window INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1 of 3061

-1

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLEATAutomatic Transmission

DDRIVELINE/AXLETFTransfer

PRPropeller Shaft

FFDFront Final Drive

RFDRear Final Drive

FAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

APAdjustable Pedal

JAIR CONDITIONERATCAutomatic Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: August 2006

Revision: December 2007

Publication No. SM7E-1J60U1

B

D

© 2007 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America, Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 44 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

ACS-31

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Go to operation check after asking the customer for symptom information. Refer to ACS- INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

ACS-31

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Go to operation check after asking the customer for symptom information. Refer to ACS-](/img/42/57029/w960_57029-43.png)

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

ACS-31

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Go to operation check after asking the customer for symptom information. Refer to ACS-9.

2. Stop the vehicle to start the self-diagnosis.

3. Turn ignition switch OFF.

4. Turn ignition switch ON, and wait 5 seconds. Press ACCEL/RES

switch 5 times, and then press COAST/SET switch 5 times all

within 5 seconds to start self-diagnosis.

CAUTION:

• Do not start the engine.

• Do not press the ICC ON/OFF switch ON.

• When operation above is not completed within the 5 to 10 sec-

ond window, DTC will not be displayed.

• If self-diagnosis mode cannot be started after several

attempts, the ICC unit may be malfunctioning and should be

replaced. Refer to "SELF-DIAGNOSIS BY ICC SYSTEM DIS-

PLAY WILL NOT RUN".

5. When self-diagnosis mode is started, DTCs are shown on set vehicle speed indicator.

CAUTION:

• DTC will disappear after 5 minutes.

• When multiple malfunctions are detected, a maximum of 3 code numbers can be stored; the lat-

est malfunction will be displayed first.

6. Check ACS-34, "

Diagnostic Trouble Code (DTC) Chart" , and repair or replace if necessary.

7. After repair, erase DTC stored in the ICC unit. Refer to "Self-Diagnostic Erasing Method".

8. DTC 55 will be shown.

9. Turn ignition switch OFF to exit the diagnosis.

10. Perform ICC system running test (drive vehicle with ICC system ON), and make sure that ICC warning

lamp does not illuminate.

Self-Diagnostic Erasing Method

1. Stop the vehicle and turn the ignition switch OFF.

2. Turn ignition switch ON and start self-diagnosis.

3. During self-diagnosis mode, press CANCEL switch 5 times, and DISTANCE switch 5 times within a 10

second time period.

CAUTION:

• Switch inputs must be received within a 10 second time period.

• When operation is not completed within 10 seconds start again from step 1.

4. DTC 55 will be shown.

CAUTION:

DTC of an existing malfunction will not be erased.

5. Turn ignition switch OFF to exit the diagnosis.

WKIA1921E

WKIA1922E

Page 48 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

45 BRAKE SW/ STOP L SW×××ו ICC brake switch or stop lamp

switch harness is open INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

45 BRAKE SW/ STOP L SW×××ו ICC brake switch or stop lamp

switch harness is open](/img/42/57029/w960_57029-47.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-35

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

45 BRAKE SW/ STOP L SW×××ו ICC brake switch or stop lamp

switch harness is open or shorted

• ICC brake switch or stop lamp

switch is stuck to OFF

• ICC brake switch or stop lamp

switch is stuck to ONACS-38,

"DTC 45

BRAKE

SW/

STOP L

SW"

46 OPERATION SW CIRC××ו ICC steering switch harness or

spiral cable is open or shorted

• ICC steering switch malfunctionACS-40,

"DTC 46

OPERA-

TION SW

CIRC"

74 LASER BEAM OFF CNTR×× ×• Laser beam of ICC sensor is off

the aiming pointACS-41,

"DTC 74

LASER

BEAM

OFF CN-

TR"

90 STOP LAMP RLY FIX×× ×• Normally open terminal of stop

lamp relay is stuckACS-41,

"DTC 90

STOP

LAMP

RLY FIX"

