key battery INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 274 of 3061

AT-204

< SERVICE INFORMATION >

A/T SHIFT LOCK SYSTEM

Shift Lock Control Unit Reference Value

INFOID:0000000003532472

SHIFT LOCK HARNESS CONNECTOR TERMINALS LAYOUT

SHIFT LOCK CONTROL UNIT INSPECTION TABLE

Data are reference values.

NOTE:

Confirm that the pointer swings only momentarily because the output time is so short. If the inspection is done with an oscilloscope, it

should be observed that the power source voltage lasts for 3.5 to 10 ms.

Component InspectionINFOID:0000000003532473

SHIFT LOCK SOLENOID

WCIA0550E

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONVOLTAGE

(Approx.)

1Y/RPower sourceIgnition switch: “ON” Battery voltage

Ignition switch: “OFF” Battery voltage

2L/R Detention switch (for

key)When selector lever is not in "P" position with key inserted. Battery voltage

Except the above 0V

3GRDetention switch (for

shift)When selector lever is not in "P" position Battery voltage

Except the above 0V

4 R/G Stop lamp switchWhen brake pedal is depressed Battery voltage

When brake pedal is released 0V

5 W/R Vehicle speed signal — —

6 G/R Ignition signalIgnition switch: “OFF” 0V

Ignition switch: “ON” Battery voltage

7 R/W Shift lock solenoidWhen brake pedal is depressed with ignition switch "ON". 0V

When brake pedal is depressed. Battery voltage

8 B Ground Always 0V

9 G/W Key lock solenoidWhen the selector lever is set to a position other than the “P” po-

sition, and the key switch is turned from “ON” to “OFF”Battery voltage for ap-

prox. 0.1 sec. (Note)

Except the above 0V

10 W/G Key unlock solenoidWhen ignition switch is not in "ON” position with key inserted.Battery voltage for ap-

prox. 0.1 sec. (Note)

Except the above 0V

Page 275 of 3061

A/T SHIFT LOCK SYSTEM

AT-205

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

• Check operation by applying battery voltage to A/T device terminal

9 and ground to terminal 10.

CAUTION:

Be sure to apply the voltage of the correct polarity to the

respective terminals. Otherwise, the part may be damaged.

DETENTION SWITCH

For key:

• Check continuity between terminals of the A/T device.

DETENTION SWITCH

For shift:

• Check continuity between terminals of the A/T device.

KEY LOCK SOLENOID

Key lock

• Check operation by applying battery voltage to key switch and key

lock solenoid terminal 1 and ground to terminal 2.

CAUTION:

Be careful not to cause burnout of the harness.

Key unlock

LCIA0328E

Condition Terminal No. Continuity

When selector lever is “P” position.

5 - 6No

When selector lever is not “P” position. Yes

LIIA1599E

Condition Terminal No. Continuity

When selector lever is “P” position.

3 - 4No

When selector lever is not “P” position. Yes

WCIA0401E

WCIA0240E

Page 276 of 3061

AT-206

< SERVICE INFORMATION >

A/T SHIFT LOCK SYSTEM

• Check operation by applying battery voltage to key switch and key

lock solenoid terminal 2 and ground to terminal 1.

CAUTION:

Be careful not to cause burnout of the harness.

KEY SWITCH

• Check continuity between terminals of the key switch and key lock

solenoid.

STOP LAMP SWITCH

• Check continuity between terminals of the stop lamp switch con-

nector.

Check stop lamp switch after adjusting brake pedal.

