power steering INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 597 of 3061

TELEPHONE

AV-57

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

Bluetooth telephone system allows users who have a Bluetooth cellular telephone to make a wireless connec-

tion between their cellular telephone and the Bluetooth control unit. Hands-free cellular telephone calls can be

sent and received. Personal memos can be created using the Infinity Voice Recognition system. Some Blue-

tooth cellular telephones may not be recognized by the Bluetooth control unit. When a cellular telephone or

the Bluetooth control unit is replaced, the telephone must be paired with the Bluetooth control unit. Different

cellular telephones may have different pairing procedures. Refer to the cellular telephone operating manual.

Bluetooth Telephone System Diagram

Bluetooth Control Unit

When the ignition switch is turned to ACC or ON, the Bluetooth control unit will power up. During power up, the

Bluetooth control unit is initialized and performs various self checks. Initialization may take up to 10 seconds.

During this time the Bluetooth ON indicator will flash until initialization is complete. Infinity Voice Recognition

will then become active and the Bluetooth ON indicator will remain on. Bluetooth telephone functions can be

turned off using the voice recognition system.

BCM

The BCM supplies power for the Bluetooth ON indicator.

Steering Wheel Audio Control Switches

When buttons on the steering wheel audio control switch are pushed, the resistance in steering wheel audio

control switch circuit changes depending on which button is pushed. The Bluetooth control module uses this

signal to perform various functions while navigating through the voice recognition system.

The following functions can be performed using the steering wheel audio control switch:

• Initiate Self Diagnosis of the Bluetooth telephone system

• Start a voice recognition session

• Answer and end telephone calls

• Adjust the volume of calls

• Record memos

AV Switch

Call volume can be adjusted using the AV switch.

Microphone

The microphone is located in the roof console assembly. The microphone sends a signal to the Bluetooth con-

trol unit.

Combination Meter

The combination meter supplies speed signals to the Bluetooth control unit. Vehicle speed signals are used to

determine which voice command functions will be disabled based on driving conditions.

Bluetooth ON Indicator

The Bluetooth ON indicator is located in the overhead console. The indicator will flash during power up while

the Bluetooth control unit is initializing. This process may take up to 10 seconds. After initialization, the indica-

tor will remain on to indicate that the system is ready for voice commands.

WKIA4569E

Page 600 of 3061

AV-60

< SERVICE INFORMATION >

TELEPHONE

Terminal and Reference Value for Bluetooth Control Unit

INFOID:0000000003533695

Bluetooth Control Unit Self-Diagnosis FunctionINFOID:0000000003533696

The Bluetooth control unit has two diagnostic checks. The first diagnostic check is performed automatically

every ignition cycle during control unit initialization. The second diagnostic check is performed by the techni-

cian using the steering wheel audio control switches prior to trouble diagnosis.

Te r m i n a l

(Wire color)

ItemSignal

input/

outputCondition

Reference value

(Approx.)Example of symptom

+–Ignition

switchOperation

1 (Y) GroundBattery pow-

erInput – – Battery voltageSystem does not

work properly.

2 (V) Ground ACC power InputACC/

ON– Battery voltageSystem does not

work properly.

3 (G/R) Ground IGN power InputON/

START– Battery voltageSystem does not

work properly.

4 (B) – Ground – – – – –

6–Shield –– – – –

7 (B) 8 (R/L) Mic-in signal Input ON – – –

9 (R/W) 10 (R) Audio out Output – – – –

11 ( B ) – M u t e – – – – –

12 (R/G) GroundRemote

control AInput ONPress MODE

switch Approx. 0V

Steering wheel audio

controls do not func-

tion. Press SEEK UP

switchApprox. 0.75V

Press VOL UP

switchApprox. 2V

Except for above Approx. 5V

13 (G/W) GroundRemote

control BInput ONPress POWER

switch Approx. 0V

Steering wheel audio

controls do not func-

tion. Press SEEK

DOWN switchApprox. 0.75V

Press VOL

DOWN switchApprox. 2V

Except for above Approx. 5V

14 (Y/R) -Remote

control

ground-- - -Steering wheel audio

controls do not func-

tion.

