radiator INFINITI QX56 2007 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1180 of 3061

TROUBLE DIAGNOSIS

EC-97

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

13. Intake valve timing control position

sensor (bank 1) (view with engine

cover and intake air duct removed)14. Intake valve timing control solenoid

valve (bank 2) (view with engine cov-

er and intake air duct removed)15. Drive belt (view with engine cover

and intake air duct removed)

16. Radiator hose (view with engine cov-

er and intake air duct removed)17. Intake valve timing control solenoid

valve (bank 1) (view with engine cov-

er and intake air duct removed)

1. Knock sensor (bank 1) (view with en-

gine removed)2. Knock sensor (bank 2) (view with en-

gine removed)3. Battery current sensor

4. Power steering pressure sensor 5. Power steering fluid reservoir 6. Intake manifold

7. Engine coolant temperature sensor 8. Ignition coils (with power transistor) 9. Ignition coil (with power transistor)

10. Injector harness connectors (bank 2) 11. Injector harness connectors (bank 1)

BBIA0774E

Page 1239 of 3061

EC-156

< SERVICE INFORMATION >

DTC P0011, P0021 IVT CONTROL

Refer to EC-143, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK INTAKE VALVE TIMING CONTROL POSITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect intake valve timing control position sensor harness connector.

2. Turn ignition switch ON.

3. Check voltage between intake valve timing control position sen-

sor terminal 3 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between intake valve timing control position sensor and ECM

• Harness for open or short between intake valve timing control position sensor and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

BBIA0354E

1. Intake valve timing control position

sensor (bank 2)2. Intake valve timing control solenoid

valve (bank 2)3. Drive belt

4. Radiator hose 5. Intake valve timing control solenoid

valve (bank 1)6. Intake valve timing control position

sensor (bank 1)

Voltage: Battery voltage

BBIA0771E

SEF509Y

Page 1241 of 3061

EC-158

< SERVICE INFORMATION >

DTC P0011, P0021 IVT CONTROL

3. Turn ignition switch ON.

4. Check voltage between intake valve timing control solenoid

valve terminal 2 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 11.

NG >> GO TO 10.

10.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between intake valve timing control solenoid valve and IPDM E/R.

>> Repair open circuit or short to ground or short to power in harness or connectors.

11 .CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN

AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between the following;

ECM terminal 10 and intake valve timing control solenoid valve (Bank 1) terminal 1 or

ECM terminal 11 and intake valve timing control solenoid valve (Bank 2) terminal 1.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 12.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

12.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE

1. Intake valve timing control position

sensor (bank 2)2. Intake valve timing control solenoid

valve (bank 2)3. Drive belt

4. Radiator hose 5. Intake valve timing control solenoid

valve (bank 1)6. Intake valve timing control position

sensor (bank 1)

Voltage: Battery voltage

BBIA0771E

PBIB0192E

Continuity should exist.

Page 1265 of 3061

EC-182

< SERVICE INFORMATION >

DTC P0075, P0081 IVT CONTROL SOLENOID VALVE

: Average voltage for pulse signal (Actual pulse signal can be confirmed by oscilloscope.)

Diagnosis ProcedureINFOID:0000000003531677

1.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect intake valve timing control solenoid valve harness connector.

3. Turn ignition switch ON.

TER-

MI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

11 L GIntake valve timing control

solenoid valve (Bank 2)[Engine is running]

•Warm-up condition

• Idle speedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

•Warm-up condition

• Engine speed: 2,000rpm7 - 12V

111 W / BECM relay

(Self shut-off)[Engine is running]

[Ignition switch: OFF]

• For a few seconds after turning ignition

switch OFF0 - 1.5V

[Ignition switch: OFF]

• More than a few seconds after turning igni-

tion switch OFFBATTERY VOLTAGE

(11 - 14V)

11 9

120BR

BRPower supply for ECM[Ignition switch: ON]BATTERY VOLTAGE

(11 - 14V)

PBIB1790E

1. Intake valve timing control position

sensor (bank 2)2. Intake valve timing control solenoid

valve (bank 2)3. Drive belt

4. Radiator hose 5. Intake valve timing control solenoid

valve (bank 1)6. Intake valve timing control position

sensor (bank 1)

BBIA0771E

Page 1301 of 3061

EC-218

< SERVICE INFORMATION >

DTC P0125 ECT SENSOR

4. Start engine and run it for 65 minutes at idle speed.

If “COOLAN TEMP/S” increases to more than 31°C (88°F)

within 65 minutes, stop engine because the test result will

be OK.

5. If 1st trip DTC is detected, go to EC-218, "

Diagnosis Procedure"

.

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000003531722

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer to EC-143, "

Ground Inspection" .

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Refer to EC-218, "

Component Inspection" .

OK or NG

OK >> GO TO 3.