92 ECM CIRCUIT×××וECM malfunction

• Accelerator pedal position sensor

malfunction

• ICC unit malfunctionACS-45,

"DTC 92

ECM

CIR-

CUIT"

96 NP RANGE××ו Park/neutral position switch har-

ness is open or shorted

• Park/neutral position switch mal-

function

•TCM malfunctionACS-45, "DTC 96

NP

RANGE"

97 AT CIRCUIT××וTCM malfunctionACS-46, "DTC 97

AT CIR-

CUIT"

98 GEAR POSITION××וTCM malfunction

• A/T turbine revolution sensor mal-

function

• A/T vehicle speed sensor mal-

functionACS-46,

"DTC 98

GEAR

POSI-

TION"

102 LASER STAIN×× ×• ICC sensor body window has

contaminationACS-47, "DTC 102

LASER

STAIN"

103 LASER SENSOR FAIL×× ×• ICC sensor internal malfunctionACS-47,

"DTC 103

LASER

SEN-

SOR

FA I L"

DTC

No.CONSULT-II screen termsICC sys-

tem

warning

lampFail-safe

Malfunctions detected where...Refer-

ence

page Veh ic le-

to-vehi-

cle dis-

tance

control

modeConven-

tional

(fixed

speed)

cruise

control

modeBrake as-

sist (with

preview

function)

Page 60 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-47

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

3.CHECK GEAR SHIFT POSITION

Check that gear positions are correct in A/T.

OK or NG

OK INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-47

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

3.CHECK GEAR SHIFT POSITION

Check that gear positions are correct in A/T.

OK or NG

OK](/img/42/57029/w960_57029-59.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-47

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

3.CHECK GEAR SHIFT POSITION

Check that gear positions are correct in A/T.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.CHECK TCM GEAR POSITION SIGNAL

With CONSULT-II

With TCM data monitor on CONSULT-II, check that gear positions are correct.

OK or NG

OK >> Replace ICC unit. Refer to ACS-55, "ICC Unit". Erase DTC and perform self-diagnosis of ICC sys-

tem again.

NG >> • Perform TCM diagnosis.

• Erase DTC and perform self-diagnosis of ICC system again.

5.CHECK TCM TURBINE ROTATION

With CONSULT-II

With TCM diagnosis, check that turbine rpm is normal. Refer to AT-103

.

OK or NG

OK >> Replace ICC unit. Refer to ACS-55, "ICC Unit". Erase DTC and perform self-diagnosis of ICC sys-

tem again.

NG >> • Perform TCM diagnosis.

• Erase DTC and perform self-diagnosis of ICC system again.

DTC 102 LASER STAININFOID:0000000003533809

1.VISUAL INSPECTION (1)

Check that there is no contamination and foreign material on ICC sensor body window.

OK or NG

OK >> GO TO 2.

NG >> • Clean ICC sensor.

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

2.VISUAL INSPECTION (2)

Check ICC sensor body window for cracks.

OK or NG

OK >> GO TO 3.

NG >> • Replace ICC sensor and adjust laser beam. Refer to ACS-12

.

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

3.ASK CUSTOMER FOR DRIVING CONDITIONS

1. Is there any trace of contamination or foreign material on ICC sensor?

2. Is there any possibility that vehicle was driven in snow or ICC sensor was frosted?

3. Is there any possibility that ICC sensor was fogged temporarily? (Front window glass may have also been

fogged.)

Ye s o r N o

Yes >> Explain system operation and parameters to customer. System may be operating normally.

No >> • Replace ICC sensor and adjust laser beam aiming. Refer to ACS-55, "

ICC Sensor".

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

DTC 103 LASER SENSOR FAILINFOID:0000000003533810

1.DIAGNOSTIC CHECK

Page 65 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-52

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

• When depressing the accelerator.

• Chime does not sound when the vehicle is not driving.

