turn signal INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1030 of 3061

COMBINATION METERSDI-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

• Depending on vehicle position or driving circumstance, the fuel in the tank shifts and the indication may fluc-

tuate.

• If the vehicle is fueled with the ignition switch ON, the indication will update slowly.

• If the vehicle is tilted when the ignition switch is turned ON, fuel in the tank may flow to one direction result-

ing in a change of reading.

LOW-FUEL WARNING LAMP

Depending on vehicle posture or driving circumstances, the fuel level in the tank varies, and the warning lamp

ON timing may be changed.

1.CHECK SELF-DIAGNOSIS

Perform the combination meter self-diagnosis. Refer to DI-12, "

Self-Diagnosis Mode of Combination Meter".

OK or NG

OK >> GO TO 2.

NG >> Replace the combination meter. Refer to IP-10, "

Removal and Installation".

2.CHECK HARNESS CONNECTOR

1. Turn the ignition switch OFF.

2. Check combination meter and fuel level sensor unit and fuel pump terminals (meter-side, and harness-

side) for poor connection.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace terminals or connectors.

3.CHECK HARNESS CONNECTOR OUTPUT SIGNAL

1. Disconnect fuel level sensor unit and fuel pump connector.

2. Turn ignition switch ON.

3. Check voltage between combination meter harness connector M24 terminal 15 and ground.

OK or NG

OK >> GO TO 4.

NG >> Replace the combination meter. Refer to IP-10,

"Removal and Installation".

4.CHECK HARNESS FOR OPEN OR SHORT CIRCUIT

1. Turn the ignition switch OFF.

2. Disconnect combination meter connector M24.

3. Check continuity between combination meter harness connector M24 (B) terminal 15 and fuel level sensor unit and fuel pump

harness connector C5 (A) terminal 2.

4. Check continuity between fuel level sensor unit and fuel pump harness connector C5 (A) terminal 2 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

5.CHECK FUEL LEVEL SENSOR CIRCUIT Battery voltage should exist.

WKIA1816E

Continuity should exist.

Continuity should not exist.

WKIA4617E

Page 1044 of 3061

WARNING LAMPS

DI-33

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

No malfunction detected>>GO TO 2.

Malfunction detected>>GO TO PG-18, "

CONSULT-II Function (IPDM E/R)".

2.CHECK IPDM E/R INPUT SIGNAL

Select "IPDM E/R" on CONSULT-II. Operate ignition switch with "OIL

P SW" of "DATA MONITOR" and check operation status.

OK or NG

OK >> Replace combination meter. Refer to IP-10, "Removal

and Installation".

NG >> GO TO 3.

3.CHECK OIL PRESSURE SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector E122 and oil pressure switch

connector F4.

3. Check continuity between IPDM E/R harness connector E122

(A) terminal 42 and oil pressure switch harness connector F4 (B)

terminal 1.

OK or NG

OK >> GO TO 4.

NG >> Repair harness or connector.

4.CHECK OIL PRESSURE SWITCH

Check oil pressure switch. Refer to DI-21, "

Electrical Component Inspection".

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R".

NG >> Replace oil pressure switch.

Oil Pressure Warning Lamp Does Not Turn Off (Oil Pressure Is Normal)INFOID:0000000003533507

NOTE:

For oil pressure inspection, refer to DI-21, "

Electrical Component Inspection".

1.CHECK ENGINE OIL PRESSURE GAUGE OPERATION

Observe operation of engine oil pressure gauge.

Does engine oil pressure gauge function properly?

YES >> Replace the combination meter. Refer to IP-10, "Removal and Installation".

NO >> GO TO DI-17, "

Engine Oil Pressure Signal Inspection". When ignition switch is in ON

position (Engine stopped): OIL P SW CLOSE

When engine running : OIL P SW OPEN

LKIA0403E

Continuity should exist.

WKIA5607E

Page 1048 of 3061

WARNING CHIME

DI-37

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

• to key switch and key lock solenoid terminal 3.

With ignition switch in ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67

• through body grounds M57, M61, and M79.

NOTE:

When ignition key warning chime, light warning chime, and seat belt warning chime are required at the same

time, the priorities for each chime are the following.

1. Light warning chime

2. Ignition key warning chime

3. Seat belt warning chime

IGNITION KEY WARNING CHIME

With the key inserted in the ignition switch, the ignition switch in OFF position, and the driver's door open, the

warning chime will sound.

