brake sensor INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 12 of 4083

ACC-4

< REMOVAL AND INSTALLATION >

ACCELERATOR CONTROL SYSTEM

REMOVAL AND INSTALLATION

ACCELERATOR CONTROL SYSTEM

Removal and InstallationINFOID:0000000001534441

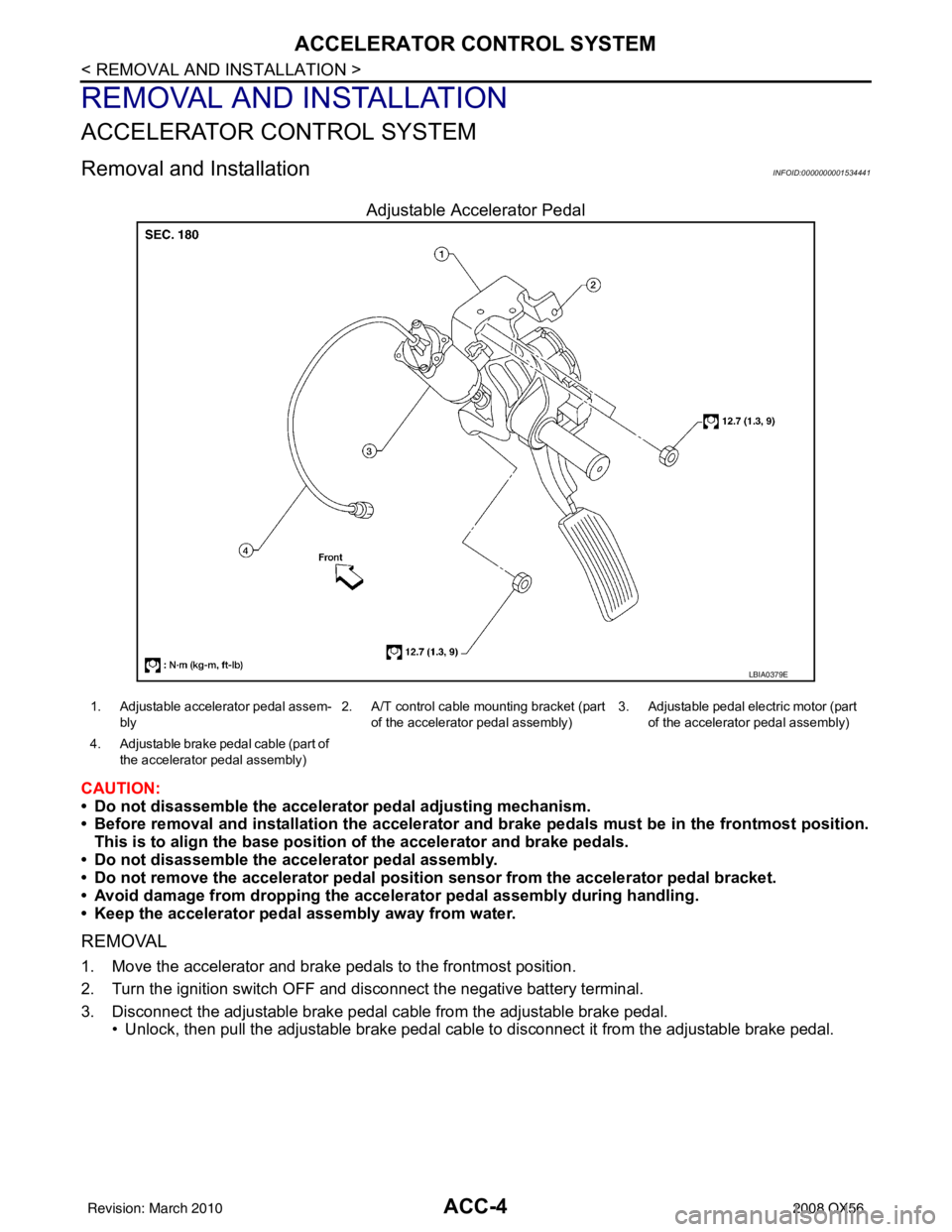

Adjustable Accelerator Pedal

CAUTION:

• Do not disassemble the accelerator pedal adjusting mechanism.

• Before removal and installation the accelerator and brake pedals must be in the frontmost position.

This is to align the base position of the accelerator and brake pedals.

• Do not disassemble the accelerator pedal assembly.

• Do not remove the accelerator pedal position sensor from the accelerator pedal bracket.

• Avoid damage from dropping the accel erator pedal assembly during handling.

• Keep the accelerator pedal assembly away from water.

