fuse diagram INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 836 of 3061

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

BL-125

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

Non self-diagnosis related item

*: CONSULT-II self-diagnostic results display screen “no malfunction is detected”.

DIAGNOSTIC SYSTEM DIAGRAM

Diagnosis Procedure 1INFOID:0000000003532995

Self-diagnostic results:

“CHAIN OF ECM-IMMU” displayed on CONSULT-II screen

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-II, then perform the trouble diagno-

sis of malfunction system indicated “SELF-DIAG RESULTS” of “BCM”. Refer to BL-119, "

CONSULT-II".

1.CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “CHAIN OF ECM-IMMU”

displayed on CONSULT-II screen.

NOTE:

In rare case, “CHAIN OF ECM-IMMU” might be stored during key

registration procedure, even if the system is not malfunctioning.

Is CONSULT-II screen displayed as above?

YES >> GO TO 2.

NO >> GO TO BL-123, "

Trouble Diagnosis".

2.CHECK POWER SUPPLY CIRCUIT FOR BCM

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM connector M20 terminal 70 and ground.

SymptomDiagnostic Procedure

(Reference page)System

(Malfunctioning part or mode)Reference Part No. Of Illustra-

tion On System Diagram

Security indicator does not light

up*.PROCEDURE 6

(BL-131

)Combination meter (security in-

dictor lamp)—

Open circuit between fuse and

BCM—

BCM A

WIIA0550E

PIIA1260E

Page 1028 of 3061

COMBINATION METERSDI-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

Refer to DI-9, "Wiring Diagram - METER -".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate caus e of malfunction before installing new fuse. Refer to PG-

3.

2.CHECK POWER SUPPLY CIRCUIT

1. Disconnect combination meter connector.

2. Check voltage between combination meter harness connector terminals and ground.

OK or NG

OK >> GO TO 3.

NG >> Check the harness for open between combination meter and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between combination meter harness connector terminal and ground.

OK or NG

OK >> Inspection End.

NG >> Repair harness or connector.

Vehicle Speed Signal InspectionINFOID:0000000003533491

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

Refer to BRC-26, "

CONSULT-II Function (ABS)".

OK or NG

OK >> Replace the combination meter. Refer to IP-10, "Removal and Installation".

NG >> Perform "Diagnostic Procedure" for displayed DTC. Refer to BRC-26, "

CONSULT-II Function

(ABS)".

Engine Oil Pressure Signal InspectionINFOID:0000000003533492

1.CHECK SELF-DIAGNOSTIC RESULTS OF IPDM E/R

Select "IPDM E/R" on CONSULT-II, and perform self-diagnosis of IPDM E/R. Refer to PG-18, "

CONSULT-II

Function (IPDM E/R)".

Unit Power source Fuse No.

Combination meter Battery 19

Ignition switch ON or START 14

Terminals Ignition switch position

(+) (–) OFF ACC ON

Connector Terminal

M24 8

Ground Battery

voltage Battery

voltage Battery

voltage

24 0V 0V Battery

voltage

WKIA5606E

Te r m i n a l s

Continuity

(+)

(–)

Connector Terminal

M24 17 Ground Yes

WKIA1526E

Page 1053 of 3061

DI-42

< SERVICE INFORMATION >

WARNING CHIME

1. Turn ignition switch OFF.

2. Disconnect BCM connector M19 and front door switch LH con-

nector B8.

3. Check continuity between BCM harness connector M19 terminal

47 and front door switch LH harness connector B8 terminal 2.

4. Check continuity between BCM harness connector M19 terminal

47 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK FRONT DOOR SWITCH LH

Check continuity between front door switch LH terminal 2 and

exposed metal of switch while pressing and releasing switch.

OK or NG

OK >> Replace the BCM. Refer to BCS-24, "BCM".

NG >> Replace the front door switch LH.

