steering INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2805 of 3061

DRIVER AIR BAG MODULE

SRS-35

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

DRIVER AIR BAG MODULE

Removal and InstallationINFOID:0000000003532873

REMOVAL

CAUTION:

• Do not attempt to repair or replace damaged direct-connect SRS component connectors. If a driver

air bag direct-connect harness connector is damaged, the spiral cable must be replaced.

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least

3 minutes.

• When servicing the SRS, do not work from directly in front of air bag module.

1. Disconnect the negative and positive battery cables, then wait at least 3 minutes.

2. Remove the left and right side lids and bolts.

3. Lift the driver air bag module from the steering wheel.

4. Disconnect the horn connector and air bag harness, then remove the driver air bag module.

• For removal/installation of the direct-connect SRS connectors, refer to SRS-6, "

Direct-connect SRS

Component Connectors" .

CAUTION:

• When servicing the SRS, do not work from directly in front of air bag module.

• Always place air bag module with pad side facing upward.

• Do not insert any foreign objects (screwdriver, etc.) into air

bag module or harness connectors.

• Do not disassemble air bag module.

• Do not use old bolts after removal; replace with new bolts.

• Do not expose the air bag module to temperatures exceeding

90°C (194°F).

1. Horn harness 2. Steering wheel hook 3. Inflator harness

4. Side lids RH/LH 5. Driver air bag module 6. Steering wheel

WHIA0159E

LHIA0052E

Page 2807 of 3061

SPIRAL CABLE

SRS-37

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

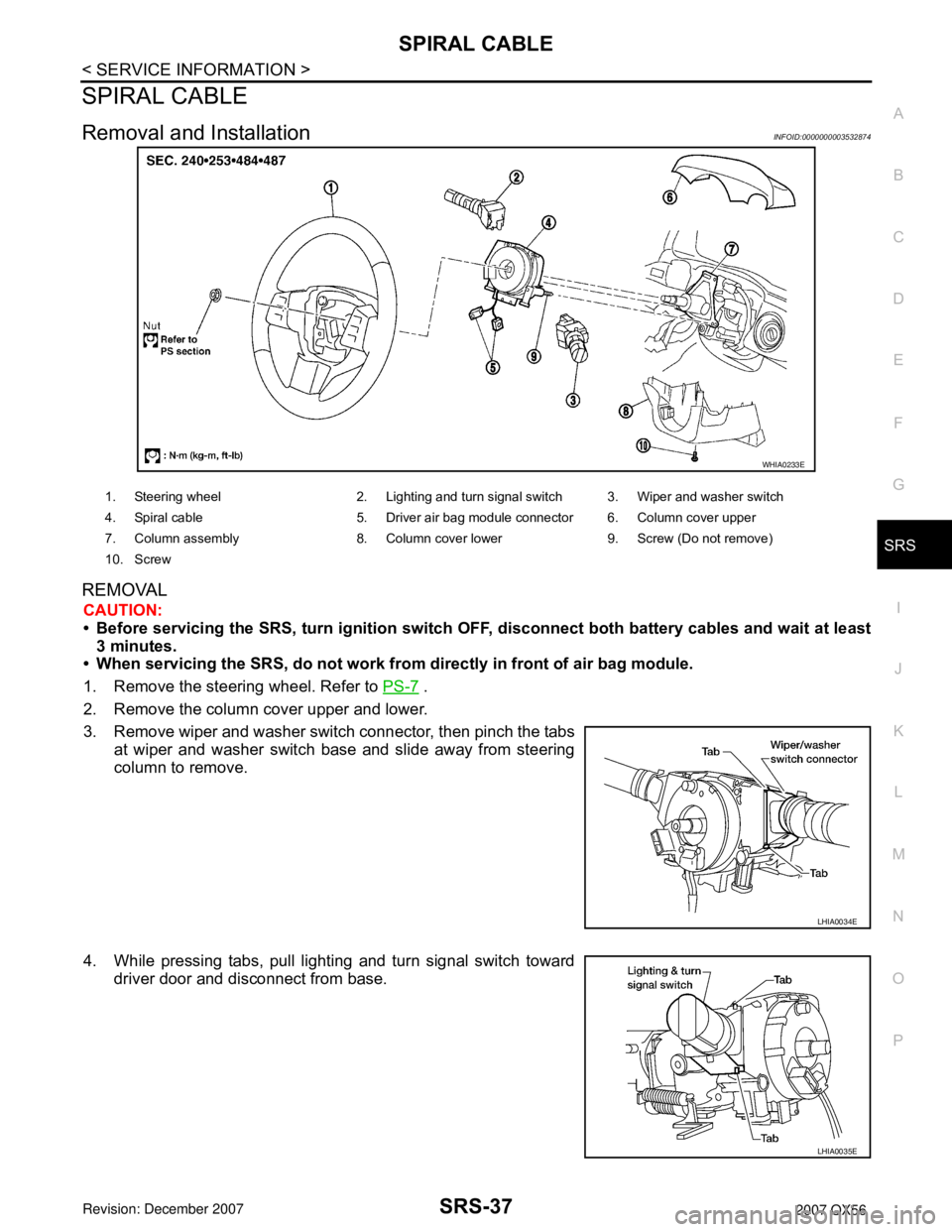

SPIRAL CABLE

Removal and InstallationINFOID:0000000003532874

REMOVAL

CAUTION:

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least

3 minutes.

• When servicing the SRS, do not work from directly in front of air bag module.

1. Remove the steering wheel. Refer to PS-7

.

2. Remove the column cover upper and lower.

3. Remove wiper and washer switch connector, then pinch the tabs

at wiper and washer switch base and slide away from steering

column to remove.

4. While pressing tabs, pull lighting and turn signal switch toward

driver door and disconnect from base.

WHIA0233E

1. Steering wheel 2. Lighting and turn signal switch 3. Wiper and washer switch

4. Spiral cable 5. Driver air bag module connector 6. Column cover upper

7. Column assembly 8. Column cover lower 9. Screw (Do not remove)

10. Screw

LHIA0034E

LHIA0035E

Page 2808 of 3061

SRS-38

< SERVICE INFORMATION >

SPIRAL CABLE

5. Remove the screws, release the clip, and remove the spiral

cable.

CAUTION:

• Do not disassemble spiral cable.

• Do not apply lubricant to the spiral cable.

6. Remove the spiral cable connectors.

CAUTION:

With the steering linkage disconnected, the spiral cable may snap by turning the steering wheel