• Chime does not sound when the syst INFINITI QX56 2007 Factory Service Manual ACS-52

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

• When depressing the accelerator.

• Chime does not sound when the vehicle is not driving.

• Chime does not sound when the syst](/img/42/57029/w960_57029-64.png)

ACS-52

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

• When depressing the accelerator.

• Chime does not sound when the vehicle is not driving.

• Chime does not sound when the system does not detect any vehicle ahead. Diagnose the conditions under

which the system is detecting the vehicle ahead and when the system is malfunctioning. If there is any mal-

function in detecting the vehicle ahead. Refer to ACS-52, "

Symptom 7 the ICC System Frequently Cannot

Detect the Vehicle Ahead/The Detection Zone Is Short".

1.CHECK ICC WARNING CHIME

With CONSULT-II

1. With "ACTIVE TEST" on the CONSULT-II, check that ICC warning chime operates normally.

OK or NG

OK >> Determine preceding vehicle detection status when malfunction occurred. If chime should have

sounded replace ICC unit. Refer to ACS-55, "

ICC Unit". Perform ICC system running test. Refer

to ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC system again.

NG >> GO TO 2.

2.CAN COMMUNICATION INSPECTION

With CONSULT-II

1. With CONSULT-II self-diagnosis, check “CAN COMM CIRCUIT”.

OK or NG

OK >> Refer to ACS-37, "DTC 20 CAN COMM CIRCUIT".

NG >> Replace combination meter. Refer to DI-21, "

Removal and Installation of Combination Meter".

Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

Symptom 6 Driving Force Is HuntingINFOID:0000000003533820

1.CHECK ECM

1. Perform self-diagnosis of ECM.

OK or NG

OK >> Refer to ACS-52, "Symptom 7 the ICC System Frequently Cannot Detect the Vehicle Ahead/The

Detection Zone Is Short".

NG >> Repair as necessary. Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC

System Running Test". Then perform self-diagnosis of ICC system again.

Symptom 7 the ICC System Frequently Cannot Detect the Vehicle Ahead/The Detec-

tion Zone Is Short

INFOID:0000000003533821

The detection function may become disrupted in the following cases:

• When the reflector of the vehicle ahead is small or not clean enough to reflect the laser.

• When driving a road with extremely sharp corners.

• When the laser cannot detect the reflector of the vehicle ahead as the vehicle ahead is passing a hill or

passing the peak.

1.VISUAL CHECK

1. Check ICC sensor body window for contamination and foreign materials.

OK or NG

OK >> If any contamination or foreign materials are found, remove them. Then perform ICC system run-

ning test. Refer to ACS-9, "

ICC System Running Test".

NG >> GO TO 2.

2.CHECK FUNCTION

1. After performing laser beam aiming adjustment, perform ICC system running test. Refer to ACS-9, "

ICC

System Running Test". Check that preceding vehicle detection performance has been improved.

OK or NG

OK >> Inspection End.

NG >> • Replace ICC sensor and perform laser beam aiming adjustment. Refer to ACS-55, "

ICC Sen-

sor".

Page 66 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-53

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

• Perform ICC system running test. Refer to ACS-9, "ICC System Running Test" . Then perform

self-d INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-53

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

• Perform ICC system running test. Refer to ACS-9, "ICC System Running Test" . Then perform

self-d](/img/42/57029/w960_57029-65.png)

TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-53

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

• Perform ICC system running test. Refer to ACS-9, "ICC System Running Test" . Then perform

self-diagnosis of ICC system again.

Symptom 8 the System Does Not Detect the Vehicle Ahead at AllINFOID:0000000003533822

1.VISUAL CHECK

1. With ignition switch turned ON (engine not started), check that all indicator lamps in ICC system display

are continuously lit. (Check for a missing segment in preceding vehicle detection display.)

OK or NG

OK >> GO TO 2.

NG >> Check combination meter. Refer to DI-15, "

How to Proceed with Trouble Diagnosis".

