service indicator INFINITI QX56 2008 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1912 of 4083

SERVICE DATA AND SPECIFICATIONS (SDS)EM-109

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Unit: mm (in)

SPARK PLUG

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

*: Total indicator reading

Valve Seal

Unit: mm (in)

Valve Lifter

Unit: mm (in)

Valve Clearance

Items

Limit

Surface distortion Exhaust manifold 0.3 (0.012)

Make NGK

Model Standard model

Standard type* DILFR5A-11

Gap (Nominal) 1.1 (0.043)

ItemsStandard

Camshaft runout [TIR*] Less than 0.02 (0.0008)

Camshaft cam height “A” Intake

44.865 - 45.055 (1.7663 - 1.7738)

Exhaust 45.075 - 45.265 (1.7746 - 1.7821)

Cam wear limit 0.02 (0.0008)

Outside diameter of camshaft journal 25.950 - 25.970 (1.0217 - 1.0224)

Camshaft bracket inside diameter 26.000 - 26.021 (1.0236 - 1.0244)

Camshaft journal clearance 0.030 - 0.071 (0.0012 - 0.0028)

Camshaft end play 0.115 - 0.188 (0.0045 - 0.0074)

Camshaft dimension "A" for #1 journal 30.500 - 30.548 (1.2008 - 1.2027)

Cylinder head dimension "B" for #1 journal 30.360 - 30.385 (1.1953 - 1.1963)

Camshaft sprocket runout [TIR*] Less than 0.15 (0.0059)

SEM671

Items Standard

Height "H" (without valve spring installed) 14.300 - 14.900 (0.5630 - 0.5870)

Items Standard

Valve lifter diameter 33.977 - 33.987 (1.3377 - 1.3381)

Valve lifter hole diameter 34.000 - 34.016 (1.3386 - 1.3392)

Clearance between lifter and lifter guide 0.013 - 0.039 (0.0005 - 0.0015)

Revision: March 2010 2008 QX56

Page 1919 of 4083

EM-116

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

*: Total indicator reading

MAIN BEARING

Unit: mm (in)

Main journal dia. “Dm” grade (No. 2, 3 and 4)StandardGrade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 1

Grade No. 2 63.963 - 63.964 (2.5182 - 2.5183)

63.962 - 63.963 (2.5182 - 2.5182)

63.961 - 63.962 (2.5181 - 2.5182)

63.960 - 63.961 (2.5181 - 2.5181)

63.959 - 63.960 (2.5181 - 2.5181)

63.958 - 63.959 (2.5180 - 2.5181)

63.957 - 63.958 (2.5180 - 2.5180)

63.956 - 63.957 (2.5179 - 2.5180)

63.955 - 63.956 (2.5179 - 2.5179)

63.954 - 63.955 (2.5179 - 2.5179)

63.953 - 63.954 (2.5178 - 2.5179)

63.952 - 63.953 (2.5178 - 2.5178)

63.951 - 63.952 (2.5178 - 2.5178)

63.950 - 63.951 (2.5177 - 2.5178)

63.949 - 63.950 (2.5177 - 2.5177)

63.948 - 63.949 (2.5176 - 2.5177)

63.947 - 63.948 (2.5176 - 2.5176)

63.946 - 63.947 (2.5176 - 2.5176)

63.945 - 63.946 (2.5175 - 2.5176)

63.944 - 63.945 (2.5175 - 2.5175)

63.943 - 63.944 (2.5174 - 2.5175)

63.942 - 63.943 (2.5174 - 2.5174)

63.941 - 63.942 (2.5174 - 2.5174)

63.940 - 63.941 (2.5173 - 2.5174)

Pin journal dia. “Dp” StandardGrade No. 0 53.968 - 53.974 (2.1247 - 2.1250)

Grade No. 1 53.962 - 53.968 (2.1245 - 2.1247)

Grade No. 2 53.956 - 53.962 (2.1243 - 2.1245)

Center distance “r” 45.96 - 46.04 (1.8094 - 1.8126)