beyond the limited number of turns. The spiral cable can be turned counterclockwise about 2.5

turns from the neutral position.

INSTALLATION

Installation is in the reverse order of removal.

• Align spiral cable correctly when installing steering wheel. Make

sure that the spiral cable is in the neutral position. The neutral

position is detected by turning left 2.5 revolutions from the right

end position and ending with the knob at the top.

• If equipped with VDC, refer to BRC-54, "

Adjustment of Steering

Angle Sensor Neutral Position" for steering angle sensor adjust-

ment.

• After the work is completed, perform self-diagnosis to make sure

no malfunction is detected. Refer to SRS-20, "

SRS Operation

Check" .

CAUTION:

• The spiral cable may snap due to steering operation if the

cable is not installed in the correct position.

• With the steering linkage disconnected, the cable may snap

by turning the steering wheel beyond the limited number of

turns. The spiral cable can be turned counterclockwise about

2.5 turns from the right end position.

LHIA0036E

WGIA0038E

PHIA0275E

Page 2819 of 3061

COLLISION DIAGNOSIS

SRS-49

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

COLLISION DIAGNOSIS

For Frontal CollisionINFOID:0000000003532882

Check the SRS components using the following table.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-

20, "SRS Operation Check" .

SRS INSPECTION (FOR FRONTAL COLLISION)

Part SRS is activated SRS is NOT activated

Driver air bag module If the driver air bag

has deployed:

REPLACE

Install with new fas-

teners.If the driver air bag has NOT been activated:

1. Remove driver air bag module. Check harness cover and connectors for dam-

age, terminals for deformities, and harness for binding.

2. Install driver air bag module into the steering wheel to check fit and alignment

with the wheel.

3. If no damage is found, reinstall with new fasteners.

4. If damaged—REPLACE. Install driver air bag modules with new fasteners.

Front passenger air

bag moduleIf the front passenger

air bag has deployed:

REPLACE

Install with new fas-

teners.If the front passenger air bag has NOT been activated:

1. Remove front passenger air bag module. Check harness cover and connectors

for damage, terminals for deformities, and harness for binding.

2. Install front passenger air bag module into the instrument panel to check fit with

the instrument panel.

3. If no damage is found, reinstall with new fasteners.

4. If damaged—REPLACE. Install front passenger air bag modules with new fas-

teners.

Crash zone sensor If any of the front air

bags or seat belt pre-

tensioners* have

been activated:

REPLACE the crash

zone sensor and

bracket with new fas-

teners.

*: Confirm seat belt

pre-tensioner activa-

tion using CONSULT-

II only.If the front air bags or seat belt pre-tensioners have NOT been activated:

1. Remove the crash zone sensor. Check harness connectors for damage, termi-

nals for deformities, and harness for binding.

