Stop INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1759 of 4083

![INFINITI QX56 2008 Factory Service Manual EC-460

< ECU DIAGNOSIS >[VK56DE]

ECM

• When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there

is malfunction on engine control system.

Therefore, INFINITI QX56 2008 Factory Service Manual EC-460

< ECU DIAGNOSIS >[VK56DE]

ECM

• When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there

is malfunction on engine control system.

Therefore,](/img/42/57030/w960_57030-1758.png)

EC-460

< ECU DIAGNOSIS >[VK56DE]

ECM

• When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there

is malfunction on engine control system.

Therefore, when electrical controlled throttle and pa rt of ECM related diagnoses are continuously detected

as NG for 5 trips, ECM warns the driver that engi ne control system malfunctions and MIL circuit is open by

means of operating fail-safe function.

The fail-safe function also operates when above diagnos es except MIL circuit are detected and demands the

driver to repair the malfunction.

DTC No. Detected items Engine operating condition in fail-safe mode

P0102

P0103 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0117

P0118 Engine coolant tempera-

ture sensor circuit Engine coolant temperature will be determined by ECM based on the following condition.

CONSULT-IIl displays the engine coolant temperature decided by ECM.

Condition Engine coolant temperature decided

(CONSULT-IIl display)

Just as ignition switch is turned ON

or START 40

°C (104 °F)

Approx 4 minutes or more after en-

gine starting. 80

°C (176 °F)

Except as shown above 40 - 80

°C (104 - 176 °F)

(Depends on the time)

When the fail-safe system for engine coolant temperature sensor is activated, the cooling

fan operates while engine is running.

P0122

P0123

P0222

P0223

P2135 Throttle position sensor The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

P0643 Sensor power supply ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5 degrees) by the return spring.

P2100

P2103 Throttle control motor relay ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2101 Electric throttle control function ECM stops the electric throttle control actuator control, throttle valve is maintained at a

fixed opening (approx. 5 degrees) by the return spring.

P2118 Throttle control motor ECM stops the electric throttle control actuator control, throttle valve is maintained at a fixed opening (approx. 5 degrees) by the return spring.

P2119 Electric throttle control ac- tuator (When electric throttle control actuator does not function properly due to the return spring

malfunction:)

ECM controls the electric throttle actuator by regulating the throttle opening around the

idle position. The engine speed will not rise more than 2,000 rpm.

(When throttle valve opening angle in fail-safe mode is not in specified range:)

ECM controls the electric throttle control actuator by regulating the throttle opening to 20

degrees or less.

(When ECM detects the throttle valve is stuck open:)

While the vehicle is driving, it slows down gradually by fuel cut. After the vehicle stops, the

engine stalls.

The engine can restart in N or P position, and engine speed will not exceed 1,000 rpm or

more.

P2122

P2123

P2127

P2128

P2138 Accelerator pedal position

sensor

The ECM controls the electric throttle control actuator in regulating the throttle opening in

order for the idle position to be within +10 degrees.

The ECM regulates the opening speed of the throttle valve to be slower than the normal

condition.

So, the acceleration will be poor.

Engine operating condition in fail-safe mode

Engine speed will not rise more than 2,500 rpm due to the fuel cut

Revision: March 2010 2008 QX56

Page 1778 of 4083

![INFINITI QX56 2008 Factory Service Manual ECM

EC-479

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-III

The emission related diagnostic informatio INFINITI QX56 2008 Factory Service Manual ECM

EC-479

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-III

The emission related diagnostic informatio](/img/42/57030/w960_57030-1777.png)

ECM

EC-479

< ECU DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC INFORMATION

How to Erase DTC

WITH CONSULT-III

The emission related diagnostic information in the ECM can be erased by selecting “All Erase” in the “Descrip-

tion” of “FINAL CHECK” mode with CONSULT-III.

WITH GST

The emission related diagnostic information in the ECM can be erased by selecting Service $04 with GST.

NOTE:

If the DTC is not for A/T related items (see EC-462, "

DTC Index"), skip step 2.

1. If the ignition switch stays ON after repair work, be su re to turn ignition switch OFF once. Wait at least 10

seconds and then turn it ON (engine stopped) again.

