fuse INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 3539 of 4083

STR-10

< COMPONENT DIAGNOSIS >

B TERMINAL CIRCUIT

COMPONENT DIAGNOSIS

B TERMINAL CIRCUIT

DescriptionINFOID:0000000001696228

Terminal "2" (B) is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000001696229

CAUTION:

Perform diagnosis under the condition that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is depleted.

1.CHECK TERMINAL 2 POWER SUPPLY VOLTAGE

1. Turn ignition switch OFF.

2. Make sure that starter motor connector F27 terminal 2 connection is clean and tight.

3. Check voltage between starter motor connector F27 terminal 2

and ground.

Is there battery voltage present?

YES >> GO TO 2

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE (VOLTAGE DROP TEST)

1. Shift the transmission into park or neutral.

2. Check voltage between battery positive terminal and starter motor connector F27 terminal 2 while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> GO TO 3

NO >> Check harness between the battery and the starter motor for high resistance.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor case and battery negative ter-

minal while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> Terminal 2 circuit is OK. Further inspection necessary. Refer to STR-5, "

Work Flow".

NO >> Check the starter motor case to engine mounting for

high resistance.

(+) (-) Voltage

Connector Terminal

F27 2 Ground Battery voltage

AWBIA0122GB

(-) (+) Condition Voltage

Connector Terminal

F27 2 Battery (+)

terminal While cranking the

engine Less than 0.2V

AWBIA0123GB

(+)

(-)Condition Voltage

Starter motor case Battery (-) terminal While cranking the

engine Less than 0.2V

AWBIA0124GB

Revision: March 2010

2008 QX56

Page 3540 of 4083

S CONNECTOR CIRCUITSTR-11

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

S CONNECTOR CIRCUIT

DescriptionINFOID:0000000001696230

Terminal "1" (S) is the power supply for the starter mo

tor magnetic switch. Terminal 1 is supplied with power

when the ignition switch is turned to the START position while the selector lever is in the P or N position.

Diagnosis ProcedureINFOID:0000000001696231

CAUTION:

Perform diagnosis under the cond ition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