Key Warning Chime Does Not OperateINFOID:0000000003533521

1.CHECK FUSE

Check if the key switch fuse [No. 19, located in the fuse block (J/B)] is blown. Refer to DI-38, "

Wiring Diagram

- CHIME -".

Is the fuse blown?

YES >> Replace the fuse. Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2.

2.CHECK WARNING CHIME OPERATION

With key removed from the ignition key cylinder and the front door LH open, turn the lighting switch to 1st or

2nd position.

Does warning chime sound?

YES >> GO TO 3.

NO >> Go to DI-41, "

All Warning Chimes Do Not Operate" or DI-41, "Key Warning Chime and Light

Warning Chime Do Not Operate (Seat Belt Warning Chime Does Operate)".

3.CHECK BCM INPUT SIGNAL

With CONSULT-IIContinuity should exist.

Continuity should not exist.

WKIA1516E

When front door switch

LH is released: Continuity should exist.

When front door switch

LH is pressed: Continuity should not exist.

WKIA2023E

Page 1064 of 3061

REAR SONAR SYSTEM

DI-53

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

DI

N

O

P

1. Push and hold rear sonar system OFF switch for three seconds

to reset time-out counter.

2. Push and hold rear sonar system OFF switch for three seconds

to clear codes.

Preliminary CheckINFOID:0000000003533532

INSPECTION FOR POWER SUPPLY AND GROUND CIRCUIT

1.CHECK FUSE

Check for blown rear sonar system fuse.

Refer to DI-48, "

Wiring Diagram - SONAR -".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of problem before installing new fuse. Refer to PG-3

.

2.CHECK POWER SUPPLY CIRCUIT

1. Disconnect sonar control unit connector.

2. Check voltage between sonar control unit connector B56 termi-

nal 8 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open between sonar control unit and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between sonar control unit B56 terminal 6 and

ground.

OK or NG

OK >> Inspection End.

NG >> Check harness ground circuit.

LKIA0391E

Unit Power Source Fuse

Sonar control unit ON or START 12

Terminals Ignition switch position

(+)

(-) ON or START

Connector Terminal

B56 8 Ground Battery voltage

WKIA1145E

Te r m i n a l s

Continuity (+)

(–)

