glove box INFINITI QX56 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: QX56, Model: INFINITI QX56 2006Pages: 3383, PDF Size: 51.76 MB

Page 549 of 3383

ATC-148

INTAKE SENSOR

Revision: November 20092006 QX56

INTAKE SENSORPFP:27723

Removal and InstallationEJS003YA

REMOVAL

1. Remove the glove box assembly. Refer to IP-15, "Glove Box" .

2. Disconnect the intake sensor electrical connector. NOTE:

The intake sensor is located on the top of the front heater and

cooling unit assembly next to the A/C evaporator cover.

3. Twist the intake sensor to remove the intake sensor from the front heater and cooling unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

LJIA0133E

Page 550 of 3383

BLOWER MOTORATC-149

C

DE

F

G H

I

K L

M A

B

AT C

Revision: November 2009 2006 QX56

BLOWER MOTORPFP:27226

ComponentsEJS003YB

Front Blower Motor

Rear Blower Motor

Removal and InstallationEJS003YC

FRONT BLOWER MOTOR

Removal

1. Remove the glove box assembly. Refer to IP-14, "Lower Instrument Panel RH and Glove Box" .

2. Disconnect the front blower motor electrical connector.

3. Remove the three screws and remove the front blower motor.

Installation

Installation is in the reverse order of removal.

LJIA0136E

1. Front heater and cooling unit assembly 2. Front blower motor 3. Variable blower control

LJIA0055E

1. Rear blower motor2. Rear blower motor case 3. Rear blower motor resistor

Page 552 of 3383

IN-CABIN MICROFILTERATC-151

C

DE

F

G H

I

K L

M A

B

AT C

Revision: November 2009 2006 QX56

IN-CABIN MICROFILTERPFP:27277

Removal and InstallationEJS003YD

FUNCTION

The air inside the passenger compartment is filtered by the in-cabin

microfilters when the heater or A/C controls are set on either the

recirculation or fresh mode. The two in-cabin microfilters are located

in the front heater and cooling unit assembly. The rear heater and

cooling unit assembly only draws in air from the passenger compart-

ment to recirculate into the passenger compartment, so the rear

heater and cooling unit assembly is not equipped with in-cabin

microfilters.

REPLACEMENT TIMING

Replacement of the two in-cabin microfilters is recommended on a regular interval depending on the driving

conditions. Refer to MA-7, "

PERIODIC MAINTENANCE" . It may also be necessary to replace the two in-cabin

microfilters as part of a component replacement if the in-cabin microfilters are damaged.

REPLACEMENT PROCEDURE

1. Remove the two lower glove box hinge pins to remove the glove

box from the instrument panel and let it hang from the cord.

2. Remove the screw and remove the in-cabin microfilter cover.

3. Remove the in-cabin microfilters from the front heater and cool- ing unit assembly housing.

4. Insert the first new in-cabin microfilter into the front heater and cooling unit assembly housing and slide it over to the right.

Insert the second new in-cabin microfilter into the front heater

and cooling unit assembly housing.

NOTE:

The in-cabin microfilters are marked with air flow arrows. The

end of the microfilter with the arrow should face the rear of the

vehicle. The arrows should point downward.

LJIA0012E

WLIA0027E

LJIA0134E

LJIA0148E

Page 553 of 3383

ATC-152

IN-CABIN MICROFILTER

Revision: November 20092006 QX56

5. Install the in-cabin microfilter cover.

6. Install the lower glove box in the instrument panel and secure it

with the two hinge pins.

LJIA0134E

WLIA0027E

Page 565 of 3383

ATC-164

VARIABLE BLOWER CONTROL

Revision: November 20092006 QX56

VARIABLE BLOWER CONTROLPFP:27200

Removal and InstallationEJS003YN

Variable Blower Control - Front Heater and Cooling Unit Assembly

REMOVAL

1. Remove the glove box assembly. Refer to IP-14, "Lower Instrument Panel RH and Glove Box" .

2. Disconnect the variable blower control electrical connector.

3. Remove the two screws and remove the variable blower control.

INSTALLATION

Installation is in the reverse order of removal.