Out-of-round (Difference between X and Y) Limit0.002 (0.0001)

Taper (Difference between A and B) 0.002 (0.0001)

Runout [TIR*] Less than 0.05 (0.002)

Crankshaft end play Standard

0.10 - 0.26 (0.0039 - 0.0102)

Limit 0.30 (0.0118)

Grade number* UPR/LWR Thickness Identification color Remarks

PBIC0189E

Revision: March 2010 2008 QX56

Page 2125 of 4083

FSU-8

< ON-VEHICLE MAINTENANCE >

ON-VEHICLE SERVICE

• Your alignment machine should be regularly calibrated in order to give correct information.

• Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-25,

"Wheelarch Height (Unladen*1)" .

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators may not be correct.

• This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com- pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

• Use the “Jacking Compensation” method. After inst alling the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

• See Instructions in the alignment machine you are using for more information.

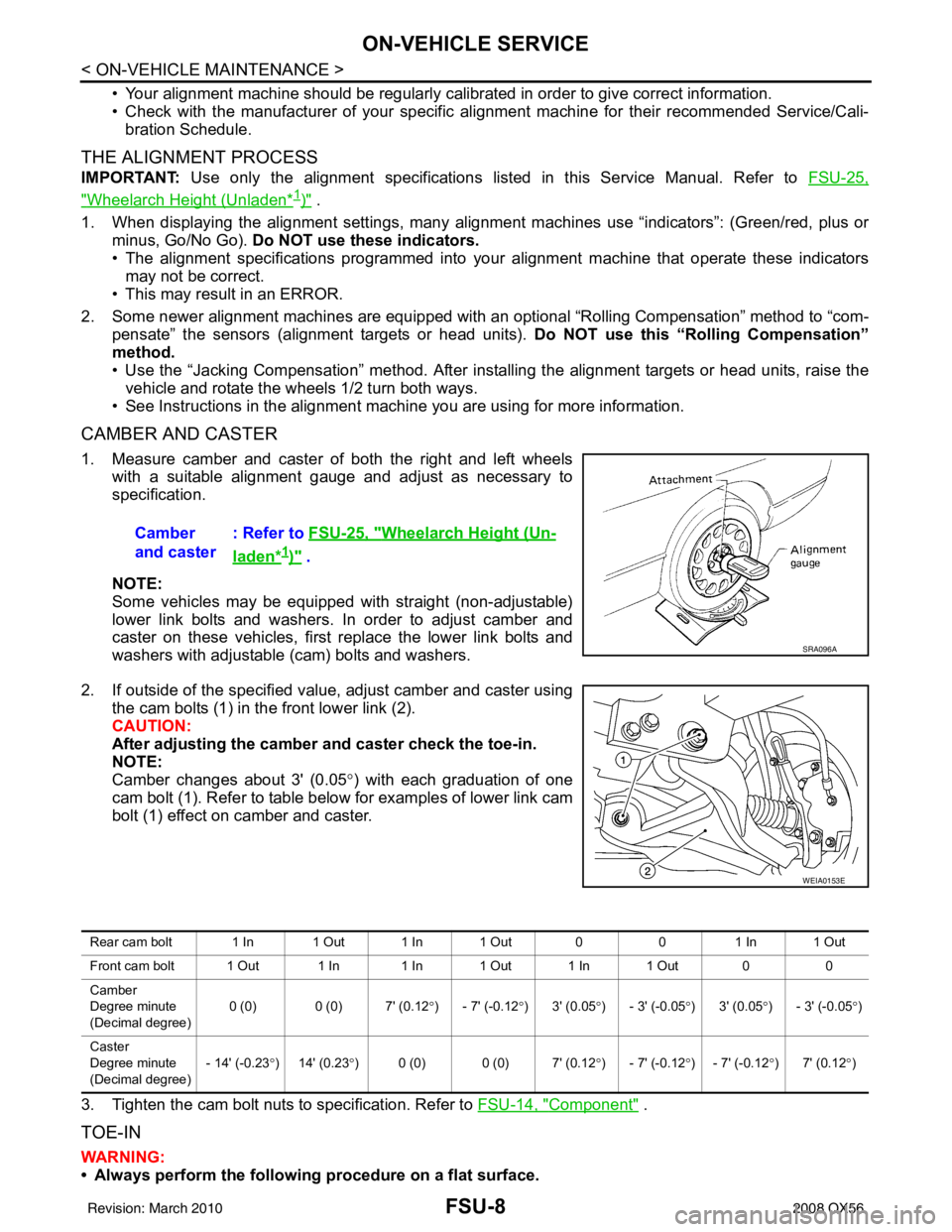

CAMBER AND CASTER

1. Measure camber and caster of both the right and left wheels

with a suitable alignment gauge and adjust as necessary to

specification.

NOTE:

Some vehicles may be equipped with straight (non-adjustable)

lower link bolts and washers. In order to adjust camber and

caster on these vehicles, first replace the lower link bolts and

washers with adjustable (cam) bolts and washers.

2. If outside of the specified value, adjust camber and caster using the cam bolts (1) in the front lower link (2).

CAUTION:

After adjusting the camber and caster check the toe-in.

NOTE:

Camber changes about 3' (0.05 °) with each graduation of one

cam bolt (1). Refer to table below for examples of lower link cam

bolt (1) effect on camber and caster.

3. Tighten the cam bolt nuts to specification. Refer to FSU-14, "

Component" .

TOE-IN

WARNING:

• Always perform the following procedure on a flat surface.

Camber

and caster

: Refer to

FSU-25, "

Wheelarch Height (Un-

laden*1)" .

SRA096A

WEIA0153E

Rear cam bolt 1 In 1 Out 1 In 1 Out 0 01 In 1 Out

Front cam bolt 1 Out 1 In 1 In 1 Out 1 In 1 Out 0 0

Camber

Degree minute

(Decimal degree) 0 (0) 0 (0) 7' (0.12

