fuel filter INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 8 of 3061

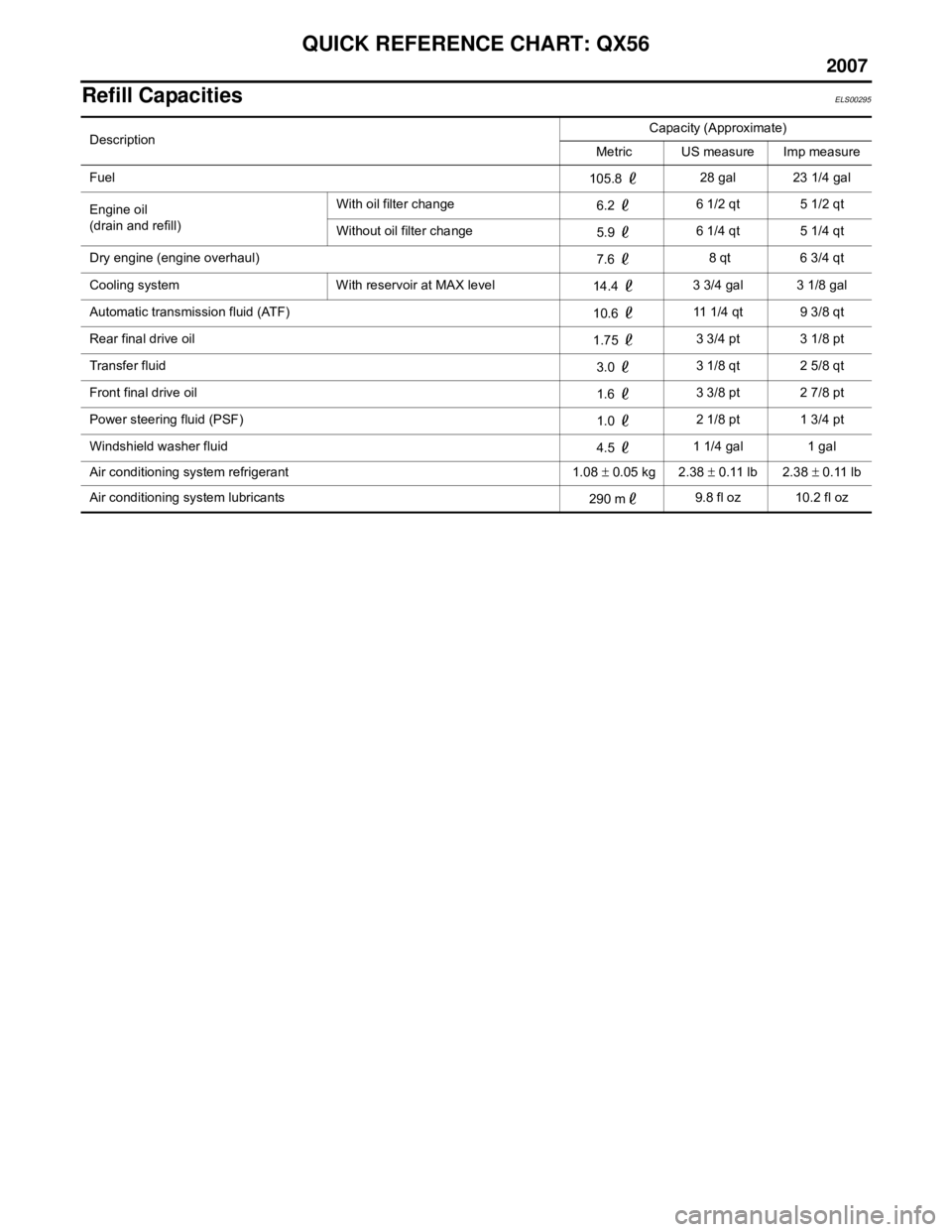

QUICK REFERENCE CHART: QX56

2007

Refill CapacitiesELS00295

DescriptionCapacity (Approximate)

