ECO mode INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 48 of 3061

![INFINITI QX56 2007 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

45 BRAKE SW/ STOP L SW×××ו ICC brake switch or stop lamp

switch harness is open INFINITI QX56 2007 Factory User Guide TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

45 BRAKE SW/ STOP L SW×××ו ICC brake switch or stop lamp

switch harness is open](/img/42/57029/w960_57029-47.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

45 BRAKE SW/ STOP L SW×××ו ICC brake switch or stop lamp

switch harness is open or shorted

• ICC brake switch or stop lamp

switch is stuck to OFF

• ICC brake switch or stop lamp

switch is stuck to ONACS-38,

"DTC 45

BRAKE

SW/

STOP L

SW"

46 OPERATION SW CIRC××ו ICC steering switch harness or

spiral cable is open or shorted

• ICC steering switch malfunctionACS-40,

"DTC 46

OPERA-

TION SW

CIRC"

74 LASER BEAM OFF CNTR×× ×• Laser beam of ICC sensor is off

the aiming pointACS-41,

"DTC 74

LASER

BEAM

OFF CN-

TR"

90 STOP LAMP RLY FIX×× ×• Normally open terminal of stop

lamp relay is stuckACS-41,

"DTC 90

STOP

LAMP

RLY FIX"

92 ECM CIRCUIT×××וECM malfunction

• Accelerator pedal position sensor

malfunction

• ICC unit malfunctionACS-45,

"DTC 92

ECM

CIR-

CUIT"

96 NP RANGE××ו Park/neutral position switch har-

ness is open or shorted

• Park/neutral position switch mal-

function

•TCM malfunctionACS-45, "DTC 96

NP

RANGE"

97 AT CIRCUIT××וTCM malfunctionACS-46, "DTC 97

AT CIR-

CUIT"

98 GEAR POSITION××וTCM malfunction

• A/T turbine revolution sensor mal-

function

• A/T vehicle speed sensor mal-

functionACS-46,

"DTC 98

GEAR

POSI-

TION"

102 LASER STAIN×× ×• ICC sensor body window has

contaminationACS-47, "DTC 102

LASER

STAIN"

103 LASER SENSOR FAIL×× ×• ICC sensor internal malfunctionACS-47,

"DTC 103

LASER

SEN-

SOR

FA I L"

DTC

No.CONSULT-II screen termsICC sys-

tem

warning

lampFail-safe

Malfunctions detected where...Refer-

ence

page Veh ic le-

to-vehi-

cle dis-

tance

control

modeConven-

tional

(fixed

speed)

cruise

control

modeBrake as-

sist (with

preview

function)

Page 49 of 3061

![INFINITI QX56 2007 Factory User Guide ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

NOTE: DTC 55 will display when no malfunction is detected.

DTC 11 CONTROL UNITINFOID:0000000003533795

1.DIAGNOSTIC CHECK INFINITI QX56 2007 Factory User Guide ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

NOTE: DTC 55 will display when no malfunction is detected.

DTC 11 CONTROL UNITINFOID:0000000003533795

1.DIAGNOSTIC CHECK](/img/42/57029/w960_57029-48.png)

ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

NOTE: DTC 55 will display when no malfunction is detected.

DTC 11 CONTROL UNITINFOID:0000000003533795

1.DIAGNOSTIC CHECK

Are any items other than “DTC 11 CONTROL UNIT” indicated on self-diagnosis display?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform ICC system running test. Refer to ACS-

9, "ICC System Running Test" . Then perform self-diagnosis of ICC system again.

NO >> Replace ICC unit. Refer to ACS-55

. Erase DTC and perform ICC system running test. Refer to

ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC system again.

DTC 12 VDC CONTROL UNITINFOID:0000000003533796

1.DIAGNOSIS CHECK

With CONSULT-II

Perform self-diagnosis of ABS actuator and electric unit (control unit). Is malfunction indicated?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform ICC system running test. Refer to ACS-

9, "ICC System Running Test". Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2.CHECK CONNECTOR ICC UNIT AND ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

1. Turn ignition switch OFF.

2. Disconnect ICC unit, and ABS actuator and electric unit (control unit) connectors, and connect them

securely again. Erase DTC, then perform self-diagnosis of ICC system again.

OK or NG

OK >> Poor connector connection. Check connector housing for disconnected, loose, bent and collapsed

terminals. If any malfunction is detected, repair as necessary. Erase DTC and perform ICC sys-

tem running test. Refer to ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC

system again.