LJIA0139E

1. Front heater and cooling unit assembly 2. Intake door motor 3. Air mix door motor (driver)

4. Variable blower control 5. Air mix door motor (passenger) 6. Mode door motor

7. Defroster door motor

Page 2245 of 3383

IDX-4

ALPHABETICAL INDEX

E

ECM input/output signal ..................... EC-105

, EC-129

ECM power supply ............................. EC-145, EC-453

ECM relay ........................................................ EC-145

ECM/PW - Wiring diagram ............................... EC-454

ECTS - Wiring diagram .................................... EC-194

Electric sunroof .................................................. RF-10

Electric throttle control actuator ......... EC-534, EC-545

Electrical load signal circuit .............................. EC-596

Electrical units location ...................................... PG-65

Electronic ignition (EI) system ........................... EC-26

Engine control circuit diagram ......................... EC-103

Engine control component parts location ........... EC-96

Engine control module (ECM) .......................... EC-457

Engine control system diagram ......................... EC-23

Engine coolant .................................................. CO-10

Engine coolant temperature sensor (ECTS) ... EC-192,

EC-205

Engine fail-safe system ...................................... EC-91

Engine oil ............................................................. LU-7

Engine oil filter replacement ............................. MA-17

Engine oil precautions .......................................... GI-7

Engine oil replacement ..................................... MA-17

Engine removal ................................................. EM-74

Engine room cover ............................................ EM-12

Engine serial number .......................................... GI-49

ETC1 - Wiring diagram .................................... EC-535

ETC2 - Wiring diagram .................................... EC-530

ETC3 - Wiring diagram .................................... EC-541

EVAP canister .................................................... EC-35

EVAP canister purge volume control solenoid valve ....