2. Perform TM-30, "

OBD-II Diagnostic Trouble Code (DTC)". (The DTC in TCM will be erased)

3. Select Service $04 with GST (Generic Scan Tool).

No Tools

NOTE:

MISFIRE A3H No.2 Cylinder Misfire

P0302 0BH 24H

EWMA (Exponential Weighted

Moving Average) misfire counts

for last 10 driving cycles

P0302 0CH 24H Misfire counts for last/current driv-

ing cycles

A4H No.3 Cylinder Misfire P0303 0BH 24H

EWMA (Exponential Weighted

Moving Average) misfire counts

for last 10 driving cycles

P0303 0CH 24H Misfire counts for last/current driv-

ing cycles

A5H No.4 Cylinder Misfire P0304 0BH 24H

EWMA (Exponential Weighted

Moving Average) misfire counts

for last 10 driving cycles

P0304 0CH 24H Misfire counts for last/current driv-

ing cycles

A6H No.5 Cylinder Misfire P0305 0BH 24H

EWMA (Exponential Weighted

Moving Average) misfire counts

for last 10 driving cycles

P0305 0CH 24H Misfire counts for last/current driv-

ing cycles

A7H No.6 Cylinder Misfire P0306 0BH 24H

EWMA (Exponential Weighted

Moving Average) misfire counts

for last 10 driving cycles

P0306 0CH 24H Misfire counts for last/current driv-

ing cycles

A8H No.7 Cylinder Misfire P0307 0BH 24H

EWMA (Exponential Weighted

Moving Average) misfire counts

for last 10 driving cycles

P0307 0CH 24H Misfire counts for last/current driv-

ing cycles

A9H No.8 Cylinder Misfire P0308 0BH 24H

EWMA (Exponential Weighted

Moving Average) misfire counts

for last 10 driving cycles

P0308 0CH 24H Misfire counts for last/current driv-

ing cycles

Item

OBD-

MID Self-diagnostic test item

DTCTest value and Test

limit

(GST display) Description

TID Unit and

Scaling ID

Revision: March 2010 2008 QX56

Page 1779 of 4083

![INFINITI QX56 2008 Factory Service Manual EC-480

< ECU DIAGNOSIS >[VK56DE]

ECM

If the DTC is not for AT related items (see

EC-462, "DTC Index"), skip step 2.

1. If the ignition switch stays ON after repair work, be sure to turn ignition swi INFINITI QX56 2008 Factory Service Manual EC-480

< ECU DIAGNOSIS >[VK56DE]

ECM

If the DTC is not for AT related items (see

EC-462, "DTC Index"), skip step 2.

1. If the ignition switch stays ON after repair work, be sure to turn ignition swi](/img/42/57030/w960_57030-1778.png)

EC-480

< ECU DIAGNOSIS >[VK56DE]

ECM

If the DTC is not for AT related items (see

EC-462, "DTC Index"), skip step 2.

1. If the ignition switch stays ON after repair work, be sure to turn ignition switch OFF once.

Wait at least 10 seconds and then turn it ON (engine stopped) again.

2. Perform TM-30, "

OBD-II Diagnostic Trouble Code (DTC)". (The DTC in the TCM will be erased.)

3. Change the diagnostic test mode from Mode II to Mode I by depressing the accelerator pedal. Refer to EC-55, "

Malfunction Indicator Lamp (MIL)".

• If the battery is disconnected, the emission-related diagnostic information will be lost within 24

hours.

• The following data are cleared when the ECM memory is erased.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

- Freeze frame data

- 1st trip freeze frame data

- System readiness test (SRT) codes

- Test values

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Revision: March 2010 2008 QX56

Page 1807 of 4083

EM-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Drain Engine CoolantINFOID:0000000001538794

Drain engine coolant when engine is cooled.

Precaution for Disconnecting Fuel PipingINFOID:0000000001538795

• Before starting work, make sure no fire or spark producing items are in the work area.

• Release fuel pressure before disconnecting and disassembly.

• After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Removal and DisassemblyINFOID:0000000001538796

• When instructed to use special service tools, use the s pecified tools. Always be careful to work safely, avoid

forceful or uninstructed operations.

• Exercise maximum care to avoid damage to mating or sliding surfaces.

• Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

• Mark and arrange disassembly parts in an organi zed way for easy troubleshooting and assembly.

• When loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally opposite, and so on. If the order of loosening is specified, do exactly as specified. Power tools may be used

where noted in the step.

