center console INFINITI QX56 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: QX56, Model: INFINITI QX56 2006Pages: 3383, PDF Size: 51.76 MB

Page 404 of 3383

ATC-3

C

DE

F

G H

I

K L

M A

B

AT C

Revision: November 2009 2006 QX56

DIAGNOSTIC PROCEDURE FOR IN-VEHICLE

SENSOR ..........................................................

. 138

COMPONENT INSPECTION ........................... . 140

Optical Sensor Circuit ......................................... . 140

COMPONENT DESCRIPTION ........................ . 140

OPTICAL INPUT PROCESS ........................... . 140

DIAGNOSTIC PROCEDURE FOR OPTICAL

SENSOR .......................................................... . 141

Intake Sensor Circuit ........................................... . 142

COMPONENT DESCRIPTION ........................ . 142

DIAGNOSTIC PROCEDURE FOR INTAKE SEN-

SOR ................................................................. . 142

COMPONENT INSPECTION ........................... . 143

CONTROL UNIT .................................................... . 144

Removal and Installation ..................................... . 144

FRONT AIR CONTROL ................................... . 144

REAR AIR CONTROL ...................................... . 144

AMBIENT SENSOR ............................................... . 145

Removal and Installation ..................................... . 145

REMOVAL ........................................................ . 145

INSTALLATION ................................................ . 145

IN-VEHICLE SENSOR ........................................... . 146

Removal and Installation ..................................... . 146

REMOVAL ........................................................ . 146

INSTALLATION ................................................ . 146

OPTICAL SENSOR ............................................... . 147

Removal and Installation ..................................... . 147

INTAKE SENSOR .................................................. . 148

Removal and Installation ..................................... . 148

REMOVAL ........................................................ . 148

INSTALLATION ................................................ . 148

BLOWER MOTOR ................................................. . 149

Components ........................................................ . 149

Removal and Installation ..................................... . 149

FRONT BLOWER MOTOR .............................. . 149

REAR BLOWER MOTOR ................................ . 150

IN-CABIN MICROFILTER ...................................... . 151

Removal and Installation ..................................... . 151

FUNCTION ....................................................... . 151

REPLACEMENT TIMING ................................. . 151

REPLACEMENT PROCEDURE ...................... . 151

HEATER & COOLING UNIT ASSEMBLY ............. . 153

Components ........................................................ . 153

Removal and Installation ..................................... . 154

FRONT HEATER AND COOLING UNIT ASSEM-

BLY ................................................................... . 154

REAR HEATER AND COOLING UNIT ASSEM-

BLY ................................................................... . 155

HEATER CORE ..................................................... . 156

Components ........................................................ . 156

Removal and Installation ..................................... . 157

FRONT HEATER CORE .................................. . 157

REAR HEATER CORE .................................... . 158

DEFROSTER DOOR MOTOR ............................... . 159

Removal and Installation ..................................... . 159

REMOVAL ........................................................ . 159

INSTALLATION ................................................ . 159INTAKE DOOR MOTOR ........................................

.160

Removal and Installation ..................................... .160

REMOVAL ........................................................ .160

INSTALLATION ................................................ .160

MODE DOOR MOTOR ........................................... .161

Removal and Installation ..................................... .161

REMOVAL ........................................................ .161

INSTALLATION ................................................ .161

AIR MIX DOOR MOTOR ........................................ .162

Components ........................................................ .162

Removal and Installation ..................................... .162

FRONT AIR MIX DOOR MOTOR (DRIVER) .... .162

FRONT AIR MIX DOOR MOTOR (PASSENGER) .163

REAR AIR MIX DOOR MOTOR ....................... .163

VARIABLE BLOWER CONTROL .......................... .164

Removal and Installation ..................................... .164

REMOVAL ........................................................ .164

INSTALLATION ................................................ .164

REAR BLOWER MOTOR RESISTOR ................... .165

Removal and Installation ..................................... .165

REMOVAL ........................................................ .165

INSTALLATION ................................................ .165

DUCTS AND GRILLES .......................................... .166

Components ........................................................ .166

Removal and Installation ..................................... .169

CENTER CONSOLE HEAT DUCT AND REAR

FINISHER ASSEMBLY GRILLE ....................... .169

DEFROSTER NOZZLE .................................... .169

RH AND LH SIDE DEMISTER DUCT .............. .169

RH AND LH VENTILATOR DUCT .................... .169

CENTER VENTILATOR DUCT ........................ .169

FLOOR DUCT .................................................. .169

REAR OVERHEAD DUCTS ............................. .170

REAR FLOOR DUCT ....................................... .170

GRILLES .......................................................... .170

REFRIGERANT LINES .......................................... .171

HFC-134a (R-134a) Service Procedure .............. .171

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ............................................................... .171