Connector Terminal

B56 6 Ground Yes

WKIA1146E

Page 1225 of 3061

EC-142

< SERVICE INFORMATION >

POWER SUPPLY AND GROUND CIRCUIT

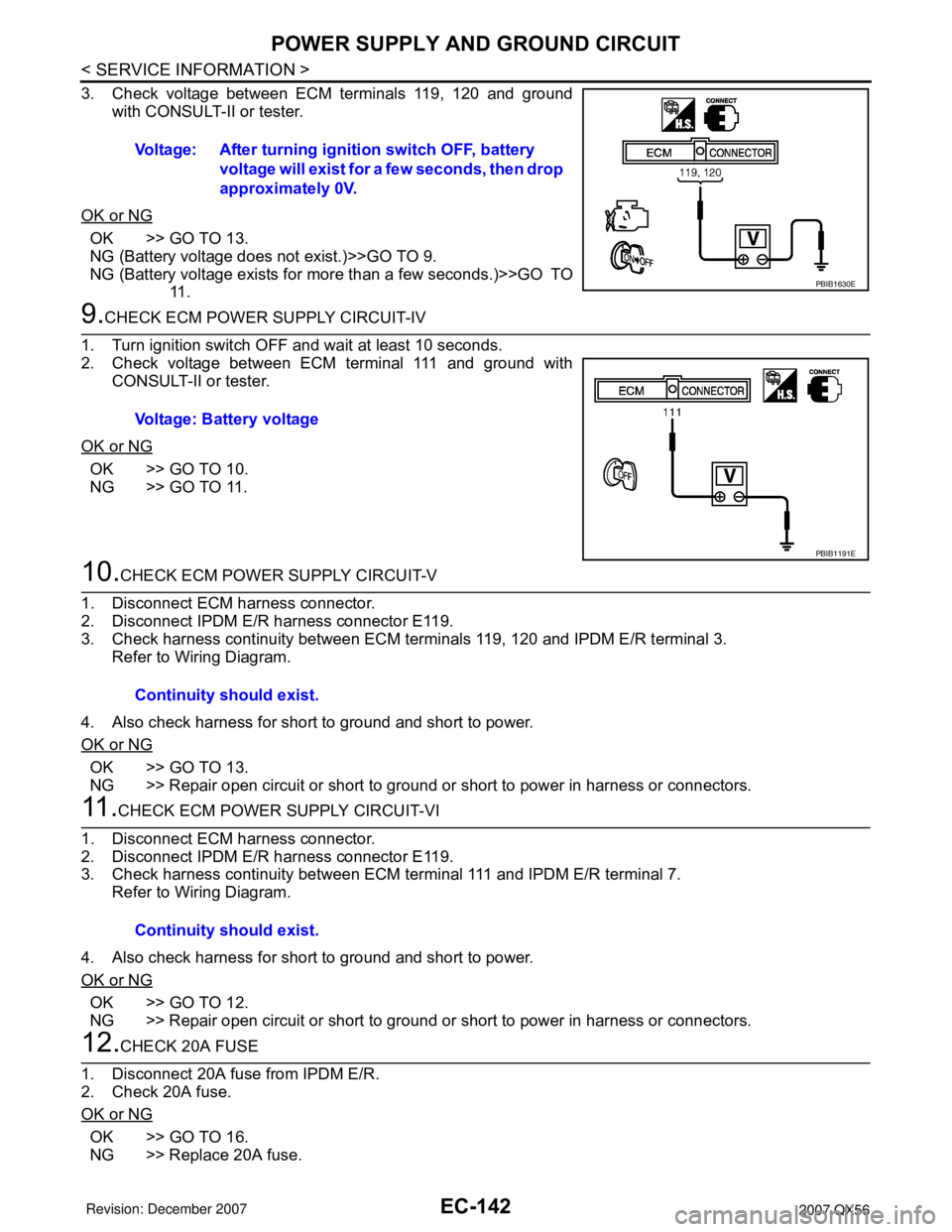

3. Check voltage between ECM terminals 119, 120 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 13.

NG (Battery voltage does not exist.)>>GO TO 9.

NG (Battery voltage exists for more than a few seconds.)>>GO TO

11 .

9.CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Check voltage between ECM terminal 111 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 10.

NG >> GO TO 11.

10.CHECK ECM POWER SUPPLY CIRCUIT-V

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E119.

3. Check harness continuity between ECM terminals 119, 120 and IPDM E/R terminal 3.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

11 .CHECK ECM POWER SUPPLY CIRCUIT-VI

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E119.

3. Check harness continuity between ECM terminal 111 and IPDM E/R terminal 7.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 12.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

12.CHECK 20A FUSE

1. Disconnect 20A fuse from IPDM E/R.

2. Check 20A fuse.

OK or NG

OK >> GO TO 16.

NG >> Replace 20A fuse.Voltage: After turning ignition switch OFF, battery

voltage will exist for a few seconds, then drop

approximately 0V.

PBIB1630E

Voltage: Battery voltage

PBIB1191E

Continuity should exist.

Continuity should exist.

Page 1251 of 3061

EC-168

< SERVICE INFORMATION >

DTC P0031, P0032, P0051, P0052 A/F SENSOR 1 HEATER

3. Check voltage between A/F sensor 1 terminal 4 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• IPDM E/R harness connector E119

• 15A fuse

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors.

4.CHECK A/F SENSOR 1 HEATER OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 2 (bank 1) or 24, 43 (bank 2) and A/F sensor 1 terminal

3.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK A/F SENSOR 1 HEATER

Refer to EC-168, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace malfunctioning air fuel ratio (A/F) sensor 1.

6.CHECK INTERMITTENT INCIDENT

Perform EC-138

.

