automatic transmission fluid INFINITI QX56 2007 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 268 of 3061

AT-198

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

1. Turn ignition switch “ON”.

2. Select "ECU INPUT SIGNALS" in "DATA MONITOR" mode for

"A/T" with CONSULT-II.

3. Read out "1 POSITION SW" switch moving selector lever to

each position.

Without CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine)

2. Check voltage between A/T device harness connector terminal

and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK A/T FLUID LEVEL

Check the A/T fluid level. Refer to AT-13, "

Checking Automatic

Transmission Fluid (ATF)".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK CONTROL CABLE

Check the control cable.

• Refer to AT-208, "

Checking of A/T Position".

OK or NG

OK >> GO TO 5.

NG >> Adjust control cable. Refer to AT-208, "

Adjustment of A/

T Position".

5.CHECK A/T FLUID CONDITION

Monitor item Condition Display value

1 POSITION SWWhen setting the selector

lever to "1" position.ON

When setting selector le-

ver to other positions.OFF

LCIA0339E

Item Connector No. Terminal No. ConditionData

(Approx.)

1st position

switchM203 7 - GroundWhen setting

the selector le-

ver to "1" posi-

tion.0V

When setting

selector lever

to other posi-

tions.Battery volt-

age

LCIA0341E

SAT638A

LCIA0345E

Page 270 of 3061

AT-200

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

1. Turn ignition switch “ON”.

2. Select "ECU INPUT SIGNALS" in "DATA MONITOR" mode for

"A/T" with CONSULT-II.

3. Read out "1 POSITION SW" moving switch selector lever to

each position.

Without CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine)

2. Check voltage between A/T device harness connector terminal

and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK A/T FLUID LEVEL

Check the A/T fluid level. Refer to AT-13, "

Checking Automatic

Transmission Fluid (ATF)".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK CONTROL CABLE

Check the control cable.

• Refer to AT-208, "

Checking of A/T Position".

OK or NG

OK >> GO TO 5.

NG >> Adjust control cable. Refer to AT-208, "

Adjustment of A/

T Position".

5.CHECK A/T FLUID CONDITION

Monitor item Condition Display value

1 POSITION SWWhen setting the selector

lever to "1" position.ON

When setting selector le-

ver to other positions.OFF

LCIA0339E

Item Connector No. Terminal No. ConditionData

(Approx.)

1st position

switchM203 7 - GroundWhen setting

the selector le-

ver to "1" posi-

tion.0V

When setting

selector lever

to other posi-

tions.Battery volt-

age

LCIA0341E

SAT638A

LCIA0345E

Page 279 of 3061

ON-VEHICLE SERVICE

AT-209

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

ON-VEHICLE SERVICE

Oil PanINFOID:0000000003532477

REMOVAL AND INSTALLATION

Removal

1. Drain A/T fluid. Refer to AT-13, "Changing Automatic Transmission Fluid (ATF)".

2. Remove oil pan clips (1).

3. Remove oil pan (2).

4. Remove oil pan gasket.

• : Front

• : Oil pan bolts

• Drain plug (3)

5. Check foreign materials in oil pan to help determine cause of malfunction. If the A/T fluid is very dark, has

some burned smell, or contains foreign particles, friction material (clutches, band) may need replacement.

A tacky film that will not wipe clean indicates varnish build up. Varnish can cause valves, servo, and

clutches to stick and can inhibit pump pressure.

CAUTION:

If friction material is detected, flush the transmission cooler after repair. Refer to AT-15, "

A/T Fluid

Cooler Cleaning".

6. Remove magnets from oil pan.

Installation

1. Install the oil pan magnets as shown.

AWDIA0023ZZ

SCIA5200E

SCIA5200E

Page 280 of 3061

AT-210

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

2. Install the oil pan (2) and new oil pan gasket.

• Oil pan clips (1)

• Drain plug (3)

• : Front

• : Oil pan bolts

CAUTION:

• Do not reuse the oil pan gasket.

• Completely remove all moisture, oil and old gasket from

the oil pan gasket mating surfaces and holes.

• Always replace the oil pan bolts as they are self-sealing.

• Be sure the oil pan drain plug hole is located to the rear of

the transmission assembly.

• Partially install the oil pan bolts in a criss-cross pattern to prevent dislocation of the gasket.