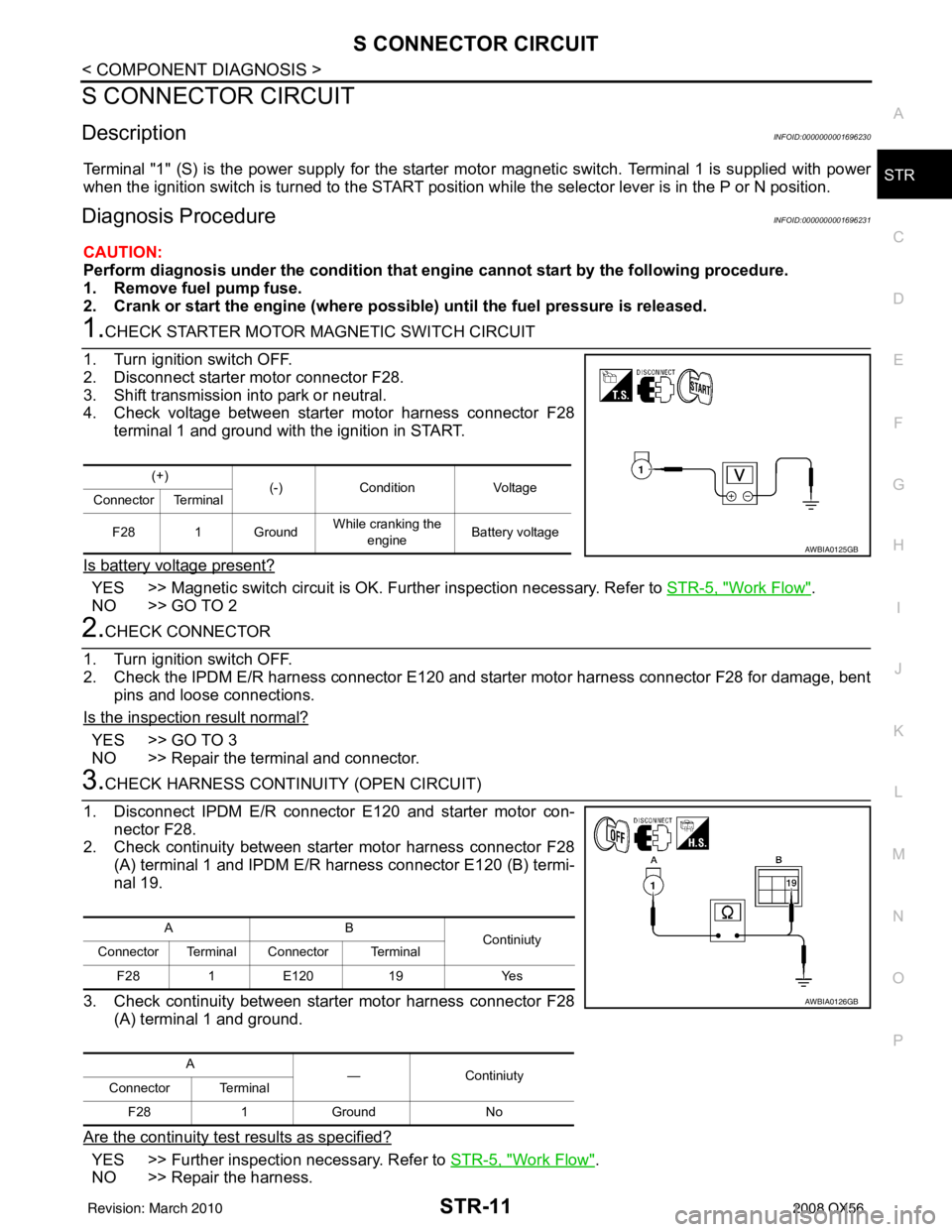

1.CHECK STARTER MOTOR MAGNETIC SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector F28.

3. Shift transmission into park or neutral.

4. Check voltage between starter motor harness connector F28 terminal 1 and ground with the ignition in START.

Is battery voltage present?

YES >> Magnetic switch circuit is OK. Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> GO TO 2

2.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check the IPDM E/R harness connector E120 and starter motor harness connector F28 for damage, bent pins and loose connections.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair the terminal and connector.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector E120 and starter motor con- nector F28.

2. Check continuity between starter motor harness connector F28 (A) terminal 1 and IPDM E/R harness connector E120 (B) termi-

nal 19.

3. Check continuity between starter motor harness connector F28 (A) terminal 1 and ground.

Are the continuity test results as specified?

YES >> Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> Repair the harness.

