drain bolt INFINITI QX56 2008 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1204 of 4083

![INFINITI QX56 2008 Factory User Guide DLN-174

< DISASSEMBLY AND ASSEMBLY >[ATX14B]

TRANSFER ASSEMBLY

21. Tighten the front case bolts to the specified torque. Refer to

DLN-140, "

Disassembly and Assembly".

CAUTION:

Be sure to install air INFINITI QX56 2008 Factory User Guide DLN-174

< DISASSEMBLY AND ASSEMBLY >[ATX14B]

TRANSFER ASSEMBLY

21. Tighten the front case bolts to the specified torque. Refer to

DLN-140, "

Disassembly and Assembly".

CAUTION:

Be sure to install air](/img/42/57030/w960_57030-1203.png)

DLN-174

< DISASSEMBLY AND ASSEMBLY >[ATX14B]

TRANSFER ASSEMBLY

21. Tighten the front case bolts to the specified torque. Refer to

DLN-140, "

Disassembly and Assembly".

CAUTION:

Be sure to install air breather hose clamp, connector

bracket and harness clip.

22. Install the drain plug with a new gasket. CAUTION:

Do not reuse gasket.

23. Align the matching mark on the front drive shaft with the mark on the companion flange, then install the companion flange.

24. Install a new companion flange self-lock nut. Tighten to the specified torque using Tool. Refer to DLN-140, "

Disassembly

and Assembly".

CAUTION:

Do not reuse self-lock nut.

25. Remove all the sealant from the check plug, switch mounting and front case.

CAUTION:

Remove old sealant adhering to mating surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mounting surfaces.

26. Install the check ball and check spring to the front case. Apply sealant to the check plug and wait detection switch and install

them to the front case. Tighten to the specified torque. Refer to

DLN-140, "

Disassembly and Assembly".

• Use Genuine Silicone RTV or equivalent. Refer to GI-15,

"Recommended Chemical Products and Sealants".

NOTE:

Wait detection switch harness connector is black.

SDIA2100E

SDIA2779E

Tool number A: KV40104000 ( — )

WDIA0219E

WDIA0158E

Revision: March 2010 2008 QX56

Page 1247 of 4083

![INFINITI QX56 2008 Factory User Guide FRONT FINAL DRIVEDLN-217

< DISASSEMBLY AND ASSEMBLY > [FRONT FINAL DRIVE: M205]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

Backlash

1. Fit a dial indicator to the drive gear face to measure the back-

lash.

• INFINITI QX56 2008 Factory User Guide FRONT FINAL DRIVEDLN-217

< DISASSEMBLY AND ASSEMBLY > [FRONT FINAL DRIVE: M205]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

Backlash

1. Fit a dial indicator to the drive gear face to measure the back-

lash.

•](/img/42/57030/w960_57030-1246.png)

FRONT FINAL DRIVEDLN-217

< DISASSEMBLY AND ASSEMBLY > [FRONT FINAL DRIVE: M205]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

Backlash

1. Fit a dial indicator to the drive gear face to measure the back-

lash.

• If the backlash is outside of the specification, adjust each sidebearing adjuster.

CAUTION:

Do not change the side bearing adjusters by different

amounts as it will change the side bearing preload torque.

Companion Flange Runout

1. Rotate companion flange and check for runout on the compan-

ion flange face (inner side of the bolt holes) and companion

flange inner side (socket diameter) using suitable tool.

2. If the runout is outside the runout limit, follow the procedure below to adjust.

a. Rotate the companion flange on the drive pinion by 90 °, 180 °

and 270° while checking for the position where the runout is minimum.

b. If the runout is still outside of the runout limit after the companion flange has been rotated on the drive pin-

ion, possible cause could be an assembly malfunction of drive pinion and drive pinion bearing or a mal-

functioning drive pinion bearing.

c. If the runout is still outside of t he runout limit after repair of the assembly of drive pinion and drive pinion

bearing or drive pinion bearing, replace the companion flange.