• Be careful not to pinch harnesses.

3. Tighten new oil pan bolts in numerical order as shown.

4. Install drain plug in oil pan with new gasket.

CAUTION:

Do not reuse the drain plug gasket.

5. Refill the transmission assembly with fluid. Refer to AT-13, "

Changing Automatic Transmission Fluid

(ATF)".

Control Valve with TCM and A/T Fluid Temperature Sensor 2INFOID:0000000003532478

COMPONENTS

AWDIA0023ZZ

Oil pan bolts : 7.9 N·m (0.81 kg-m, 70 in-lb)

SCIA4113E

Drain plug : 34 N·m (3.5 kg-m, 25 ft-lb)

Page 288 of 3061

AT-218

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

17. Install snap ring to A/T assembly harness connector.

18. Connect A/T assembly harness connector.

19. Connect the negative battery terminal

20. Refill the A/T with fluid and check fluid level and for fluid leak-

age. Refer to AT-13, "

Changing Automatic Transmission Fluid

(ATF)".

CAUTION:

After completing installation, check A/T fluid leakage and fluid

level. Refer to AT-13, "

Changing Automatic Transmission Fluid

(ATF)", AT-13, "Checking Automatic Transmission Fluid (ATF)".

A/T FLUID TEMPERATURE SENSOR 2 REMOVAL AND INSTALLATION

Removal

1. Disconnect negative battery terminal

2. Remove oil pan and oil pan gasket. Refer to AT-209, "

Oil Pan".

3. Disconnect A/T fluid temperature sensor 2 connector (A).

CAUTION:

Be careful not to damage connector.

4. Straighten terminal clip to free A/T fluid temperature sensor 2

harness.