WCIA0241E

Condition Terminal No. Continuity

Key inserted

3 - 4Ye s

Key withdrawn No

SCIA5662E

Condition Terminal No. Continuity

When brake pedal is depressed

3 - 4Ye s

When brake pedal is released No

WCIA0559E

Page 693 of 3061

BCS-6

< SERVICE INFORMATION >

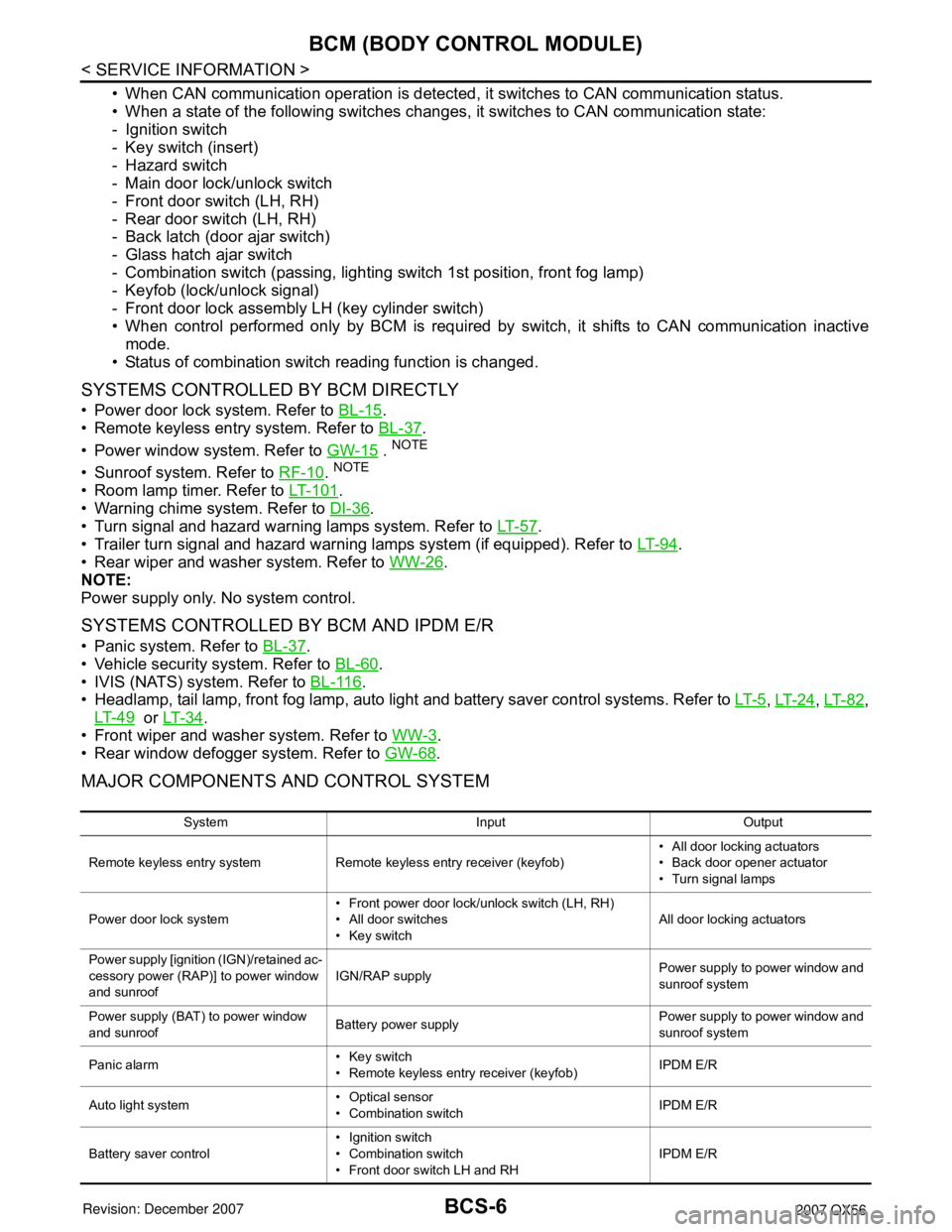

BCM (BODY CONTROL MODULE)

• When CAN communication operation is detected, it switches to CAN communication status.

• When a state of the following switches changes, it switches to CAN communication state:

- Ignition switch

- Key switch (insert)

- Hazard switch

- Main door lock/unlock switch

- Front door switch (LH, RH)

- Rear door switch (LH, RH)

- Back latch (door ajar switch)

- Glass hatch ajar switch

- Combination switch (passing, lighting switch 1st position, front fog lamp)

- Keyfob (lock/unlock signal)

- Front door lock assembly LH (key cylinder switch)

• When control performed only by BCM is required by switch, it shifts to CAN communication inactive

mode.