2. VISUAL CHECK

• Check ICC sensor body window for contamination and foreign materials.

OK or NG

OK >> If any contamination or foreign materials are found, remove them. Perform ICC system running

test. Refer to ACS-9, "

ICC System Running Test".

NG >> GO TO 3.

3.VISUAL CHECK

• Check ICC sensor body window for cracks and scratches.

OK or NG

OK >> GO TO 4.

NG >> • Replace ICC sensor and perform laser beam aiming adjustment. Refer to ACS-55, "

ICC Sen-

sor".

• Perform ICC system running test. Refer to ACS-9, "

ICC System Running Test". Then perform

self-diagnosis of ICC system again.

4.ADJUST ICC SENSOR

• After performing laser beam aiming adjustment, perform ICC system running test. Refer to ACS-9, "

ICC Sys-

tem Running Test". Check that preceding vehicle detection performance has been improved.

OK or NG

OK >> Inspection End.

NG >> • Replace ICC sensor and perform laser beam aiming adjustment. Refer to ACS-55, "

ICC Sen-

sor".

• Perform ICC system running test. Refer to ACS-9, "

ICC System Running Test". Then perform

self-diagnosis of ICC system again.

Page 395 of 3061

AIR CONDITIONER CONTROLATC-25

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

TEMPERATURE CONTROL DIAL (TEMPE RATURE CONTROL) (DRIVER SIDE)

Increases or decreases the set temperature.

TEMPERATURE CONTROL DIAL (TEMPERATURE CONTROL) (PASSENGER SIDE)

Increases or decreases the set temperature.

TEMPERATURE CONTROL DIAL (TEMPERA TURE AND MODE CONTROL) (REAR)

Increases or decreases the set temperature. The mode al so changes from foot at full hot setting, to foot/vent

mid-range (warm) setting, and then to panel on full cold setting.

RECIRCULATION ( ) SWITCH

• When REC switch is ON, REC switch indicator turns ON, and air inlet is set to REC.

• When REC switch is turned OFF, or when compressor is turned from ON to OFF, REC switch is automati-

cally turned OFF. REC mode can be re-entered by pressing REC switch again.

• REC switch is not operated when DEF switch is tu rned ON, at the D/F position or in floor position.

DEFROSTER ( ) SWITCH

Positions the air outlet doors to the defrost position. Al so positions the intake doors to the outside air position.

REAR WINDOW DEFOGGER SWITCH

When switch is ON, rear window and door mirrors are defogged.

OFF SWITCH

The compressor and blower are OFF, the intake doors are set to the outside air position, and the air outlet

doors are set to the foot (75% foot and 25% defrost) position.

A/C SWITCH

The compressor is ON or OFF.

(Pressing the A/C switch when the AUTO switch is ON will turn off the A/C switch and compressor.)

MODE SWITCH (FRONT)

Controls the air discharge outlets.

FRONT BLOWER CONTROL DIAL

Manually control the blower speed. Seven speeds are av ailable for manual control (as shown on the display

screen).