• : Terminal clip

5. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

6. Remove bracket from A/T fluid temperature sensor 2.

Installation

SCIA5039E

SCIA8125E

SCIA5253E

SCIA5264E

Page 289 of 3061

ON-VEHICLE SERVICE

AT-219

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

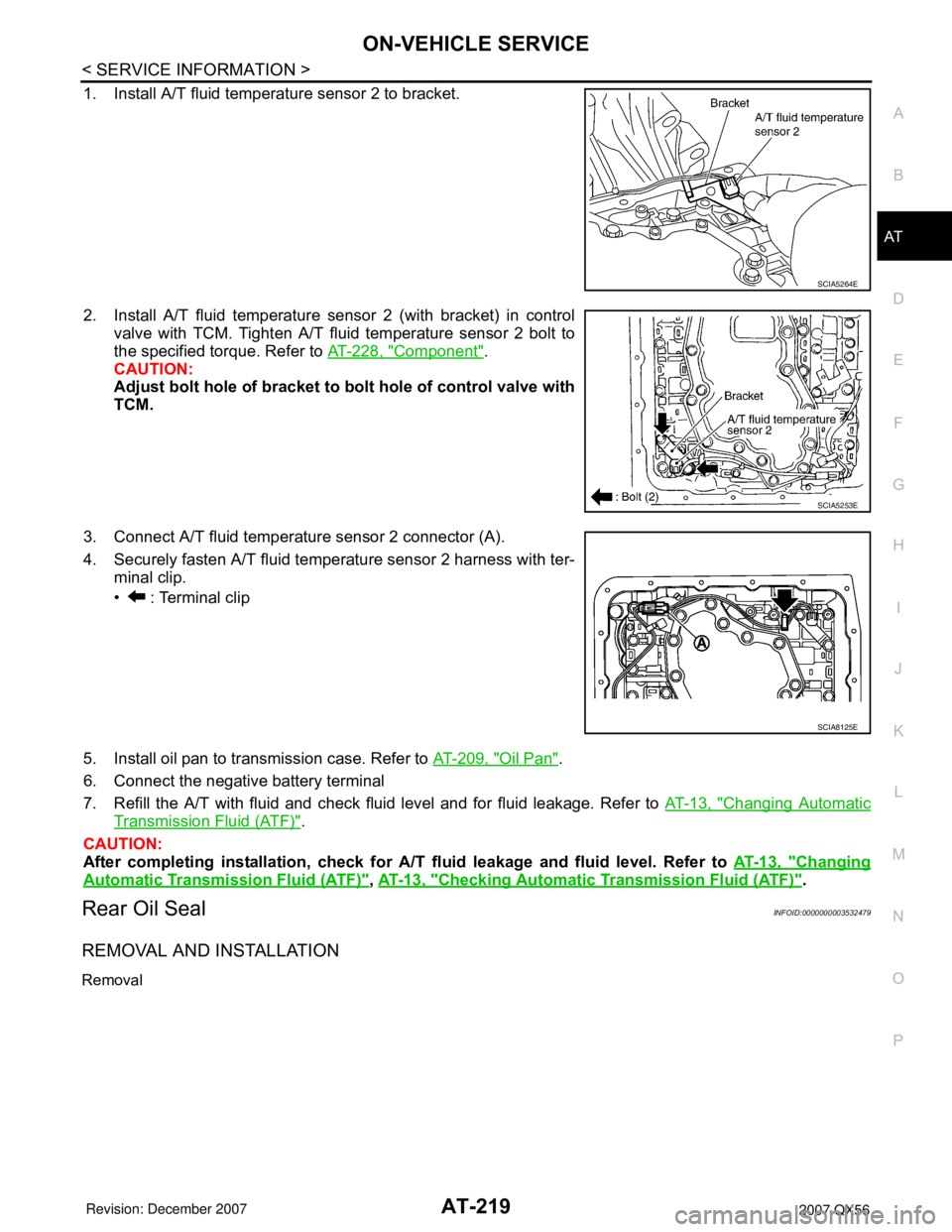

1. Install A/T fluid temperature sensor 2 to bracket.

2. Install A/T fluid temperature sensor 2 (with bracket) in control

valve with TCM. Tighten A/T fluid temperature sensor 2 bolt to

the specified torque. Refer to AT-228, "

Component".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

3. Connect A/T fluid temperature sensor 2 connector (A).

4. Securely fasten A/T fluid temperature sensor 2 harness with ter-

minal clip.

• : Terminal clip

5. Install oil pan to transmission case. Refer to AT-209, "

Oil Pan".

6. Connect the negative battery terminal

7. Refill the A/T with fluid and check fluid level and for fluid leakage. Refer to AT-13, "

Changing Automatic

Transmission Fluid (ATF)".

CAUTION:

After completing installation, check for A/T fluid leakage and fluid level. Refer to AT-13, "

Changing

Automatic Transmission Fluid (ATF)", AT-13, "Checking Automatic Transmission Fluid (ATF)".

Rear Oil SealINFOID:0000000003532479

REMOVAL AND INSTALLATION

Removal

SCIA5264E

SCIA5253E

SCIA8125E

Page 290 of 3061

AT-220

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

1. Remove rear propeller shaft. Refer to PR-8, "Removal and

Installation".

2. Remove transfer from transmission (4WD models). Refer to TF-

128, "Removal and Installation".

3. Remove rear oil seal using suitable tool.

CAUTION:

Be careful not to scratch rear extension assembly (2WD

models) or adapter case assembly (4WD models).

Installation

1. Install new rear oil seal until it is flush with component face into

the extension case (2WD models) using Tool, or adapter case

(4WD models) using suitable tool.

CAUTION:

• Apply ATF to rear oil seal.

• Do not reuse rear oil seal.

2. Install transfer to transmission (4WD models). Refer to TF-128,

"Removal and Installation".

3. Install rear propeller shaft. Refer to PR-8, "

Removal and Installa-

tion".

CAUTION:

After completing installation, check for A/T fluid leakage and

fluid level. Refer to AT-13, "

Changing Automatic Transmission

Fluid (ATF)" and AT-13, "Checking Automatic Transmission

Fluid (ATF)".

SCIA5254E

Tool number : ST33400001 (J-26082)