Precaution for Inspection, Repair and ReplacementINFOID:0000000001538797

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and InstallationINFOID:0000000001538798

• Use torque wrench to tighten bolts or nuts to specification.

• When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with theones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

• Replace with new gasket, packing, oil seal or O-ring.

• Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for any restriction and blockage.

• Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust. Before assembly, oil sliding surfaces well.

• Release air within route when refilling after draining engine coolant.

• Before starting engine, apply fuel pressure to fuel lines with turning ignition switch ON (with engine stopped). Then make sure that there are no leaks at fuel line connections.

• After repairing, start engine and increase engine s peed to check engine coolant, fuel, oil, and exhaust sys-

tems for leakage.

Parts Requiring Angular TighteningINFOID:0000000001538799

• For final tightening of the following engine parts use Tool:

- Cylinder head bolts

- Main bearing cap bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angle tightening)

• Do not use a torque value for final tightening.

• The torque value for these parts are for a preliminary step.

• Ensure thread and seat surfaces are clean and lightly coated with engine oil. Tool number : KV10112100 (BT-8653-A)

Revision: March 2010

2008 QX56

Page 1810 of 4083

PREPARATIONEM-7

< PREPARATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

KV10115600

(J-38958)

Valve oil seal drift

Installing valve oil seal

Use side A.

a: 20 (0.79) dia. d: 8 (0.31) dia.

b: 13 (0.51) dia. e: 10.7 (0.421) dia.

c: 10.3 (0.406) dia. f: 5 (0.20) dia.

Unit: mm (in)

EM03470000

(J-8037)

Piston ring compressor Installing piston assembly into cylinder bore

ST16610001

(J-23907)

Pilot bushing puller Removing crankshaft pilot bushing

WS39930000

(—)

Tube presser Pressing the tube of liquid gasket

—

(J-47245)

Ring gear stopper Removing and installing crankshaft pulley

16441 6N210

(J-45488)

Quick connector release Removing fuel tube quick connectors in en-

gine room

(Available in SEC. 164 of PARTS CATALOG:

Part No. 16441 6N210)

—

(J-46535)

Drive belt tension releaser Releasing drive belt tension

Tool number

(Kent-Moore No.)

Tool name

Description

S-NT603

S-NT044

S-NT045

S-NT052

LBIA0451E

PBIC0198E

WBIA0536E

Revision: March 2010

2008 QX56

Page 1816 of 4083

DRIVE BELTSEM-13

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

ON-VEHICLE MAINTENANCE

DRIVE BELTS

Checking Drive BeltsINFOID:0000000001538805

WARNING:

Be sure to perform when the engine is stopped.

1. Remove air duct and resonator assembly when inspecting drive belt.

2. Make sure that indicator (single line notch) of eac

h auto tensioner is within the allowable working range

“A” (between three line notches) as shown.

NOTE:

• Check the drive belt auto tensioner indication when the engine is cold.

• The indicator notch is located on the moving side of the drive belt auto tensioner.

3. Visually check entire belt for wear, damage or cracks.

4. If the indicator is out of allowable working range or belt is damaged, replace the belt. Refer to EM-13

.

DRIVE BELT TENSION

There is no manual drive belt tension adjustment. The driv e belt tension is automatically adjusted by the drive

belt auto tensioner.

Removal and InstallationINFOID:0000000001538806

REMOVAL

1. Remove the air duct and resonator assembly. Refer to EM-25, "Removal and Installation".

1. Drive belt2. Power steering pump pulley 3. Generator pulley

4. Crankshaft pulley 5. A/C compressor6. Idler pulley

7. Cooling fan pulley 8. Water pump pulley9. Drive belt auto tensioner

LBIA0391E

Revision: March 2010 2008 QX56

Page 1821 of 4083

EM-18

< ON-VEHICLE MAINTENANCE >

CAMSHAFT VALVE CLEARANCE

CAMSHAFT VALVE CLEARANCE

Valve ClearanceINFOID:0000000001538810

INSPECTION

NOTE:

Perform the following inspection after removal, installation or replacement of camshaft or valve-related parts,

or if there are unusual engine conditions due to changes in valve clearance over time (starting, idling, and/or

noise).

1. Warm up the engine. Then stop the engine.

2. Remove the engine room cover. Refer to EM-24, "

Removal and Installation".

3. Remove the air cleaner and air duct assembly. Refer to EM-25, "

Removal and Installation".