15 (GR) - LED - - - - -

17 (V) - - - - - - -

18 (G/O) - - - - - - -

19 (R/B) - - - - - - -

21 (B) – Ground – – – – –

28 (W/R) –Speed sig-

nal–– – – –

29 (R/W) –Microphone

power–– – – –

33 –Bluetooth

antenna sig-

nalInput – – – –

Page 601 of 3061

TELEPHONE

AV-61

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

BLUETOOTH CONTROL UNIT INITIALIZATION CHECKS

• Internal control unit failure

• Bluetooth antenna connection open or shorted

• Steering wheel audio control switches (SEND/END) stuck closed

• Vehicle speed pulse count

• Microphone connection test (with playback to operator)

• Bluetooth inquiry check

STARTING THE DIAGNOSTIC MODE

1. Turn ignition switch to ACC or ON.

2. Wait for the Bluetooth system to complete initialization and the Bluetooth ON indicator to stop flashing.

This may take up to 10 seconds.

3. Press and hold the steering wheel audio control switch SEND

button for at least 5 seconds. The Bluetooth system will begin to

play a verbal prompt.

4. While the prompt is playing, momentarily press both the steering

wheel audio control switches SEND and END buttons simulta-

neously. The Bluetooth system will sound a 5 second beep.

5. While the beep is sounding, momentarily press both the steering

wheel audio control switches SEND and END buttons simulta-

neously again.

6. The Bluetooth system has now entered into the diagnostic

mode. Results of the diagnostic checks will be verbalized to the

technician by the system.

Power Supply and Ground Circuit Inspection for Bluetooth Control UnitINFOID:0000000003533697

1.CHECK FUSES

Make sure the following fuses for the Bluetooth control unit are not blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of blown fuse before installing new fuse. Refer to PG-

3.

2.CHECK POWER SUPPLY CIRCUIT

1. Disconnect Bluetooth control unit connector B141.

WKIA4446E

WKIA4447E

Te r m i n a l s

Ignition Switch Fuse No.

Connector Terminal

B1411 All positions 31

2 ACC/ON 4

3 ON/START 12

Page 637 of 3061

NAVIGATION SYSTEM

AV-97

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

Terminal and Reference Value for BCMINFOID:0000000003533717

Refer to BCS-11, "Terminal and Reference Value for BCM".

On Board Self-Diagnosis FunctionINFOID:0000000003533718

DESCRIPTION

• Diagnosis function consists of the self-diagnosis mode performed automatically and the CONFIRMATION/

ADJUSTMENT mode operated manually.

• Self-diagnosis mode checks for connections between the units constituting this system, analyzes each indi-

vidual unit at the same time, and displays the results on the LCD screen.

• CONFIRMATION/ADJUSTMENT mode is used to perform trouble diagnosis that require operation and judg-

ment by an operator (trouble that cannot be automatically judged by the system), to check/change the set

value, and to display the History of Errors of the navigation system.

4 (BR) GroundIllumination

control signalInput ONIllumination control

switch is operated

by lighting switch in

1st position.Changes between 0 and 12V.AV switch illumi-

nation cannot be

controlled.

5 (B) Ground Ground - ON - 0V -

6 (V) GroundCommunica-

tion signal (+)Input/

outputON -System does not

work properly.

7 - Shield ground - - - - -

8 (LG) GroundCommunica-

tion signal (-)Input/

outputON -System does not

work properly.

12 (R) GroundRemote con-

trol AInput ONPress MODE switch 0V

Steering wheel

audio controls

do not function. Press SEEK UP

switch0.75V

Press VOL UP

switch2V

Except for above 5V

13 (G) GroundRemote con-

trol BInput ONPress POWER

switch 0V

Steering wheel

audio controls

do not function. Press SEEK

DOWN switch0.75V

Press VOL DOWN

switch2V

Except for above 5V

14 (L) -Remote con-

trol ground-- - -Steering wheel

audio controls

do not function. Te r m i n a l N o .

(Wire color)

ItemSignal

input/

outputCondition

Vol tag e

(Approx.)Example of

symptom

+–Ignition

switchOperation

SKIA0175E

SKIA0176E

Page 929 of 3061

BRC-1

BRAKES

C

D

E

G

H

I

J

K

L

M

SECTION BRC

A

B

BRC

N

O

P

CONTENTS

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

SERVICE INFORMATION ............................

3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Brake System ....................................3

Precaution When Using CONSULT-II .......................3

Precaution for Brake Control .....................................4

Precaution for CAN System ......................................4

PREPARATION ...................................................6

Special Service Tool .................................................6

Commercial Service Tool ..........................................6

SYSTEM DESCRIPTION .....................................7

System Component ...................................................7

ABS Function ............................................................8

EBD Function ............................................................8

TCS Function ............................................................8

VDC Function ............................................................8

Fail-Safe Function .....................................................8

Hydraulic Circuit Diagram .........................................9

CAN COMMUNICATION ....................................10

System Description .................................................10

TROUBLE DIAGNOSIS .....................................11

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ......................................................