°) - 7' (-0.12 °)3' (0.05 °) - 3' (-0.05 °)3' (0.05 °) - 3' (-0.05 °)

Caster

Degree minute

(Decimal degree) - 14' (-0.23

°) 14' (0.23 °) 0 (0) 0 (0) 7' (0.12 °) - 7' (-0.12 °) - 7' (-0.12 °)7' (0.12 °)

Revision: March 2010 2008 QX56

Page 2160 of 4083

GI-18

< HOW TO USE THIS MANUAL >

TERMINOLOGY

Nonvolatile random access memory NVRAM***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Transmission range switch *** Park/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain cont rol module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sole-

noid valve PAIRC solenoid valve

AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI***

Simultaneous multiport fuel injection sys-

tem ***

Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVVThermal vacuum valve

Three way catalyst TWCCatalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OCCatalyst

Three way + oxidation catalytic converter

system TWC + OC system

***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

Lock-up solenoid

NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

Revision: March 2010

2008 QX56

Page 2278 of 4083

![INFINITI QX56 2008 Factory User Guide MODE DOOR MOTORHAC-25

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

The mode door motor (front) is attached to the heater & cooling unit

assembly. It rotates so INFINITI QX56 2008 Factory User Guide MODE DOOR MOTORHAC-25

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

The mode door motor (front) is attached to the heater & cooling unit

assembly. It rotates so](/img/42/57030/w960_57030-2277.png)

MODE DOOR MOTORHAC-25

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

The mode door motor (front) is attached to the heater & cooling unit

assembly. It rotates so that air is discharged from the outlet as indi-

cated by the A/C auto amp. Motor rotation is conveyed to a link

which activates the mode door.

Mode Door Motor (Front) Component Function CheckINFOID:0000000001679783

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING O PERATIONAL CHECK - DISCHARGE AIR

1. Press mode switch four times and then press the (DEF) switch. Each position indicator should change shape (on display).

