 5

20 (GR)Mirror switch RIGHT operation 0

Other than above 5

PIIA4771E