• Status of combination switch reading function is changed.

SYSTEMS CONTROLLED BY BCM DIRECTLY

• Power door lock system. Refer to BL-15.

• Remote keyless entry system. Refer to BL-37

.

• Power window system. Refer to GW-15

. NOTE

• Sunroof system. Refer to RF-10. NOTE

• Room lamp timer. Refer to LT-101.

• Warning chime system. Refer to DI-36

.

• Turn signal and hazard warning lamps system. Refer to LT- 5 7

.

• Trailer turn signal and hazard warning lamps system (if equipped). Refer to LT- 9 4

.

• Rear wiper and washer system. Refer to WW-26

.

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

• Panic system. Refer to BL-37.

• Vehicle security system. Refer to BL-60

.

• IVIS (NATS) system. Refer to BL-116

.

• Headlamp, tail lamp, front fog lamp, auto light and battery saver control systems. Refer to LT- 5

, LT- 2 4, LT- 8 2,

LT- 4 9

or LT- 3 4.

• Front wiper and washer system. Refer to WW-3

.

• Rear window defogger system. Refer to GW-68

.

MAJOR COMPONENTS AND CONTROL SYSTEM

System Input Output

Remote keyless entry system Remote keyless entry receiver (keyfob)• All door locking actuators

• Back door opener actuator

• Turn signal lamps

Power door lock system• Front power door lock/unlock switch (LH, RH)

• All door switches

• Key switchAll door locking actuators

Power supply [ignition (IGN)/retained ac-

cessory power (RAP)] to power window

and sunroofIGN/RAP supplyPower supply to power window and

sunroof system

Power supply (BAT) to power window

and sunroofBattery power supplyPower supply to power window and

sunroof system

Panic alarm• Key switch

• Remote keyless entry receiver (keyfob)IPDM E/R

Auto light system• Optical sensor

• Combination switchIPDM E/R

Battery saver control• Ignition switch

• Combination switch

• Front door switch LH and RHIPDM E/R

Page 698 of 3061

BCM (BODY CONTROL MODULE)

BCS-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

BCS

N

O

P

Terminal and Reference Value for BCMINFOID:0000000003533600

Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value or waveform

(Approx.) Ignition

switchOperation or condition

1BR/WIgnition keyhole illumi-

nationOutput OFFDoor is locked (SW OFF) Battery voltage

Door is unlocked (SW ON) 0V

2SBCombination switch

input 5Input ONLighting, turn, wiper OFF

Wiper dial position 4

3G/YCombination switch

input 4Input ONLighting, turn, wiper OFF

Wiper dial position 4

4YCombination switch

input 3Input ONLighting, turn, wiper OFF

Wiper dial position 4

5G/BCombination switch

input 2

Input ONLighting, turn, wiper OFF

Wiper dial position 4

6VCombination switch

input 1

9Y/BRear window defogger

switchInput ONRear window defogger switch

ON0V

Rear window defogger switch

OFF5V

10 G Hazard lamp flash Input OFFON (opening or closing) 0V

OFF (other than above) Battery voltage

11 OIgnition switch (ACC

or ON)InputACC or

ONIgnition switch ACC or ON Battery voltage

12 R/L Front door switch RH Input OFFON (open) 0V

OFF (closed) Battery voltage

13 GR Rear door switch RH Input OFFON (open) 0V

OFF (closed) Battery voltage

15 L/WTire pressure warning

check connectorInput OFF — 5V

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Page 699 of 3061

BCS-12

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

18 PRemote keyless entry

receiver and optical

sensor (ground)Output OFF — 0V

19 V/WRemote keyless entry

receiver (power sup-

ply)Output OFF Ignition switch OFF

20 G/WRemote keyless entry

receiver signal (Sig-

nal)Input OFFStand-by (keyfob buttons re-

leased)

When remote keyless entry

receiver receives signal from

keyfob (keyfob buttons

pressed)

21 G NATS antenna amp. InputOFF →

ONIgnition switch (OFF → ON)Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then

return to battery voltage.