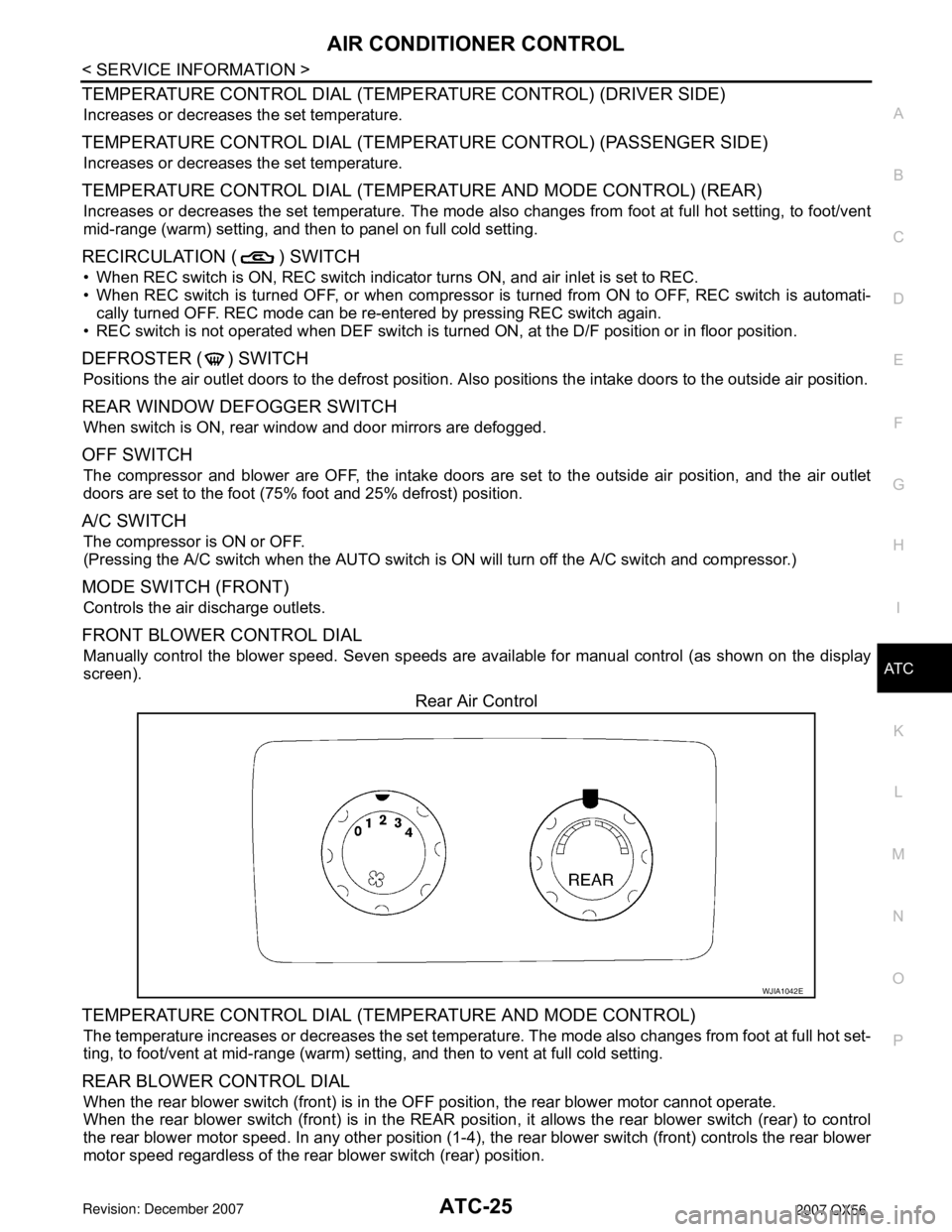

Rear Air Control

TEMPERATURE CONTROL DIAL (TEM PERATURE AND MODE CONTROL)

The temperature increases or decreases the set temperat ure. The mode also changes from foot at full hot set-

ting, to foot/vent at mid-range (warm) setti ng, and then to vent at full cold setting.

REAR BLOWER CONTROL DIAL

When the rear blower switch (front) is in the OFF position, the rear blower motor cannot operate.

When the rear blower switch (front) is in the REAR positi on, it allows the rear blower switch (rear) to control

the rear blower motor speed. In any other position (1-4), the rear blower switch (front) controls the rear blower

motor speed regardless of the rear blower switch (rear) position.