REMOVAL

1. Move the accelerator and brake pedals to the frontmost position.

2. Turn the ignition switch OFF and disconnect the negative battery terminal.

3. Disconnect the adjustable brake pedal cable from the adjustable brake pedal. • Unlock, then pull the adjustable brake pedal cable to disconnect it from the adjustable brake pedal.

LBIA0379E

1. Adjustable accelerator pedal assem-

bly 2. A/T control cable mounting bracket (part

of the accelerator pedal assembly) 3. Adjustable pedal electric motor (part

of the accelerator pedal assembly)

4. Adjustable brake pedal cable (part of the accelerator pedal assembly)

Revision: March 2010 2008 QX56

Page 209 of 4083

![INFINITI QX56 2008 Factory Service Manual AV-28

< FUNCTION DIAGNOSIS >[AUDIO SYSTEM]

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

Speaker Test

Select “Speaker Test” to display the speaker diagnosis screen. Press

“Start” to generate a test tone INFINITI QX56 2008 Factory Service Manual AV-28

< FUNCTION DIAGNOSIS >[AUDIO SYSTEM]

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

Speaker Test

Select “Speaker Test” to display the speaker diagnosis screen. Press

“Start” to generate a test tone](/img/42/57030/w960_57030-208.png)

AV-28

< FUNCTION DIAGNOSIS >[AUDIO SYSTEM]

DIAGNOSIS SYSTEM (AV CONTROL UNIT)

Speaker Test

Select “Speaker Test” to display the speaker diagnosis screen. Press

“Start” to generate a test tone in speakers. Touch “End” to stop the

test tones.

Navigation

STEERING ANGLE ADJUSTMENT

The steering angle output value detected with the gyroscope is

adjusted.

SPEED CALIBRATION

During normal driving, distance error caused by tire wear and tire

pressure change is automatically adjusted for by the automatic dis-

tance correction function. This function, on the other hand, is for

immediate adjustment, in cases such as driving with tire chain fitted

on tires.

Diagnosis itemDis-

play Vehicle status

Remarks

Vehicle speed ON Vehicle speed > 0 km/h

Changes in indication may be delayed by approxi-

mately 1.5 seconds. This is normal.

OFF Vehicle speed = 0 km/h

− Ignition switch in ACC position

Parking brake ON Parking brake is applied.

OFF Parking brake is released.

Lights ON Light switch ON

Block the light beam from the auto light optical sensor.

OFF Light switch OFF

Ignition ON Ignition switch ON

—

OFF Ignition switch in ACC position

Reverse ON Selector lever in R position

Changes in indication may be delayed by approxi-

mately 1.5 seconds. This is normal.

OFF Selector lever in any position other

than R

− Ignition switch in ACC position

ALNIA0221GB

ALNIA0223GB

ALNIA0224GB

Revision: March 2010 2008 QX56

Page 286 of 4083

![INFINITI QX56 2008 Factory Service Manual AV

AV CONTROL UNITAV-105

< ECU DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

ECU DIAGNOSIS

AV CONTROL UNIT

Reference ValueINFOID:0000000001696141

VALUES ON THE DIAGNOSIS TOOL

CONSULT-III da INFINITI QX56 2008 Factory Service Manual AV

AV CONTROL UNITAV-105

< ECU DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

ECU DIAGNOSIS

AV CONTROL UNIT

Reference ValueINFOID:0000000001696141

VALUES ON THE DIAGNOSIS TOOL

CONSULT-III da](/img/42/57030/w960_57030-285.png)

AV

AV CONTROL UNITAV-105

< ECU DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

ECU DIAGNOSIS

AV CONTROL UNIT

Reference ValueINFOID:0000000001696141

VALUES ON THE DIAGNOSIS TOOL

CONSULT-III data monitor item

TERMINAL LAYOUT

PHYSICAL VALUES

Display Item Dis-

play Vehicle status

Remarks

VHCL SPD SIG ON Vehicle speed >0 km/h (0 MPH)

Changes in indication may be delayed. This is

normal.

OFF Vehicle speed =0 km/h (0 MPH)

PKB SIG ON Parking brake is applied.

Changes in indication may be delayed. This is

normal.

OFF Parking brake is released.

ILLUM SIG ON

Block the light beam from the auto

light optical sensor when the light

SW is ON.

—

OFF Expose the auto light optical sensor

to light when the light SW is OFF or

ON.

IGN SIG ON Ignition switch ON

—

OFF Ignition switch in ACC position

REV SIG ON Selector lever in R position

Changes in indication may be delayed. This is

normal.

OFF Selector lever in any position other

than R

ALNIA0670GB

Te r m i n a l

(Wire color) Description

ConditionReference value

(Approx.)