Metric US measure Imp measure

Fuel 105.8 28 gal 23 1/4 gal

Engine oil

(drain and refill) With oil filter change

6.2 6 1/2 qt 5 1/2 qt

Without oil filter change 5.9 6 1/4 qt 5 1/4 qt

Dry engine (engine overhaul) 7.6 8 qt 6 3/4 qt

Cooling system With reservoir at MAX level 14.4 3 3/4 gal 3 1/8 gal

Automatic transmission fluid (ATF) 10.6 11 1/4 qt 9 3/8 qt

Rear final drive oil 1.75 3 3/4 pt 3 1/8 pt

Transfer fluid 3.0 3 1/8 qt 2 5/8 qt

Front final drive oil 1.6 3 3/8 pt 2 7/8 pt

Power steering fluid (PSF) 1.0 2 1/8 pt 1 3/4 pt

Windshield washer fluid 4.5 1 1/4 gal 1 gal

Air conditioning system refrigerant 1.08 ± 0.05 kg 2.38 ± 0.11 lb 2.38 ± 0.11 lb

Air conditioning system lubricants 290 m9.8 fl oz 10.2 fl oz

Page 1025 of 3061

DI-14

< SERVICE INFORMATION >

COMBINATION METERS

Next test requested ot0XXDisplays oil pressure tell-

tale "off" threshold in A/D

counts in Hex format.$00 - $FF

Next test requested XXXXX Raw uncompensated en-

glish speed value in hun-

dredths of MPH.

Speedometer indicates

present speed.Will display "-----"

if message is

not received. Will display

"99999" if data received is in-

valid

Next test requested XXXXX Raw uncompensated

metric speed value in hun-

dredths of KPH. Speed-

ometer indicates present

speed.Will display "-----"

if message is

not received. Will display

"99999" if data received is in-

valid

Next test requested tXXXX Tachometer value in

RPM. Tachometer indi-

cates present RPM.Will display "-----"

if message is

not received.

Next test requested F1 XXXX Present ratioed fuel level

A/D input 1 in decimal for-

mat. Fuel gauge indicates

present filtered level.000-009 = Short circuit

010-254 = Normal range

255 = Open circuit

--- = Missing 5 seconds

Next test requested F2 XXX Present FLPS. 010-254 normal range

Next test requested FS X Fuel filter rate 0 = Normal

1 = Fast

Next test requested XXXC Last temperature gauge

input value in degrees C.

Temperature gauge indi-

cates present filtered tem-

perature.Will display "---"

C if message is

not received.

Will display "999" if data re-

ceived is invalid.

Next test requested BAtXX.X Estimated present battery

voltage.

Next test requested rES -X Seat belt buckle switch LH

status.0 = Unbuckled

1 = Buckled

Next test requested PA -XX Hex value port A.

Next test requested Pb -XX Hex value port B.

Next test requested PE -XX Hex value port E.

Next test requested PL -XX Hex value port L.

Next test requested P6 -XX Hex value port K.

Next test requested Pn -XX Hex value port M.

Next test requested PP -XX Hex value port P.

Next test requested PS -XX Hex value port S.

Next test requested Pt -XX Hex value port T.

Next test requested Pu -XX Hex value port U.

Next test requested P4 -XX Hex value port V.

Next test requested Puu -XX Hex value port W.

Next test requested A00XXX A/D port A/D value (non-

ratioed).0-255

Next test requested A01XXX A/D port A/D value (non-

ratioed).

0-255

Next test requested A02XXX A/D port A/D value (non-

ratioed).0-255

Next test requested A03XXX A/D port A/D value (non-

ratioed).0-255

Event Odometer Display Description of Test/Data Notes:

Page 1164 of 3061

BASIC SERVICE PROCEDURE

EC-81

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

4. Install Fuel Pressure Adapter J-44321-6 and Fuel Pressure

Gauge (from kit J-44321) as shown in figure.

• Do not distort or bend fuel rail tube when installing fuel pres-

sure gauge adapter.

• When reconnecting fuel hose, check the original fuel hose for

damage and abnormality.

5. Turn ignition switch ON (reactivate fuel pump), and check for

fuel leakage.

6. Start engine and check for fuel leakage.

7. Read the indication of fuel pressure gauge.

• During fuel pressure check, check for fuel leakage from fuel

connection every 3 minutes.

8. If result is unsatisfactory, go to next step.

9. Check the following.

• Fuel hoses and fuel tubes for clogging

• Fuel filter for clogging

• Fuel pump

• Fuel pressure regulator for clogging

If OK, replace fuel pressure regulator.

If NG, repair or replace.

