cooling INFINITI QX56 2007 Factory Manual PDF

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1209 of 3061

EC-126

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

COOLING FAN• Engine: After warming up, idle the

engine

• Air conditioner switch: OFFEngine coolant temperature: 99°C

(210°F) or lessOFF

Engine coolant temperature: 100°C

(212°F) or moreHI

HO2S2 HTR (B1)

HO2S2 HTR (B2)• Engine speed: Below 3,600 rpm after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and

at idle for 1 minute under no loadON

• Engine speed: Above 3,600 rpm OFF

I/P PULLY SPD • Vehicle speed: More than 20 km/h (12 MPH)Almost the same speed as the

tachometer indication

VEHICLE SPEED• Turn drive wheels and compare CONSULT-II value with the speedometer

indication.Almost the same speed as the

speedometer indication

TRVL AFTER MIL • Ignition switch: ONVehicle has traveled after MIL has

turned ON.0 - 65,535 km

(0 - 40,723 mile)

A/F S1 HTR (B1)

A/F S1 HTR (B2)• Engine: After warming up, idle the engine 4 - 100%

AC PRESS SEN• Engine: Idle

• Both A/C switch and blower fan switch: ON (Compressor operates.)1.0 - 4.0V

VHCL SPEED SE• Turn drive wheels and compare CONSULT-II value with the speedometer

indication.Almost the same speed as the

speedometer indication

SET VHCL SPD • Engine: Running ASCD: Operating.The preset vehicle speed is dis-

played.

MAIN SW • Ignition switch: ONMAIN switch: Pressed ON

MAIN switch: Released OFF

CANCEL SW • Ignition switch: ONCANCEL switch: Pressed ON

CANCEL switch: Released OFF

RESUME/ACC SW • Ignition switch: ONRESUME/ACCELERATE switch:

PressedON

RESUME/ACCELERATE switch: Re-

leasedOFF

SET SW • Ignition switch: ONSET/COAST switch: Pressed ON

SET/COAST switch: Released OFF

DIST SW • Ignition switch: ONDISTANCE switch: Pressed ON

DISTANCE switch: Released OFF

BRAKE SW1 • Ignition switch: ONBrake pedal: Fully released ON

Brake pedal: Slightly depressed OFF

BRAKE SW2 • Ignition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

CRUISE LAMP • Ignition switch: ONMAIN switch: Pressed at the 1st time

→ at the 2nd timeON → OFF

SET LAMP• MAIN switch: ON

• Vehicle speed: Between 40 km/h

(25 MPH) and 144 km/h (89

MPH)ASCD: Operating ON

ASCD: Not operating OFF

ALT DUTY • Engine: Idle 0 - 80%

BAT CUR SEN• Engine speed: Idle

• Battery: Fully charged*

2

• Selector lever: P or N

• Air conditioner switch: OFF

•No loadApprox. 2,600 - 3,500mV MONITOR ITEM CONDITION SPECIFICATION

Page 1289 of 3061

EC-206

< SERVICE INFORMATION >

DTC P0117, P0118 ECT SENSOR

DTC Confirmation Procedure

INFOID:0000000003531706

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go to EC-207, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Detected items Engine operating condition in fail-safe mode

Engine coolant temper-

ature sensor circuitEngine coolant temperature will be determined by ECM based on the time after turning ignition switch ON

or START.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided

(CONSULT-II display)

Just as ignition switch is turned ON or START 40°C (104°F)

More than approx. 4 minutes after ignition ON or

START80°C (176°F)

Except as shown above40 - 80°C (104 - 176°F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling fan operates while

engine is running.

SEF058Y

Page 1512 of 3061

DTC P0500 VSS

EC-429

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0500 VSS

DescriptionINFOID:0000000003531931

NOTE:

•If DTC P0500 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-145

.

•If DTC P0500 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer

to EC-147

.