DISASSEMBLY

Differential Assembly

1. Drain the differential gear oil if necessary. Backlash: 0.12 - 0.20 mm (0.0050 - 0.0078 in)

SPD513

If the backlash is greater than specification:

Loosen side bearing adjuster A and tighten side bear-

ing adjuster B by the same amount.

If the backlash is less than specification: Loosen side bearing adjuster B and tighten side bear-

ing adjuster A by the same amount.

SDIA2262E

Runout limit

Companion flange face: 0.10 mm (0.0039 in)

Companion flange inner side: 0.13 mm (0.0051 in)

SDIA2078E

Revision: March 2010 2008 QX56

Page 1285 of 4083

![INFINITI QX56 2008 Factory User Guide REAR FINAL DRIVEDLN-255

< DISASSEMBLY AND ASSEMBLY > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

1. Rotate companion flange and check for runout on the outer face of the companion flange INFINITI QX56 2008 Factory User Guide REAR FINAL DRIVEDLN-255

< DISASSEMBLY AND ASSEMBLY > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

1. Rotate companion flange and check for runout on the outer face of the companion flange](/img/42/57030/w960_57030-1284.png)

REAR FINAL DRIVEDLN-255

< DISASSEMBLY AND ASSEMBLY > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

1. Rotate companion flange and check for runout on the outer face of the companion flange using suitable tool.

2. If the runout is outside of the runout limit, follow the procedure

below to adjust.

a. Rotate the companion flange on the drive pinion by 90 °, 180 °

and 270 ° while checking for the position where the runout is

minimum.

b. If the runout is still outside of the runout limit after the companion

flange has been rotated on the drive pinion, possible cause

could be an assembly malfunction of drive pinion and drive pinion bearing or a malfunctioning drive pinion

bearing.

c. If the runout is still outside of t he runout limit after repair of the assembly of drive pinion and drive pinion

bearing or drive pinion bearing, replace the companion flange.

DISASSEMBLY

Side Flange

1. Drain the differential gear oil if necessary.

2. Remove the side flange using Tools.

3. Remove the side oil seal using suitable tool. CAUTION:

Do not to damage gear carrier.

Differential Assembly

1. Remove the side flanges. Refer to "Side Flange".

2. Remove the carrier cover bolts.

3. Remove the carrier cover bolts and separate the carrier cover

from the gear carrier using Tool.

CAUTION:

• Do not damage the mating surface.

• Do not insert flat-bladed screw driver, this will damage the

mating surface. Runout limit : 0.08 mm (0.0031 in) or less

WDIA0231E

Tool numbers A: KV40104100 ( — )

B: ST36230000 (J-25840-A)

WDIA0115E

LDIA0109E

Tool number : KV10111100 (J-37228)

WDIA0123E

Revision: March 2010 2008 QX56

Page 1807 of 4083

EM-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Drain Engine CoolantINFOID:0000000001538794

Drain engine coolant when engine is cooled.

Precaution for Disconnecting Fuel PipingINFOID:0000000001538795

• Before starting work, make sure no fire or spark producing items are in the work area.

• Release fuel pressure before disconnecting and disassembly.

• After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Removal and DisassemblyINFOID:0000000001538796

• When instructed to use special service tools, use the s pecified tools. Always be careful to work safely, avoid

forceful or uninstructed operations.

• Exercise maximum care to avoid damage to mating or sliding surfaces.

• Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

• Mark and arrange disassembly parts in an organi zed way for easy troubleshooting and assembly.

• When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally opposite, and so on. If the order of loosening is specified, do exactly as specified. Power tools may be used

where noted in the step.

Precaution for Inspection, Repair and ReplacementINFOID:0000000001538797

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and InstallationINFOID:0000000001538798

• Use torque wrench to tighten bolts or nuts to specification.

• When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with theones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

• Replace with new gasket, packing, oil seal or O-ring.

• Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for any restriction and blockage.

• Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust. Before assembly, oil sliding surfaces well.

• Release air within route when refilling after draining engine coolant.

• Before starting engine, apply fuel pressure to fuel lines with turning ignition switch ON (with engine stopped). Then make sure that there are no leaks at fuel line connections.

• After repairing, start engine and increase engine s peed to check engine coolant, fuel, oil, and exhaust sys-

tems for leakage.