11

Component Parts and Harness Connector Loca-

tion ..........................................................................

14

Schematic ...............................................................15

Wiring Diagram - VDC - ..........................................16

Basic Inspection ......................................................22

Warning Lamp and Indicator Timing .......................23

Control Unit Input/Output Signal Standard ..............23

CONSULT-II Function (ABS) ..................................26

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

34

Wheel Sensor System Inspection ............................34

Engine System Inspection .......................................35

ABS/TCS/VDC Control Unit Inspection ...................35

Steering Angle Sensor System ................................36

Yaw Rate/Side/Decel G Sensor System Inspec-

tion ...........................................................................

37

Solenoid and VDC Change-Over Valve System

Inspection ................................................................

38

Actuator Motor, Motor Relay, and Circuit Inspec-

tion ...........................................................................

39

Stop Lamp Switch System Inspection .....................40

ABS/TCS/VDC Control Unit Power and Ground

Systems Inspection .................................................

41

Brake Fluid Level Switch System Inspection ...........42

Active Booster System Inspection ...........................43

Delta Stroke Sensor System Inspection ..................44

Pressure Sensor System Inspection .......................45

Steering Angle Sensor Safe Mode Inspection .........47

CAN Communication System Inspection .................48

ICC System Inspection ............................................48

Inspection for Self-Diagnosis Result "ST ANG

SEN SIGNAL" ..........................................................

48

Inspection for Self-Diagnosis Result "DECEL G

SEN SET" ................................................................

49

TROUBLE DIAGNOSES FOR SYMPTOMS .....50

ABS Works Frequently ............................................50

Unexpected Pedal Action ........................................50

Long Stopping Distance ..........................................51

ABS Does Not Work ................................................51

Pedal Vibration or ABS Operation Noise .................51

Vehicle Jerks During TCS/VDC Activation ..............52

Component Inspection .............................................53

ON-VEHICLE SERVICE ....................................54

Adjustment of Steering Angle Sensor Neutral Po-

sition ........................................................................

54

Calibration of Decel G Sensor .................................54

Page 952 of 3061

![INFINITI QX56 2007 Factory User Guide BRC-24

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Monitor item Display contentData monitor

Note: Error inspection

checklist

ConditionReference value in

normal operation

N POSI SIGPNP swi INFINITI QX56 2007 Factory User Guide BRC-24

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Monitor item Display contentData monitor

Note: Error inspection

checklist

ConditionReference value in

normal operation

N POSI SIGPNP swi](/img/42/57029/w960_57029-951.png)

BRC-24

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Monitor item Display contentData monitor

Note: Error inspection

checklist

ConditionReference value in

normal operation

N POSI SIGPNP switch signal ON/

OFF conditionA/T shift position = N position ON

LAN-7

A/T shift position = other than N

positionsOFF

P POSI SIGPNP switch signal ON/

OFF conditionA/T shift position P position ON

LAN-7

A/T shift position = other than P

positionsOFF

GEAR A/T gear position1st gear 1

— 2nd gear 2

3rd gear 3

4th gear 4

5th gear 5

FR RH SENSOR

FR LH SENSOR

RR RH SENSOR

RR LH SENSORWheel speedVehicle stopped 0 [km/h (MPH)]

BRC-34, "

Wheel Sensor

System Inspection"Vehicle running (Note 1)Almost in accor-

dance with speed-

ometer display

(within ±10%)

ACCEL POS SIG Open/close condition

of throttle valve (linked

with accelerator pedal).Accelerator pedal not de-

pressed (ignition switch is ON)0%

LAN-7

Depress accelerator pedal (ig-

nition switch is ON)0 to 100%

ENGINE SPEED With engine runningWith engine stopped 0 rpm

BRC-35, "

Engine System

Inspection"Engine runningAlmost in accor-

dance with ta-

chometer display

STR ANGLE SIGSteering angle detect-

ed by steering angle

sensorStraight-ahead Approx. 0 deg

BRC-36, "

Steering Angle

Sensor System"Steering wheel turned –756 to 756 deg

YAW RATE SENYaw rate detected by

yaw rate sensorVehicle stopped Approx. 0 d/sBRC-37, "