The vehicle speed signal is sent to the combination meter from the “ABS actuator and electric unit (control

unit)” by CAN communication line. The c combination meter then sends a signal to the ECM by CAN commu-

nication line.

On Board Diagnosis LogicINFOID:0000000003531932

FA I L - S A F E M O D E

When the malfunction is detected, the ECM enters fail-safe mode.

DTC Confirmation ProcedureINFOID:0000000003531933

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Steps 1 and 2 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-II

1. Start engine (VDC switch OFF).

2. Read “VHCL SPEED SE” in “DATA MONITOR” mode with CONSULT-II. The vehicle speed on CONSULT-

II should exceed 10 km/h (6 MPH) when rotating wheels with suitable gear position.

If NG, go to EC-430, "

Diagnosis Procedure".

If OK, go to following step.

3. Select “DATA MONITOR” mode with CONSULT-II.

4. Warm engine up to normal operating temperature.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0500

0500Vehicle speed sensorThe almost 0 km/h (0 MPH) signal from

vehicle speed sensor is sent to ECM even

when vehicle is being driven.• Harness or connectors

(The CAN communication line is open or short-

ed)

• Harness or connectors

(The vehicle speed signal circuit is open or

shorted)

• Wheel sensor

• Combination meter

• ABS actuator and electric unit (control unit)

Detected items Engine operating condition in fail-safe mode

Vehicle speed sensorWhen the fail-safe system for vehicle speed sensor is activated, the cooling fan operates (High) while

engine is running.

Page 1514 of 3061

DTC P0506 ISC SYSTEM

EC-431

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0506 ISC SYSTEM

DescriptionINFOID:0000000003531936

NOTE:

If DTC P0506 is displayed with other DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified level through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric throttle control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idling speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is the lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

On Board Diagnosis LogicINFOID:0000000003531937

DTC Confirmation ProcedureINFOID:0000000003531938

NOTE:

• If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

•If the target idle speed is out of the specified value, perform EC-78, "

Idle Air Volume Learning" ,

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-645

.

TESTING CONDITION:

•Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

•Always perform the test at a temperature above −10°C (14°F).

WITH CONSULT-II

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON again and select “DATA MONITOR”

mode with CONSULT-II.

5. Start engine and run it for at least 1 minute at idle speed.

6. If 1st trip DTC is detected, go to EC-431, "

Diagnosis Procedure"

.

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000003531939

1.CHECK INTAKE AIR LEAK

1. Start engine and let it idle.

2. Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK >> GO TO 2.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0506

0506Idle speed control system

RPM lower than expectedThe idle speed is less than the target idle speed

by 100 rpm or more.• Electric throttle control actuator

• Intake air leak

SEF174Y

Page 1516 of 3061

DTC P0507 ISC SYSTEM

EC-433

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P0507 ISC SYSTEM

DescriptionINFOID:0000000003531940

NOTE:

If DTC P0507 is displayed with other DTC, first perform the trouble diagnosis for the other DTC.

The ECM controls the engine idle speed to a specified level through the fine adjustment of the air, which is let

into the intake manifold, by operating the electric throttle control actuator. The operating of the throttle valve is

varied to allow for optimum control of the engine idling speed. The crankshaft position sensor (POS) detects

the actual engine speed and sends a signal to the ECM.

The ECM controls the electric throttle control actuator so that the engine speed coincides with the target value

memorized in the ECM. The target engine speed is the lowest speed at which the engine can operate steadily.

The optimum value stored in the ECM is determined by taking into consideration various engine conditions,

such as during warming up, deceleration, and engine load (air conditioner, power steering and cooling fan

operation, etc.).

On Board Diagnosis LogicINFOID:0000000003531941

DTC Confirmation ProcedureINFOID:0000000003531942

NOTE:

• If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

•If the target idle speed is out of the specified value, perform EC-78, "

Idle Air Volume Learning" ,

before conducting DTC Confirmation Procedure. For the target idle speed, refer to the EC-645

.