SCIA5583E

Page 295 of 3061

TRANSMISSION ASSEMBLY

AT-225

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

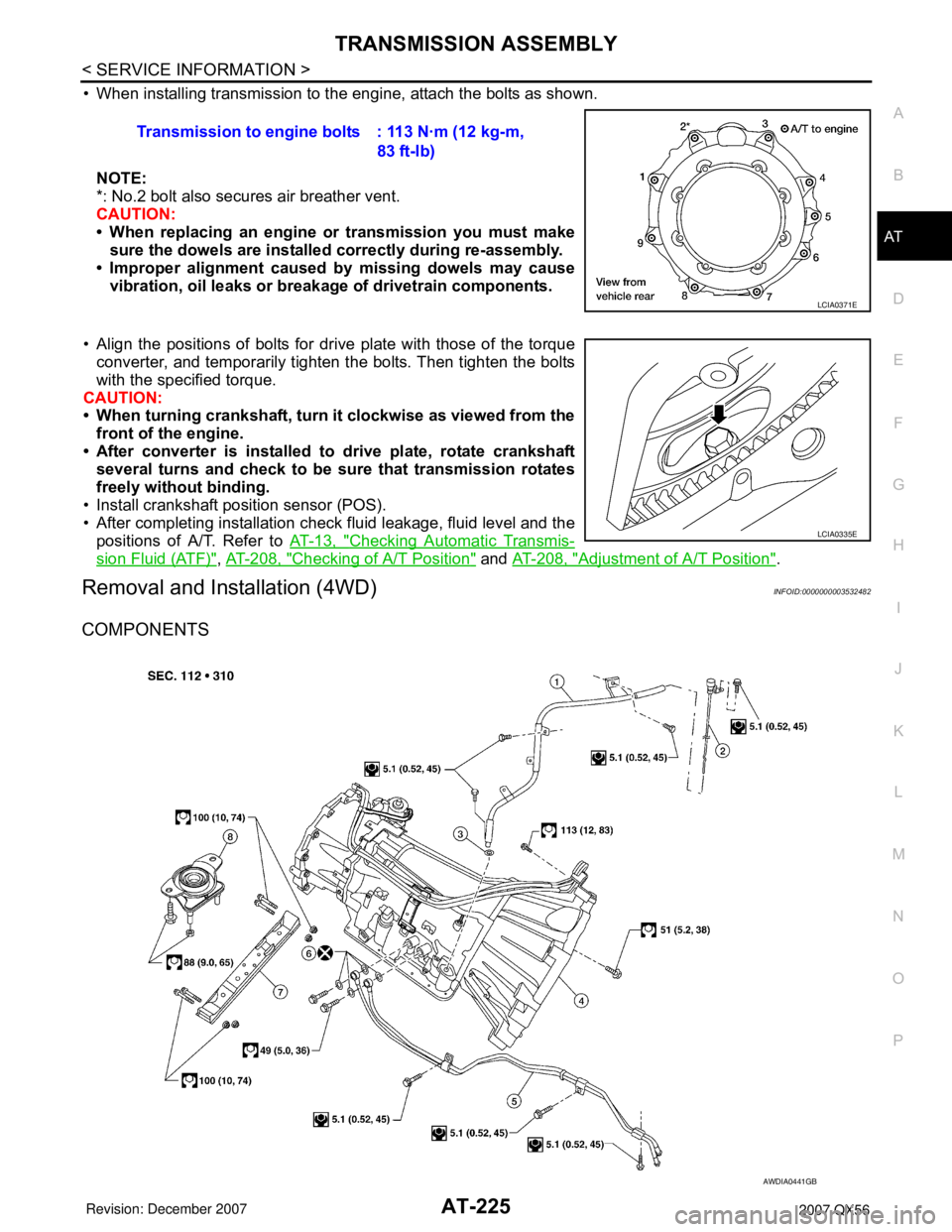

• When installing transmission to the engine, attach the bolts as shown.

NOTE:

*: No.2 bolt also secures air breather vent.

CAUTION:

• When replacing an engine or transmission you must make

sure the dowels are installed correctly during re-assembly.

• Improper alignment caused by missing dowels may cause

vibration, oil leaks or breakage of drivetrain components.

• Align the positions of bolts for drive plate with those of the torque

converter, and temporarily tighten the bolts. Then tighten the bolts

with the specified torque.

CAUTION:

• When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

• After converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission rotates

freely without binding.

• Install crankshaft position sensor (POS).

• After completing installation check fluid leakage, fluid level and the

positions of A/T. Refer to AT-13, "

Checking Automatic Transmis-

sion Fluid (ATF)", AT-208, "Checking of A/T Position" and AT-208, "Adjustment of A/T Position".

Removal and Installation (4WD)INFOID:0000000003532482

COMPONENTS

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

AWDIA0441GB

Page 297 of 3061

TRANSMISSION ASSEMBLY

AT-227

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

17. Plug any openings such as the fluid charging pipe hole.

18. Remove A/T assembly to engine bolts using power tool.

19. Remove A/T assembly with transfer from vehicle.

CAUTION:

• Secure torque converter to prevent it from dropping.