EC-373

, EC-381

EVAP canister vent control valve ....... EC-388, EC-395

EVAP control system (small leak) diagnosis .. EC-365,

EC-419

, EC-427

EVAP control system pressure sensor .... EC-402, EC-

405, EC-411

EVAP control system purge flow monitoring diagnosis

EC-360

EVAP vapor lines inspection ............................. MA-20

Evaporative emission (EVAP) system ............... EC-32

Evaporator ..................................................... ATC-184

Exhaust manifold .............................................. EM-21

Exhaust system ................................................... EX-3

Exhaust system inspection .................................. EX-3

Expansion valve ............................................. ATC-186

F

F/FOG - Wiring diagram ..................................... LT-71

F/PUMP - Wiring diagram ................................ EC-605

Final drive pre-inspection ................................. FFD-15

Final drive removal and installation .. FFD-12, RFD-13

Flow charts ......................................................... GI-28

Fluid temperature sensor (A/T) ........................ AT-127

Fluids ................................................................ MA-11

Fluorescent leak detector .............................. ATC-187

Fog lamp, front .................................................... LT-69

Fog lamp, front, removal and installation ........... LT-79

Foot lamp ......................................................... LT-135

Freeze frame data ............................... EC-53, EC-118

Front brake solenoid valve ................. AT-143, AT-145

Front bumper ...................................................... EI-13

Front case (Transfer) .......................... TF-149, TF-176

Front combination lamp removal and installation LT-31

Front door ............................. BL-128, BL-131, GW-65

Front Door Trim ................................................... EI-32

Front drive shaft (Transfer) ................. TF-149, TF-176

Front fog lamp .................................................... LT-69

Front fog lamp removal and installation ............. LT-79

Front passenger air bag .................................. SRS-50

Front seat ........................................................... SE-91

Front seat belt ...................................................... SB-3

Front seat belt pre-tensioner ............... SRS-3, SRS-57

Front washer ...................................................... WW-4

Front wiper ......................................................... WW-4

FTS - Wiring diagram ....................................... AT-128

FTTS - Wiring diagram ...................... EC-311, EC-316

Fuel cut control (at no load high engine speed) EC-27

Fuel filter replacement ......................................... FL-6

Fuel gauge ............................................................ DI-5

Fuel injection system (Bank 1) .......... EC-288, EC-299

Fuel injection system (Bank 2) .......... EC-288, EC-299

Fuel injector .................................................... EC-598

Fuel injector and fuel tube ................................. EM-31

Fuel level sensor ................. EC-436, EC-438, EC-440

Fuel line inspection .............................................. FL-4

Fuel precautions ................................................... GI-5

Fuel pressure check .......................................... EC-80

Fuel pressure release ....................................... EC-80

Fuel pump ....................................................... EC-604

Fuel pump and gauge .......................................... FL-6

Fuel system .......................................................... FL-4

Fuel tank ............................................................ FL-10

Fuel tank temperature sensor ........... EC-309, EC-315

Fuel tank vacuum relief valve ........................... EC-35

FUELB1 - Wiring diagram ................. EC-290, EC-301

FUELB2 - Wiring diagram ................. EC-292, EC-303

Fuse ...................................................... PG-17, PG-77

Fuse and fusible link box .................................. PG-77

Fuse block ......................................................... PG-76

Fusible link ............................................ PG-17, PG-77

G

Garage jack and safety stand ............................. GI-41

Gauges ................................................................. DI-5

Generator .......................................................... SC-17

Generic scan tool (GST) ................................. EC-127

Glass ...................................... GW-11, GW-65, GW-68

Glove box lamp ................................................ LT-158

GPS antenna ..................................................... AV-85

Grease .............................................................. MA-11

Ground distribution ............................................ PG-31

Page 2250 of 3383

IP-1

INSTRUMENT PANEL

I BODY

CONTENTS

C

DE

F

G H

J

K L

M

SECTION

A

B

IP

Revision: November 2009 2006 QX56

PRECAUTIONS .....................................................

..... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ............................................................. ..... 2

PREPARATION ...................................................... ..... 3

Special Service Tools .......................................... ..... 3

Commercial Service Tools ................................... ..... 3

SQUEAK AND RATTLE TROUBLE DIAGNOSIS . ..... 4

Work Flow ................................................................ 4 CUSTOMER INTERVIEW ................................ ..... 4

DUPLICATE THE NOISE AND TEST DRIVE .. ..... 5

CHECK RELATED SERVICE BULLETINS ...... ..... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ................................................. ..... 5

REPAIR THE CAUSE ...................................... ..... 5

CONFIRM THE REPAIR .................................. ..... 6

Generic Squeak and Rattle Troubleshooting ...... ..... 6

INSTRUMENT PANEL ..................................... ..... 6

CENTER CONSOLE ........................................ ..... 6

DOORS ............................................................ ..... 6

TRUNK ............................................................. ..... 7

SUNROOF/HEADLINING ................................ ..... 7

OVERHEAD CONSOLE (FRONT AND REAR) ..... 7

SEATS .............................................................. ..... 7UNDERHOOD ..................................................

..... 7

Diagnostic Worksheet .......................................... ..... 8

INSTRUMENT PANEL ASSEMBLY ...................... ... 10

Removal and Installation ..................................... ... 10

REMOVAL ........................................................ ... 11

INSTALLATION ................................................ ... 11

CLUSTER LID C .............................................. ... 12

CLUSTER LID D .............................................. ... 12

INSTRUMENT LOWER COVER LH ................ ... 13

COMBINATION METER ................................... ... 13

A/T FINISHER .................................................. ... 13

Lower Instrument Panel RH and Glove Box ........ ... 14

REMOVAL AND INSTALLATION ..................... ... 14

Glove Box ............................................................ ... 15

DISASSEMBLY AND ASSEMBLY .................... ... 15

Center Console ....................................................... 16 REMOVAL AND INSTALLATION ..................... ... 16

Center Console ....................................................... 17 DISASSEMBLY AND ASSEMBLY .................... ... 17

ASSEMBLY ...................................................... ... 17

Rear Console .......................................................... 18 REMOVAL AND INSTALLATION ..................... ... 18

Rear Console .......................................................... 19 DISASSEMBLY AND ASSEMBLY .................... ... 19