2. Confirm that discharge air comes out accordi ng to the air distribution table. Refer to HAC-15, "

Discharge

Air Flow (Front)".

NOTE:

Confirm that the compressor clutch is engaged (visual inspection) and intake door position is at FRESH

when DEF ( ) or D/F ( ) is selected.

Can a symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to HAC-4, "

Operational Check

(Front)".

Can a symptom be duplicated?

YES >> Refer to HAC-3, "How to Perform Trouble Diagnosis For Quick And Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK MODE DOOR OPERATION

Check and verify mode door mechanism for smooth operation in each mode.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair as necessary.

5.PERFORM A/C AUTO AMP. SELF-DIAGNOSIS

Perform self-diagnosis to check for any codes. Refer to HAC-22, "

A/C Auto Amp. Self-Diagnosis".

Are any self-diagnosis codes present?

YES >> Refer to HAC-23, "A/C System Self-Diagnosis Code Chart".

NO >> GO TO 6.

6.PERFORM A/C AND AV SWITCH ASSEMBLY SELF-DIAGNOSIS

Perform self-diagnosis to check the A/C and AV switch assembly. Refer to HAC-22, "

A/C and AV Switch

Assembly Self-Diagnosis".

Is the inspection result normal?

YES >> Replace A/C and AV switch assembly. Refer to VTL-7, "Removal and Installation".

NO >> GO TO 7.

WJIA0587E

Revision: March 2010 2008 QX56

Page 2294 of 4083

![INFINITI QX56 2008 Factory User Guide INTAKE DOOR MOTORHAC-41

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

COMPONENT DESCRIPTION

Intake door motor

The intake door motor is attached to the intake un INFINITI QX56 2008 Factory User Guide INTAKE DOOR MOTORHAC-41

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

COMPONENT DESCRIPTION

Intake door motor

The intake door motor is attached to the intake un](/img/42/57030/w960_57030-2293.png)

INTAKE DOOR MOTORHAC-41

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

COMPONENT DESCRIPTION

Intake door motor

The intake door motor is attached to the intake unit. It rotates so that

air is drawn from inlets set by the A/C auto amp. Motor rotation is

conveyed to a lever which activates the intake door.

Intake Door Motor Component Function CheckINFOID:0000000001679790

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - REC ( )

1. Press the mode switch to vent mode( ).

2. Press REC ( ) switch. The REC ( )indicator should illuminate.

3. Press REC ( ) switch again. The REC ( ) indicator should go out.

4. Listen for intake door position change (you should hear blower sound change slightly).

Can a symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to HAC-4, "

Operational Check

(Front)".

Can a symptom be duplicated?

YES >> Refer to HAC-3, "How to Perform Trouble Diagnosis For Quick And Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK INTAKE DOOR OPERATION

Check and verify intake door me chanism for smooth operation.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair intake door mechanism.

5.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis to check for any codes. Refer to HAC-22, "

A/C and AV Switch Assembly Self-Diagno-

sis".

Are any self-diagnosis codes present?

YES >> Refer to HAC-23, "A/C System Self-Diagnosis Code Chart".

NO >> GO TO 6.

6.RECHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to HAC-4, "

Operational Check (Front)".

Does another symptom exist?

YES >> Refer to HAC-3, "How to Perform Trouble Diagnosis For Quick And Accurate Repair".

NO >> Replace A/C auto amp. Refer to VTL-7, "

Removal and Installation".

WJIA0552E

Revision: March 2010 2008 QX56

Page 2298 of 4083

![INFINITI QX56 2008 Factory User Guide DEFROSTER DOOR MOTOR CIRCUITHAC-45

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Defroster Door Motor Co mponent Function CheckINFOID:0000000001679793

INSPECTIO INFINITI QX56 2008 Factory User Guide DEFROSTER DOOR MOTOR CIRCUITHAC-45

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Defroster Door Motor Co mponent Function CheckINFOID:0000000001679793

INSPECTIO](/img/42/57030/w960_57030-2297.png)

DEFROSTER DOOR MOTOR CIRCUITHAC-45

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Defroster Door Motor Co mponent Function CheckINFOID:0000000001679793

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING O PERATIONAL CHECK - DEFROSTER DOOR

1. Press the mode switch and select vent ( ).

2. Press the defrost switch ( ). Defroster indicator should illuminate (on display).

3. Listen for defroster door position change (blower sound should change slightly).

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to HAC-4, "

Operational Check (Front)".