• Secure A/T assembly to transmission jack.

20. Remove transfer from A/T assembly. Refer to TF-128, "

Removal and Installation".

INSPECTION

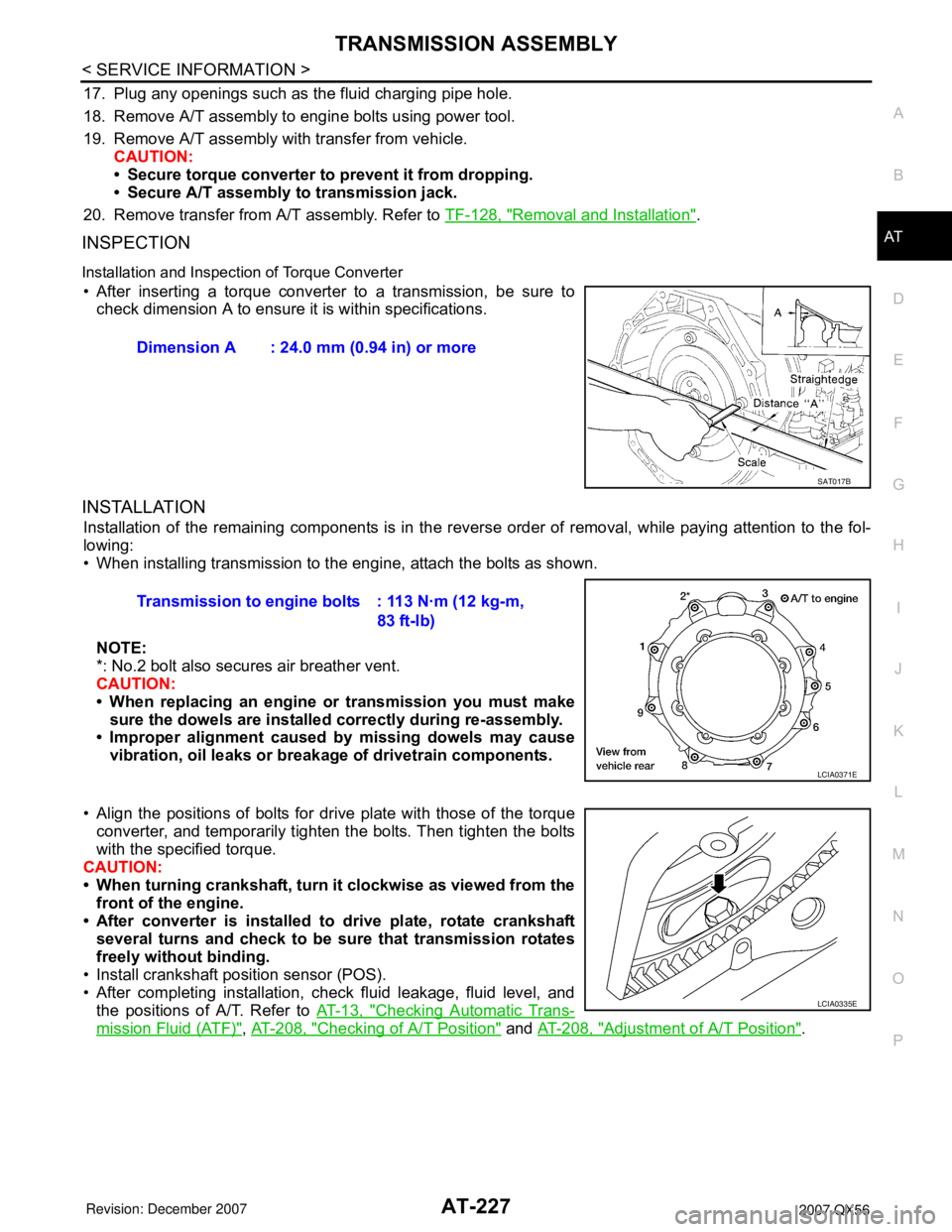

Installation and Inspection of Torque Converter

• After inserting a torque converter to a transmission, be sure to

check dimension A to ensure it is within specifications.