NG >> GO TO 3.

3.CHECK HARNESS BETWEEN ICC UNIT AND ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

104 LASER AIMING INCMP×× ×• Laser beam aiming of ICC sensor

is not adjustedACS-48,

"DTC 104

LASER

AIMING

INCMP"

107 LASER COMM FAIL×× ×• CAN data received by ICC sensor

is strange (from ICC unit, combi-

nation meter or ECM)ACS-48,

"DTC 107

LASER

COMM

FA IL"

109 LASER HIGH TEMP×× ×• Temperature around ICC sensor

is excessively highACS-48,

"DTC 109

LASER

HIGH

TEMP"

DTC

No.CONSULT-II screen termsICC sys-

tem

warning

lampFail-safe

Malfunctions detected where...Refer-

ence

page Vehicle-

to-vehi-

cle dis-

tance

control

modeConven-

tional

(fixed

speed)

cruise

control

modeBrake as-

sist (with

preview

function)

Page 109 of 3061

ON BOARD DIAGNOSTIC (OBD) SYSTEM

AT-39

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000003532238

The A/T system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (OBD-II) performed by the TCM in combination

with the ECM. The malfunction is indicated by the MIL (malfunction indicator lamp) and is stored as a DTC in

the ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the A/T CHECK indicator lamp. The malfunction is

stored in the TCM memory. The detected items are overlapped with OBD-II self-diagnostic items. For detail,

refer to AT-83, "

CONSULT-II Function (A/T)".

OBD-II Function for A/T SystemINFOID:0000000003532239

The ECM provides emission-related on board diagnostic (OBD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-related parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-related part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indicator lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBD-IIINFOID:0000000003532240

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st Trip

If the same malfunction as that experienced during the first test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd Trip

The “Trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)INFOID:0000000003532241

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-II or GST) CONSULT-II or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-II also displays the malfunctioning component or system.)

•1st trip DTC No. is the same as DTC No.

•Output of the diagnostic trouble code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-II can identify them as shown below, therefore, CONSULT-II (if available) is recommended.

A sample of CONSULT-II display for DTC and 1st trip DTC is shown

on the next page. DTC or 1st trip DTC of a malfunction is displayed

in SELF-DIAGNOSTIC RESULTS mode for “ENGINE” with CON-

SULT-II. Time data indicates how many times the vehicle was driven

after the last detection of a DTC.

BCIA0030E

Page 111 of 3061

ON BOARD DIAGNOSTIC (OBD) SYSTEM

AT-41

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

•System readiness test (SRT) codes

•Test values

HOW TO ERASE DTC (WITH CONSULT-II)

•If a DTC is displayed for both ECM and TCM, it is necessary to be erased for both ECM and TCM.

1. If the ignition switch stays “ON” after repair work, be sure to turn ignition switch “OFF” once. Wait at least

10 seconds and then turn it “ON” (engine stopped) again.

2. Turn CONSULT-II “ON” and touch “A/T”.

3. Touch “SELF-DIAG RESULTS”.

4. Touch “ERASE”. (The DTC in the TCM will be erased.) Then touch “BACK” twice.

5. Touch “ENGINE”.

6. Touch “SELF-DIAG RESULTS”.

7. Touch “ERASE”. (The DTC in the ECM will be erased.)

HOW TO ERASE DTC (WITH GST)

1. If the ignition switch stays “ON” after repair work, be sure to turn ignition switch “OFF” once. Wait at least

10 seconds and then turn it “ON” (engine stopped) again.

2. Select Mode 4 with the Generic Scan Tool (GST). For details refer to EC-122, "

Generic Scan Tool (GST)

Function".

HOW TO ERASE DTC (NO TOOLS)