WJIA1042E

Page 475 of 3061

TROUBLE DIAGNOSISATC-105

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

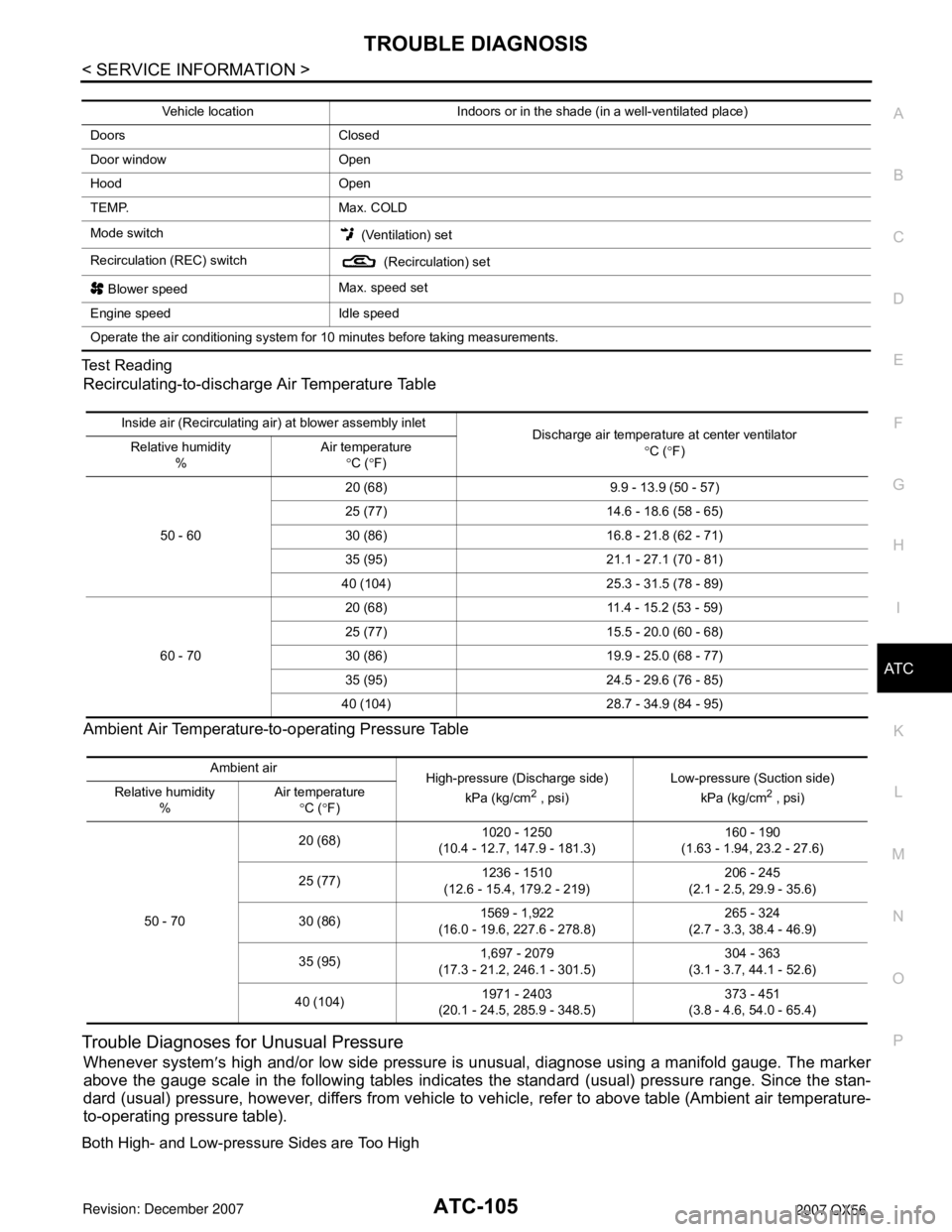

Test Reading

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Trouble Diagnoses for Unusual Pressure

Whenever system

′s high and/or low side pressure is unusual, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicate s the standard (usual) pressure range. Since the stan-

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High- and Low-pressure Sides are Too High

Vehicle location Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Recirculation (REC) switch (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68) 9.9 - 13.9 (50 - 57)