+ – Signal nameInput/

Output

1

(GR/L) Ground Amp. ON signal

OutputIgnition

switch ON —

Battery voltage

2

(LG) 3

(V) Pre-amp. audio signal front

LH

OutputIgnition

switch ON Audio output

SKIB3609E

Revision: March 2010

2008 QX56

Page 445 of 4083

BRAKE MASTER CYLINDERBR-25

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE MASTER CYLINDER

Removal and InstallationINFOID:0000000004894510

REMOVAL

CAUTION:

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• Before removing brake master cylinder, depress the brake pedal 5-6 times with the key OFF to deplete vacuum in the booster.

1. Remove brake reservoir cap.

2. Disconnect harness connectors for fluid level sensor, front and rear pressure sensors.

3. Using suitable tool, disconnect brake tube from master cylinder assembly.

4. Remove master cylinder assembly nuts, and remove master cylinder assembly.

INSTALLATION

Installation is in the reverse order of removal.

• Refill brake fluid and bleed air. Refer to BR-17, "

Bleeding Brake System".

CAUTION:

• Refill with new brake fluid. Refer to MA-12, "

Fluids and Lubricants".

• Do not reuse drained brake fluid.

• Adjust brake pedal. Refer to BR-15, "

Inspection and Adjustment".

1. Reservoir cap 2. Fluid level sensor 3. Grommet

4. Master cylinder assembly 5. Rear pressure sensor6. Front pressure sensor

7. Seal 8. Reservoir tankB. Brake fluid

R. Rubber grease

AWFIA0415GB

Revision: March 2010 2008 QX56

Page 446 of 4083

BR-26

< ON-VEHICLE REPAIR >

BRAKE BOOSTER

BRAKE BOOSTER

Removal and InstallationINFOID:0000000004894511

CAUTION:

• Be careful not to deform or bend brake piping while removing and installing brake booster.

• Replace clevis pin if it is damaged.

• Be careful not to damage brake booster stud bolt threads. If brake booster is tilted or inclined during

installation, dash panel may damage the threads.

• Attach the check valve in the correct direction.

REMOVAL

1. Remove air duct and resonator assembly. Refer to EM-25, "Removal and Installation".

2. Remove cowl top assembly. Refer to EXT-18, "

Removal and Installation".

3. Remove master cylinder assembly from brake booster. Refer to BR-25, "

Removal and Installation".

4. Remove vacuum hose from brake booster. Refer to BR-28, "

Removal and Installation".

5. Disconnect active booster and delta stroke s ensor harness connectors from brake booster.

6. Remove the instrument lower panel LH. Refer to IP-11, "

Exploded View".