Does another symptom exist?

YES >> Refer to HAC-3, "How to Perform Trouble Diagnosis For Quick And Accurate Repair".

NO >> SYSTEM OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK DEFROSTER DOOR MOTOR

Perform diagnostic procedure for defroster door motor. Refer to HAC-45, "

Defroster Door Motor Component

Function Check".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair PBR circuit or replace defroster door motor. Refer to VTL-21, "

Removal and Installation".

5.CHECK DEFROSTER DOOR OPERATION

Check and verify defroster door mechanism for smooth operation.

Is the inspection result normal?

YES >> Replace defroster door motor. Refer to VTL-21, "Removal and Installation".

NO >> Repair defroster door mechanism.

Defroster Door Motor Diagnosis ProcedureINFOID:0000000001679794

SYMPTOM:

• Defroster door does not change.

• Defroster door motor does not operate normally.

DIAGNOSTIC PROCEDURE FOR DEFROSTER DOOR MOTOR

1.CHECK A/C AUTO AMP. FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Press the defroster switch ( ).

3. Check voltage between A/C auto amp. harness connector M49 terminal 24 and terminal 23 and press the defroster switch ( )

again.

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

A/C auto amp.: M49 24 23 Press de-

froster switch Battery

voltage

AWIIA0152ZZ

Revision: March 2010 2008 QX56

Page 2309 of 4083

![INFINITI QX56 2008 Factory User Guide HAC-56

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

System Operation

Rear Blower Control

When the rear blower control dial (front) REAR CTRL switch is pressed (indica INFINITI QX56 2008 Factory User Guide HAC-56

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

System Operation

Rear Blower Control

When the rear blower control dial (front) REAR CTRL switch is pressed (indica](/img/42/57030/w960_57030-2308.png)

HAC-56

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

System Operation

Rear Blower Control

When the rear blower control dial (front) REAR CTRL switch is pressed (indicator on), it allows the rear air

control (rear) to control the rear blower motor speed. If t

he REAR CTRL switch is off (indicator off), the rear air

control (front) controls the rear blower motor s peed regardless of the rear air control (rear) position.

Rear Blower Motor Component Function CheckINFOID:0000000001679800

INSPECTION FLOW

SYMPTOM:

• Rear blower motor does not operate from the rear air control (front) and the rear air control (rear).

• Rear blower motor operates from rear air control (front) only.

• Rear blower motor operates in high at all times.

INSPECTION FLOW

1.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 2.

2.CONFIRM SYMPTOM BY PERFORMING REAR BLOW ER MOTOR OPERATIONAL CHECK FROM REAR

AIR CONTROL (FRONT)

1. Turn ignition switch ON.

2. Turn the rear air control (front) blower control dial to the lowest speed and check for rear blower operation

(REAR CTRL indicator off).

3. Continue checking that rear blower speed increases as the rear blower control dial is rotated clockwise.

Does the rear blower motor operate correctly?

YES >> GO TO 3.

NO >> Check the rear blower motor operation. Refer to HAC-56, "

Rear Blower Motor Component Func-

tion Check".

3.CONFIRM SYMPTOM BY PERFORMING REAR BLOWER MOTOR OPERATIONAL CHECK FROM

REAR AIR CONTROL (REAR)

1. Press the REAR CTRL switch (indicator on) on the rear air control (front) to send control of the rear blower

motor back the rear air control (rear).

2. Turn the rear air control (rear) blower control dial to the lowest speed and check for rear blower operation.

3. Continue checking that rear blower speed increases as the rear blower control dial is rotated clockwise.

Does the rear blower motor operate correctly?