25 (77) 14.6 - 18.6 (58 - 65)

30 (86) 16.8 - 21.8 (62 - 71)

35 (95) 21.1 - 27.1 (70 - 81)

40 (104) 25.3 - 31.5 (78 - 89)

60 - 70 20 (68) 11.4 - 15.2 (53 - 59)

25 (77) 15.5 - 20.0 (60 - 68)

30 (86) 19.9 - 25.0 (68 - 77)

35 (95) 24.5 - 29.6 (76 - 85)

40 (104) 28.7 - 34.9 (84 - 95)

Ambient air High-pressure (Discharge side)

kPa (kg/cm

2 , psi) Low-pressure (Suction side)

kPa (kg/cm2 , psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

1020 - 1250

(10.4 - 12.7, 147.9 - 181.3) 160 - 190

(1.63 - 1.94, 23.2 - 27.6)

25 (77) 1236 - 1510

(12.6 - 15.4, 179.2 - 219) 206 - 245

(2.1 - 2.5, 29.9 - 35.6)

30 (86) 1569 - 1,922

(16.0 - 19.6, 227.6 - 278.8) 265 - 324

(2.7 - 3.3, 38.4 - 46.9)

35 (95) 1,697 - 2079

(17.3 - 21.2, 246.1 - 301.5) 304 - 363

(3.1 - 3.7, 44.1 - 52.6)

40 (104) 1971 - 2403

(20.1 - 24.5, 285.9 - 348.5) 373 - 451

(3.8 - 4.6, 54.0 - 65.4)

Page 536 of 3061

ATC-166

< SERVICE INFORMATION >

REFRIGERANT LINES

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace the O-rings on the A/C refrigerant pipes with new ones, then apply compressor oil to them

when installing them.

• After charging refrigerant, check for leaks.

Checking of Refrigerant LeaksINFOID:0000000003533307

PRELIMINARY CHECK

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C oil leak-

age, damage, and corrosion. Any A/C oil leakage may indi cate an area of refrigerant leakage. Allow extra

inspection time in these areas when using either an el ectronic refrigerant leak detector (J-41995) or fluores-

cent dye leak detector (J-42220).

If any dye is observed using a fluorescent dye leak detector (J-42220), confirm the leak using a electronic

refrigerant leak detector (J-41995). It is possible that the dye is from a prior leak that was repaired and not

properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electronic refrigerant leak detector (J-41995), move the probe

along the suspected leak area at 25 - 50 mm (1 - 2 in) per second and no further than 6 mm (1/4 in) from the

component.

CAUTION:

Moving the electronic refrigerant l eak detector probe slower and clo ser to the suspected leak area will

improve the chances of finding a leak.

Checking System for L eaks Using the Fluoresc ent Dye Leak DetectorINFOID:0000000003533308

1. Check the A/C system for leaks using the fluorescent dye leak detector and safety goggles (J-42220) in a

low sunlight area (area without windows preferable). Il luminate all components, fittings and lines. The dye

will appear as a bright green/yellow area at the point of leakage. Fluorescent dye observed at the evapo-

rator drain opening indicates an evaporator core asse mbly leak (tubes, core or expansion valve).

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, then inspect the shop rag or cloth with the fl uorescent dye leak detector (J-42220) for dye residue.

3. After the leak is repaired, remove any residual dye using refrigerant dye cleaner (J-43872) to prevent

future misdiagnosis.

4. Perform a system performance check and then verify t he leak repair using a electronic refrigerant leak

detector (J-41995).

NOTE:

• Other gases in the work area or substances on the A/C components, for example, anti-freeze, wind-

shield washer fluid, solvents and oils, may falsely tri gger the leak detector. Make sure the surfaces to be

checked are clean.

• Clean with a dry cloth or blow off with shop air.

• Do not allow the sensor tip of the electronic refri gerant leak detector (J-41995) to contact with any sub-

stance. This can also cause false readings and may damage the detector.