1. Disconnect battery for 24 hours.

2. Reconnect battery.

Malfunction Indicator Lamp (MIL)INFOID:0000000003532242

DESCRIPTION

SCIA5671E

Page 113 of 3061

TROUBLE DIAGNOSIS

AT-43

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

TROUBLE DIAGNOSIS

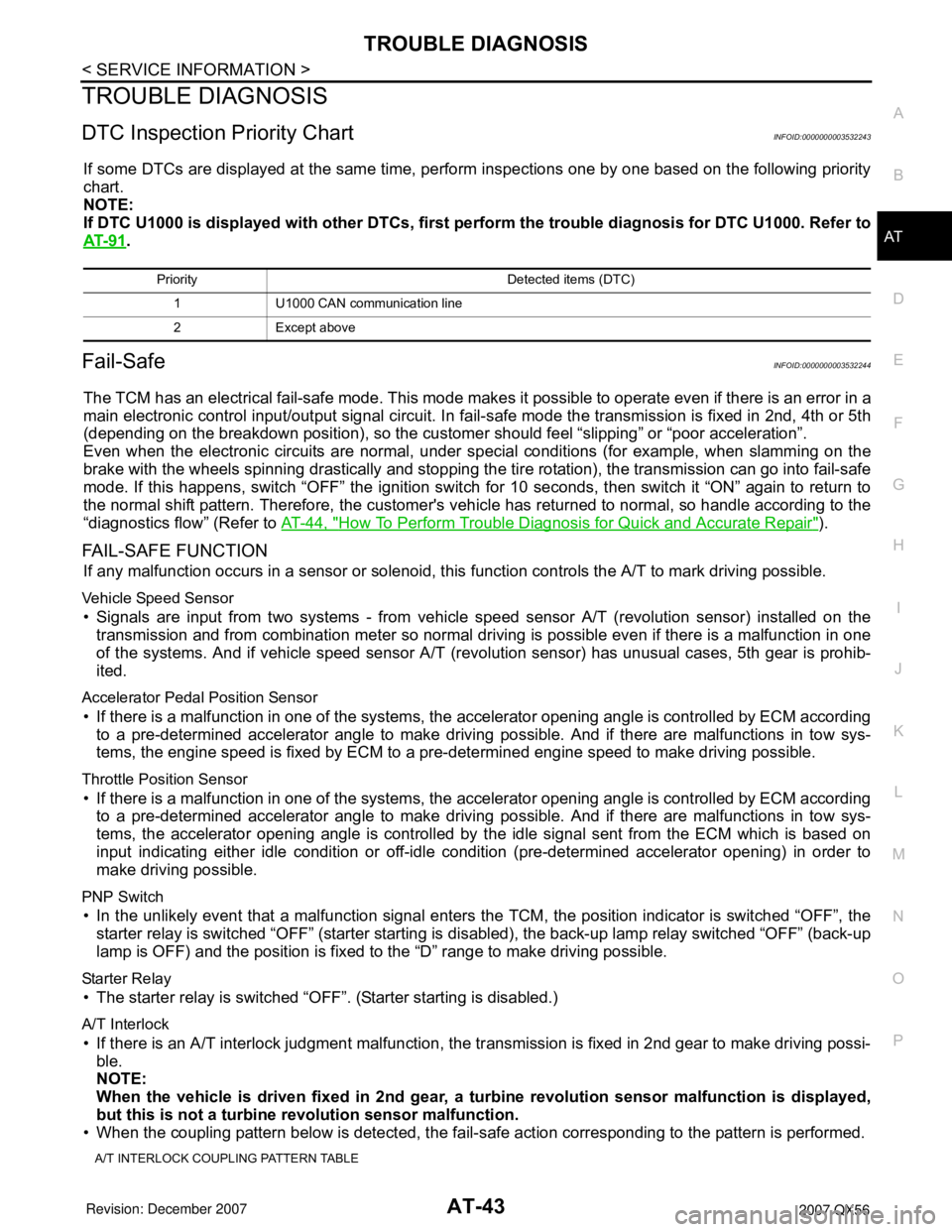

DTC Inspection Priority ChartINFOID:0000000003532243

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC U1000 is displayed with other DTCs, first perform the trouble diagnosis for DTC U1000. Refer to

AT- 9 1

.

Fail-SafeINFOID:0000000003532244

The TCM has an electrical fail-safe mode. This mode makes it possible to operate even if there is an error in a

main electronic control input/output signal circuit. In fail-safe mode the transmission is fixed in 2nd, 4th or 5th

(depending on the breakdown position), so the customer should feel “slipping” or “poor acceleration”.

Even when the electronic circuits are normal, under special conditions (for example, when slamming on the

brake with the wheels spinning drastically and stopping the tire rotation), the transmission can go into fail-safe

mode. If this happens, switch “OFF” the ignition switch for 10 seconds, then switch it “ON” again to return to

the normal shift pattern. Therefore, the customer's vehicle has returned to normal, so handle according to the

“diagnostics flow” (Refer to AT-44, "

How To Perform Trouble Diagnosis for Quick and Accurate Repair").