Components ........................................................ .173

Removal and Installation for Compressor ........... .175

REMOVAL ........................................................ .175

INSTALLATION ................................................ .176

Removal and Installation for Compressor Clutch . 176 REMOVAL ........................................................ .176

INSPECTION ................................................... .177

INSTALLATION ................................................ .177

BREAK-IN OPERATION ................................... .179

Removal and Installation for Low-pressure Flexible

Hose .................................................................... .179

REMOVAL ........................................................ .179

INSTALLATION ................................................ .179

Removal and Installation for High-pressure Flexible

Hose .................................................................... .179

REMOVAL ........................................................ .179

INSTALLATION ................................................ .179

Removal and Installation for High-pressure Pipe . 179 REMOVAL ........................................................ .179

INSTALLATION ................................................ .179

Page 562 of 3383

MODE DOOR MOTORATC-161

C

DE

F

G H

I

K L

M A

B

AT C

Revision: November 2009 2006 QX56

MODE DOOR MOTORPFP:27731

Removal and InstallationEJS003YK

Mode Door Motor - Front Heater and Cooling Unit Assembly

REMOVAL

1. Remove the center console lower cover LH. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect the mode door motor electrical connector.

3. Remove the two screws and remove the mode door motor.

INSTALLATION

Installation is in the reverse order of removal.

LJIA0139E

1. Front heater and cooling unit assembly 2. Intake door motor 3. Air mix door motor (driver)

4. Variable blower control 5. Air mix door motor (passenger) 6. Mode door motor

7. Defroster door motor

Page 564 of 3383

AIR MIX DOOR MOTORATC-163

C

DE

F

G H

I

K L

M A

B

AT C

Revision: November 2009 2006 QX56

FRONT AIR MIX DOOR MOTOR (PASSENGER)

Removal

1. Remove the center console lower cover LH. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect the air mix door motor electrical connector.

3. Remove the three screws and remove the air mix door motor.

Installation

Installation is in the reverse order of removal.

REAR AIR MIX DOOR MOTOR

Removal

1. Remove the luggage side lower finisher RH. Refer to EI-40, "LUGGAGE FLOOR TRIM" .

2. Disconnect the rear air mix door motor electrical connector.

3. Remove the three screws and remove the rear air mix door motor.

Installation

Installation is in the reverse order of removal.

LJIA0021E

Page 570 of 3383

DUCTS AND GRILLESATC-169

C

DE

F

G H

I

K L

M A

B

AT C

Revision: November 2009 2006 QX56

Removal and InstallationEJS003YQ

CENTER CONSOLE HEAT DUCT AND REAR FINISHER ASSEMBLY GRILLE

Removal

The center console must be removed and disassembled to remove the heat duct and rear finisher assembly

grille. Refer to IP-16, "

REMOVAL AND INSTALLATION" .

Installation

Installation is in the reverse order of removal.

DEFROSTER NOZZLE

Removal

1. Remove the instrument panel trim. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove the front heater and cooling unit assembly. Refer to ATC-154, "

FRONT HEATER AND COOLING

UNIT ASSEMBLY" .

3. Remove the defroster nozzle.

Installation

Installation is in the reverse order of removal.

RH AND LH SIDE DEMISTER DUCT

Removal

1. Remove the instrument panel trim. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove the front heater and cooling unit assembly. Refer to ATC-154, "

FRONT HEATER AND COOLING

UNIT ASSEMBLY" .

3. Remove the RH or LH side demister duct.

Installation

Installation is in the reverse order of removal.

RH AND LH VENTILATOR DUCT

Removal

1. Remove the instrument panel trim. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove the front heater and cooling unit assembly. Refer to ATC-154, "

FRONT HEATER AND COOLING

UNIT ASSEMBLY" .

3. Remove the RH or LH ventilator duct.

Installation

Installation is in the reverse order of removal.

CENTER VENTILATOR DUCT

Removal

1. Remove the instrument panel trim. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove the front heater and cooling unit assembly. Refer to ATC-154, "

FRONT HEATER AND COOLING

UNIT ASSEMBLY" .