>>INSPECTION END

Component InspectionINFOID:0000000003531662

AIR FUEL RATIO (A/F) SENSOR 1 HEATER

Voltage: Battery voltage

PBIB3308E

Continuity should exist.

Page 1259 of 3061

EC-176

< SERVICE INFORMATION >

DTC P0037, P0038, P0057, P0058 HO2S2 HEATER

2. Turn ignition switch ON.

3. Check voltage between HO2S2 terminal 3 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• IPDM E/R harness connector E119

• 15A fuse

• Harness for open or short between heated oxygen sensor 2 and fuse

>> Repair harness or connectors.

4.CHECK HO2S2 HEATER OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal and HO2S2 terminal as follows.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK HEATED OXYGEN SENSOR 2 HEATER

Refer to EC-176, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace malfunctioning heated oxygen sensor 2.

6.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

>>INSPECTION END

Component InspectionINFOID:0000000003531670

HEATED OXYGEN SENSOR 2 HEATER

Voltage: Battery voltage

PBIB0112E

DTCTe r m i n a l s

Bank

ECM Sensor

P0037, P0038 6 2 1

P0057, P0058 25 2 2

Continuity should exist.

Page 1315 of 3061

EC-232

< SERVICE INFORMATION >

DTC P0130, P0150 A/F SENSOR 1

3. Check voltage between A/F sensor 1 terminal 4 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• IPDM E/R harness connector E119

• 15A fuse

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors.

4.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between the following terminals. Refer to Wiring Diagram.

4. Check harness continuity between the following terminals and ground.

Refer to Wiring Diagram.

5. Also check harness for short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK INTERMITTENT INCIDENT

Perform EC-138

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace.

6.REPLACE AIR FUEL RATIO (A/F) SENSOR 1Voltage: Battery voltage

PBIB3308E

A/F sensor 1 terminal ECM terminal

Bank1135

256

Bank 2116

275

Continuity should exist.

Bank 1 Bank 2

A/F sensor 1 terminal ECM terminal A/F sensor 1 terminal ECM terminal

135116

256275

Continuity should not exist.

Page 1323 of 3061

EC-240

< SERVICE INFORMATION >

DTC P0131, P0151 A/F SENSOR 1

3. Check voltage between A/F sensor 1 terminal 4 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• IPDM E/R harness connector E119

• 15A fuse

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors.

4.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between A/F sensor 1 terminal and ECM terminal as follows.

Refer to Wiring Diagram.

4. Check harness continuity between the following terminals and ground.

Refer to Wiring Diagram.

5. Also check harness for short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK INTERMITTENT INCIDENT

Refer to EC-138

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace.Voltage: Battery voltage

PBIB3308E

A/F sensor 1 terminal ECM terminal

Bank1135

256

Bank 2116

275

Continuity should exist.

Bank 1 Bank 2

A/F sensor 1 terminal ECM terminal A/F sensor 1 terminal ECM terminal

135116

256275

Continuity should not exist.

Page 1331 of 3061

EC-248

< SERVICE INFORMATION >

DTC P0132, P0152 A/F SENSOR 1

3. Check voltage between A/F sensor 1 terminal 4 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E5, F14

• IPDM E/R harness connector E119

• 15A fuse

• Harness for open or short between A/F sensor 1 and fuse

>> Repair or replace harness or connectors.

4.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between A/F sensor 1 terminal and ECM terminal as follows.

Refer to Wiring Diagram.

4. Check harness continuity between the following terminals and ground.

Refer to Wiring Diagram.

5. Also check harness for short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK INTERMITTENT INCIDENT

Perform EC-138

.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace.Voltage: Battery voltage

PBIB3308E

A/F sensor 1 terminal ECM terminal

Bank1135

256

Bank 2116

275

Continuity should exist.

Bank 1 Bank 2

A/F sensor 1 terminal ECM terminal A/F sensor 1 terminal ECM terminal

135116

256275

Continuity should not exist.