Yaw Rate/Side/

Decel G Sensor System

Inspection"Vehicle running –100 to 100 d/s

SIDE G-SENSORTransverse G detected

by side G-sensorVehicle stopped

Approx. 0 m/s

2BRC-37, "Yaw Rate/Side/

Decel G Sensor System

Inspection"Vehicle running

–16.7 to 16.7 m/s2

BATTERY VOLTBattery voltage sup-

plied to ABS actuator

and electric unit (con-

trol unit)Ignition switch ON 10 to 16VBRC-41, "

ABS/TCS/VDC

Control Unit Power and

Ground Systems Inspec-

tion"

STOP LAMP SWStop lamp switch oper-

ationBrake pedal depressed ONBRC-40, "

Stop Lamp

Switch System Inspec-

tion"Brake pedal not depressed OFF

OFF SWVDC OFF switch

ON/OFF status VDC OFF switch ON

(When VDC OFF indicator

lamp is ON)ON

BRC-53, "

Component In-

spection"VDC OFF switch OFF

(When VDC OFF indicator

lamp is OFF)OFF

ABS WARN LAMPABS warning lamp ON

condition (Note 2)ABS warning lamp ON ON

—

ABS warning lamp OFF OFF

Page 956 of 3061

![INFINITI QX56 2007 Factory User Guide BRC-28

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

DECEL G SEN SET

[C1160]ABS decel sensor adjustment is incomplete.BRC-49, "Inspection for

Self-Diagnosis Result

"DECEL G SEN SET""

ST ANG INFINITI QX56 2007 Factory User Guide BRC-28

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

DECEL G SEN SET

[C1160]ABS decel sensor adjustment is incomplete.BRC-49, "Inspection for

Self-Diagnosis Result

"DECEL G SEN SET""

ST ANG](/img/42/57029/w960_57029-955.png)

BRC-28

< SERVICE INFORMATION >[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

DECEL G SEN SET

[C1160]ABS decel sensor adjustment is incomplete.BRC-49, "Inspection for

Self-Diagnosis Result

"DECEL G SEN SET""

ST ANGL SEN SAFE

[C1163]When steering angle sensor is in safe mode.BRC-47, "Steering Angle

Sensor Safe Mode In-

spection"

ST ANG SEN CIRCUIT

[C1143]Neutral position of steering angle sensor is dislocated, or steering

angle sensor is malfunctioning.BRC-36, "Steering Angle

Sensor System"

YAW RATE SENSOR

[C1145]Yaw rate sensor has generated an error, or yaw rate sensor signal

line is open or shorted.BRC-37, "Yaw Rate/

Side/Decel G Sensor

System Inspection"

FR LH IN ABS SOL

[C1120]Circuit of front LH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

BRC-38, "

Solenoid and

VDC Change-Over Valve

System Inspection"

FR LH OUT ABS SOL

[C1121]Circuit of front LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH IN ABS SOL

[C1126]Circuit of rear RH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR RH OUT ABS SOL

[C1127]Circuit of rear RH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH IN ABS SOL

[C1122]Circuit of front RH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

FR RH OUT ABS SOL

[C1123]Circuit of front RH OUT ABS solenoid is open or shorted, or con-

trol line is open or shorted to power supply or ground.

RR LH IN ABS SOL

[C1124]Circuit of rear LH IN ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

RR LH OUT ABS SOL

[C1125] Circuit of rear LH OUT ABS solenoid is open or shorted, or control

line is open or shorted to power supply or ground.

CV1

[C1164]Front side VDC switch-over solenoid valve (cut valve) is open or

shorted, or control line is open or shorted to power supply or

ground.

CV2

[C1165]Rear side VDC switch-over solenoid valve (cut valve) is open or

shorted, or control line is open or shorted to power supply or

ground.

SV1

[C1166]Front side VDC switch-over solenoid valve (suction valve) is open

or shorted, or control line is open or shorted to power supply or

ground.

SV2

[C1167]Rear side VDC switch-over solenoid valve (suction valve) is open

or shorted, or control line is open or shorted to power supply or

ground.

PUMP MOTOR

[ C 1111 ]During actuator motor operation with ON, when actuator motor

turns OFF or when control line for actuator motor relay is open.BRC-39, "

Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection"During actuator motor operation with OFF, when actuator motor

turns ON or when control line for relay is shorted to ground.