3. Remove the defroster nozzle.

4. Remove the RH and LH side demister ducts.

5. Remove the RH and LH ventilator ducts.

6. Remove the center ventilator duct.

Installation

Installation is in the reverse order of removal.

FLOOR DUCT

Removal

1. Remove the floor carpet. Refer to EI-37, "FLOOR TRIM" .

7. LH ventilator grille 8. RH ventilator grille 9. RH side ventilator and demister grille

10. Storage tray bottom cover (RH)

Page 648 of 3383

AUDIOAV-55

C

DE

F

G H

I

J

L

M A

B

AV

Revision: November 2009 2006 QX56

Removal and InstallationEKS00BIQ

AUDIO UNIT

Removal

1. Remove cluster lid C. Refer to IP-12, "Removal" .

2. Remove audio unit screws, using power tool.

3. Pull out audio unit and disconnect audio unit connectors.

Installation

Installation is in the reverse order of removal.

AV S W I T C H

Removal

1. Disconnect battery negative terminal.

2. Remove center console. Refer to IP-16, "

REMOVAL AND INSTALLATION" .

3. Disconnect center speaker.

4. Remove AV switch screws.

5. Carefully remove the AV switch.

Installation

Installation is in the reverse order of removal.

BOSE SPEAKER AMP.

Removal

1. Remove the accelerator pedal. Refer to ACC-3, "ACCELERATOR CONTROL SYSTEM" .

2. Remove BCM. Refer to BCS-20, "

BCM" .

3. Disconnect Bose speaker amp. and satellite radio tuner (if equipped) connectors.

4. Remove Bose speaker amp./satellite radio tuner bracket screws and slide Bose speaker amp./satellite radio tuner bracket down.

WKIA1490E

WKIA1798E

WKIA1605E

Page 649 of 3383

AV-56

AUDIO

Revision: November 20092006 QX56

5. Remove Bose speaker amp. screws (A) and remove Bose

speaker amp. from Bose speaker amp./satellite radio tuner

bracket.

Installation

Installation is in the reverse order of removal.

CENTER SPEAKER

Removal

1. Remove center console. Refer to IP-16, "REMOVAL AND INSTALLATION" .

2. Remove cluster lid D. Refer to IP-12, "

Removal" .

3. Disconnect center speaker connectors.

4. Remove the center speaker screws and remove the center speaker.

Installation

Installation is in the reverse order of removal.

FRONT DOOR SPEAKER

Removal

1. Remove front door finisher. Refer to EI-32, "DOOR FINISHER" .

2. Remove the four front door speaker screws.

3. Disconnect connector and remove front door speaker.

Installation

Installation is in the reverse order of removal.

FRONT TWEETER

Removal

1. Remove front tweeter grille. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

LKIA0678E

WKIA1799E

WKIA1498E

Page 676 of 3383

DVD ENTERTAINMENT SYSTEMAV-83

C

DE

F

G H

I

J

L

M A

B

AV

Revision: November 2009 2006 QX56

Removal and InstallationEKS00BJB

DVD PLAYER

Removal

1. Disconnect battery negative terminal.

2. Remove center console compartment. Refer to IP-16, "

REMOVAL AND INSTALLATION" .

3. Remove the DVD player screws.

4. Disconnect DVD connectors and remove DVD player.

Installation

Installation is in reverse order of removal.

VIDEO MONITOR

Removal

1. Remove rear roof console assembly. Refer to EI-38, "HEADLINING" .

2. Disconnect the video monitor connector.

3. Remove the video housing screws.

4. Remove the video monitor and housing.

5. Remove the video monitor hinge screws and remove the video monitor.

Installation

Installation is in reverse order of removal.

WKIA1503E

WKIA1502E

WKIA1219E

Page 760 of 3383

NAVIGATION SYSTEMAV-167

C

DE

F

G H

I

J

L

M A

B

AV

Revision: November 2009 2006 QX56

Removal and InstallationEKS00GFE

AV S W I T C H

Refer to AV- 5 5 , "AV SWITCH" .

DISPLAY CONTROL UNIT

Removal

1. Remove display unit. Refer to AV- 1 6 7 , "DISPLAY UNIT" .

2. Remove display control unit.

Installation

Installation is in reverse order of removal.