2. Check for visible signs of damage (dents, cracks, deformation) of the crash zone

sensor and bracket.

3. Install the crash zone sensor to check fit.

4. If no damage is found, reinstall with new fasteners.

5. If damaged—REPLACE the crash zone sensor and bracket with new fasteners.

Seat belt pre-tension-

er assemblies

(All applicable loca-

tions: buckle, reel, lap

outer)If either the driver or

passenger seat belt

pre-tensioner* has

been activated:

REPLACE all seat

belt pre-tensioner as-

semblies with new

fasteners.

*: Confirm seat belt

pre-tensioner activa-

tion using CONSULT-

II only.If the pre-tensioners have NOT been activated:

1. Remove seat belt pre-tensioners.

Check harness cover and connectors for damage, terminals for deformities, and

harness for binding.

2. Check belts for damage and anchors for loose mounting.

3. Check retractor for smooth operation.

4. Check seat belt adjuster for damage.

5. Check for deformities of the center pillar inner.

6. If the center pillar inner has no damage, REPLACE the seat belt pre-tensioner

assembly.

7. If no damage is found, reinstall seat belt pre-tensioner assembly.

8. If damaged—REPLACE. Install the seat belt pre-tensioners with new fasteners.

Diagnosis sensor unit If any of the SRS com-

ponents have been

activated:

REPLACE the diag-

nosis sensor unit.

Install with new fas-

teners.If none of the SRS components have been activated:

1. Check case for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new fasteners.

4. If damaged—REPLACE. Install diagnosis sensor unit with new fasteners.

Page 2820 of 3061

SRS-50

< SERVICE INFORMATION >

COLLISION DIAGNOSIS

For Side and Rollover Collision

INFOID:0000000003532883

Check the SRS components using the following table.

• After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to SRS-

20, "SRS Operation Check" .

WHEN SRS IS ACTIVATED IN THE SIDE OR ROLLOVER COLLISION

1. Replace the following components:

- Front seat back assembly (on the side on which side air bag is activated)

- Diagnosis sensor unit

- (LH or RH) side air bag (satellite) sensor (on the side on which side air bag is activated)

2. Check the SRS components and the related parts using the following table.

- Replace any SRS components and the related parts showing visible signs of damage (dents, cracks,

deformation).

3. Conduct self-diagnosis using CONSULT-II and “AIR BAG” warning lamp. Refer to SRS-20, "

SRS Opera-

tion Check" for details. Ensure entire SRS operates properly.

WHEN SRS IS NOT ACTIVATED IN THE SIDE OR ROLLOVER COLLISION

1. Check the SRS components and the related parts using the following table.

- If the front seat back assembly is damaged, the front seat back assembly must be replaced.

2. Conduct self-diagnosis using CONSULT-II and “AIR BAG” warning lamp. Refer to SRS-20, "

SRS Opera-

tion Check" for details. Ensure entire SRS operates properly.

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for deformities.

3. Install driver air bag module into the steering wheel to check fit and alignment with the wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall.

6. If damaged—REPLACE.

Spiral cable If the driver front air

bag has deployed:

REPLACE the spiral

cable.If the driver front air bag has not deployed:

1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall.

5. If damaged—REPLACE.

Occupant classifica-

tion system (Passen-

ger seat)1. Remove passenger seat.

2. Check control unit case for dents, cracks of deformities.

3. Check connectors and pressure sensor tube for damage, and terminals for deformities.

4. Check seat frame and cushion pan for dents or deformities.

5. If no damage is found, reinstall seat with new fasteners.

6. If damaged — REPLACE seat cushion assembly with new fasteners.

Harness and connec-

tors1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. If damaged—REPLACE the damaged harness. Do not attempt to repair, splice or modify any SRS har-

ness.

Instrument panel If the passenger front

air bag has deployed:

REPLACE the instru-

ment panel assembly.If the passenger front air bag has NOT deployed:

1. Visually check instrument panel for damage.

2. If no damage is found, reinstall the instrument panel.

3. If damaged—REPLACE the instrument panel. Part SRS is activated SRS is NOT activated

Page 2855 of 3061

TROUBLE DIAGNOSIS

TF-33

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

1. Brake pedal depressed.

2. Move A/T selector lever to “N” position.

3. Set 4WD shift switch to “2WD”, “AUTO”, “4H”, “4LO”, “4H”,

“AUTO” and “2WD” in order. (Stay at each switch position for at

least 1 second.)

Do 4WD shift indicator and 4LO indicator lamps change properly?