Power is supplied

• through key switch and key lock solenoid terminal 4

• to BCM terminal 37.

Ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2.

Front door switch LH is case grounded.

BCM detects key inserted into the ignition switch, and sends key warning signal to combination meter via CAN

communication lines. When the combination meter receives key warning signal, it sounds warning chime.

LIGHT WARNING CHIME

With the key removed from the ignition switch, the driver's door open, and the lighting switch (part of the com-

bination switch) in 1st or 2nd position, the warning chime will sound. [Except when headlamp battery saver

control operates (5 minutes after ignition switch is turned to OFF or ACC position) and headlamps do not illu-

minate.]

Signal is supplied

• from combination switch (lighting switch) terminals 1, 2, 3, 4, 5, 6, 7, 8, 9 and 10

• to BCM terminals 2, 3, 4, 5, 6, 32, 33, 34, 35 and 36.

NOTE:

BCM detected lighting switch in 1st or 2nd position. Refer to LT-72, "

Combination Switch Reading Function".

Ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2.

Front door switch LH is case grounded.

BCM detects headlamps are illuminated, and sends light warning signal to combination meter CAN communi-

cation lines. When the combination meter receives light warning signal, it sounds warning chime.

SEAT BELT WARNING CHIME

When the ignition switch is turned ON with the seat belt unfastened [seat belt buckle pre-tensioner assembly

LH (seat belt buckle switch) unfastened], warning chime will sound for approximately 6 seconds.

Ground is supplied

• to combination meter terminal 27

• through seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) terminal 4.

Seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) terminal 3 is grounded through body

grounds B7 and B19.

The combination meter sends seat belt buckle switch LH unfastened signal to BCM via CAN communication

line.

BCM receives seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) unfastened signal from

combination meter via CAN communication line, and sends seat belt warning signal to the combination meter

via CAN communication line. When the combination meter receives the seat belt warning signal, it sounds the

warning chime. The BCM controls the (6 second) duration of the seat belt warning chime.

CAN Communication System DescriptionINFOID:0000000003533512

Refer to LAN-4.

Page 1053 of 3061

DI-42

< SERVICE INFORMATION >

WARNING CHIME

1. Turn ignition switch OFF.

2. Disconnect BCM connector M19 and front door switch LH con-

nector B8.

3. Check continuity between BCM harness connector M19 terminal

47 and front door switch LH harness connector B8 terminal 2.

4. Check continuity between BCM harness connector M19 terminal

47 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK FRONT DOOR SWITCH LH

Check continuity between front door switch LH terminal 2 and

exposed metal of switch while pressing and releasing switch.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Replace the front door switch LH.

Key Warning Chime Does Not OperateINFOID:0000000003533521

1.CHECK FUSE

Check if the key switch fuse [No. 19, located in the fuse block (J/B)] is blown. Refer to DI-38, "

Wiring Diagram

- CHIME -".

Is the fuse blown?

YES >> Replace the fuse. Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2.

2.CHECK WARNING CHIME OPERATION

With key removed from the ignition key cylinder and the front door LH open, turn the lighting switch to 1st or

2nd position.

Does warning chime sound?

YES >> GO TO 3.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate" or DI-41, "Key Warning Chime and Light

Warning Chime Do Not Operate (Seat Belt Warning Chime Does Operate)".

3.CHECK BCM INPUT SIGNAL

With CONSULT-IIContinuity should exist.

Continuity should not exist.

WKIA1516E

When front door switch

LH is released: Continuity should exist.

When front door switch

LH is pressed: Continuity should not exist.