DISPLAY UNIT

Removal

1. Remove center console. Refer to IP-16, "Center Console" .

2. Remove cluster lid D. Refer to IP-12, "

CLUSTER LID D" .

3. Disconnect center speaker connector.

4. Disconnect display unit connectors.

5. Remove display unit.

6. Remove display unit brackets.

Installation

Installation is in reverse order of removal.

GPS ANTENNA

Removal

1. Remove center console. Refer to IP-16, "Center Console" .

2. Remove cluster lid D. Refer to IP-12, "

CLUSTER LID D" .

3. Disconnect center speaker.

4. Remove defroster grille. Refer to IP-10, "

INSTRUMENT PANEL ASSEMBLY" .

WKIA1512E

WKIA1512E

Page 782 of 3383

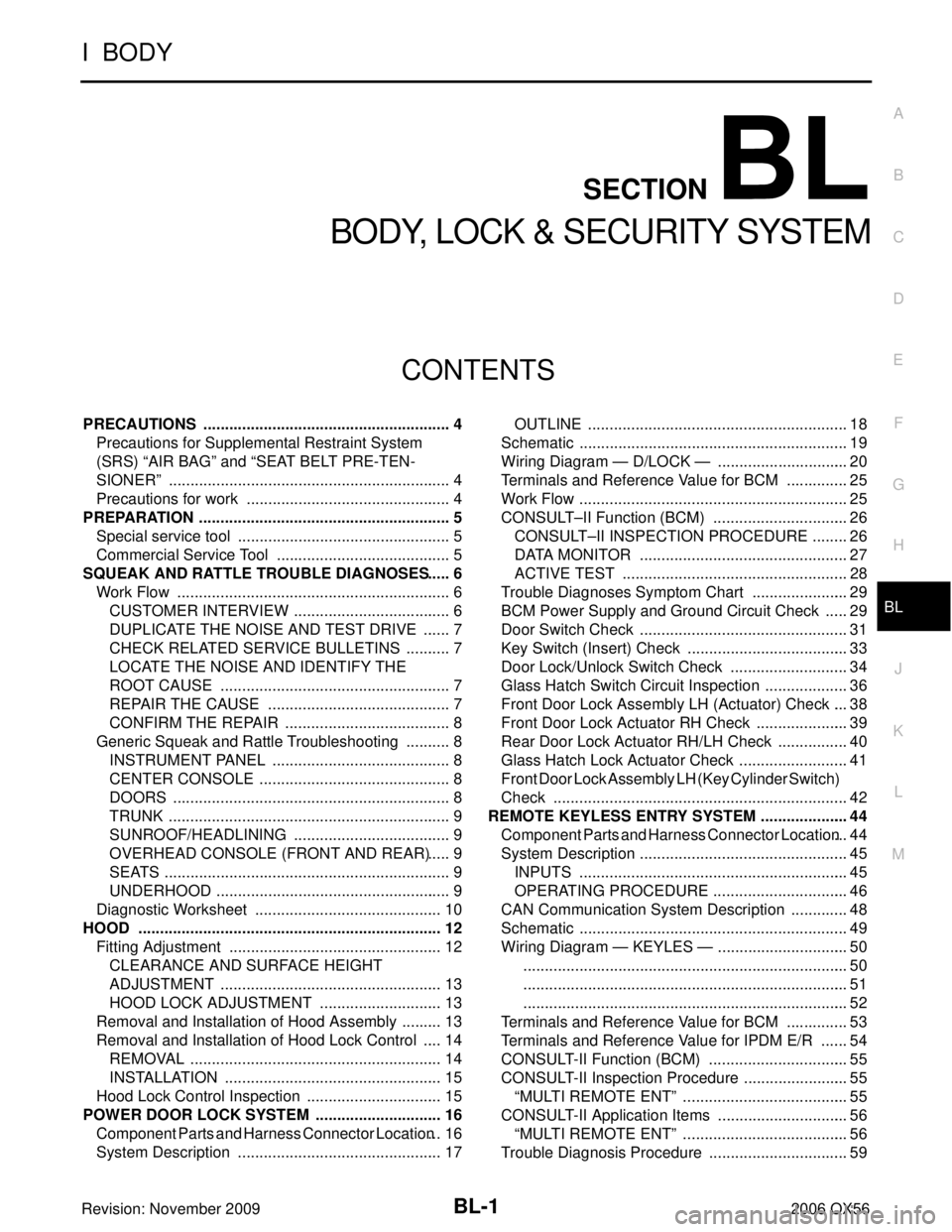

BL-1

BODY, LOCK & SECURITY SYSTEM

I BODY

CONTENTS

C

DE

F

G H

J

K L

M

SECTION

A

B

BL

Revision: November 2009 2006 QX56

PRECAUTIONS .....................................................