Does buzzer sound?

YES >> GO TO "CRUISE TEST".

NO >> GO TO TF-107, "

4WD Shift Indicator Lamp or 4LO Indi-

cator Lamp Does Not Change" .

CRUISE TEST

1.CHECK INPUT SIGNAL

1. Warm up engine to normal operating temperature.

2. Park vehicle on flat surface.

3. Move A/T selector lever to “P” position.

4. Set 4WD shift switch to “AUTO” position.

5. Start engine.

6. Drive vehicle for at least 30 seconds at a speed higher than 20 km/h (12 MPH).

Check 4WD warning lamp turned ON?

On steady>>Perform the self-diagnosis. Refer to TF-48, "Self-Diagnosis Procedure" or TF-48, "Self-Diagno-

sis Procedure".

Flash rapidly>>GO TO T F - 111 , "

4WD Warning Lamp Flashes Rapidly" .

Flash slowly>>GO TO TF-112, "

4WD Warning Lamp Flashes Slowly".

NO >> GO TO 2.

2.CHECK TIGHT CORNER BRAKING SYMPTOM (1)

1. Set 4WD shift switch to “AUTO” position.

2. Drive vehicle at speed lower than 20 km/h (12 MPH) with steering wheel fully turned.

Does tight corner braking symptom occur?

YES >> GO TO TF-113, "Heavy Tight-corner Braking Symptom Occurs".

NO >> GO TO 3.

3.CHECK TIGHT CORNER BRAKING SYMPTOM (2)

1. Set 4WD shift switch to “4HI” position.

2. Drive vehicle at speed lower than 20 km/h (12 MPH) with steering wheel fully turned.

Does tight corner braking symptom occur?

YES >> Inspection End.

NO >> GO TO TF-114, "

4WD System Does Not Operate" .

WDIA0136E

Page 2856 of 3061

TF-34

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Trouble Diagnosis Chart by Symptom

INFOID:0000000003532525

If 4WD warning lamp turns ON, perform self-diagnosis. Refer to TF-48, "Self-Diagnosis Procedure" .

NOTE:

• Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode. This is not a

malfunction.

Symptom Condition Check item Reference page

4WD shift indicator lamp and 4LO indicator

lamp do not turn ON

(4WD shift indicator lamp and 4LO indicator

lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-102

Transfer shut off relay

Combination meter

4WD warning lamp does not turn ON

(4WD warning lamp check)Ignition switch: ONPower supply and ground for transfer

control unit

TF-104

Transfer shut off relay

Combination meter

4WD shift indicator lamp or 4LO indicator

lamp does not changeEngine running4WD shift switch

TF-107

Wait detection switch

Neutral-4LO switch

ATP switch

2-4WD solenoid

Transfer control device

Actuator motor

Actuator position switch

Transfer inner parts

ATP warning lamp turns ON Engine runningCAN communication line

TF-109

4WD shift switch

PNP switch signal

ATP switch

Combination meter

Transfer inner parts

4LO indicator lamp repeats flashing Engine runningWait detection switch

TF-110

Neutral-4LO switch

Transfer inner parts

4WD warning lamp flashes rapidly (2 times/

second)While drivingTransfer fluid temperature

TF-111

Tire size is different between front and

rear of vehicle

4WD warning lamp flashes slowly

(1 time/2 seconds)While drivingTire size is different between front and

rear of vehicle.

TF-112

Transfer fluid temperature

Clutch pressure switch

Heavy tight-corner braking symptom occurs

(See NOTE.)• While driving

•AUTO mode

• Steering wheel is

turned fully to either

sideCAN communication line

TF-113

4WD shift switch

Accelerator pedal position signal

Clutch pressure solenoid

Transfer inner parts

4WD system does not operate While driving4WD shift switch

TF-114

Clutch pressure switch

Transfer inner parts

Page 2857 of 3061

TROUBLE DIAGNOSIS

TF-35

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

• Heavy tight-corner braking symptom occurs when vehicle is driven in the following conditions: 4WD shift

switch is "4H" or "4LO", steering wheel is turned fully to either side.