7. Remove brake pedal to clevis attachment snap pin and clevis pin from inside the vehicle.

8. Remove brake booster to brake pedal assembly nuts.

9. Reposition the A/C line out of the way.

10. Remove brake booster and spacer from dash panel.

INSPECTION AFTER REMOVAL

Output Rod Length Inspection

1. Reservoir tank 2. Master cylinder assembly3. Gasket

4. Brake pedal 5. Lock nut 6. Spacer block

7. Brake booster 8. Active booster9. Delta stroke sensor

AWFIA0416GB

Revision: March 2010 2008 QX56

Page 449 of 4083

FRONT DISC BRAKEBR-29

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT DISC BRAKE

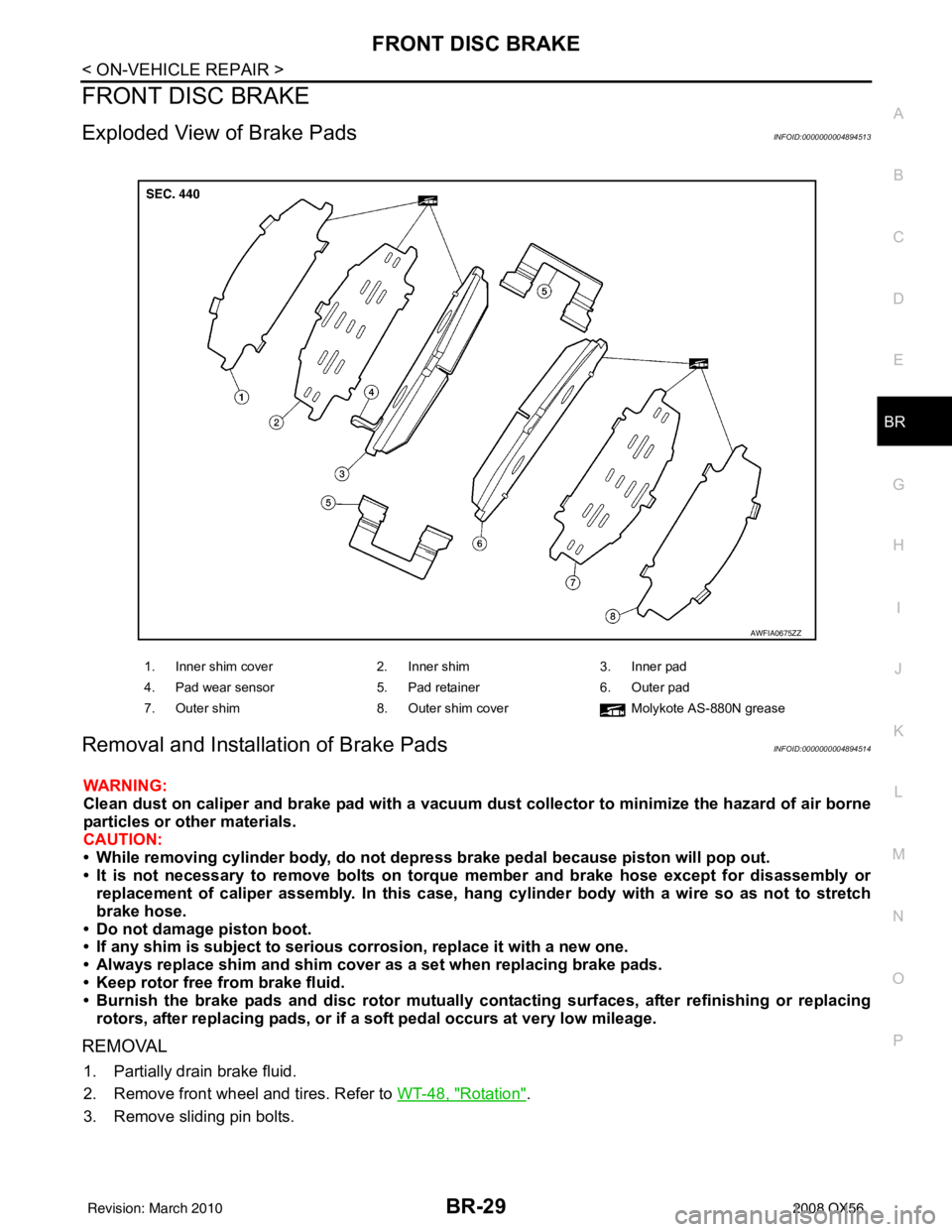

Exploded View of Brake PadsINFOID:0000000004894513

Removal and Installation of Brake PadsINFOID:0000000004894514

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder bod y, do not depress brake pedal because piston will pop out.

• It is not necessary to remove bolts on torque member and brake hose except for disassembly or replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shim and shim cover as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing rotors, after replacing pads, or if a so ft pedal occurs at very low mileage.

REMOVAL

1. Partially drain brake fluid.

2. Remove front wheel and tires. Refer to WT-48, "

Rotation".

3. Remove sliding pin bolts.

1. Inner shim cover 2. Inner shim3. Inner pad

4. Pad wear sensor 5. Pad retainer6. Outer pad

7. Outer shim 8. Outer shim cover Molykote AS-880N grease

AWFIA0675ZZ

Revision: March 2010 2008 QX56

Page 450 of 4083

BR-30

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

4. Hang cylinder body with a wire, and remove pads, pad retainers,shims, and shim cover from torque member.

CAUTION:

When removing the pad retainer from the torque member,

lift it in the direction indi cated by the arrow as shown so

that it does not deform.

INSTALLATION

1. Push piston in using suitable tool.

CAUTION:

In the case of replacing a pad with new one, ch eck the brake fluid level in the reservoir tank

because brake fluid returns to reservoir tank when pressing piston in.

NOTE:

Use a suitable tool to easily press in piston.

2. Apply Molykote AS-880N grease or equivalent to between shim cover and shim. Install inner shim, inner shim cover to inner pad, and install outer shim, outer shim cover to outer pad.

3. Install pad retainers and pads to torque member. CAUTION:

• Securely assemble pad retainers so that they ar e not being lifted up from torque member.

• Both inner and outer pads have a pad return system on the pad retainer. Install pad return lever

securely to pad wear sensor.

4. Install cylinder body to torque member.

5. Install sliding pin bolts, and tighten to specified torque. Refer to BR-31, "

Exploded View of Brake Caliper".

6. Check front disc brake for drag and correct as necessary.

7. Install front wheel and tire. Refer to WT-48, "

Rotation".