TESTING CONDITION:

•Before performing the following procedure, confirm that battery voltage is more than 11V at idle.

•Always perform the test at a temperature above −10°C (14°F).

WITH CONSULT-II

1. Open engine hood.

2. Start engine and warm it up to normal operating temperature.

3. Turn ignition switch OFF and wait at least 10 seconds.

4. Turn ignition switch ON again and select “DATA MONITOR”

mode with CONSULT-II.

5. Start engine and run it for at least 1 minute at idle speed.

6. If 1st trip DTC is detected, go to EC-433, "

Diagnosis Procedure"

.

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnosis ProcedureINFOID:0000000003531943

1.CHECK PCV HOSE CONNECTION

Confirm that PCV hose is connected correctly.

OK or NG

OK >> GO TO 2.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0507

0507Idle speed control system

RPM higher than expectedThe idle speed is more than the target idle

speed by 200 rpm or more.• Electric throttle control actuator

• Intake air leak

• PCV system

SEF174Y

Page 1552 of 3061

DTC P1217 ENGINE OVER TEMPERATURE

EC-469

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

DTC P1217 ENGINE OVER TEMPERATURE

DescriptionINFOID:0000000003531989

SYSTEM DESCRIPTION

NOTE:

•If DTC P1217 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-145

.

•If DTC P1217 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer

to EC-147

.

Cooling Fan Control

*1: The ECM determines the start signal status by the signals of engine speed and battery voltage.

*2: This signal is sent to ECM through CAN communication line.

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The control system has 2-step control [HI/OFF].

Cooling Fan Operation

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003531990

Specification data are reference values.

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

1

Cooling fan

controlIPDM E/R

(Cooling fan relay) Battery

Battery voltage*

1

Wheel sensor

Vehicle speed*2

Engine coolant temperature sensor Engine coolant temperature

Air conditioner switch

Air conditioner ON signal*

2

Refrigerant pressure sensor Refrigerant pressure

PBIB2060E

MONITOR ITEM CONDITION SPECIFICATION

AIR COND SIG• Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

Page 1553 of 3061

EC-470

< SERVICE INFORMATION >

DTC P1217 ENGINE OVER TEMPERATURE

On Board Diagnosis Logic

INFOID:0000000003531991

If the cooling fan or another component in the cooling system malfunctions, engine coolant temperature will

rise.

When the engine coolant temperature reaches an abnormally high temperature condition, a malfunction is

indicated.

This self-diagnosis has the one trip detection logic.

CAUTION:

When a malfunction is indicated, be sure to replace the coolant. Refer to CO-9, "

Changing Engine

Coolant". Also, replace the engine oil. Refer to LU-9, "Changing Engine Oil".

1. Fill radiator with coolant up to specified level with a filling speed of 2 liters per minute. Be sure to

use coolant with the proper mixture ratio. Refer to MA-10, "

SAE Viscosity Number".

2. After refilling coolant, run engine to ensure that no water-flow noise is emitted.

Overall Function CheckINFOID:0000000003531992

Use this procedure to check the overall function of the cooling fan. During this check, a DTC might not be con-

firmed.

WARNING:

Never remove the radiator cap and/or reservoir tank cap when the engine is hot. Serious burns could

be caused by high pressure fluid escaping from the radiator and/or reservoir tank.

Wrap a thick cloth around cap. Carefully remove the cap by turning it a quarter turn to allow built-up

pressure to escape. Then turn the cap all the way off.