Transfer Control Unit Input/Output Signal Reference ValueINFOID:0000000003532526

TRANSFER CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Monitored item [Unit] Content Condition Display value

VHCL/S SEN·FR [km/h]

or [mph]Front wheel speedVehicle stopped 0 km/h (0 MPH)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indica-

tion on speedome-

ter (Inside of

±10%)

VHCL/S SEN·RR [km/h]

or [mph]Rear wheel speedVehicle stopped 0 km/h (0 MPH)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition.Approximately

equal to the indica-

tion on speedome-

ter (Inside of

±10%)

ENGINE SPEED [rpm] Engine speedEngine stopped

(Engine speed: Less than 400 rpm)0 rpm

Engine running

(Engine speed: 400 rpm or more)Approximately

equal to the indica-

tion on tachometer

THRTL POS SEN [V]Accelerator pedal posi-

tion (APP) sensor signal

voltageAccelerator pedal: Release Approx. 0.5V

Accelerator pedal: Fully depressed Approx. 4.0V

FLUID TEMP SE [V]Transfer fluid tempera-

ture signal voltageTransfer fluid temperature approx. 20 - 80°C (68 - 176°F) Approx. 1.1 - 0.3V

BATTERY VOLT [V]Power supply voltage for

transfer control unitIgnition switch: ON Battery voltage

2WD SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 2WD ON

4WD shift switch: AUTO, 4H or 4LO OFF

AUTO SWITCH [ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: AUTO ON

4WD shift switch: 2WD, 4H or 4LO OFF

LOCK SWITCH [ON/

OFF]Input condition from 4WD

shift switch4WD shift switch: 4H ON

4WD shift switch: 2WD, AUTO or 4LO OFF

4L SWITCH [ON/OFF]Input condition from 4WD

shift switch4WD shift switch: 4LO ON

4WD shift switch: 2WD, AUTO or 4H OFF

N POSI SW TF [ON/

OFF]Condition of neutral-4LO

switch• Vehicle stopped

• Engine running

• A/T selector lever “N” posi-

tion

• Brake pedal depressed4WD shift switch: 2WD,

AUTO or 4HOFF

4WD shift switch: 4H to

4LO (While actuator mo-

tor is operating.)OFF → ON

4WD shift switch: 4LO to

4H (While actuator motor

is operating.)ON → OFF

4WD shift switch: 4LO ON

Page 2935 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-113

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

NG >> GO TO 5.

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

OK >> Inspection End.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

Heavy Tight-corner Braking Symptom OccursINFOID:0000000003532560

SYMPTOM:

Heavy tight-corner braking symptom occurs when vehicle is driven in AUTO mode and steering wheel

is turned fully to either side.

DIAGNOSTIC PROCEDURE

NOTE:

• Light tight-corner braking symptom may occur depending on driving conditions in AUTO mode. This is not a

malfunction.

• Heavy tight-corner braking symptom occurs when vehicle is driven in the following conditions: 4WD shift

switch is "4H" or "4LO", steering wheel is turned fully to either side.

1.CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-48, "

Self-Diagnosis Procedure".

Is "CAN COMM CIRCUIT [U1000]" displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-99, "CAN Communication

Line" .

NO >> GO TO 2.

2.CHECK SYSTEM FOR 4WD SHIFT SWITCH

Perform trouble diagnosis for 4WD shift switch system. Refer to TF-57, "

4WD Shift Switch".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK ACCELERATOR PEDAL POSITION SIGNAL CIRCUIT

Perform self diagnosis for ECM. Refer to E C - 111 , "

CONSULT-II Function (ENGINE)".

Is any malfunction deteced by self-diagnosis?

YES >> Check the malfunctioning system.

NO >> GO TO 4.

4.CHECK SYSTEM FOR CLUTCH PRESSURE SOLENOID

Perform trouble diagnosis for clutch pressure solenoid system. Refer toTF-92, "

Clutch Pressure Switch" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.SYMPTOM CHECK

Check again.

OK or NG

OK >> Inspection End.

NG >> GO TO 6.

6.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

Page 2993 of 3061

WT-4

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003532688

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

WT-5WT-6WT-28WT-7—

—

WT-28

FFD-6, "

NVH Troubleshooting Chart

" (FFD),

RFD-7, "

NVH Troubleshooting Chart

" (RFD)

FA X - 4 , "

NVH Troubleshooting Chart

" (FAX),

FSU-4, "

NVH Troubleshooting Chart

" (FSU)

RAX-4, "

NVH Troubleshooting Chart

" (RAX),

RSU-4, "

NVH Troubleshooting Chart

" (RSU)

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

BR-4, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKE

STEERING

SymptomTIRESNoise× ××××× × × × × ××

Shake× ×××× × × × × ××

Vibration××××××

Shimmy× ×××××× × × × ××

Shudder× ×××× × × × × ××

Poor quality ride or

handling× ×××× × × × ×

ROAD

WHEELNoise×× × ××× ×××

Shake×× × ×× ×××

Shimmy, shudder×× × ×× ×××

Poor quality ride or

handling×× × ×× ×