NG >> Replace engine coolant temperature sensor.

3.CHECK THERMOSTAT OPERATION

When the engine is cold [lower than 70°C (158°F)] condition, grasp lower radiator hose and confirm the engine

coolant does not flow.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace thermostat. Refer to CO-20

.

4.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

Refer to EC-207, "

Wiring Diagram" .

>>INSPECTION END

Component InspectionINFOID:0000000003531723

ENGINE COOLANT TEMPERATURE SENSOR

SEF174Y

BBIA0354E

Page 1429 of 3061

EC-346

< SERVICE INFORMATION >

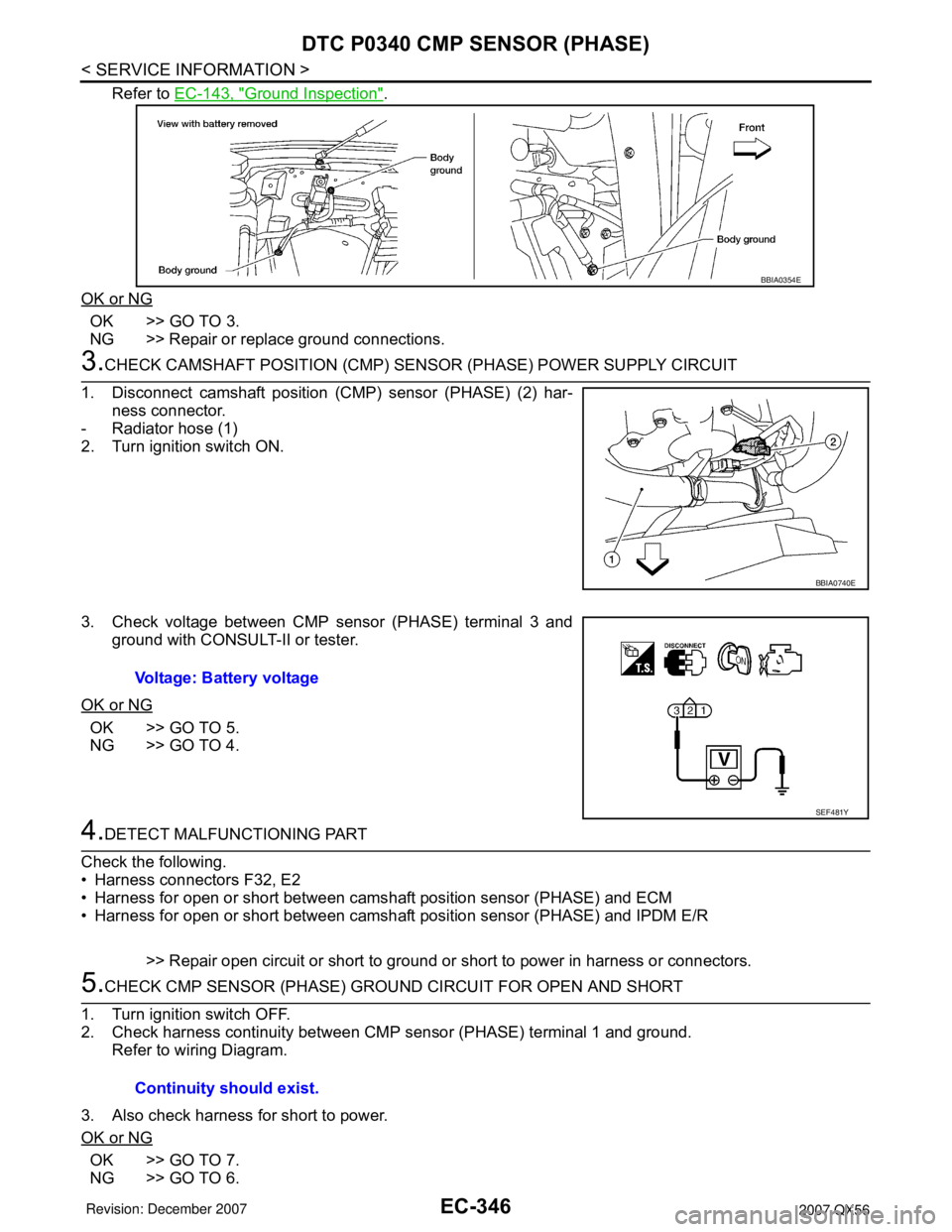

DTC P0340 CMP SENSOR (PHASE)

Refer to EC-143, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK CAMSHAFT POSITION (CMP) SENSOR (PHASE) POWER SUPPLY CIRCUIT

1. Disconnect camshaft position (CMP) sensor (PHASE) (2) har-

ness connector.