FAIL-SAFE FUNCTION

If any malfunction occurs in a sensor or solenoid, this function controls the A/T to mark driving possible.

Vehicle Speed Sensor

• Signals are input from two systems - from vehicle speed sensor A/T (revolution sensor) installed on the

transmission and from combination meter so normal driving is possible even if there is a malfunction in one

of the systems. And if vehicle speed sensor A/T (revolution sensor) has unusual cases, 5th gear is prohib-

ited.

Accelerator Pedal Position Sensor

• If there is a malfunction in one of the systems, the accelerator opening angle is controlled by ECM according

to a pre-determined accelerator angle to make driving possible. And if there are malfunctions in tow sys-

tems, the engine speed is fixed by ECM to a pre-determined engine speed to make driving possible.

Throttle Position Sensor

• If there is a malfunction in one of the systems, the accelerator opening angle is controlled by ECM according

to a pre-determined accelerator angle to make driving possible. And if there are malfunctions in tow sys-

tems, the accelerator opening angle is controlled by the idle signal sent from the ECM which is based on

input indicating either idle condition or off-idle condition (pre-determined accelerator opening) in order to

make driving possible.

PNP Switch

• In the unlikely event that a malfunction signal enters the TCM, the position indicator is switched “OFF”, the

starter relay is switched “OFF” (starter starting is disabled), the back-up lamp relay switched “OFF” (back-up

lamp is OFF) and the position is fixed to the “D” range to make driving possible.

Starter Relay

• The starter relay is switched “OFF”. (Starter starting is disabled.)

A/T Interlock

• If there is an A/T interlock judgment malfunction, the transmission is fixed in 2nd gear to make driving possi-

ble.

NOTE:

When the vehicle is driven fixed in 2nd gear, a turbine revolution sensor malfunction is displayed,

but this is not a turbine revolution sensor malfunction.

• When the coupling pattern below is detected, the fail-safe action corresponding to the pattern is performed.

A/T INTERLOCK COUPLING PATTERN TABLE

Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 159 of 3061

TROUBLE DIAGNOSIS

AT-89

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

DTC WORK SUPPORT MODE

Display Items List

ATF WARN LAMP (ON-OFF display) — — X

BACK-UP LAMP (ON-OFF display) — — X

STARTER RELAY (ON-OFF display) — — X

PNP SW3 MON (ON-OFF display) — — X

C/V CLB ID1 — — X

C/V CLB ID2 — — X

C/V CLB ID3 — — X

UNIT CLB ID1 — — X

UNIT CLB ID2 — — X

UNIT CLB ID3 — — X

TRGT GR RATIO — — X

TRGT PRES TCC (kPa) — — X

TRGT PRES L/P (kPa) — — X

TRGT PRES I/C (kPa) — — X

TRGT PRE FR/B (kPa) — — X

TRGT PRES D/C (kPa) — — X

TRG PRE HLR/C (kPa) — — X

SHIFT PATTERN — — X

DRV CST JUDGE — — X

START RLY MON — — X

NEXT GR POSI — — X

SHIFT MODE — — X

MANU GR POSI — — X

VEHICLE SPEED (km/h) — XX Vehicle speed recognized by the TCM.

Voltage (V) — — XDisplays the value measured by the voltage

probe.

Frequency (Hz) — — X

The value measured by the pulse probe is dis-

played. DUTY-HI (high) (%) — — X

DUTY-LOW (low) (%) — — X

PLS WIDTH-HI (ms) — — X

PLS WIDTH-LOW (ms) — — XMonitored item (Unit)Monitor Item Selection

Remarks ECU IN-

PUT SIG-

NALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

DTC work support itemDescription Check item

I/C SOL FUNCTN CHECK* — —

FR/B SOL FUNCTN CHECK* — —

D/C SOL FUNCTN CHECK* — —

HLR/C SOL FUNCTN CHECK* — —

Page 161 of 3061

DTC U1000 CAN COMMUNICATION LINE

AT-91

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

DTC U1000 CAN COMMUNICATION LINE

DescriptionINFOID:0000000003532260

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent malfunction detection ability.

Many electronic control units are equipped onto a vehicle, and each control unit shares information and links

with other control units during operation (not independent). In CAN communication, control units are con-

nected with 2 communication lines (CAN H line, CAN L line) allowing a high rate of information transmission

with less wiring. Each control unit transmits/receives data but selectively reads required data only.