WKIA2023E

Page 1055 of 3061

DI-44

< SERVICE INFORMATION >

WARNING CHIME

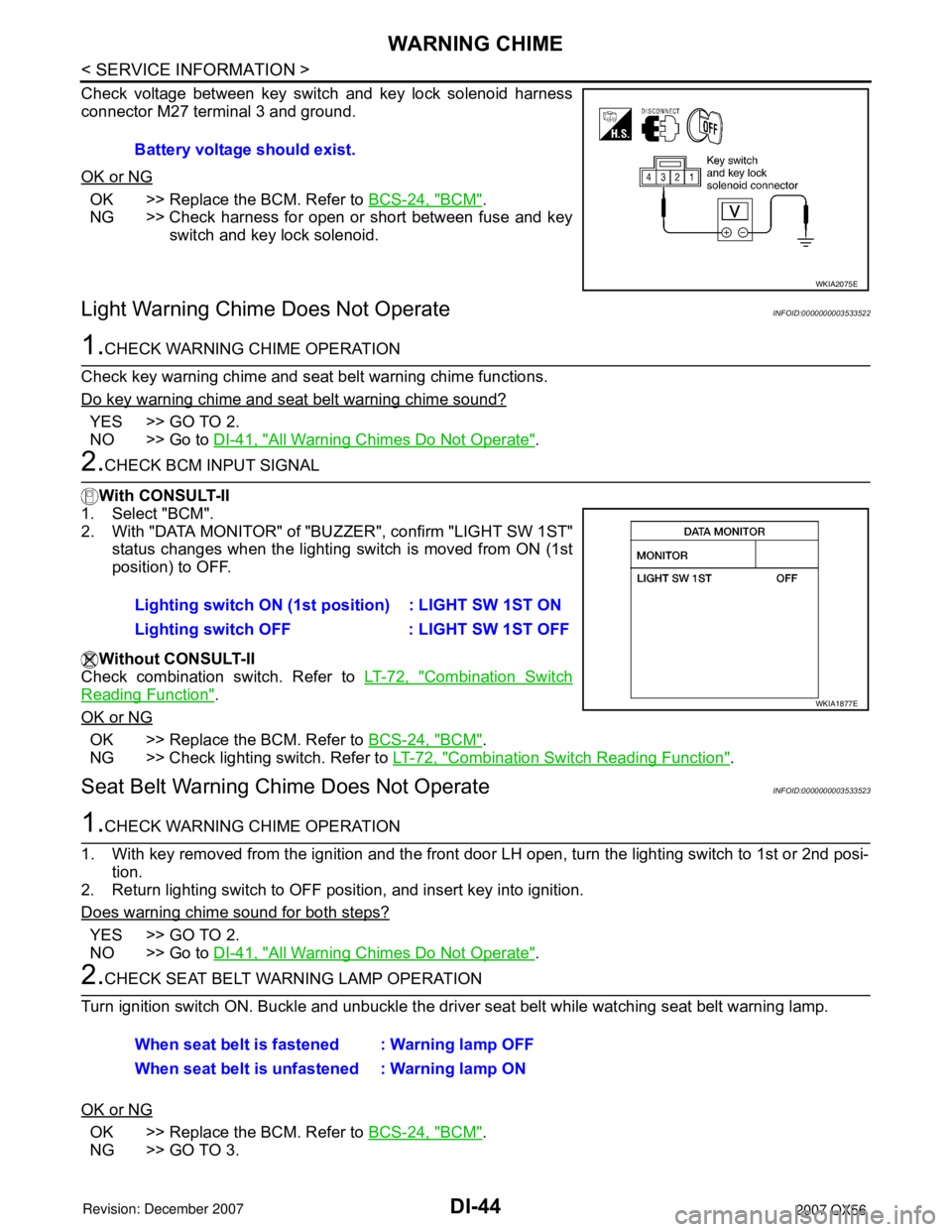

Check voltage between key switch and key lock solenoid harness

connector M27 terminal 3 and ground.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Check harness for open or short between fuse and key

switch and key lock solenoid.

Light Warning Chime Does Not OperateINFOID:0000000003533522

1.CHECK WARNING CHIME OPERATION

Check key warning chime and seat belt warning chime functions.

Do key warning chime and seat belt warning chime sound?

YES >> GO TO 2.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate".

2.CHECK BCM INPUT SIGNAL

With CONSULT-II

1. Select "BCM".

2. With "DATA MONITOR" of "BUZZER", confirm "LIGHT SW 1ST"

status changes when the lighting switch is moved from ON (1st

position) to OFF.

Without CONSULT-II

Check combination switch. Refer to LT-72, "

Combination Switch

Reading Function".

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Check lighting switch. Refer to LT-72, "

Combination Switch Reading Function".

Seat Belt Warning Chime Does Not OperateINFOID:0000000003533523

1.CHECK WARNING CHIME OPERATION

1. With key removed from the ignition and the front door LH open, turn the lighting switch to 1st or 2nd posi-

tion.

2. Return lighting switch to OFF position, and insert key into ignition.

Does warning chime sound for both steps?

YES >> GO TO 2.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate".