22 W/V BUS — —Ignition switch ON or power

window timer operates

23 G/OSecurity indicator

lampOutput OFFGoes OFF → illuminates (Ev-

ery 2.4 seconds)Battery voltage → 0V

25 BR NATS antenna amp. InputOFF →

ONIgnition switch (OFF → ON)Just after turning ignition switch

ON: Pointer of tester should

move for approx. 1 second, then

return to battery voltage.

26 Y/LRear wiper auto stop

switch 2Input ONRise up position (rear wiper

arm on stopper)0V

A Position (full clockwise stop

position)0V

Forward sweep (counterclock-

wise direction)Fluctuating

B Position (full counterclock-

wise stop position)Battery voltage

Reverse sweep (clockwise di-

rection)Fluctuating Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value or waveform

(Approx.) Ignition

switchOperation or condition

LIIA1893E

LIIA1894E

LIIA1895E

PIIA2344E

Page 700 of 3061

BCM (BODY CONTROL MODULE)

BCS-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

BCS

N

O

P

27 W/RCompressor ON sig-

nalInput ONA/C switch OFF 5V

A/C switch ON 0V

28 L/R Front blower monitor Input ONFront blower motor OFF Battery voltage

Front blower motor ON 0V

29 W/B Hazard switch Input OFFON 0V

OFF 5V

30 Y/BR Glass hatch switch Input OFFGlass hatch switch released

→ Glass hatch switch pressedBattery voltage → 0V

32 R/GCombination switch

output 5Output ONLighting, turn, wiper OFF

Wiper dial position 4

33 R/YCombination switch

output 4Output ONLighting, turn, wiper OFF

Wiper dial position 4

34 LCombination switch

output 3Output ONLighting, turn, wiper OFF

Wiper dial position 4

35 O/BCombination switch

output 2

Output ONLighting, turn, wiper OFF

Wiper dial position 4

36 R/WCombination switch

output 1

37 B/RKey switch and key

lock solenoidInput OFFKey inserted Battery voltage

Key removed 0V

38 W/L Ignition switch (ON) Input ON — Battery voltage

39 L CAN-H — — — —

40 P CAN-L — — — —

42 GRGlass hatch ajar

switchInput ONGlass hatch open 0

Glass hatch closed Battery

43 R/BBack door latch (door

ajar switch)Input OFFON (open) 0V

OFF (closed) Battery voltage Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value or waveform

(Approx.) Ignition

switchOperation or condition

SKIA5291E

SKIA5292E

SKIA5291E

SKIA5292E

Page 704 of 3061

BCM (BODY CONTROL MODULE)

BCS-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

BCS

N

O

P

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

ITEMS OF EACH PART

NOTE:

CONSULT-II will only display systems the vehicle possesses.

WORK SUPPORT

BCM diagnostic

test itemDiagnostic mode Content

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM for

setting the status suitable for required operation, input/output signals are received

from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT

MNTRThe results of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

System and itemCONSULT-II

displayDiagnostic test mode (Inspection by part)

WORK

SUPPORTSELF−

DIAG RE-

SULTSCAN DIAG

SUPPORT

MNTRDATA

MONITORECU

PA R T

NUMBERAC-

TIVE

TESTCON-

FIGU-

RATION

BCM BCM×× × × ×

Power door lock system DOOR LOCK×××

Rear defoggerREAR

DEFOGGER××

Warning chime BUZZER××

Room lamp timer INT LAMP×××

Remote keyless entry

systemMULTI REMOTE

ENT×××

Headlamp HEAD LAMP×××

Wiper (front/rear) WIPER×××

Turn signal lamp

Hazard lampFLASHER××

Blower fan switch signal

Air conditioner switch

signalAIR

CONDITIONER×

Combination switch COMB SW×

IVIS (NATS) IMMU××

Interior lamp battery

saverBATTERY SAV-

ER×××

Back door TRUNK××

Theft alarm THEFT ALM×××

Retained accessory

power controlRETAINED PWR×××

Oil pressure switch SIGNAL BUFFER××

Low tire pressure moni-

tor systemAIR PRESSURE

MONITOR×× × ×

Panic alarm PANIC ALARM×

Page 711 of 3061

BCS-24

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

14. Touch "OK" on "WRITE CONFIGURATION" screen.

WRITE CONFIGURATION is completed.