WITH CONSULT-II

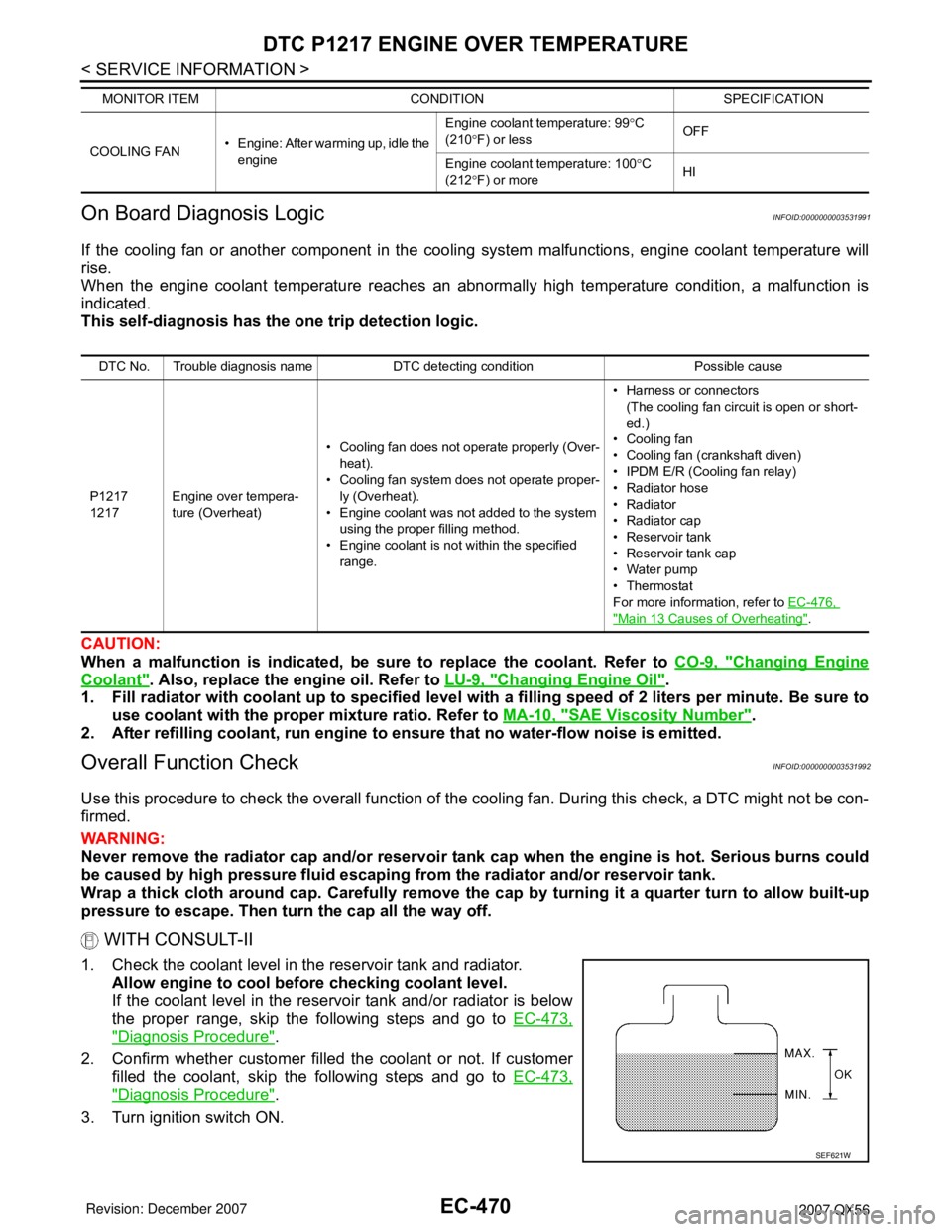

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-473,

"Diagnosis Procedure".

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-473,

"Diagnosis Procedure".

3. Turn ignition switch ON.

COOLING FAN• Engine: After warming up, idle the

engineEngine coolant temperature: 99°C

(210°F) or lessOFF

Engine coolant temperature: 100°C

(212°F) or moreHI MONITOR ITEM CONDITION SPECIFICATION

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P1217

1217Engine over tempera-

ture (Overheat)• Cooling fan does not operate properly (Over-

heat).

• Cooling fan system does not operate proper-

ly (Overheat).