Page 2260 of 3383

INSTRUMENT PANEL ASSEMBLYIP-11

C

DE

F

G H

J

K L

M A

B

IP

Revision: November 2009 2006 QX56

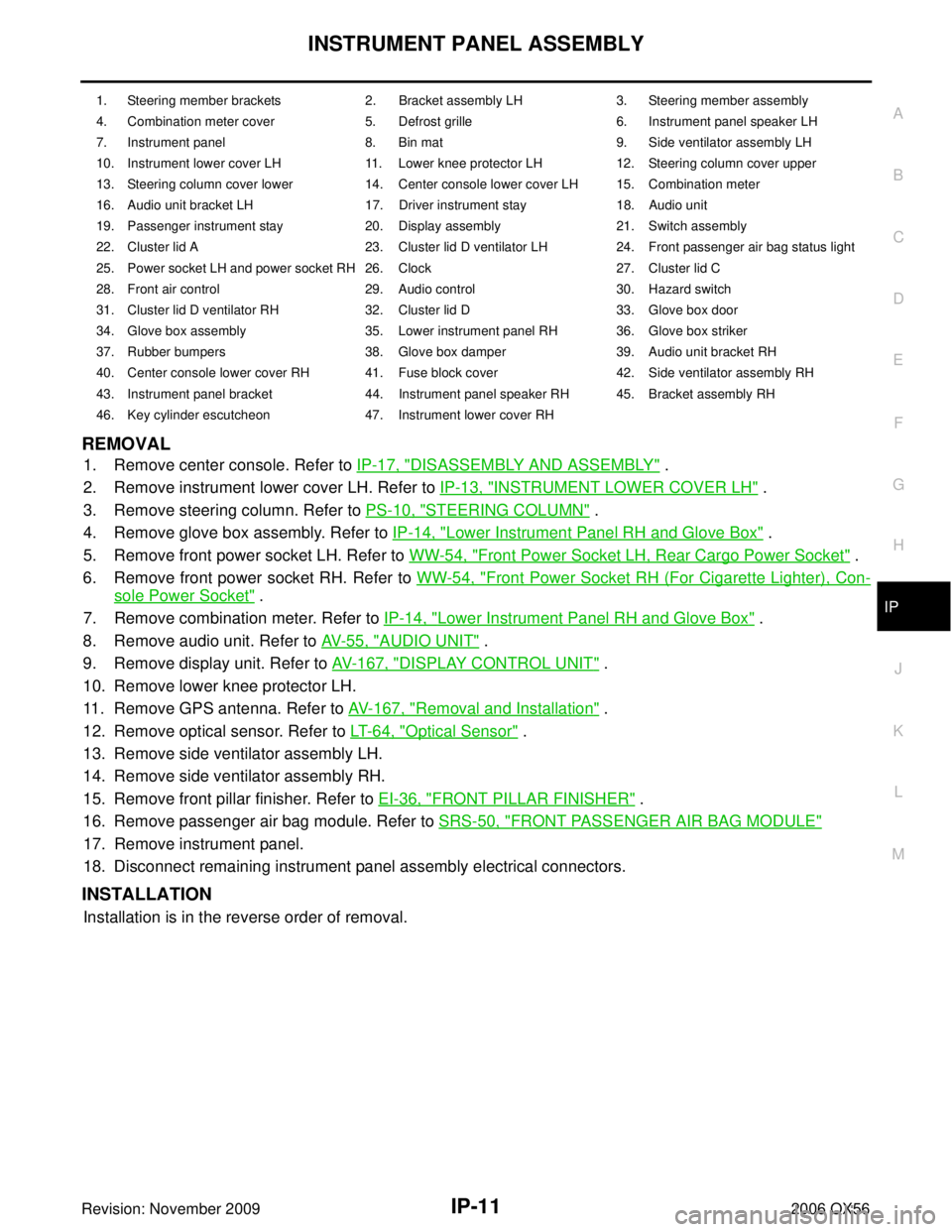

REMOVAL

1. Remove center console. Refer to IP-17, "DISASSEMBLY AND ASSEMBLY" .

2. Remove instrument lower cover LH. Refer to IP-13, "

INSTRUMENT LOWER COVER LH" .