(+) (-)Condition Voltage

Connector Terminal

F28 1 Ground While cranking the

engine Battery voltage

AWBIA0125GB

AB

Continiuty

Connector Terminal Connector Terminal

F28 1E120 19 Yes

A —Continiuty

Connector Terminal

F28 1Ground No

AWBIA0126GB

Revision: March 2010 2008 QX56

Page 3639 of 4083

TM-92

< COMPONENT DIAGNOSIS >

MAIN POWER SUPPLY AND GROUND CIRCUIT

MAIN POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000001604160

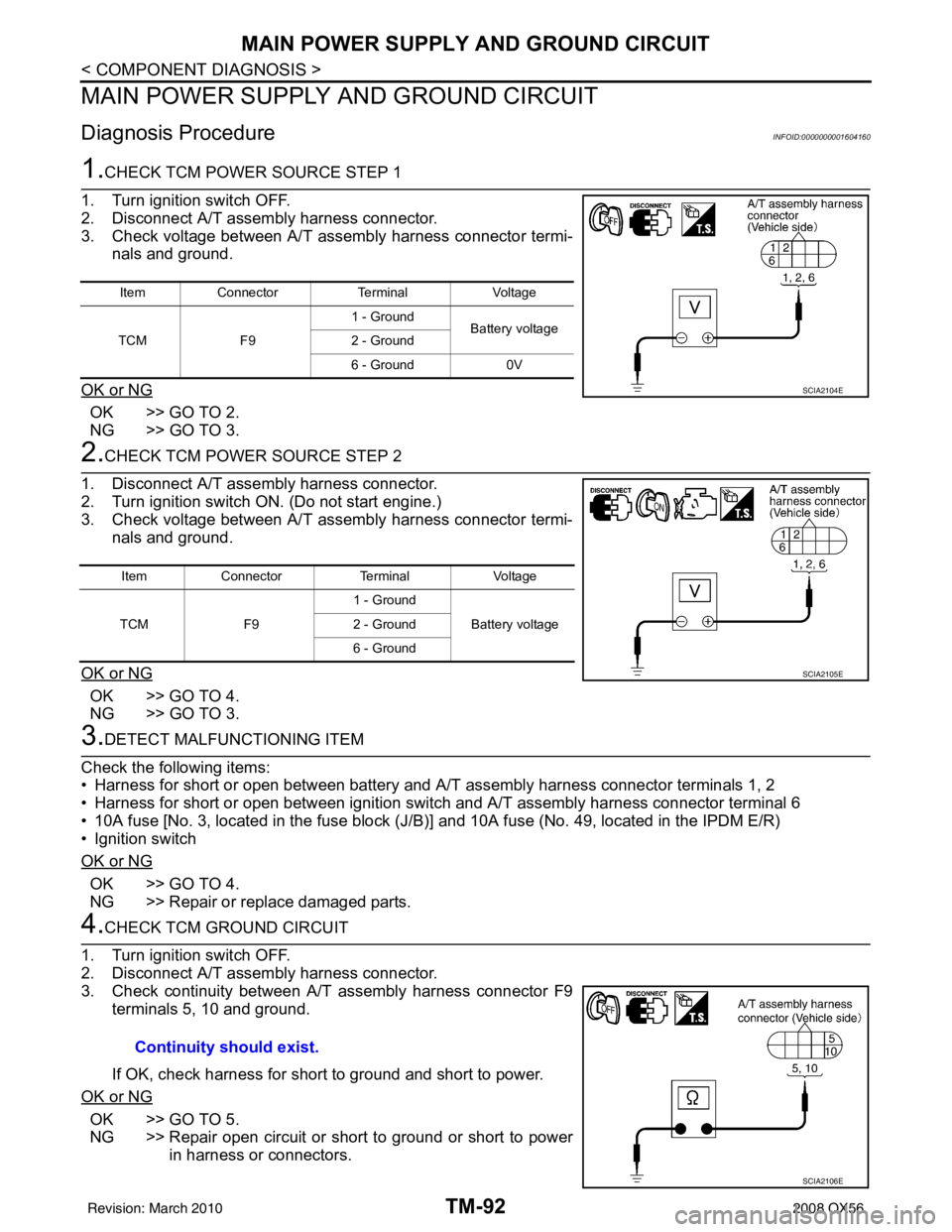

1.CHECK TCM POWER SOURCE STEP 1

1. Turn ignition switch OFF.

2. Disconnect A/T assembly harness connector.

3. Check voltage between A/T assembly harness connector termi- nals and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK TCM POWER SOURCE STEP 2

1. Disconnect A/T assembly harness connector.

2. Turn ignition switch ON. (Do not start engine.)

3. Check voltage between A/T assembly harness connector termi- nals and ground.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING ITEM

Check the following items:

• Harness for short or open between battery and A/T assembly harness connector terminals 1, 2

• Harness for short or open between ignition switch and A/T assembly harness connector terminal 6

• 10A fuse [No. 3, located in the fuse block (J/B )] and 10A fuse (No. 49, located in the IPDM E/R)

• Ignition switch

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK TCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect A/T assembly harness connector.

3. Check continuity between A/T assembly harness connector F9 terminals 5, 10 and ground.

If OK, check harness for short to ground and short to power.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

Item Connector TerminalVoltage

TCM F91 - Ground

Battery voltage

2 - Ground

6 - Ground 0V

SCIA2104E

ItemConnector TerminalVoltage

TCM F91 - Ground

Battery voltage

2 - Ground

6 - Ground

SCIA2105E

Continuity should exist.