YES >> GO TO 4.

AWIIA0181GB

Revision: March 2010 2008 QX56

Page 2314 of 4083

![INFINITI QX56 2008 Factory User Guide REAR AIR CONTROL SYSTEMHAC-61

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REAR AIR CONTROL SYSTEM

Rear Air Control System DescriptionINFOID:0000000001679804

S INFINITI QX56 2008 Factory User Guide REAR AIR CONTROL SYSTEMHAC-61

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REAR AIR CONTROL SYSTEM

Rear Air Control System DescriptionINFOID:0000000001679804

S](/img/42/57030/w960_57030-2313.png)

REAR AIR CONTROL SYSTEMHAC-61

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REAR AIR CONTROL SYSTEM

Rear Air Control System DescriptionINFOID:0000000001679804

SYSTEM DESCRIPTION

Component Parts

Rear air control system components are:

• A/C auto amp.

• Rear air control (front)

• Rear air control (rear)

• Air mix door motor (rear)

• Mode door motor (rear)

System Operation

Rear Air Control

When the REAR CTRL indicator is off the rear air cont rol (front) will control all rear blower motor speeds and

the rear temperature and mode operations. When the REAR CTRL switch is pressed (indicator on), the rear

air control (rear) will control all the rear blower motor speeds and the rear temperature and mode operations.

Rear Air Control Component Function CheckINFOID:0000000001679805

SYMPTOM:

• Temperature cannot be adjusted from the rear air controls.

• Mode cannot be adjusted from the rear air controls.

INSPECTION FLOW

1.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 2.

2.CONFIRM SYMPTOM BY PERFORMING REAR AIR CONTROL (FRONT) AIR MIX DOOR MOTOR OP-

ERATIONAL CHECK

AWIIA0197GB

Revision: March 2010 2008 QX56

Page 2541 of 4083

![INFINITI QX56 2008 Factory User Guide LAN-46

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

NOTE:

CAN data of the air bag diagnosis sensor unit is not us

ed by usual service work, thus it is omitted.

Tire pressure data signal R T

T INFINITI QX56 2008 Factory User Guide LAN-46

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

NOTE:

CAN data of the air bag diagnosis sensor unit is not us

ed by usual service work, thus it is omitted.

Tire pressure data signal R T

T](/img/42/57030/w960_57030-2540.png)

LAN-46

< FUNCTION DIAGNOSIS >[CAN]

CAN COMMUNICATION SYSTEM

NOTE:

CAN data of the air bag diagnosis sensor unit is not us

ed by usual service work, thus it is omitted.

Tire pressure data signal R T

Tire pressure signal R TR

Turn indicator signal TR

Buzzer output signal TR

Door lock/unlock request signal RT

Hazard request signal RT

Hazard warning lamp request signal RT

Ignition knob switch signal RT

KEY warning signal TR

LOCK warning signal TR

Panic alarm request signal RT

Power window open request signal RT

1st position switch signal R T

4th position switch signal R T

Distance to empty signal RT

Fuel level low warning signal RT

Fuel level sensor signal R T

Parking brake switch signal RT

Seat belt buckle switch signal RT

Stop lamp switch signal R T

Tow mode switch signal R T

Vehicle speed signal RRR RRR R T

RRRT

Steering angle sensor signal TR

ABS malfunction signal RT

ABS warning lamp signal RT

Brake pressure sensor signal RT

Brake warning lamp signal RT

SLIP indicator lamp signal RT

TCS malfunction signal RT

VDC malfunction signal RT

VDC OFF indicator lamp signal RRT

VDC operation signal RT

Front wiper stop position signal RT

High beam status signal R T

Hood switch signal RT

Low beam status signal R T

Rear window defogger control signal R RT

Ambient sensor signal RT

Signal name/Connecting unit

ECM

TCM

LASER ICC

ADP

AV

BCM

HVAC I-KEY M&A

STRG 4WDABS

IPDM-E

Revision: March 2010 2008 QX56