Parts Requiring Angular TighteningINFOID:0000000001538799

• For final tightening of the following engine parts use Tool:

- Cylinder head bolts

- Main bearing cap bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angle tightening)

• Do not use a torque value for final tightening.

• The torque value for these parts are for a preliminary step.

• Ensure thread and seat surfaces are clean and lightly coated with engine oil. Tool number : KV10112100 (BT-8653-A)

Revision: March 2010

2008 QX56

Page 1836 of 4083

OIL PAN AND OIL STRAINEREM-33

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

OIL PAN AND OIL STRAINER

Removal and InstallationINFOID:0000000001538816

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the engine is hot.

1. Remove the engine. Refer to

EM-78, "

Removal and Installation".

2. Remove the oil pan (lower) using the following steps.

a. Remove the oil pan (lower) bolts using power tool.

1. Oil pan (upper) 2. O-ring3. O-ring

4. O-ring 5. O-ring (with collar)6. Oil level gauge guide

7. Oil level gauge 8. O-ring9. Connector bolt

10. Oil filter 11. Oil cooler12. Relief valve

13. Oil pressure switch 14. Gasket15. Drain plug

16. Oil pan (lower) 17. Oil strainer

KBIA2465E

KBIA2466E

Revision: March 2010 2008 QX56

Page 1881 of 4083

EM-78

< REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

Removal and InstallationINFOID:0000000001538831

WARNING:

• Situate vehicle on a flat and solid surface.

• Place chocks at front and back of rear wheels.

• For engines not equipped with engine slingers, attach proper slingers and bolts described in PARTS

CATALOG.

CAUTION:

• Always be careful to work safely, avoid forceful or uninstructed operations.

• Do not start working until exh aust system and engine coolant are cooled sufficiently.

• If items or work required are no t covered by the engine section, follow the applicable procedures.

• Always use the support poin t specified for lifting.

• Use either 2-point lift type or separate type lift. If board-on type is used for unavoidable reasons,

support at the rear axle jacking point with transmission jack or similar tool before starting work, in

preparation for the backward shift of center of gravity.

• For supporting points for lifting and jacking point at rear axle, refer to GI-30, "

Garage Jack and

Safety Stand".

REMOVAL

Preparation

1. Drain the engine coolant. Refer to CO-11, "Changing Engine Coolant".

2. Partially drain the A/T fluid. Refer to TM-180, "

Changing the A/T Fluid (ATF)".

3. Release the fuel pressure. Refer to EC-494, "

Fuel Pressure Check".

1. Rear engine mounting insulator 4WD 2. Rear engine mounting insulator 2WD 3. LH engine mounting bracket

4. LH heat shield plate 5. LH engine mounting insulator 6. RH engine mounting bracket

7. RH heat shield plate 8. RH engine mounting insulator

LBIA0397E

Revision: March 2010 2008 QX56

Page 1886 of 4083

ENGINE UNITEM-83

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

DISASSEMBLY

NOTE:

Explained here is how to disassemble with engine stand supporting transmission surface. When using differ-

ent type of engine stand, some steps may be different.

1. Remove engine assembly and mount to engine stand. Refer to

EM-78, "

Removal and Installation".

CAUTION:

Before removing the hanging chains, make sure engi ne stand is stable and there is no risk of over-

turning.

2. Drain engine oil. Refer to LU-9, "

Changing Engine Oil".

3. Drain engine coolant by removing the cylinder block drain plugs “A”, “B”, “C” and “D” as shown.

4. Remove the following components and associated parts (the parts referred to in step 1 are not included here).

• Oil pan (upper and lower) and oil strainer. Refer to EM-33, "

Removal and Installation".

• Crankshaft pulley, front cover and timing chain. Refer to EM-45, "

Removal and Installation".

• Camshaft. Refer to EM-53, "

Removal and Installation".

• Cylinder head. Refer to EM-68, "

Removal and Installation".

5. Remove knock sensor and sub harness. CAUTION:

Carefully handle sensor, avoiding shocks.