4. Remove the RH bank and LH bank rocker covers using power tool. Refer to EM-38, "

Removal and Instal-

lation".

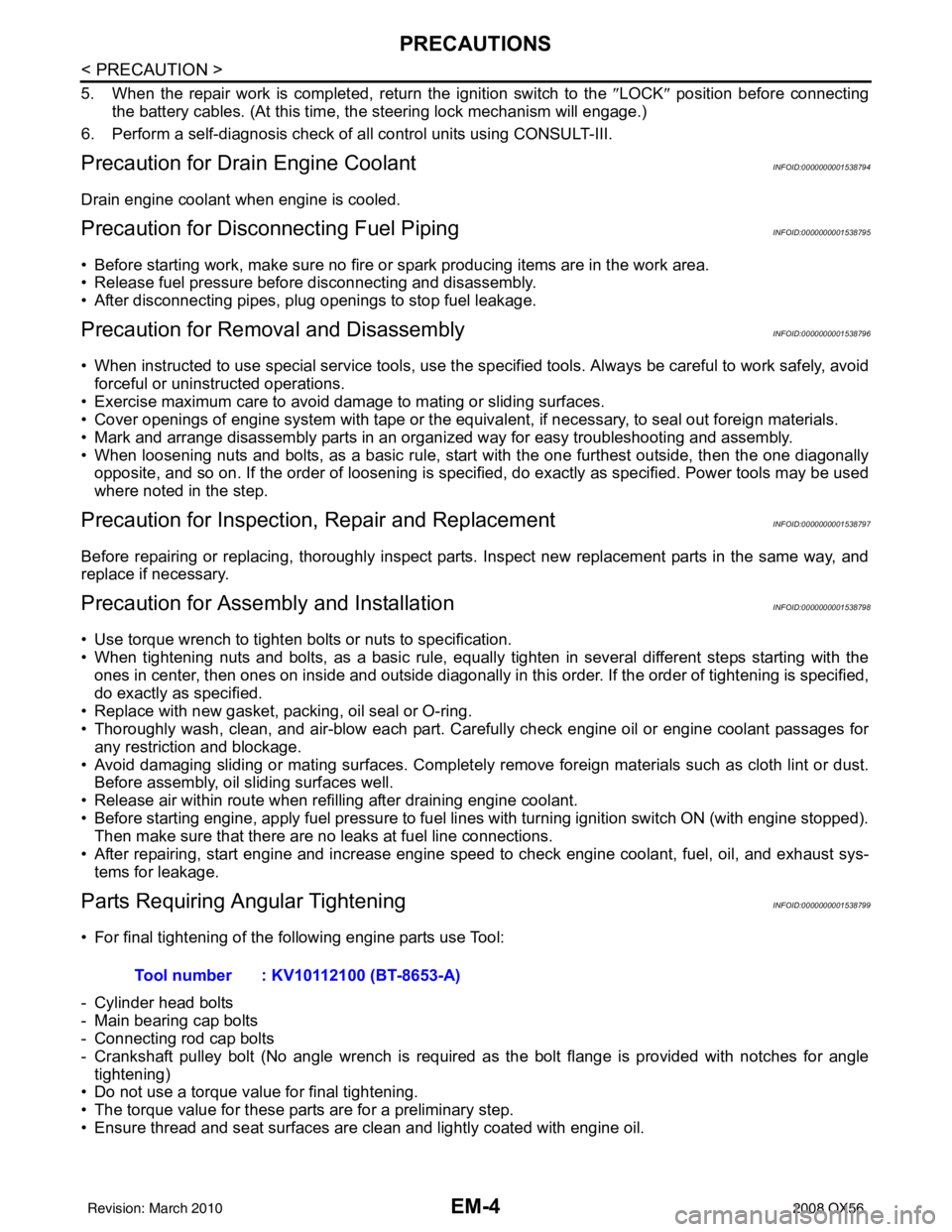

5. Turn the crankshaft pulley in the normal direction (clockwise when viewed from engine front) to align TDC identification notch

(without paint mark) with timing indicator.