10. Before disconnecting Fuel Pressure Gauge and Fuel Pressure Adapter J-44321-6, release fuel pressure

to zero. Refer to "FUEL PRESSURE RELEASE" .At idling:

Approximately 350 kPa (3.57 kg/cm

2 , 51 psi)

BBIA0390E

Page 1176 of 3061

TROUBLE DIAGNOSIS

EC-93

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

1 - 6: The numbers refer to the order of inspection.Exhaust Exhaust manifold/Tube/Muffler/

Gasket

55555 55 5EM-21

, EX-

3Three way catalyst

Lubrica-

tionOil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery/Oil cooler

55555 55 5EM-24

, LU-

14 , LU-11 ,

LU-12

Oil level (Low)/Filthy oilLU-8

Cooling Radiator/Hose/Radiator filler cap

55555 55 45CO-13

Thermostat 5CO-20

Water pumpCO-18

Water galleryCO-8

Cooling fan 5CO-16

Coolant level (Low)/Contaminat-

ed coolant5CO-9

IVIS (INFINITI Vehicle Immobilizer System —

NATS)11BL-116

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Page 1216 of 3061

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

EC-133

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

6.CHECK FUEL PRESSURE

Check fuel pressure. (Refer to EC-80, "

Fuel Pressure Check" .)

OK or NG

OK >> GO TO 9.

NG (Fuel pressure is too high)>>Replace fuel pressure regulator, refer to EC-80, "

Fuel Pressure Check" .

GO TO 8.

NG (Fuel pressure is too low)>>GO TO 7.

7.DETECT MALFUNCTIONING PART

1. Check the following.

- Clogged and bent fuel hose and fuel tube

- Clogged fuel filter

- Fuel pump and its circuit (Refer to EC-613

.)

2. If NG, repair or replace the malfunctioning part. (Refer to EC-80, "

Fuel Pressure Check" .)

If OK, replace fuel pressure regulator.

>> GO TO 8.

8.CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG >> GO TO 9.