6. Check connecting rod side clearance. Refer to EM-90, "

Inspection After Disassembly".

7. Remove piston and connecting rod assembly as follows.

a. Position the crankshaft pin corresponding to the connecting rod to be removed onto bottom dead center.

b. Remove connecting rod cap.

16. Thrust bearing lower 17. Main bearing lower18. Crankshaft

19. Pilot converter 20. Thrust bearing upper21. Side bolt

22. Drive plate 23. Reinforcement plate24. Rear oil seal retainer

25. Rear oil seal 26. Transmission27. O-ring

28. Crankshaft position sensor (POS) 29. Gasket 30. Cylinder block heater

31. Connector cap

WBIA0419E

KBIA2549E

Revision: March 2010 2008 QX56

Page 2132 of 4083

COIL SPRING AND SHOCK ABSORBERFSU-15

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

REMOVAL AND INSTALLATION

COIL SPRING AN D SHOCK ABSORBER

Removal and InstallationINFOID:0000000001534629

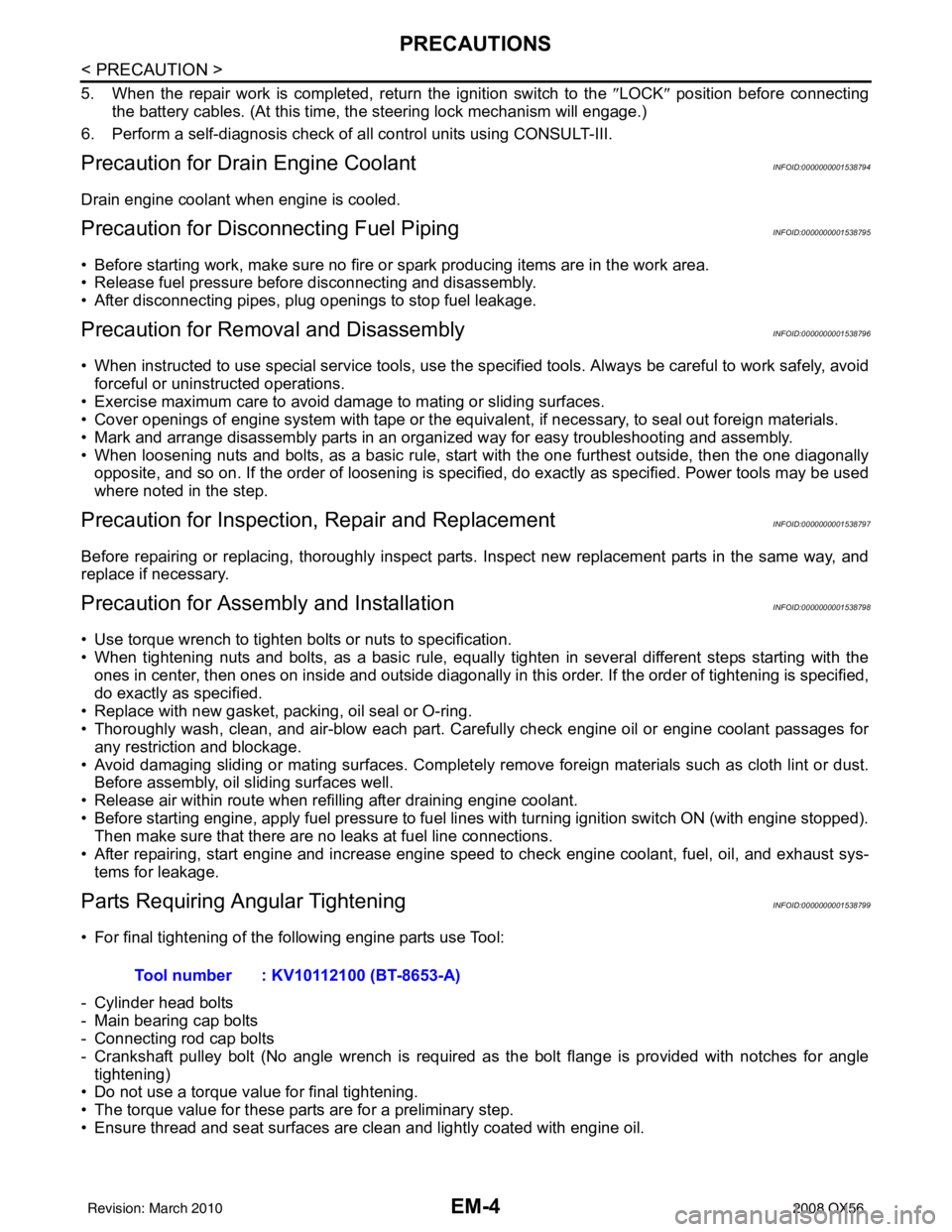

REMOVAL

1. Remove the wheel and tire using power tool.

2. Remove the shock absorber lower bolt using power tool.

3. Remove the three shock absorber upper nuts using power tool.

4. Remove the coil spring and shock absorber assembly.

• Turn steering knuckle out to gain enough clearance forremoval.

INSTALLATION

Installation is in the reverse order of removal.

• The lower seat step (2) in the shock absorber assembly (1) faces

outside of vehicle.

- Upper spring insulator (3)

- ⇐ : Front

• Tighten all nuts and bolts to specification. Refer to FSU-14, "

Com-

ponent" .

• When installing wheel and tire, refer to WT-48, "

Rotation".