2.CHECK SEAT BELT WARNING LAMP OPERATION

Turn ignition switch ON. Buckle and unbuckle the driver seat belt while watching seat belt warning lamp.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> GO TO 3.Battery voltage should exist.

WKIA2075E

Lighting switch ON (1st position) : LIGHT SW 1ST ON

Lighting switch OFF : LIGHT SW 1ST OFF

WKIA1877E

When seat belt is fastened : Warning lamp OFF

When seat belt is unfastened : Warning lamp ON

Page 1056 of 3061

WARNING CHIME

DI-45

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

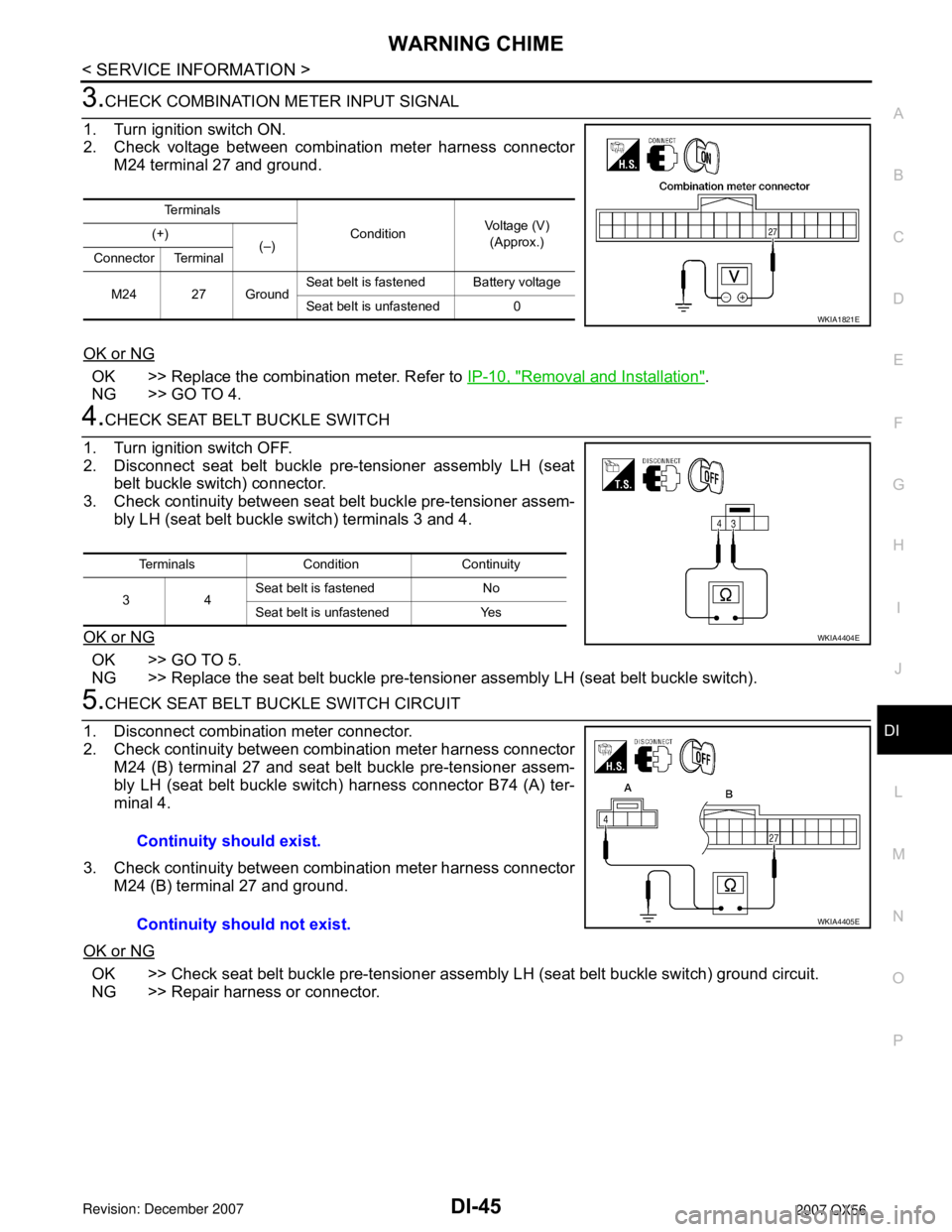

3.CHECK COMBINATION METER INPUT SIGNAL

1. Turn ignition switch ON.

2. Check voltage between combination meter harness connector

M24 terminal 27 and ground.