• Engine coolant was not added to the system

using the proper filling method.

• Engine coolant is not within the specified

range.• Harness or connectors

(The cooling fan circuit is open or short-

ed.)

• Cooling fan

• Cooling fan (crankshaft diven)

• IPDM E/R (Cooling fan relay)

•Radiator hose

•Radiator

•Radiator cap

• Reservoir tank

• Reservoir tank cap

• Water pump

•Thermostat

For more information, refer to EC-476,

"Main 13 Causes of Overheating".

SEF621W

Page 1554 of 3061

DTC P1217 ENGINE OVER TEMPERATURE

EC-471

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

4. Perform “COOLING FAN” in “ACTIVE TEST” mode with CON-

SULT-II.

5. If the results are NG, go to EC-473, "

Diagnosis Procedure".

WITH GST

1. Check the coolant level in the reservoir tank and radiator.

Allow engine to cool before checking coolant level.

If the coolant level in the reservoir tank and/or radiator is below

the proper range, skip the following steps and go to EC-473,

"Diagnosis Procedure".

2. Confirm whether customer filled the coolant or not. If customer

filled the coolant, skip the following steps and go to EC-473,

"Diagnosis Procedure".

3. Disconnect engine coolant temperature sensor harness connec-

tor.

4. Connect 150Ω resistor to engine coolant temperature sensor

harness connector.

5. Start engine and make sure that cooling fan operates.

CAUTION:

Be careful not to overheat engine.

6. If NG, go to EC-473, "

Diagnosis Procedure".

SEF646X

SEF621W

SEF882V

Page 1556 of 3061

DTC P1217 ENGINE OVER TEMPERATURE

EC-473

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Diagnosis ProcedureINFOID:0000000003531994

1.CHECK COOLING FAN (CRANKSHAFT DRIVEN) OPERATION

1. Start engine and let it idle.

2. Make sure that cooling fan (crankshaft driven) operates normally.

OK or NG

OK (With CONSULT-II)>>GO TO 2.

AWBWA0160G

Page 1557 of 3061

EC-474

< SERVICE INFORMATION >

DTC P1217 ENGINE OVER TEMPERATURE

OK (Without CONSULT-II)>>GO TO 3.

NG >> Check cooling fan (crankshaft driven). Refer to CO-16, "

Removal and Installation (Crankshaft

Driven Type)".

2.CHECK COOLING FAN MOTOR OPERATION

With CONSULT-II

1. Start engine and let it idle.

2. Select “COOLING FAN” in “ACTIVE TEST” mode with CON-

SULT-II.

3. Make sure that cooling fan operates.

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control circuit. (Go to "PROCEDURE

A".)

3.CHECK COOLING FAN MOTOR OPERATION

Without CONSULT-II

1. Disconnect engine coolant temperature sensor harness connector.

2. Connect 150Ω resistor to engine coolant temperature sensor harness connector.

3. Start engine and let it idle.

4. Make sure that cooling fan operates.

OK or NG

OK >> GO TO 4.

NG >> Check cooling fan control circuit. (Go to "PROCEDURE

A".)

4.CHECK COOLING SYSTEM FOR LEAK

Refer to CO-9, "

Inspection".

OK or NG

OK >> GO TO 5.

NG >> Check the following for leak.

•Hose

• Radiator

• Radiator cap

• Water pump

• Reservoir tank

5.CHECK COMPONENT PARTS

Check the following.

• RESERVOIR TANK CAP (Refer to CO-9, "

Inspection".)

• Thermostat. (Refer to CO-20

.)

• Engine coolant temperature sensor. (Refer to EC-209, "

Component Inspection".)

OK or NG

OK >> GO TO 7.

NG >> Replace malfunctioning component.

6.CHECK MAIN 13 CAUSES

If the cause cannot be isolated, go to EC-476, "

Main 13 Causes of Overheating".

SEF646X

SEF882V