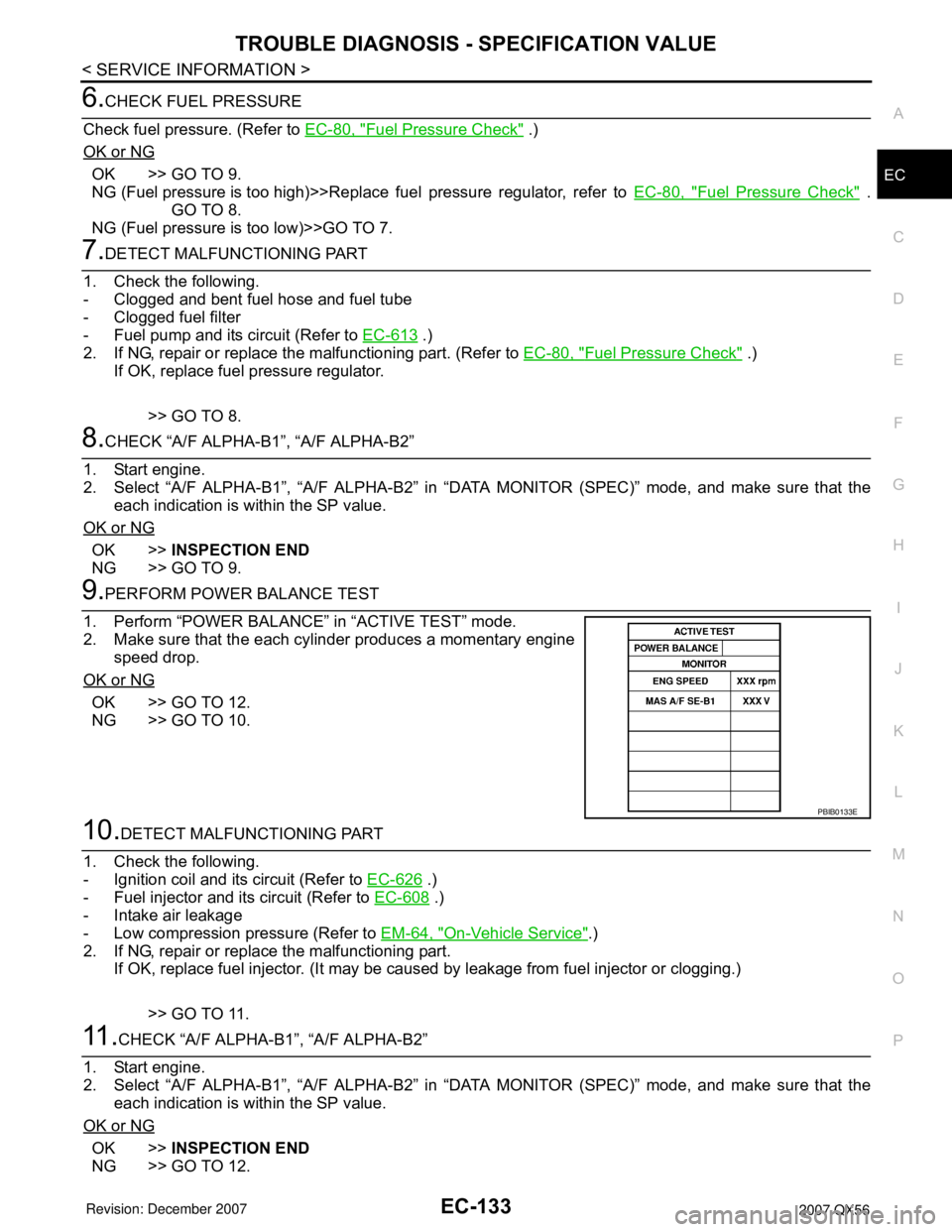

9.PERFORM POWER BALANCE TEST

1. Perform “POWER BALANCE” in “ACTIVE TEST” mode.

2. Make sure that the each cylinder produces a momentary engine

speed drop.

OK or NG

OK >> GO TO 12.

NG >> GO TO 10.

10.DETECT MALFUNCTIONING PART

1. Check the following.

- Ignition coil and its circuit (Refer to EC-626

.)

- Fuel injector and its circuit (Refer to EC-608

.)

- Intake air leakage

- Low compression pressure (Refer to EM-64, "

On-Vehicle Service".)

2. If NG, repair or replace the malfunctioning part.

If OK, replace fuel injector. (It may be caused by leakage from fuel injector or clogging.)

>> GO TO 11.

11 .CHECK “A/F ALPHA-B1”, “A/F ALPHA-B2”

1. Start engine.

2. Select “A/F ALPHA-B1”, “A/F ALPHA-B2” in “DATA MONITOR (SPEC)” mode, and make sure that the

each indication is within the SP value.

OK or NG

OK >>INSPECTION END

NG >> GO TO 12.

PBIB0133E

Page 1382 of 3061

DTC P0171, P0174 FUEL INJECTION SYSTEM FUNCTION

EC-299

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

• Fuel pump and circuit (Refer to EC-613.)

• Fuel pressure regulator (Refer to EC-80, "

Fuel Pressure Check".)

• Fuel lines

• Fuel filter for clogging

>> Repair or replace.

6.CHECK MASS AIR FLOW SENSOR

With CONSULT-II

1. Install all removed parts.

2. Check “MASS AIR FLOW” in “DATA MONITOR” mode with CONSULT-II.

With GST

1. Install all removed parts.

2. Check mass air flow sensor signal in Service $01 with GST.

OK or NG

OK >> GO TO 7.

NG >> Check connectors for rusted terminals or loose connections in the mass air flow sensor circuit or

grounds. Refer to EC-186

.

7.CHECK FUNCTION OF FUEL INJECTOR

With CONSULT-II

1. Start engine.

2. Perform “POWER BALANCE” in “ACTIVE TEST” mode with

CONSULT-II.

3. Make sure that each circuit produces a momentary engine

speed drop.

Without CONSULT-II

1. Start engine.

2. Listen to each fuel injector operating sound.

OK or NG

OK >> GO TO 8.

NG >> Perform trouble diagnosis for FUEL INJECTOR, refer to

EC-608

.

8.CHECK FUEL INJECTOR

1. Confirm that the engine is cooled down and there are no fire hazards near the vehicle.

2. Turn ignition switch OFF.3.0 - 9.0 g·m/sec: at idling

9.0 - 28.0 g·m/sec: at 2,500 rpm

3.0 - 9.0 g·m/sec: at idling

9.0 - 28.0 g·m/sec: at 2,500 rpm

PBIB0133E

Clicking noise should be heard.

PBIB1986E

Page 1412 of 3061

DTC P0300 - P0308 MULTIPLE CYLINDER MISFIRE, NO. 1 - 8 CYLINDER MIS-

FIRE

EC-329

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Check compression pressure. Refer to EM-64, "On-Vehicle Service".

OK or NG

OK >> GO TO 10.