OK or NG

OK >> Replace the combination meter. Refer to IP-10, "Removal and Installation".

NG >> GO TO 4.

4.CHECK SEAT BELT BUCKLE SWITCH

1. Turn ignition switch OFF.

2. Disconnect seat belt buckle pre-tensioner assembly LH (seat

belt buckle switch) connector.

3. Check continuity between seat belt buckle pre-tensioner assem-

bly LH (seat belt buckle switch) terminals 3 and 4.

OK or NG

OK >> GO TO 5.

NG >> Replace the seat belt buckle pre-tensioner assembly LH (seat belt buckle switch).

5.CHECK SEAT BELT BUCKLE SWITCH CIRCUIT

1. Disconnect combination meter connector.

2. Check continuity between combination meter harness connector

M24 (B) terminal 27 and seat belt buckle pre-tensioner assem-

bly LH (seat belt buckle switch) harness connector B74 (A) ter-

minal 4.

3. Check continuity between combination meter harness connector

M24 (B) terminal 27 and ground.

OK or NG

OK >> Check seat belt buckle pre-tensioner assembly LH (seat belt buckle switch) ground circuit.

NG >> Repair harness or connector.

Te r m i n a l s

ConditionVoltage (V)

(Approx.) (+)

(–)

Connector Terminal

M24 27 GroundSeat belt is fastened Battery voltage

Seat belt is unfastened 0

WKIA1821E

Terminals Condition Continuity

34Seat belt is fastened No

Seat belt is unfastened Yes

WKIA4404E

Continuity should exist.

Continuity should not exist.

WKIA4405E

Page 1058 of 3061

REAR SONAR SYSTEM

DI-47

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

Ground is supplied

• to sonar control unit terminal 6

• through body grounds B7 and B19.

With the ignition switch in the ON or START position, and the transmission gear selector lever in the R posi-

tion, power is supplied

• to sonar control unit terminal 5

• from back-up lamp relay terminal 5.

With power and ground supplied, transmission gear selector lever in R position, and the rear sonar system

OFF switch ON, the rear sonar system will detect obstacles within 1.8 m (5.9 ft.) of the rear sonar sensors. The

vehicle operator is notified of obstacles by varied rate of tone from the sonar buzzer depending on distance of

obstacle being sensed.

REAR SONAR SYSTEM OFF SWITCH

With power and ground supplied to the sonar control unit, transmission gear selector lever in R position, the

sonar system can be disabled and the sonar buzzer silenced by momentarily pressing the rear sonar system

OFF switch. The rear sonar system OFF indicator lamp will be illuminated in the rear sonar system OFF

switch.

To disable the rear sonar system, ground is supplied

• to sonar control unit terminal 13

• through rear sonar system OFF switch terminal 1

• through rear sonar system OFF switch terminal 2

• from body grounds M57, M61, and M79.

To light the rear sonar system OFF indicator, power is supplied

• from sonar control unit terminal 4

• to the rear sonar system OFF switch terminal 5.

Ground is supplied

• to the rear sonar system OFF switch terminal 6

• from body grounds M57, M61, and M79.

The rear sonar system and buzzer will be disabled and the rear sonar system OFF indicator will be illuminated

until the ignition switch is turned OFF. When the ignition switch is turned ON, the rear sonar system will be

enabled. Depressing the rear sonar system OFF switch momentarily will enable the rear sonar system also.

Enabling the rear sonar system will cause the rear sonar system OFF indicator to go out.

SONAR BUZZER

With power supplied to the sonar control unit and the transmission gear selector lever in R position, a station-

ary object that is at least 7.0 cm (2.8 in.) wide and 1.0 m (39.0 in.) tall and that is closer than 1.8 meters (5.9 ft.)

will be detected by the rear sonar sensors, causing the sonar buzzer to sound a tone. As the vehicle moves

closer to the object, the rate of the tone will increase. When the object is less than 25.0 cm (10 in.) from the

rear bumper, the tone will sound continuously.

Power is supplied

• from sonar control unit terminal 7

• to sonar buzzer terminal +.

Ground is supplied

• to sonar buzzer terminal -

• from sonar control unit terminal 3.

REAR SONAR SENSOR

With power and ground supplied to the rear sonar sensors, the sonar sensors transmit a 38.4 kHz ultrasonic

signal. This signal is reflected back to the sensor by objects large enough and close enough to be detected.