SCIA2106E

Revision: March 2010 2008 QX56

Page 3857 of 4083

HEATER & COOLING UNIT ASSEMBLYVTL-17

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

1. Move the two front seats to the rear most position on the seat track.

2. Disconnect the battery negative terminal and battery positive terminal.

3. Discharge the refrigerant from the A/C system. Refer to HA-20, "

HFC-134a (R-134a) Service Procedure".

4. Drain the coolant from the engine cooling system. Refer to CO-11, "

Changing Engine Coolant".

5. Disconnect the front heater hoses from the front heater core.

6. Disconnect the high/low pressure pipes from the front expansion valve.

7. Remove the instrument panel and console panel. Refer to IP-12, "

Removal and Installation".

8. Remove the steering column. Refer to ST-20, "

Removal and Installation".

9. Disconnect the instrument panel wire harness at t he RH and LH in-line connector brackets, and the fuse

block (J/B) electrical connectors. Refer to PG-9, "

Wiring Diagram — Battery Power Supply —".

10. Disconnect the steering member from each side of the vehicle body.

11. Remove the front heater and cooling unit assembly with it attached to the steering member, from the vehi- cle.

CAUTION:

Use care not to damage the seats and interior trim panels when removing the front heater and

cooling unit assembly with it at tached to the steering member.

12. Remove the front heater and cooling uni t assembly from the steering member.

Installation

Installation is in the reverse order of removal.

CAUTION:

• Replace the O-ring of the low-pressure pipe and high-pressure pipe with a new one, and apply com-

pressor oil to it when installing it.

• After charging the refrigerant, check for leaks.

NOTE:

• Fill the engine cooling system with the specified coolant mixture. Refer to CO-11, "

Changing Engine Cool-

ant".

• Recharge the A/C system. Refer to HA-20, "

HFC-134a (R-134a) Service Procedure".

REAR HEATER AND COOLING UNIT ASSEMBLY

Removal

1. Discharge the refrigerant from the A/C system. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Drain the coolant from the engine cooling system. Refer to CO-11, "

Changing Engine Coolant".

3. Remove the luggage side finisher lower RH. Refer to INT-19, "

Removal and Installation".

4. Disconnect the rear heater core hoses from the rear heater core.

5. Disconnect the rear A/C pipes from the rear expansion valve.

6. Disconnect the following electrical connectors: • Rear blower motor

• Rear variable blower control

• Rear air mix door motor

7. Disconnect the ducts from the rear heater and cooling unit assembly.

8. Remove the rear heater and cooling unit assembly.

Installation

Installation is in the reverse order of removal.

CAUTION:

• Replace the O-ring of the low-pressure pipe and high-pressure pipe with a new one, and apply com- pressor oil to it when installing it.

• After charging the refrigerant, check for leaks.

NOTE:

• Fill the engine cooling system with the specified coolant mixture. Refer to CO-11, "

Changing Engine Cool-

ant".

• Recharge the A/C system. Refer to HA-20, "

HFC-134a (R-134a) Service Procedure".

Revision: March 2010 2008 QX56

Page 3894 of 4083

WCS

POWER SUPPLY AND GROUND CIRCUITWCS-17

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

COMPONENT DIAGNOSIS

POWER SUPPLY AND GROUND CIRCUIT

COMBINATION METER

COMBINATION METER : Diagnosis ProcedureINFOID:0000000004873060

1.CHECK FUSES

Check for blown combination meter fuses.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.POWER SUPPLY CIRCUIT CHECK

1. Disconnect combination meter connector M24.

2. Check voltage between combination meter harness connector M24 terminals 21, 37, 40 and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Check harness for open between combination meter and fuse.

3.GROUND CIRCUIT CHECK

1. Turn ignition switch OFF.

2. Disconnect combination meter connector M23.

3. Check continuity between combination meter harness connector M23 terminal 47, 52 and ground, and connector M24 terminal 20

and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> Check ground harness.

Unit Power source Fuse No.