- Radiator hose (1)

2. Turn ignition switch ON.

3. Check voltage between CMP sensor (PHASE) terminal 3 and

ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors F32, E2

• Harness for open or short between camshaft position sensor (PHASE) and ECM

• Harness for open or short between camshaft position sensor (PHASE) and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK CMP SENSOR (PHASE) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between CMP sensor (PHASE) terminal 1 and ground.

Refer to wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

BBIA0354E

BBIA0740E

Voltage: Battery voltage

SEF481Y

Continuity should exist.

Page 1545 of 3061

EC-462

< SERVICE INFORMATION >

DTC P1140, P1145 IVT CONTROL POSITION SENSOR

2. Turn ignition switch ON.

3. Check voltage between intake valve timing control position sen-

sor terminal 3 and ground with CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between intake valve timing control position sensor and IPDM E/R

• Harness for open or short between intake valve timing control position sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK INTAKE VALVE TIMING CONTROL POSITION SENSOR GROUND CIRCUIT FOR OPEN AND

SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between intake valve timing control position sensor terminal 1 and ground.

Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

1. Intake valve timing control position

sensor (bank 2)2. Intake valve timing control solenoid

valve (bank 2)3. Drive belt

4. Radiator hose 5. Intake valve timing control solenoid

valve (bank 1)6. Intake valve timing control position

sensor (bank 1)

Voltage: Battery voltage

BBIA0771E

SEF509Y

Continuity should exist.

Page 1553 of 3061

EC-470

< SERVICE INFORMATION >

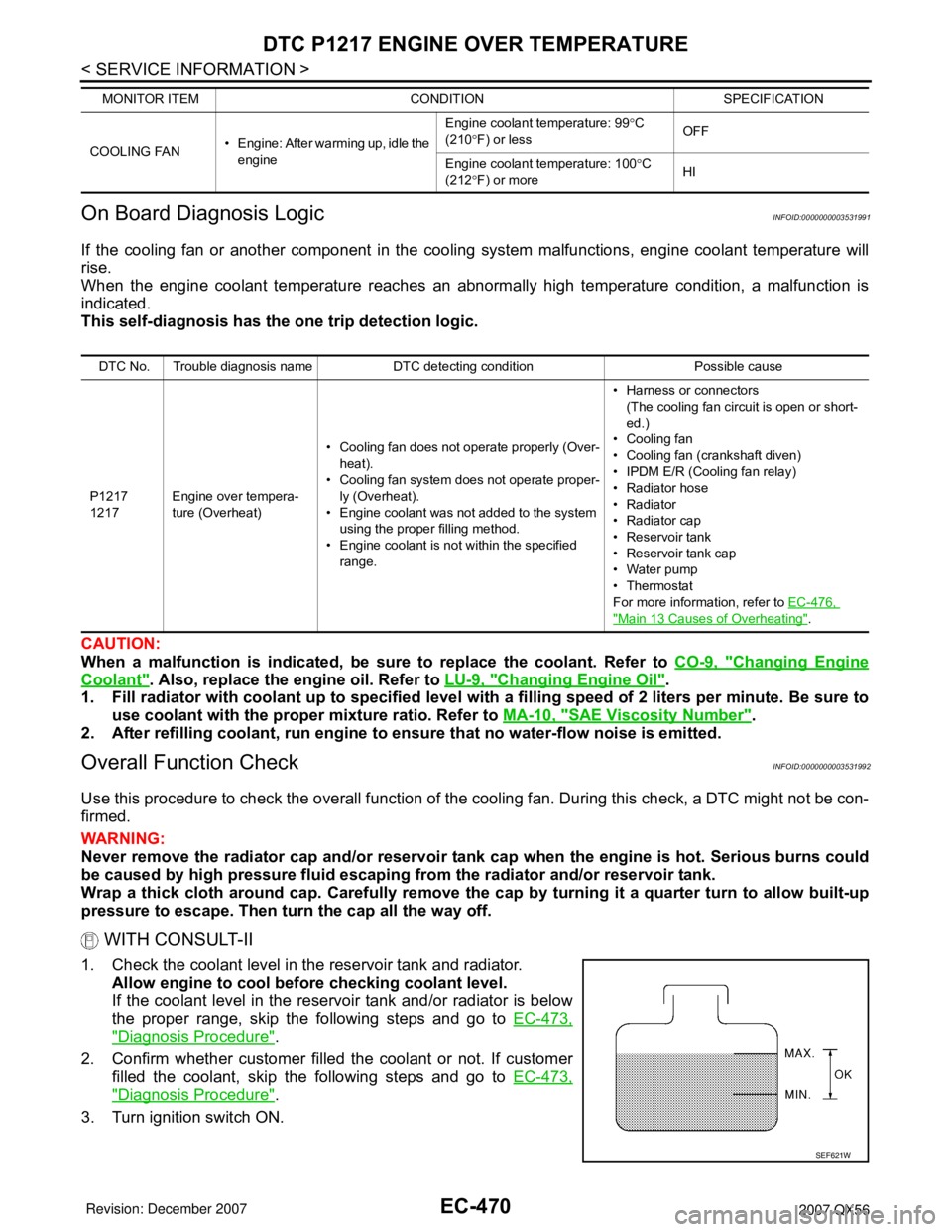

DTC P1217 ENGINE OVER TEMPERATURE

On Board Diagnosis Logic

INFOID:0000000003531991

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

This self-diagnosis has the one trip detection logic.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant. Refer to CO-9, "

Changing Engine

Coolant". Also, replace the engine oil. Refer to LU-9, "Changing Engine Oil".