..... 4

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ............................................................. ..... 4

Precautions for work ................................................ 4

PREPARATION ...................................................... ..... 5

Special service tool ............................................. ..... 5

Commercial Service Tool .................................... ..... 5

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 6

Work Flow ................................................................ 6 CUSTOMER INTERVIEW ................................ ..... 6

DUPLICATE THE NOISE AND TEST DRIVE .. ..... 7

CHECK RELATED SERVICE BULLETINS ...... ..... 7

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ................................................. ..... 7

REPAIR THE CAUSE ...................................... ..... 7

CONFIRM THE REPAIR .................................. ..... 8

Generic Squeak and Rattle Troubleshooting ...... ..... 8

INSTRUMENT PANEL ..................................... ..... 8

CENTER CONSOLE ........................................ ..... 8

DOORS ............................................................ ..... 8

TRUNK ............................................................. ..... 9

SUNROOF/HEADLINING ................................ ..... 9

OVERHEAD CONSOLE (FRONT AND REAR) ..... 9

SEATS .............................................................. ..... 9

UNDERHOOD .................................................. ..... 9

Diagnostic Worksheet ......................................... ... 10

HOOD .................................................................... ... 12

Fitting Adjustment ............................................... ... 12

CLEARANCE AND SURFACE HEIGHT

ADJUSTMENT ................................................. ... 13

HOOD LOCK ADJUSTMENT .......................... ... 13

Removal and Installation of Hood Assembly ....... ... 13

Removal and Installation of Hood Lock Control .. ... 14

REMOVAL ........................................................ ... 14

INSTALLATION ................................................ ... 15

Hood Lock Control Inspection ............................. ... 15

POWER DOOR LOCK SYSTEM ........................... ... 16

Component Parts and Harness Connector Location ... 16

System Description ............................................. ... 17OUTLINE ..........................................................

... 18

Schematic ............................................................ ... 19

Wiring Diagram — D/LOCK — ............................ ... 20

Terminals and Reference Value for BCM ............ ... 25

Work Flow ............................................................... 25

CONSULT–II Function (BCM) ............................. ... 26

CONSULT–II INSPECTION PROCEDURE ...... ... 26

DATA MONITOR .............................................. ... 27

ACTIVE TEST ..................................................... 28

Trouble Diagnoses Symptom Chart .................... ... 29

BCM Power Supply and Ground Circuit Check ... ... 29

Door Switch Check ................................................. 31

Key Switch (Insert) Check ................................... ... 33

Door Lock/Unlock Switch Check ............................ 34

Glass Hatch Switch Circuit Inspection ................. ... 36

Front Door Lock Assembly LH (Actuator) Check . ... 38

Front Door Lock Actuator RH Check ................... ... 39

Rear Door Lock Actuator RH/LH Check .............. ... 40

Glass Hatch Lock Actuator Check .......................... 41

Front Door Lock Assembly LH (Key Cylinder Switch)

Check .................................................................. ... 42

REMOTE KEYLESS ENTRY SYSTEM .................. ... 44

Component Parts and Harness Connector Location ... 44

System Description .............................................. ... 45

INPUTS ............................................................ ... 45

OPERATING PROCEDURE ............................. ... 46

CAN Communication System Description ........... ... 48

Schematic ............................................................ ... 49

Wiring Diagram — KEYLES — ............................ ... 50

......................................................................... ... 50

......................................................................... ... 51

......................................................................... ... 52

Terminals and Reference Value for BCM ............ ... 53

Terminals and Reference Value for IPDM E/R .... ... 54

CONSULT-II Function (BCM) .............................. ... 55

CONSULT-II Inspection Procedure ...................... ... 55

“MULTI REMOTE ENT” .................................... ... 55

CONSULT-II Application Items ............................ ... 56

“MULTI REMOTE ENT” .................................... ... 56

Trouble Diagnosis Procedure .............................. ... 59

Page 789 of 3383

BL-8

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Revision: November 20092006 QX56

80845-71L00: 30 mm (1.18 in) thick, 30×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingEIS00627

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.