INSTALLATION

Installation of the remaining components is in the reverse order of removal, while paying attention to the fol-

lowing:

• When installing transmission to the engine, attach the bolts as shown.

NOTE:

*: No.2 bolt also secures air breather vent.

CAUTION:

• When replacing an engine or transmission you must make

sure the dowels are installed correctly during re-assembly.

• Improper alignment caused by missing dowels may cause

vibration, oil leaks or breakage of drivetrain components.

• Align the positions of bolts for drive plate with those of the torque

converter, and temporarily tighten the bolts. Then tighten the bolts

with the specified torque.

CAUTION:

• When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

• After converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission rotates

freely without binding.

• Install crankshaft position sensor (POS).

• After completing installation, check fluid leakage, fluid level, and

the positions of A/T. Refer to AT-13, "

Checking Automatic Trans-

mission Fluid (ATF)", AT-208, "Checking of A/T Position" and AT-208, "Adjustment of A/T Position". Dimension A : 24.0 mm (0.94 in) or more

SAT017B

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

Page 368 of 3061

AT-298

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

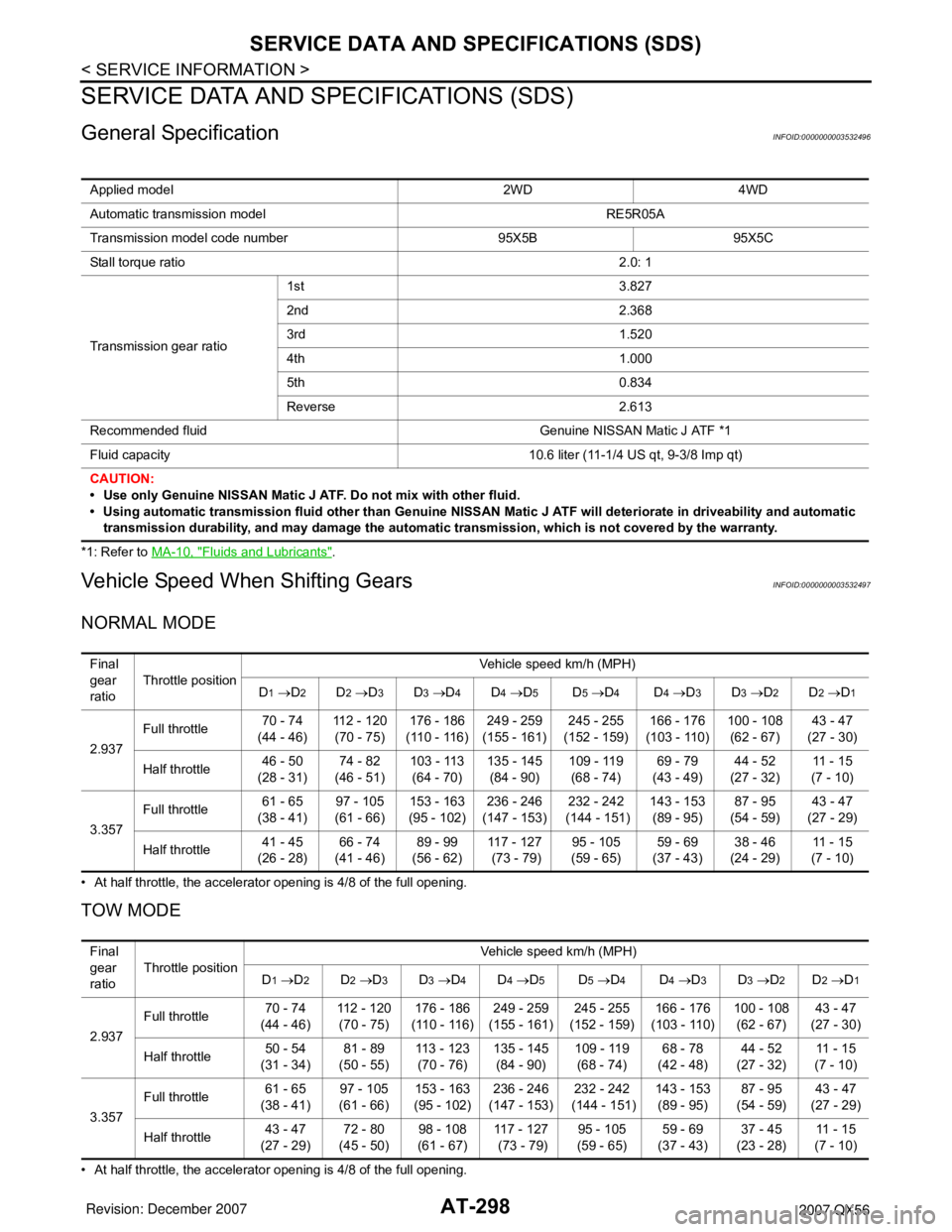

General SpecificationINFOID:0000000003532496

*1: Refer to MA-10, "Fluids and Lubricants".