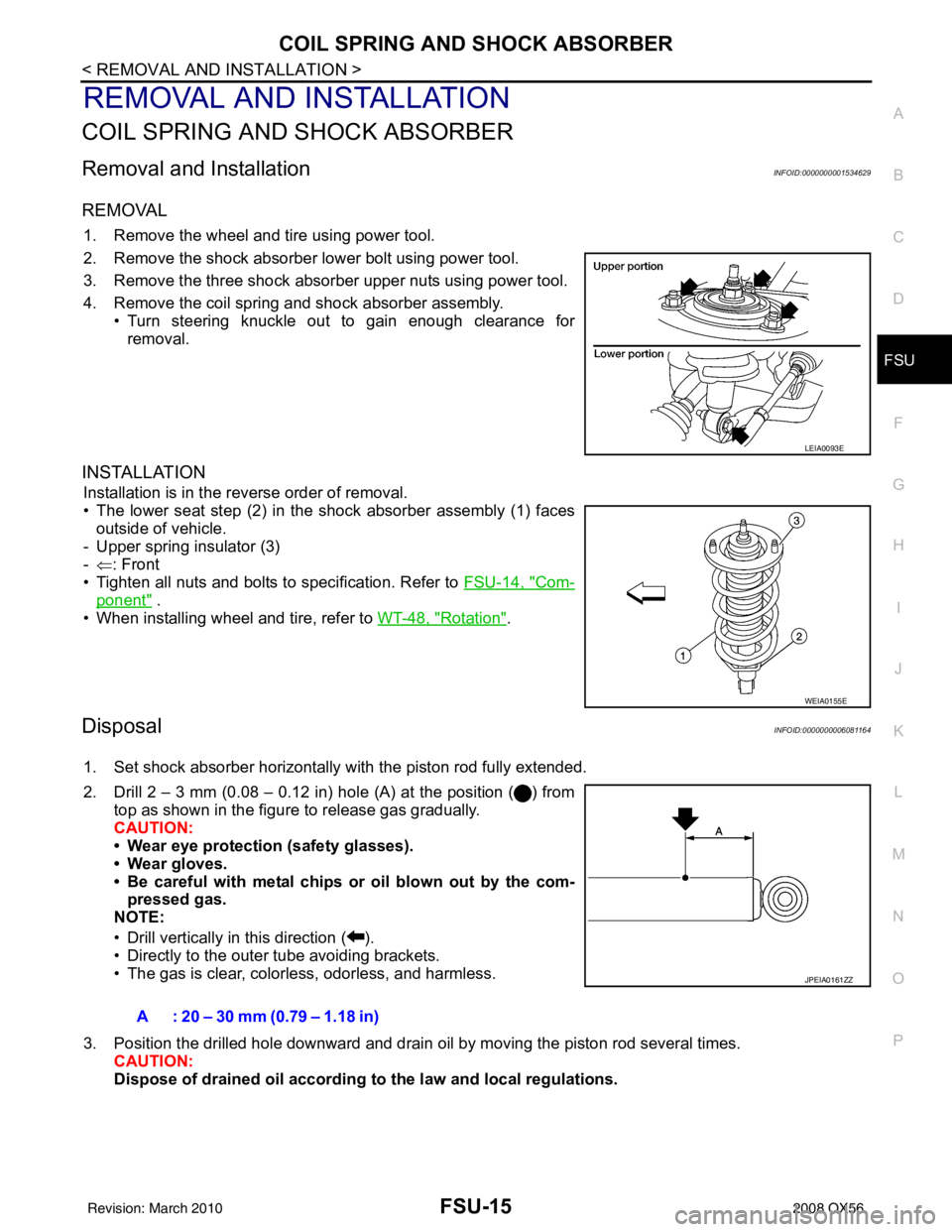

DisposalINFOID:0000000006081164

1. Set shock absorber horizontally with the piston rod fully extended.

2. Drill 2 – 3 mm (0.08 – 0.12 in) hole (A) at the position ( ) from

top as shown in the figure to release gas gradually.

CAUTION:

• Wear eye protection (safety glasses).

• Wear gloves.

• Be careful with metal chips or oil blown out by the com-pressed gas.

NOTE:

• Drill vertically in this direction ( ).

• Directly to the outer tube avoiding brackets.

• The gas is clear, colorless, odorless, and harmless.

3. Position the drilled hole downward and drain oil by moving the piston rod several times. CAUTION:

Dispose of drained oil according to the law and local regulations.

LEIA0093E

WEIA0155E

A : 20 – 30 mm (0.79 – 1.18 in)

JPEIA0161ZZ

Revision: March 2010 2008 QX56

Page 2235 of 4083

HA-30

< ON-VEHICLE REPAIR >

REFRIGERATION SYSTEM

Rear A/C System

NOTE:

Refer to HA-5, "

Precaution for Refrigerant Connection".

1. High-pressure service valve 2. Grommet 3. High-pressure pipe

4. Refrigerant pressure sensor 5. Condenser 6. Compressor shaft seal

7. High-pressure flexible hose 8. Low-pressure flexible hose 9. Low-pressure service valve

10. Low-pressure pipe 11. Expansion valve (front)12. Drain hose

AWIIA0134GB

1. Rear heater and cooling unit assembly 2. Rear A/C pipes 3. Rear A/C heater core pipes

4. Rear heater core hose 5. Rear blower motor6. Underfloor rear A/C pipes

7. Underfloor rear heater core pipes A. Bolt torque specification B. Leak checking order (l - r)

C. Tightening torque D. Wrench sizeE. O-ring size

⇐ Front

NOTE: The O-ring size 8 is the high-side and the O-ring size 16 is the low-side.

Revision: March 2010 2008 QX56

Page 2242 of 4083

LOW-PRESSURE PIPEHA-37

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

LOW-PRESSURE PIPE

Removal and Installation for Low-Pressure PipeINFOID:0000000001516655

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Remove the cowl top and the cowl top extension. Refer to EXT-18, "

Removal and Installation".

3. Remove the low-pressure pipe. CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "

Component".

CAUTION:

• Replace the O-ring of the high/low-pressure pipe with a new one, then apply compressor oil to it

when installing it.

• After charging refrigerant, check for leaks.

Removal and Installation for Rear High- and Low-Pressure A/C and Heater Core Pipes