The rear sonar sensors measure the time from the transmitted signal to the time the signal is reflected back

and sends this information to the sonar control unit.

Power is supplied

• from sonar control unit terminal 16

• to each rear sonar sensor terminal 1.

Ground is supplied

• to each rear sonar sensor terminal 3

• from sonar control unit terminal 15.

Signal is supplied

• from each rear sonar sensor terminal 2

• to sonar control unit terminals 9, 10, 11 and 12.

Page 1061 of 3061

DI-50

< SERVICE INFORMATION >

REAR SONAR SYSTEM

Sonar Control Unit Harness Connector Terminal Layout

INFOID:0000000003533527

Terminal and Reference Value for Sonar Control UnitINFOID:0000000003533528

WKIA5222E

Te r m i n a l

(color)ItemCondition

Reference value (V)

(Approx.) Ignition

switchOperation

3 (R) Sonar buzzer return ON — 0 - 12 (variable)

4 (BR/Y)Rear sonar system

OFF indicator outputONRear sonar system OFF

switch ON 0

OFF Battery voltage

5 (G/W) Reverse signal ONTransmission gear se-

lector leverR position Battery voltage

Transmission gear se-

lector leverNot R position 0

6 (B)Sonar control unit

ground —— 0

7 (L) Sonar buzzer drive

signalON — Battery voltage

8 (G/R)Sonar control unit

powerON — Battery voltage

9 (GR)Rear sonar sensor

signal - RH outerON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstaclesBattery voltage

10 (P)Rear sonar sensor

signal - LH outerON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstaclesBattery voltage

11 ( O )Rear sonar sensor

signal - LH innerON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstaclesBattery voltage

12 (LG)Rear sonar sensor

signal - RH innerON• Rear sonar system OFF switch ON

• Transmission gear selector lever in R po-

sition

• No obstaclesBattery voltage

13 (LG)Rear sonar system

OFF switch signalONRear sonar system OFF

switchON 0

OFF Battery voltage

15 (Y)Rear sonar sensor

groundON — 0

16 (LG/B)Rear sonar sensor

powerON Ignition switch ON Battery voltage

Page 1076 of 3061

REAR VIEW MONITOR

DI-65

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

WORK SUPPORT

Refer to DI-65, "Side Distance Guideline Correction" for details.

DATA MONITOR

Display Item List

Side Distance Guideline CorrectionINFOID:0000000003533545

This mode is used to modify the side distance guidelines if they are dislocated from the rear view monitor

image, because of variations of body/camera mounting conditions.

SIDE DISTANCE GUIDELINE CORRECTION PROCEDURE

1. Create a correction line to modify the screen.

Draw lines on the rearward of the vehicle passing through the

following points: 200 mm (7.87 inch) from both sides of the vehi-

cle, and

• *1: 0.5 m (1.5 feet)

• *2: 1 m (3 feet)

• *3: 2 m (7 feet)

• *4: 3 m (10 feet)

and from the rear end of the bumper

2. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II CONVERTER to the data link connector, then turn igni-

tion switch ON. Touch “REARVIEW CAMERA” on “SELECT

SYSTEM” screen.

CAUTION:

Stop engine for safety when correcting side distance guide-

line.

REARVIEW CAMERA

diagnostic modeDescription

WORK SUPPORTSupports inspection and adjustments. Commands are transmitted to the rearview camera control unit

for setting the status suitable for required operation, input/output signals are received from the rearview

camera control unit and received data is displayed.

DATA MONITOR Displays rearview camera control unit input/output data in real time.

ECU PART NUMBER Rearview camera control unit part number can be read.

Display item [Unit]ALL SIG-

NALSSELECTION

FROM MENUContents

R POSI SIG [ON/OFF] X X Indicates [ON/OFF] condition of R position signal input.

SKIA5637E

Page 1079 of 3061

DI-68

< SERVICE INFORMATION >

REAR VIEW MONITOR

1. Turn ignition switch ON.

2. Shift A/T selector lever to R position.

Does back-up lamp illuminate?

YES >> GO TO 2.

NO >> Check back-up lamp system. Refer to LT- 8 0

.