NG >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

10.CHECK FUEL PRESSURE

1. Install all removed parts.

2. Release fuel pressure to zero. Refer to EC-80, "

Fuel Pressure Check" .

3. Install fuel pressure gauge and check fuel pressure. Refer to EC-80, "

Fuel Pressure Check" .

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the following.

• Fuel pump and circuit (Refer to EC-613

.)

• Fuel pressure regulator (Refer to EC-80, "

Fuel Pressure Check" .)

• Fuel lines

• Fuel filter for clogging

>> Repair or replace.

12.CHECK IGNITION TIMING

Check the following items. Refer to EC-71, "

Basic Inspection" .

OK or NG

OK >> GO TO 13.

NG >> Follow the EC-71, "

Basic Inspection" .

13.CHECK A/F SENSOR 1 INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect A/F sensor 1 harness connector.

3. Disconnect ECM harness connector.

4. Check harness continuity between the following terminals.

Refer to Wiring Diagram.At idling: Approximately 350 kPa (3.57 kg/cm

2 , 51 psi)

Items Specifications

Target idle speed 650 ± 50 rpm (in P or N position)

Ignition timing 15 ± 5° BTDC (in P or N position)

A/F sensor 1 terminal ECM terminal

Bank 1135

256

BBIA0376E

Page 1932 of 3061

FL-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION FL

A

FL

N

O

P

CONTENTS

FUEL SYSTEM

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

FUEL SYSTEM ....................................................4

Checking Fuel Line ...................................................4

General Precaution ...................................................4

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY .........................

5

Removal and Installation ..........................................5

Disassembly and Assembly ......................................9

FUEL TANK ......................................................10

Removal and Installation .........................................10

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

15

Standard and Limit ..................................................15

Page 1936 of 3061

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-5

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

FL

N

P O

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

Removal and InstallationINFOID:0000000003532205

REMOVAL

WARNING:

Follow the “General Precautions” before working on the fuel system. Refer to GI-3, "

General Precau-

tion" .

1. Remove the fuel filler cap to release the pressure from inside the fuel tank.

2. Check the fuel level on level gauge. If the fuel gauge indicates

more than the level as shown (full or almost full), drain the fuel

from the fuel tank until the fuel gauge indicates the level as

shown, or less.

• If the fuel pump does not operate, use the following procedure

to drain the fuel to the specified level.

a. Insert a suitable hose of less than 15 mm (0.59 in) diameter into

the fuel filler pipe through the fuel filler opening to drain the fuel

from fuel filler pipe.

b. Remove the LH rear wheel and tire. Refer to WT-7, "

Rotation" .

c. Remove the four clips and remove the rear fender protector,

front.

1. Inspection hole cover 2. Inspection hole cover O-ring 3. Lock ring

4. Fuel level sensor, fuel filter, and fuel

pump assembly5. Fuel tank 6. Fuel level sensor, fuel filter, and fuel

pump assembly O-ring

LBIA0381E

WBIA0390E

Page 1937 of 3061

FL-6

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

d. Disconnect the fuel filler hose from the fuel filler pipe.

e. Insert a suitable hose into the fuel tank through the fuel filler hose to drain the fuel from the fuel tank.

• As a guide, the fuel level reaches the fuel gauge position as shown, or less, when approximately 14

liters (3 3/4 US gal, 3 1/8 Imp gal) of fuel are drained from the fuel tank.

3. Release the fuel pressure from the fuel lines. Refer to EC-80, "

Fuel Pressure Check" .

4. Disconnect the battery negative terminal.

5. Remove the second row LH seat and the third row LH seat. Refer to SE-89, "

Removal and Installation"

(second row), SE-95, "LH Side Seat" (third row).

6. Remove the second and third row rear seat belt buckles mounted on the floor. Refer to SB-3

.

7. Remove the LH center pillar trim, the LH rear trim panel, and the LH rear side door kick plate and weather

stripping. Refer to EI-34

.

8. Remove the second row rear center console and base, if equipped. Refer to EI-36

.

9. Reposition the floor carpet out of the way to access the inspection hole cover, located under the center LH

rear seat.

10. Remove the inspection hole cover by turning the retainers 90°

degrees clockwise.

• Remove the O-ring.

11. Disconnect the fuel level sensor, fuel filter, and fuel pump

assembly electrical connector, the EVAP hose, and the fuel feed

hose.

LBIA0386E

LBIA0382E

LBIA0383E