BATTERY VOLTAGE

[ABNORMAL]

[C1109]ABS actuator and electric unit (control unit) power voltage is too

low.BRC-41, "

ABS/TCS/VDC

Control Unit Power and

Ground Systems Inspec-

tion"

ST ANG SEN SIGNAL

[C1144]Neutral position correction of steering angle sensor is not finished.BRC-48, "Inspection for

Self-Diagnosis Result

"ST ANG SEN SIGNAL""

ST ANG SEN COM CIR

[C1156]CAN communication line or steering angle sensor has generated

an error.BRC-36, "Steering Angle

Sensor System"

G-SENSOR

[ C 111 3 ]Longitudinal G-sensor is malfunctioning, or signal line of longitu-

dinal G-sensor is open or shorted.BRC-37, "Yaw Rate/

Side/Decel G Sensor

System Inspection"

Self-diagnostic item Malfunction detecting condition Check system

Page 1108 of 3061

ENGINE CONTROL SYSTEM

EC-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

*1: This sensor is not used to control the engine system. This is used only for the on board diagnosis.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Knock sensor Engine knocking condition

Battery

Battery voltage*

3

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit)

VDC/TCS operation command*

2

Air conditioner switch

Air conditioner operation*2

Wheel sensor

Vehicle speed*2

PBIB3020E

Page 1112 of 3061

AIR CONDITIONING CUT CONTROL

EC-29

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

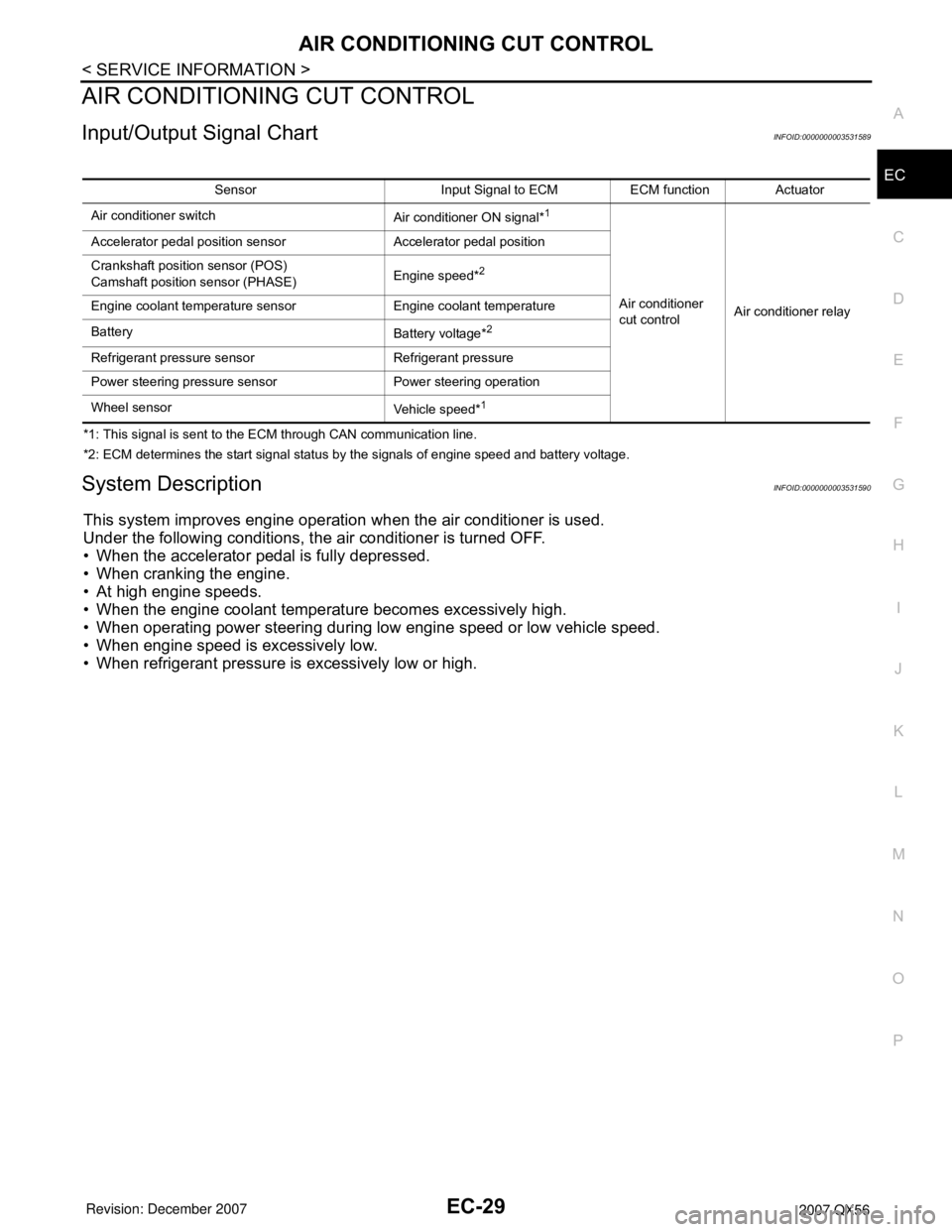

AIR CONDITIONING CUT CONTROL

Input/Output Signal ChartINFOID:0000000003531589

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

System DescriptionINFOID:0000000003531590

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned OFF.

• When the accelerator pedal is fully depressed.

• When cranking the engine.

• At high engine speeds.

• When the engine coolant temperature becomes excessively high.

• When operating power steering during low engine speed or low vehicle speed.

• When engine speed is excessively low.

• When refrigerant pressure is excessively low or high.

Sensor Input Signal to ECM ECM function Actuator

Air conditioner switch

Air conditioner ON signal*

1

Air conditioner

cut controlAir conditioner relay Accelerator pedal position sensor Accelerator pedal position

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

2

Engine coolant temperature sensor Engine coolant temperature

Battery

Battery voltage*

2

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

Wheel sensor

Vehicle speed*

1

Page 1113 of 3061

EC-30

< SERVICE INFORMATION >

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System DescriptionINFOID:0000000003531591

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line

BASIC ASCD SYSTEM

Refer to Owner's Manual for ASCD operating instructions.