Dye InjectionINFOID:0000000003533309

NOTE:

This procedure is only necessary when recharging the system or when the compressor has seized and must

be replaced.

1. Check the A/C system static (at rest) pressure . Pressure must be at least 345 kPa (3.52 kg/cm

2 , 50 psi).

2. Pour one bottle 7.4 cc (1/4 ounce) of the HFC-134a (R -134a) fluorescent leak detection dye (J-41447) into

the HFC-134a (R-134a) dye injector (J-41459).

CAUTION: Expansion valve bolts : 4 N·m (0.41 kg-m, 35 in-lb)

A/C refrigerant pipe to exp

ansion valve bolt : Refer to ATC-152, "

Component".

Page 541 of 3061

AV-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION AV

A

B

AV

N

O

P

CONTENTS

AUDIO, VISUAL, NAVIGATION & TELEPHONE SYS-

TEM

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

PREPARATION ...................................................4

Commercial Service Tool ..........................................4

AUDIO .................................................................5

Component Parts and Harness Connector Loca-

tion ............................................................................

5

System Description ...................................................6

Schematic .................................................................8

Wiring Diagram - AUDIO - .........................................9

Terminal and Reference Value for Audio Unit .........20

Terminal and Reference Value for BOSE Speaker

Amp .........................................................................

23

Terminal and Reference Value for Rear Audio Re-

mote Control Unit ....................................................

25

Terminal and Reference Value for AV Switch .........26

Terminal and Reference Value for Satellite Radio

Tuner (Factory Installed) .........................................

28

AV Switch Self-Diagnosis Function .........................28

Trouble Diagnosis ...................................................29

Noise Inspection ......................................................31

Power Supply Circuit Inspection .............................31

Satellite Radio Tuner (Factory Installed) Power

and Ground Supply Circuit Inspection .....................

32

Satellite Radio Tuner (Factory Installed) Commu-

nication Circuit Inspection .......................................

33

Satellite Radio Tuner (Factory Installed) Left

Channel Audio Signal Circuit Inspection .................

35

Satellite Radio Tuner (Factory Installed) Right

Channel Audio Signal Circuit Inspection .................

36

Steering Switch Check ............................................37

AV Switch Check .....................................................38

Audio Communication Line Check ..........................38

Sound Is Not Heard from Front Door Speaker or

Front Tweeter ..........................................................

39

Sound Is Not Heard from Rear Door Speaker or

Rear Door Tweeter ..................................................

41

Sound Is Not Heard from Center Speaker ...............44

Sound Is Not Heard from Subwoofer .......................44

Removal and Installation .........................................46

AUDIO ANTENNA .............................................52

System Description ..................................................52

Wiring Diagram - W/ANT - .......................................53

Location of Antenna .................................................54

Window Antenna Repair ..........................................54

TELEPHONE .....................................................56

Component Parts and Harness Connector Loca-

tion ...........................................................................

56

System Description ..................................................56

Wiring Diagram - H/PHONE - ..................................58

Terminal and Reference Value for Bluetooth Con-

trol Unit ....................................................................

60

Bluetooth Control Unit Self-Diagnosis Function ......60

Power Supply and Ground Circuit Inspection for

Bluetooth Control Unit .............................................

61

Removal and Installation .........................................62

DVD ENTERTAINMENT SYSTEM ....................64

Component Parts and Harness Connector Loca-

tion ...........................................................................

64

Description ...............................................................64

Schematic ................................................................66

Wiring Diagram - DVD - ...........................................67

Trouble Diagnosis ....................................................70

Power Supply Circuit Inspection ..............................70

Removal and Installation .........................................71

NAVIGATION SYSTEM ....................................73

System Description ..................................................73

CAN Communication System Description ...............75

Component Parts Location ......................................76

Schematic ................................................................77

Wiring Diagram - NAVI - ..........................................78

Schematic ................................................................85