3. Remove steering column. Refer to PS-10, "

STEERING COLUMN" .

4. Remove glove box assembly. Refer to IP-14, "

Lower Instrument Panel RH and Glove Box" .

5. Remove front power socket LH. Refer to WW-54, "

Front Power Socket LH, Rear Cargo Power Socket" .

6. Remove front power socket RH. Refer to WW-54, "

Front Power Socket RH (For Cigarette Lighter), Con-

sole Power Socket" .

7. Remove combination meter. Refer to IP-14, "

Lower Instrument Panel RH and Glove Box" .

8. Remove audio unit. Refer to AV- 5 5 , "

AUDIO UNIT" .

9. Remove display unit. Refer to AV- 1 6 7 , "

DISPLAY CONTROL UNIT" .

10. Remove lower knee protector LH.

11. Remove GPS antenna. Refer to AV- 1 6 7 , "

Removal and Installation" .

12. Remove optical sensor. Refer to LT- 6 4 , "

Optical Sensor" .

13. Remove side ventilator assembly LH.

14. Remove side ventilator assembly RH.

15. Remove front pillar finisher. Refer to EI-36, "

FRONT PILLAR FINISHER" .

16. Remove passenger air bag module. Refer to SRS-50, "

FRONT PASSENGER AIR BAG MODULE"

17. Remove instrument panel.

18. Disconnect remaining instrument panel assembly electrical connectors.

INSTALLATION

Installation is in the reverse order of removal.