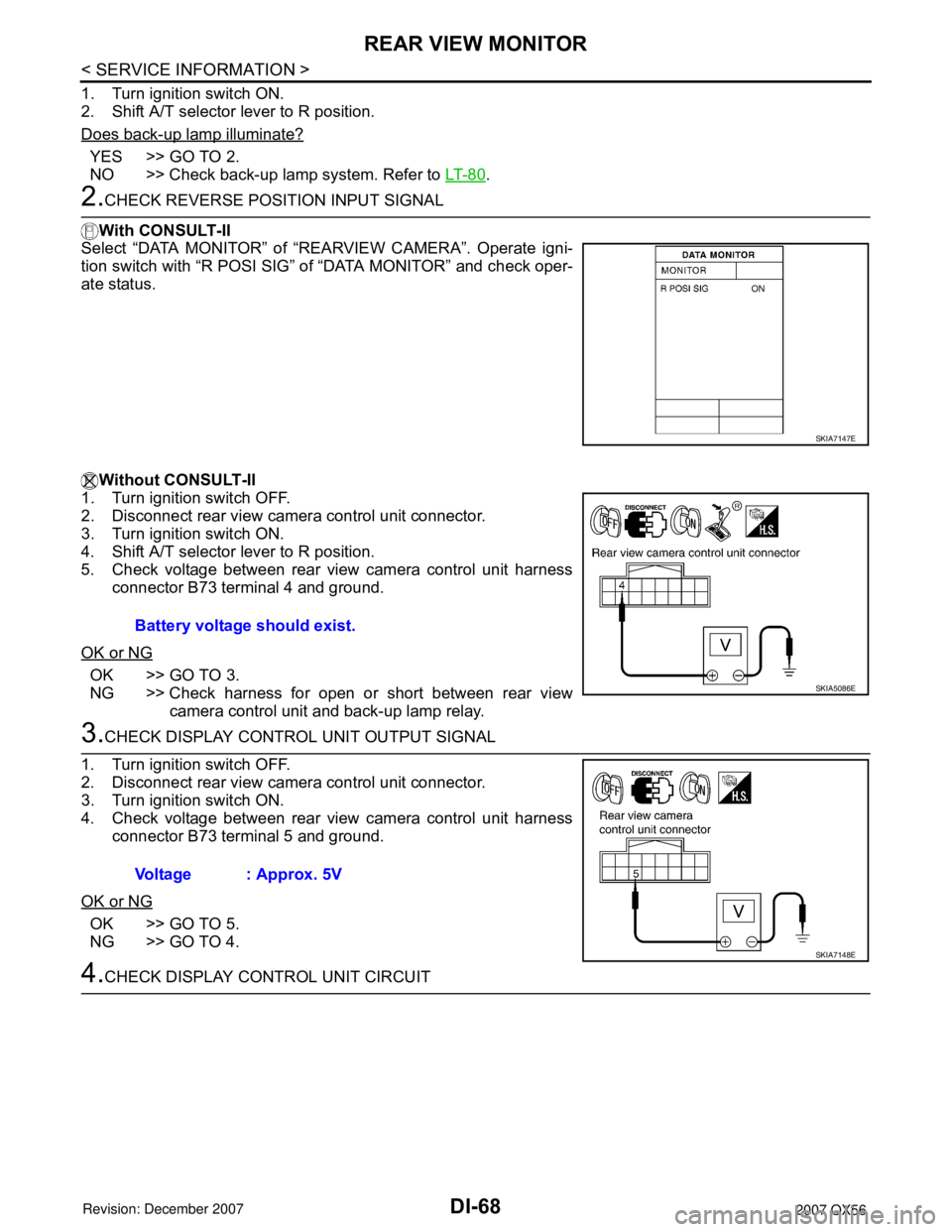

2.CHECK REVERSE POSITION INPUT SIGNAL

With CONSULT-II

Select “DATA MONITOR” of “REARVIEW CAMERA”. Operate igni-

tion switch with “R POSI SIG” of “DATA MONITOR” and check oper-

ate status.

Without CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Turn ignition switch ON.

4. Shift A/T selector lever to R position.

5. Check voltage between rear view camera control unit harness

connector B73 terminal 4 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open or short between rear view

camera control unit and back-up lamp relay.

3.CHECK DISPLAY CONTROL UNIT OUTPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Turn ignition switch ON.

4. Check voltage between rear view camera control unit harness

connector B73 terminal 5 and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK DISPLAY CONTROL UNIT CIRCUIT

SKIA7147E

Battery voltage should exist.

SKIA5086E

Voltage : Approx. 5V

SKIA7148E