8. Check brake fluid level. Refer to BR-17, "

On Board Inspection".

Brake Burnishing ProcedureINFOID:0000000004894515

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

SBR556E

Revision: March 2010 2008 QX56

Page 457 of 4083

BRAKE MASTER CYLINDERBR-37

< DISASSEMBLY AND ASSEMBLY >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

DISASSEMBLY AND ASSEMBLY

BRAKE MASTER CYLINDER

Disassembly and AssemblyINFOID:0000000004894496

DISASSEMBLY

CAUTION:

• Master cylinder assembly cannot be disassembled.

• Do not drop parts. If a part is dropped, do not use it.

1. Pull the reservoir tank off the master cylinder assembly.

2. Remove the grommets from master cylinder assembly and discard the grommets. CAUTION:

Discard the grommets, do not reuse.

3. Remove the fluid level sensor from the reservoir tank.

4. Remove the front and rear pressure sensors and discard. CAUTION:

Discard the front and rear pressure sensors, do not reuse.

ASSEMBLY

CAUTION:

• Never use mineral oil such as kerosene, g asoline during the cleaning and assembly process.

• Do not drop parts. If a part is dropped, do not use it.

1. Reservoir cap 2. Fluid level sensor 3. Grommet

4. Master cylinder assembly 5. Rear pressure sensor6. Front pressure sensor

7. Seal 8. Reservoir tankB. Brake fluid

R. Rubber grease

AWFIA0415GB

Revision: March 2010 2008 QX56

Page 458 of 4083

BR-38

< DISASSEMBLY AND ASSEMBLY >

BRAKE MASTER CYLINDER

1. Apply brake fluid or rubber grease to the new grommets, then insert the new grommets into the mastercylinder assembly.

CAUTION:

Do not reuse the grommets.

2. Install the reservoir tank onto the master cylinder assembly.

3. Install the fluid level sensor on the reservoir tank.

4. Install the new front and rear pressure sensors. CAUTION:

Do not reuse the front and rear pressure sensors.

Revision: March 2010 2008 QX56

Page 468 of 4083

BRC-1

BRAKES

C

DE

G H

I

J

K L

M

SECTION BRC

A

B

BRC

N

O P

CONTENTS

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

BASIC INSPECTION ....... .............................

4

DIAGNOSIS AND REPAIR WORKFLOW ..... .....4

Work Flow ........................................................... ......4

Diagnostic Work Sheet ..............................................7

INSPECTION AND ADJUSTMENT .....................8

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ......

8

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Description ..................................

8

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

8

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION ............................................ ......

8

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Description ..........................

8

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Special Repair Require-

ment ..........................................................................

8

CALIBRATION OF DECEL G SENSOR ............... ......9

CALIBRATION OF DECEL G SENSOR : Descrip-

tion ............................................................................

9

CALIBRATION OF DECEL G SENSOR : Special

Repair Requirement ..................................................

9

FUNCTION DIAGNOSIS ..............................11

VDC ................................................................ ....11

System Diagram .................................................. ....11

Hydraulic Circuit Diagram .......................................12

System Description ............................................. ....12

Component Parts Location ......................................13

Component Description ...........................................14

TCS .....................................................................15

System Diagram .................................................. ....15

System Description .................................................15

Component Parts Location .................................. ....16

Component Description ...........................................17

ABS ...................................................................18

System Diagram ......................................................18

System Description ..................................................18

Component Parts Location ......................................19

Component Description ...........................................20

EBD ...................................................................21

System Diagram ......................................................21

System Description ..................................................21

Component Parts Location ......................................22

Component Description ...........................................23

DIAGNOSIS SYSTEM [ABS ACTUATOR

AND ELECTRIC UNIT (CONTROL UNIT)] .......

24

CONSULT-III Function (ABS) ..................................24

COMPONENT DIAGNOSIS .........................29

C1101, C1102, C1103, C1104 WHEEL SEN-

SOR-1 ................................................................

29

Description ........................................................... ....29

DTC Logic ................................................................29

Diagnosis Procedure ...............................................29

Component Inspection .............................................31

Special Repair Requirement ....................................31

C1105, C1106, C1107, C1108 WHEEL SEN-

SOR-2 ................................................................

32

Description ...............................................................32

DTC Logic ................................................................32

Diagnosis Procedure ...............................................32

Component Inspection .............................................34

Special Repair Requirement ....................................34

C1109 POWER AND GROUND SYSTEM ........35

Description ...............................................................35

DTC Logic ................................................................35

Diagnosis Procedure ...............................................35

Special Repair Requirement ....................................36

Revision: March 2010 2008 QX56