1. Steering member brackets2. Bracket assembly LH3. Steering member assembly

4. Combination meter cover 5. Defrost grille6. Instrument panel speaker LH

7. Instrument panel 8. Bin mat9. Side ventilator assembly LH

10. Instrument lower cover LH 11. Lower knee protector LH12. Steering column cover upper

13. Steering column cover lower 14. Center console lower cover LH 15. Combination meter

16. Audio unit bracket LH 17. Driver instrument stay18. Audio unit

19. Passenger instrument stay 20. Display assembly21. Switch assembly

22. Cluster lid A 23. Cluster lid D ventilator LH24. Front passenger air bag status light

25. Power socket LH and power socket RH 26. Clock 27. Cluster lid C

28. Front air control 29. Audio control30. Hazard switch

31. Cluster lid D ventilator RH 32. Cluster lid D33. Glove box door

34. Glove box assembly 35. Lower instrument panel RH 36. Glove box striker

37. Rubber bumpers 38. Glove box damper39. Audio unit bracket RH

40. Center console lower cover RH 41. Fuse block cover 42. Side ventilator assembly RH

43. Instrument panel bracket 44. Instrument panel speaker RH 45. Bracket assembly RH

46. Key cylinder escutcheon 47. Instrument lower cover RH

Page 2261 of 3383

IP-12

INSTRUMENT PANEL ASSEMBLY

Revision: November 20092006 QX56

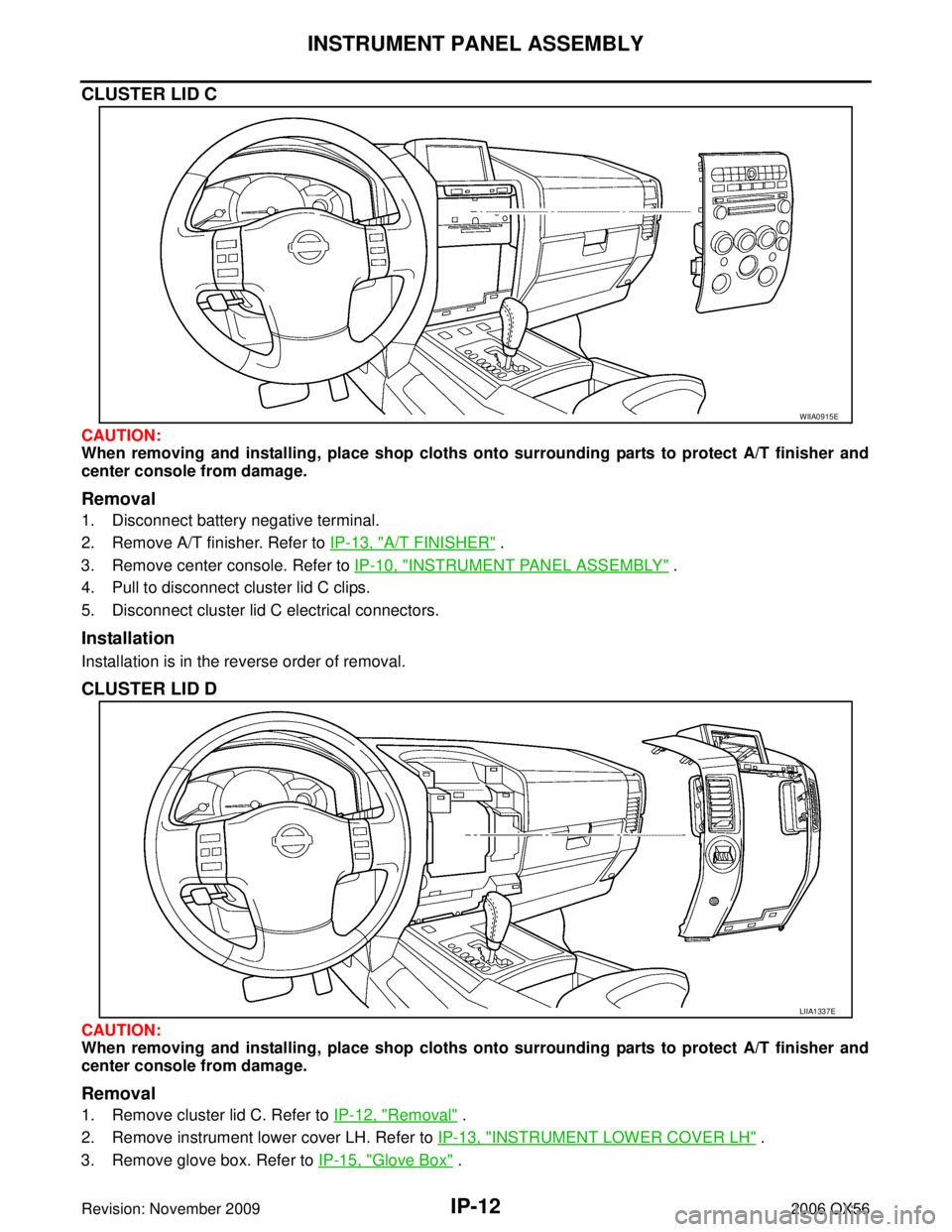

CLUSTER LID C

CAUTION:

When removing and installing, place shop cloths onto surrounding parts to protect A/T finisher and

center console from damage.

Removal

1. Disconnect battery negative terminal.

2. Remove A/T finisher. Refer to IP-13, "

A/T FINISHER" .

3. Remove center console. Refer to IP-10, "

INSTRUMENT PANEL ASSEMBLY" .

4. Pull to disconnect cluster lid C clips.

5. Disconnect cluster lid C electrical connectors.

Installation

Installation is in the reverse order of removal.

CLUSTER LID D

CAUTION:

When removing and installing, place shop cloths onto surrounding parts to protect A/T finisher and

center console from damage.

Removal

1. Remove cluster lid C. Refer to IP-12, "Removal" .

2. Remove instrument lower cover LH. Refer to IP-13, "

INSTRUMENT LOWER COVER LH" .

3. Remove glove box. Refer to IP-15, "

Glove Box" .

WIIA0915E

LIIA1337E

Page 2263 of 3383

IP-14

INSTRUMENT PANEL ASSEMBLY

Revision: November 20092006 QX56

Lower Instrument Panel RH and Glove BoxEIS007X9

REMOVAL AND INSTALLATION

Removal

1. Remove the instrument lower cover RH.

1. Clip2. Damper clip 3. Glove box damper

4. Glove box housing 5. Rubber stopper 6. Glove box pin

7. Glove box door 8. Glove box striker 9. Fuse block cover

10. Glove box assembly

LIIA1251E

LLIA0072E