Combination meter Battery 19

Ignition switch ON or START 14

Ignition switch ACC or ON 4

TerminalsIgnition switch position

(+) (–) OFF ACC ON START

Connector Terminal

M24 21

Ground 0V 0V

Battery

voltage Battery

voltage

37 0VBattery

voltage Battery

voltage 0V

40 Battery

voltage Battery

voltage Battery

voltage Battery

voltage

AWNIA0204ZZ

Te r m i n a l s

Continuity

(+)

(–)

Connector Terminal

A: M23 47

Ground Yes

52

B: M24 20

AWNIA0205ZZ

Revision: March 2010 2008 QX56

Page 3895 of 4083

WCS-18

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000004873061

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> INSPECTION END

NO >> Repair or replace harness.

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

ConnectorTe r m i n a l s

Power

source Condition

Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch

OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

LIIA2415E

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Revision: March 2010 2008 QX56

Page 3899 of 4083

WCS-22

< COMPONENT DIAGNOSIS >

KEY SWITCH SIGNAL CIRCUIT

KEY SWITCH SIGNAL CIRCUIT

DescriptionINFOID:0000000001697685

Transmits a key switch signal to the BCM.

Component Function CheckINFOID:0000000001697686

1.CHECK BCM INPUT SIGNAL

Select “DATA MONITOR” for “BCM” and check the “KEY ON SW” monitor value.

>> Inspection End.

Diagnosis ProcedureINFOID:0000000001697687

1.CHECK FUSE

Check if the key switch and ignition knob switch 10A fuse (No. 62, located in the fuse and relay box) is blown.

Is the fuse blown?

YES >> Be sure to repair the cause of malfunction before installing new fuse.

NO >> GO TO 2

2.CHECK BCM INPUT SIGNAL

Check voltage between BCM harness connector and ground.

Is the inspection result normal?

YES >> Inspection End.

NO >> GO TO 3

3.CHECK KEY SWITCH CIRCUIT

1. Disconnect BCM and key switch and ignition knob switch con- nectors.

2. Check continuity between BCM harness connector M18 (A) and key switch and ignition knob switch harness connector M12 (B).

3. Check continuity between BCM harness connector M18 (A) and ground.KEY ON SW

When key is inserted into key cylinder : ON

When key is removed from key cylinder : OFF

Te r m i n a l s

ConditionVo l ta g e

(Approx.)

(+)

(−)

BCM

connector Te r m i n a l

M18 37 Ground Key is inserted Battery voltage

Key is removed

0

PKIC0721E

AB

Continuity

Connector Terminal Connector Terminal

M183 7M 12 4 Y es

A GroundContinuity

Connector Terminal

M18 37 No

AWNIA0159ZZ

Revision: March 2010 2008 QX56

Page 3926 of 4083

WCS

COMBINATION METERWCS-49

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

DTC IndexINFOID:0000000004871171

Function Specifications

Speedometer

Zero indication.

Tachometer

Fuel gauge

Engine coolant temperature gauge

Engine oil pressure gauge

Voltage gauge

A/T oil temperature gauge

Illumination control

Meter illumination Change to nighttime mode when communication is lost.

Segment LCD Odometer

Freeze current indication.

A/T position Display turns off.

Buzzer Buzzer turns off.

Warning lamp/indicator lamp ABS warning lamp

Lamp turns on when communication is lost.

Brake warning lamp

VDC OFF indicator lamp

SLIP indicator lamp

A/T CHECK warning lamp

Lamp turns off when communication is lost.

Oil pressure/coolant temperature

warning lamp

Light indicator

Malfunction indicator lamp

Master warning lamp

Air bag warning lamp

High beam indicator

Turn signal indicator lamp

CRUISE indicator lamp

Driver and passenger seat belt warn-

ing lamp

Lamp turns off when disconnected.

Charge warning lamp

Security indicator lamp

4WD indicator lamp

ATP indicator lamp

CK SUSP warning lamp

Low tire pressu

re warning lamp Lamp will flash every second for 1 minute and then stay on con-

tinuously thereafter.

CONSULT-III display

MalfunctionReference

page

CAN COMM CIRC

[U1000] Malfunction is detected in CAN communication.