Automatic Speed Control Device (ASCD) allows a driver to keep vehicle at predetermined constant speed

without depressing accelerator pedal. Driver can set vehicle speed in advance between approximately 40 km/

h (25 MPH) and 144 km/h (89 MPH).

ECM controls throttle angle of electric throttle control actuator to regulate engine speed.

Operation status of ASCD is indicated by CRUISE indicator and SET indicator in combination meter. If any

malfunction occurs in ASCD system, it automatically deactivates control.

NOTE:

Always drive vehicle in safe manner according to traffic conditions and obey all traffic laws.

SET OPERATION

Press MAIN switch. (The CRUISE indicator in combination meter illuminates.)

When vehicle speed reaches a desired speed between approximately 40 km/h (25 MPH) and 144 km/h (89

MPH), press SET/COAST switch. (Then SET indicator in combination meter illuminates.)

ACCELERATE OPERATION

If the RESUME/ACCELERATE switch is pressed during cruise control driving, increase the vehicle speed until

the switch is released or vehicle speed reaches maximum speed controlled by the system.

And then ASCD will keep the new set speed.

CANCEL OPERATION

When any of following conditions exist, cruise operation will be canceled.

• CANCEL switch is pressed

• More than 2 switches at ASCD steering switch are pressed at the same time (Set speed will be cleared)

• Brake pedal is depressed

• Selector lever is changed to N, P, R position

• Vehicle speed decreased to 13 km/h (8 MPH) lower than the set speed

• VDC system is operated

When the ECM detects any of the following conditions, the ECM will cancel the cruise operation and inform

the driver by blinking indicator lamp.

• Engine coolant temperature is slightly higher than the normal operating temperature, CRUISE lamp may

blink slowly.

When the engine coolant temperature decreases to the normal operating temperature, CRUISE lamp will

stop blinking and the cruise operation will be able to work by pressing SET/COAST switch or RESUME/

ACCELERATE switch.

• Malfunction for some self-diagnoses regarding ASCD control: SET lamp will blink quickly.

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operations will be canceled and vehicle

speed memory will be erased.

COAST OPERATION

When the SET/COAST switch is pressed during cruise control driving, decrease vehicle set speed until the

switch is released. And then ASCD will keep the new set speed.

RESUME OPERATION

Sensor Input signal to ECM ECM function Actuator

ASCD brake switch Brake pedal operation

ASCD vehicle speed controlElectric throttle control

actuator Stop lamp switch Brake pedal operation

ASCD steering switch ASCD steering switch operation

Park/neutral position (PNP) switch Gear position

Wheel sensor Vehicle speed*

TCM Powertrain revolution*