INFOID:0000000002975446

REMOVAL

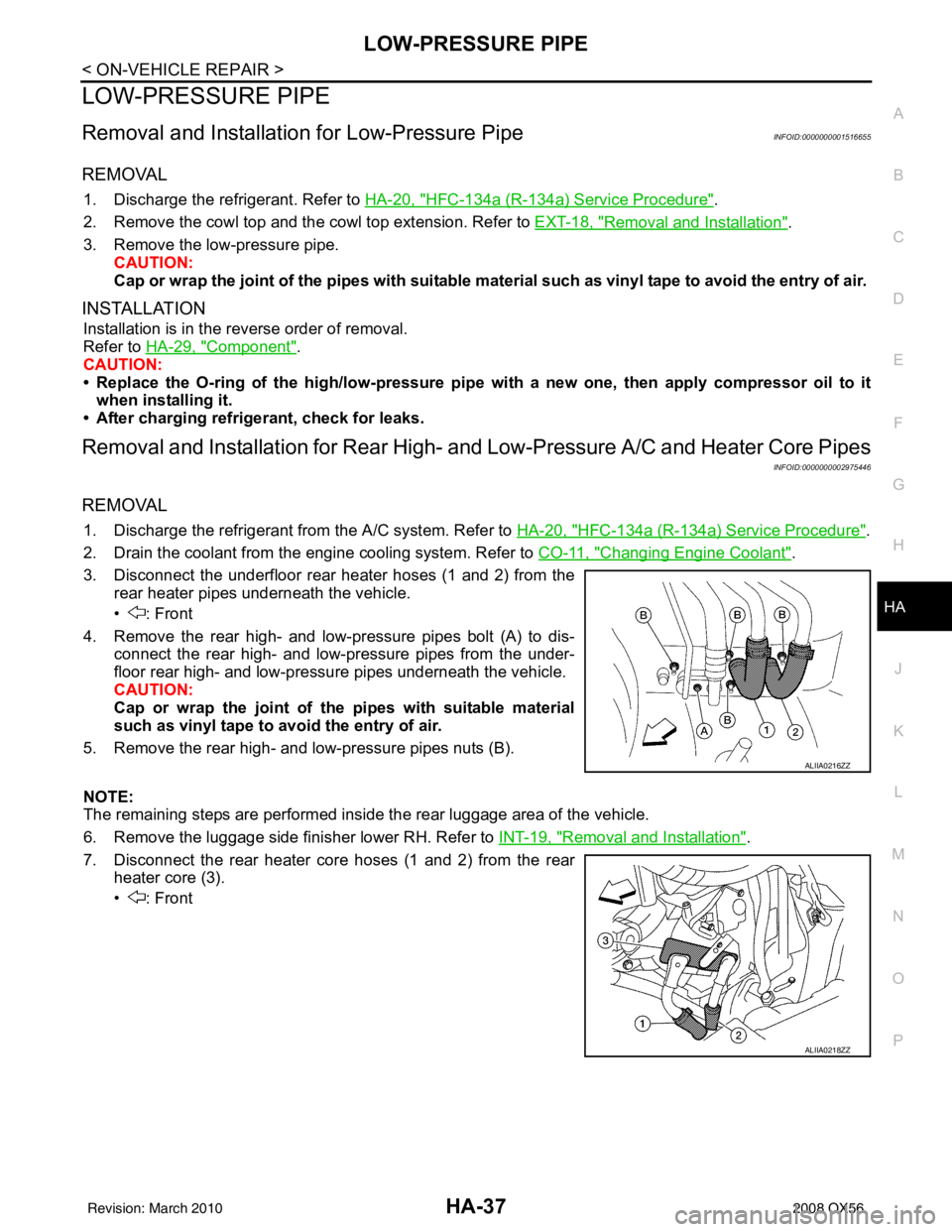

1. Discharge the refrigerant from the A/C system. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Drain the coolant from the engine cooling system. Refer to CO-11, "

Changing Engine Coolant".

3. Disconnect the underfloor rear heater hoses (1 and 2) from the rear heater pipes underneath the vehicle.

• : Front

4. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the under-

floor rear high- and low-pressure pipes underneath the vehicle.

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avo id the entry of air.

5. Remove the rear high- and low-pressure pipes nuts (B).

NOTE:

The remaining steps are performed inside the rear luggage area of the vehicle.

6. Remove the luggage side finisher lower RH. Refer to INT-19, "

Removal and Installation".

7. Disconnect the rear heater core hoses (1 and 2) from the rear heater core (3).

• : Front

ALIIA0216ZZ

ALIIA0218ZZ

Revision: March 2010 2008 QX56