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA-10, "

SAE Viscosity Number".

2. After refilling coolant, run engine to ensure that no water-flow noise is emitted.

Overall Function CheckINFOID:0000000003531992

Use this procedure to check the overall function of the cooling fan. During this check, a DTC might not be con-

firmed.

WARNING:

Never remove the radiator cap and/or reservoir tank cap when the engine is hot. Serious burns could

be caused by high pressure fluid escaping from the radiator and/or reservoir tank.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up

pressure to escape. Then turn the cap all the way off.

WITH CONSULT-II

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-473,

"Diagnosis Procedure".

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-473,

"Diagnosis Procedure".

3. Turn ignition switch ON.

COOLING FAN• Engine: After warming up, idle the

engineEngine coolant temperature: 99°C

(210°F) or lessOFF

Engine coolant temperature: 100°C

(212°F) or moreHI MONITOR ITEM CONDITION SPECIFICATION

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1217

1217Engine over tempera-

ture (Overheat)• Cooling fan does not operate properly (Over-

heat).

• Cooling fan system does not operate proper-

ly (Overheat).

• Engine coolant was not added to the system

using the proper filling method.

• Engine coolant is not within the specified

range.• Harness or connectors

(The cooling fan circuit is open or short-

ed.)

• Cooling fan

• Cooling fan (crankshaft diven)

• IPDM E/R (Cooling fan relay)

•Radiator hose

•Radiator

•Radiator cap

• Reservoir tank

• Reservoir tank cap

• Water pump

•Thermostat

For more information, refer to EC-476,

"Main 13 Causes of Overheating".

SEF621W

Page 1554 of 3061

DTC P1217 ENGINE OVER TEMPERATURE

EC-471

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

4. Perform “COOLING FAN” in “ACTIVE TEST” mode with CON-

SULT-II.

5. If the results are NG, go to EC-473, "

Diagnosis Procedure".

WITH GST

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-473,

"Diagnosis Procedure".

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-473,

"Diagnosis Procedure".

3. Disconnect engine coolant temperature sensor harness connec-

tor.

4. Connect 150Ω resistor to engine coolant temperature sensor

harness connector.

5. Start engine and make sure that cooling fan operates.

CAUTION:

Be careful not to overheat engine.

6. If NG, go to EC-473, "

Diagnosis Procedure".

SEF646X

SEF621W

SEF882V

Page 1557 of 3061

EC-474

< SERVICE INFORMATION >

DTC P1217 ENGINE OVER TEMPERATURE

OK (Without CONSULT-II)>>GO TO 3.

NG >> Check cooling fan (crankshaft driven). Refer to CO-16, "

Removal and Installation (Crankshaft

Driven Type)".

2.CHECK COOLING FAN MOTOR OPERATION

With CONSULT-II

1. Start engine and let it idle.

2. Select “COOLING FAN” in “ACTIVE TEST” mode with CON-

SULT-II.

3. Make sure that cooling fan operates.

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control circuit. (Go to "PROCEDURE

A".)

3.CHECK COOLING FAN MOTOR OPERATION

Without CONSULT-II

1. Disconnect engine coolant temperature sensor harness connector.

2. Connect 150Ω resistor to engine coolant temperature sensor harness connector.

3. Start engine and let it idle.

4. Make sure that cooling fan operates.

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control circuit. (Go to "PROCEDURE

A".)

4.CHECK COOLING SYSTEM FOR LEAK

Refer to CO-9, "

Inspection".

OK or NG

OK >> GO TO 5.

NG >> Check the following for leak.

•Hose

• Radiator

• Radiator cap

• Water pump

• Reservoir tank

5.CHECK COMPONENT PARTS

Check the following.

• RESERVOIR TANK CAP (Refer to CO-9, "

Inspection".)

• Thermostat. (Refer to CO-20

.)

• Engine coolant temperature sensor. (Refer to EC-209, "

Component Inspection".)

OK or NG

OK >> GO TO 7.

NG >> Replace malfunctioning component.

6.CHECK MAIN 13 CAUSES

If the cause cannot be isolated, go to EC-476, "

Main 13 Causes of Overheating".

SEF646X

SEF882V