On Board Diagnosis LogicINFOID:0000000003532261

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “U1000 CAN COMM CIRCUIT” with CONSULT-II is detected when TCM cannot

communicate to other control units.

Possible CauseINFOID:0000000003532262

Harness or connectors

(CAN communication line is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000003532263

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-II.

3. Start engine and wait for at least 6 seconds.

4. If DTC is detected, go to AT-93, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II”.

BCIA0031E

Page 164 of 3061

AT-94

< SERVICE INFORMATION >

DTC P0615 START SIGNAL CIRCUIT

DTC P0615 START SIGNAL CIRCUIT

DescriptionINFOID:0000000003532266

• TCM prohibits cranking other than at “P” or “N” position.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532267

On Board Diagnosis LogicINFOID:0000000003532268

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0615 STARTER RELAY/CIRC” with CONSULT-II is detected when park/neutral

(PNP) relay (starter relay) is switched “ON” other than at “P” or “N” position. (Or when switched “OFF” at “P”

or “N” position).

Possible CauseINFOID:0000000003532269

• Harness or connectors

[The park/neutral position (PNP) relay (starter relay) and TCM circuit is open or shorted.]

• Park/neutral position (PNP) relay (starter relay)

DTC Confirmation ProcedureINFOID:0000000003532270

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “A/T” with CONSULT-II.

3. Start engine.

4. Drive vehicle for at least 2 consecutive seconds.

5. If DTC is detected, go to AT-93, "

Diagnosis Procedure" .

Item name Condition Display value

STARTER RELAYSelector lever in “N”,“P” position. ON

Selector lever in other position. OFF

BCIA0031E

Page 168 of 3061

AT-98

< SERVICE INFORMATION >

DTC P0700 TCM

DTC P0700 TCM

DescriptionINFOID:0000000003532273

The TCM consists of a microcomputer and connectors for signal input and output and for power supply. The

TCM controls the A/T.

On Board Diagnosis LogicINFOID:0000000003532274

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0700 TCM” with CONSULT-II is detected when the TCM is malfunctioning.

Possible CauseINFOID:0000000003532275

TCM.

DTC Confirmation ProcedureINFOID:0000000003532276

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “A/T” with CONSULT-II.

3. Start engine.

4. Run engine for at least 2 consecutive seconds at idle speed.

5. If DTC is detected, go to AT-98, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-II”.

Diagnosis ProcedureINFOID:0000000003532277

1.CHECK DTC

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELF DIAG RESULTS” mode for “A/T” with CONSULT-

II.

3. Touch “ERASE”.

4. Turn ignition switch “OFF” and wait at least 10 seconds.

5. Perform DTC Confirmation Procedure, AT-98, "

DTC Confirma-

tion Procedure".

Is the

“TCM” displayed again?

YES >> Replace the control valve with TCM. Refer to AT-210,

"Control Valve with TCM and A/T Fluid Temperature

Sensor 2".

NO >>INSPECTION END

BCIA0031E

BCIA0031E

Page 169 of 3061

DTC P0705 PARK/NEUTRAL POSITION SWITCH

AT-99

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

DTC P0705 PARK/NEUTRAL POSITION SWITCH

DescriptionINFOID:0000000003532278

• The park/neutral position (PNP) switch includes a transmission position switch.

• The transmission range switch detects the selector lever position and sends a signal to the TCM.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532279

On Board Diagnosis LogicINFOID:0000000003532280

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0705 PNP SW/CIRC” with CONSULT-II is detected under the following condi-

tions.

- When TCM does not receive the correct voltage signal from the PNP switch 1, 2, 3, 4 based on the gear

position.

- When no other position but “P” position is detected from “N” positions.

Possible CauseINFOID:0000000003532281

• Harness or connectors

[The park/neutral position (PNP) switch 1, 2, 3, 4 and TCM circuit is open or shorted.]

• Park/neutral position (PNP) switch 1, 2, 3, 4

DTC Confirmation ProcedureINFOID:0000000003532282

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “ENGINE” with CONSULT-II.

3. Start engine.

4. Drive vehicle and maintain the following conditions for at least 2

consecutive seconds.

THRTL POS SEN: More than 1.2V

5. If DTC is detected, go to AT-100, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-II”.

Item name Condition Display value

SLCTLVR POSI Selector lever in “N”,“P” positions. N/P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “4” position. 4

Selector lever in “3” position. 3

Selector lever in “2” position. 2

Selector lever in “1” position. 1

BCIA0031E