BCMINFOID:0000000003533605

REMOVAL AND INSTALLATION

NOTE:

If possible, before removing BCM, retrieve current BCM configuration to use for reference when configuring

brand-new BCM after installation. Refer to BCS-18, "

Configuration".

Removal

1. Disconnect battery negative terminal.

2. Remove instrument lower panel LH. Refer to IP-10

.

3. Remove knee protector. IP-10

.

4. Disconnect BCM electrical connectors.

5. Remove BCM screws and remove BCM.

Installation

Installation is in the reverse order of removal.

NOTE:

• When replacing BCM, it must be configured. Refer to BCS-18, "

Configuration".

• When replacing BCM, perform initialization of NATS system and registration of all NATS ignition key IDs.

Refer to BL-116

.

• When replacing BCM, perform ID registration procedure of low tire pressure warning system. Refer to WT-

12, "ID Registration Procedure".

LKIA0400E

LEIA0068E

Page 712 of 3061

BL-1

BODY

C

D

E

F

G

H

J

K

L

M

SECTION BL

A

B

BL

N

O

P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for work ...................................................3

PREPARATION ...................................................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .......................................................................

5

Work Flow .................................................................5

Generic Squeak and Rattle Troubleshooting ............7

Diagnostic Worksheet ...............................................9

HOOD .................................................................11

Fitting Adjustment ...................................................11

Removal and Installation of Hood Assembly ...........12

Removal and Installation of Hood Lock Control ......13

Hood Lock Control Inspection .................................14

POWER DOOR LOCK SYSTEM ........................15

Component Parts and Harness Connector Loca-

tion ..........................................................................

15

System Description .................................................15

Schematic ...............................................................18

Wiring Diagram - D/LOCK - .....................................19

Terminal and Reference Value for BCM .................23

Work Flow ...............................................................23

CONSULT-II Function (BCM) ..................................24

Trouble Diagnosis Symptom Chart .........................25

BCM Power Supply and Ground Circuit Inspection

....

25

Door Switch Check ..................................................25

Key Switch (Insert) Check .......................................27

Door Lock/Unlock Switch Check .............................28

Glass Hatch Switch Circuit Inspection ....................30

Front Door Lock Assembly LH (Actuator) Check ....32

Front Door Lock Actuator RH Check .......................32

Rear Door Lock Actuator RH/LH Check ..................33

Glass Hatch Lock Actuator Check ...........................34

Front Door Lock Assembly LH (Key Cylinder

Switch) Check ..........................................................

35

REMOTE KEYLESS ENTRY SYSTEM .............37

Component Parts and Harness Connector Loca-

tion ...........................................................................

37

System Description ..................................................37

CAN Communication System Description ...............40

Schematic ................................................................41

Wiring Diagram - KEYLES - ....................................42

Terminal and Reference Value for BCM ..................44

Terminal and Reference Value for IPDM E/R ..........44

CONSULT-II Function (BCM) ..................................45

CONSULT-II Start Procedure ..................................45

CONSULT-II Application Item ..................................45

Trouble Diagnosis Procedure ..................................47

BCM Power Supply and Ground Circuit Inspection

....

47

Trouble Diagnosis ....................................................47

Key Switch (Insert) Check .......................................49

Door Switch Check ..................................................49

Keyfob Battery and Function Check ........................52

Remote Keyless Entry Receiver System Inspec-

tion ...........................................................................

53

ACC Power Check ...................................................54

IPDM E/R Operation Check .....................................54

Check Hazard Function ...........................................55

Check Horn Function ...............................................55

Check Headlamp Function ......................................55

Check Map Lamp Illumination Function ..................56

ID Code Entry Procedure ........................................56

Keyfob Battery Replacement ...................................59

VEHICLE SECURITY (THEFT WARNING)

SYSTEM ............................................................

60

Component Parts and Harness Connector Loca-

tion ...........................................................................

60

System Description ..................................................61