CAUTION:

Even when there is no ma

lfunction on CAN communication system, malfunction may be

misinterpreted when battery has low voltag e (when maintaining 7 - 8 V for about 2 sec-

onds) or 10A fuse [No. 19, located in the fuse block (J/B)] is disconnected. MWI-28

VEHICLE SPEED

CIRC

[B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunction may be misin-

terpreted when battery has low voltage (whe

n maintaining 7 - 8 V for about 2 seconds). MWI-29

Revision: March 2010

2008 QX56

Page 3998 of 4083

WW-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION WW

A

B

WW

N

O P

CONTENTS

WIPER & WASHER

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

FUNCTION DIAGNOSIS ...............................4

FRONT WIPER AND WASHER SYSTEM ..... .....4

System Diagram .................................................. ......4

System Description ...................................................4

Component Parts Location ........................................7

Component Description ............................................7

REAR WIPER AND WASHER SYSTEM ............8

System Diagram .................................................. ......8

System Description ...................................................8

Component Parts Location ......................................10

Component Description ..........................................10

DIAGNOSIS SYSTEM (BCM) ............................11

COMMON ITEM ..................................................... ....11

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

11

WIPER ................................................................... ....11

WIPER : CONSULT-III Function (BCM - WIPER) ....11

DIAGNOSIS SYSTEM (IPDM E/R) .....................13

Diagnosis Description ......................................... ....13

CONSULT - III Function (IPDM E/R) .......................15

COMPONENT DIAGNOSIS .........................18

WIPER AND WASHER FUSE ........................ ....18

Description .......................................................... ....18

Diagnosis Procedure ...............................................18

FRONT WIPER MOTOR LO CIRCUIT ...............19

Component Function Check ................................ ....19

Diagnosis Procedure ...............................................19

FRONT WIPER MOTOR HI CIRCUIT ................21

Component Function Check ................................ ....21

Diagnosis Procedure ...............................................21

FRONT WIPER AUTO STOP SIGNAL CIR-

CUIT ..................................................................

23

Component Function Check ....................................23

Diagnosis Procedure ...............................................23

FRONT WIPER MOTOR GROUND CIRCUIT ...25

Diagnosis Procedure ...............................................25

WASHER SWITCH ............................................26

Description ...............................................................26

Component Inspection .............................................26

REAR WIPER MOTOR CIRCUIT ......................28

Component Function Check ....................................28

Diagnosis Procedure ...............................................28

REAR WIPER AUTO STOP SIGNAL CIRCUIT

...

30

Component Function Check ................................ ....30

Diagnosis Procedure ...............................................30

FRONT WIPER AND WASHER SYSTEM ........31

Wiring Diagram ........................................................31

REAR WIPER AND WASHER SYSTEM ..........35

Wiring Diagram ........................................................35

ECU DIAGNOSIS .........................................41

BCM (BODY CONTROL MODULE) .................41

Reference Value .................................................. ....41

Terminal Layout .......................................................43

Physical Values ................................................... ....43

Wiring Diagram ........................................................49

Fail Safe ..................................................................52

DTC Inspection Priority Chart ...............................53

DTC Index ...............................................................53

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

55

Revision: March 2010 2008 QX56

Page 4015 of 4083

WW-18

< COMPONENT DIAGNOSIS >

WIPER AND WASHER FUSE

COMPONENT DIAGNOSIS

WIPER AND WASHER FUSE

DescriptionINFOID:0000000001735577

Fuse list

Diagnosis ProcedureINFOID:0000000001735578

1. CHECK FUSES

Check that the following fuses are not blown.

Is the fuse blown?

YES >> Replace the fuse after repairing the applicable circuit.

NO >> The fuse is normal.

Unit LocationFuse No. Capacity

Front wiper motor IPDM E/R3930 A

Front and rear washer motor Fuse block (J/B)910 A

Unit LocationFuse No. Capacity

Front wiper motor IPDM E/R3930 A

Front and rear washer motor Fuse block (J/B)910 A

Revision: March 2010 2008 QX56