Vehicle Speed When Shifting GearsINFOID:0000000003532497

NORMAL MODE

• At half throttle, the accelerator opening is 4/8 of the full opening.

TOW MODE

• At half throttle, the accelerator opening is 4/8 of the full opening.Applied model 2WD 4WD

Automatic transmission model RE5R05A

Transmission model code number 95X5B 95X5C

Stall torque ratio2.0: 1

Transmission gear ratio1st 3.827

2nd 2.368

3rd 1.520

4th 1.000

5th 0.834

Reverse 2.613

Recommended fluid Genuine NISSAN Matic J ATF *1

Fluid capacity 10.6 liter (11-1/4 US qt, 9-3/8 Imp qt)

CAUTION:

• Use only Genuine NISSAN Matic J ATF. Do not mix with other fluid.

• Using automatic transmission fluid other than Genuine NISSAN Matic J ATF will deteriorate in driveability and automatic

transmission durability, and may damage the automatic transmission, which is not covered by the warranty.

Final

gear

ratioThrottle positionVehicle speed km/h (MPH)

D

1 →D2D2 →D3D3 →D4D4 →D5D5 →D4D4 →D3D3 →D2D2 →D1

2.937Full throttle 70 - 74

(44 - 46)112 - 120

(70 - 75)176 - 186

(110 - 116)249 - 259

(155 - 161)245 - 255

(152 - 159)166 - 176

(103 - 110)100 - 108

(62 - 67)43 - 47

(27 - 30)

Half throttle 46 - 50

(28 - 31)74 - 82

(46 - 51)103 - 113

(64 - 70)135 - 145

(84 - 90)109 - 119

(68 - 74)69 - 79

(43 - 49)44 - 52

(27 - 32)11 - 1 5

(7 - 10)

3.357Full throttle 61 - 65

(38 - 41)97 - 105

(61 - 66)153 - 163

(95 - 102)236 - 246

(147 - 153)232 - 242

(144 - 151)143 - 153

(89 - 95)87 - 95

(54 - 59)43 - 47

(27 - 29)

Half throttle 41 - 45

(26 - 28)66 - 74

(41 - 46)89 - 99

(56 - 62)117 - 127

(73 - 79)95 - 105

(59 - 65)59 - 69

(37 - 43)38 - 46

(24 - 29)11 - 1 5

(7 - 10)

Final

gear

ratioThrottle positionVehicle speed km/h (MPH)

D

1 →D2D2 →D3D3 →D4D4 →D5D5 →D4D4 →D3D3 →D2D2 →D1

2.937Full throttle 70 - 74

(44 - 46)112 - 120

(70 - 75)176 - 186

(110 - 116)249 - 259

(155 - 161)245 - 255

(152 - 159)166 - 176

(103 - 110)100 - 108

(62 - 67)43 - 47

(27 - 30)

Half throttle 50 - 54

(31 - 34)81 - 89

(50 - 55)113 - 123

(70 - 76)135 - 145

(84 - 90)109 - 119

(68 - 74)68 - 78

(42 - 48)44 - 52

(27 - 32)11 - 1 5

(7 - 10)

3.357Full throttle 61 - 65

(38 - 41)97 - 105

(61 - 66)153 - 163

(95 - 102)236 - 246

(147 - 153)232 - 242

(144 - 151)143 - 153

(89 - 95)87 - 95

(54 - 59)43 - 47

(27 - 29)

Half throttle 43 - 47

(27 - 29)72 - 80

(45 - 50)98 - 108

(61 - 67)117 - 127

(73 - 79)95 - 105

(59 - 65)59 - 69

(37 - 43)37 - 45

(23 - 28)11 - 1 5

(7 - 10)