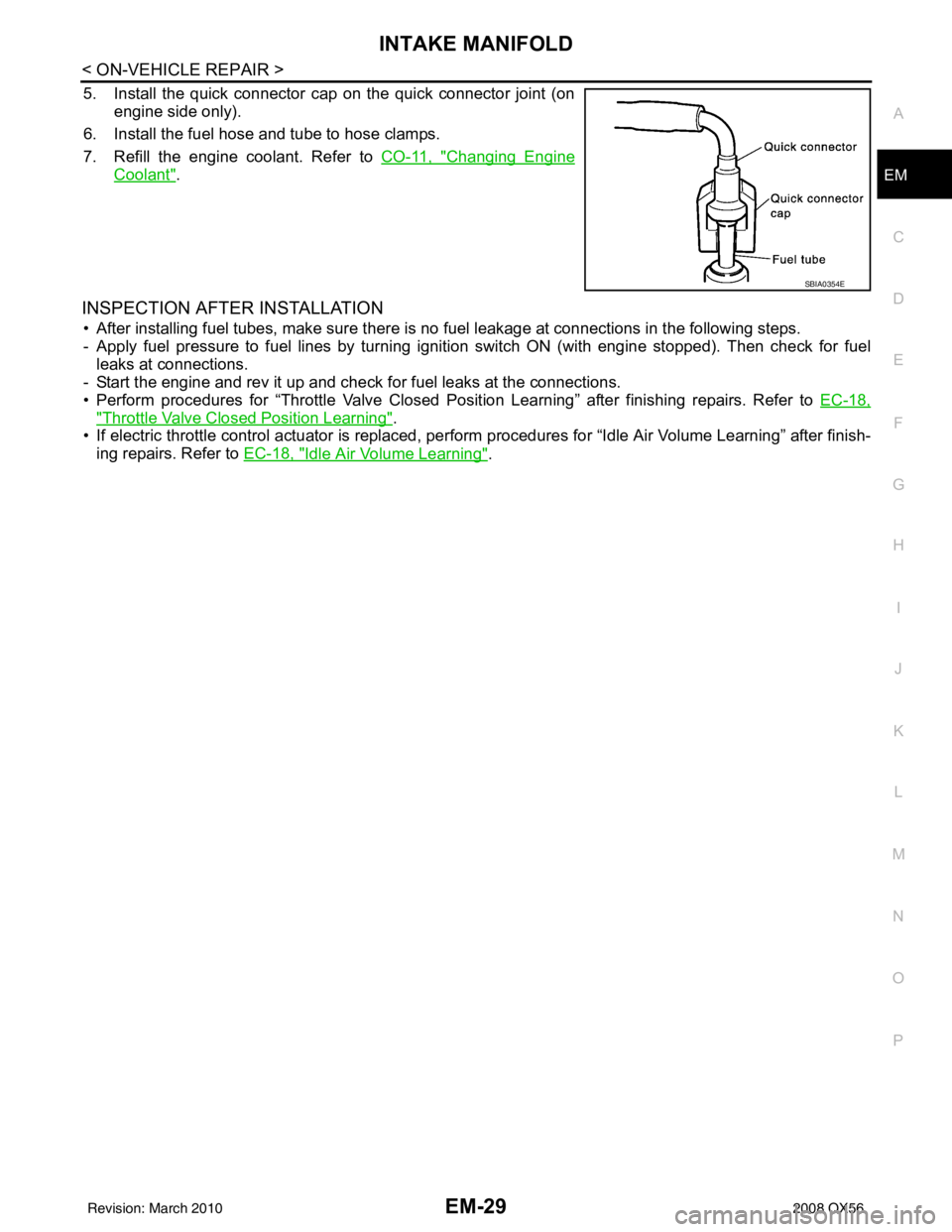

6. At this time, make sure both the intake and exhaust cam noses of No. 1 cylinder (top front on LH bank) face outside.

• If they do not face outside, turn crankshaft pulley once more.

KBIA2476E

KBIA0400J

Revision: March 2010 2008 QX56

Page 1826 of 4083

COMPRESSION PRESSUREEM-23

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

COMPRESSION PRESSURE

Checking Compression PressureINFOID:0000000001538811

1. Warm up the engine thoroughly. Then stop the engine.

2. Release the fuel pressure. Refer to EC-494, "

Fuel Pressure Check".

CAUTION:

If CONSULT-III is not used to release fuel pressure leave the fuel pump fuse disconnected until

step 7.

3. Remove the spark plug from each cylinder. Refer to EM-16, "

Removal and Installation".

4. Connect the engine tachometer (not required in use of CONSULT-III).

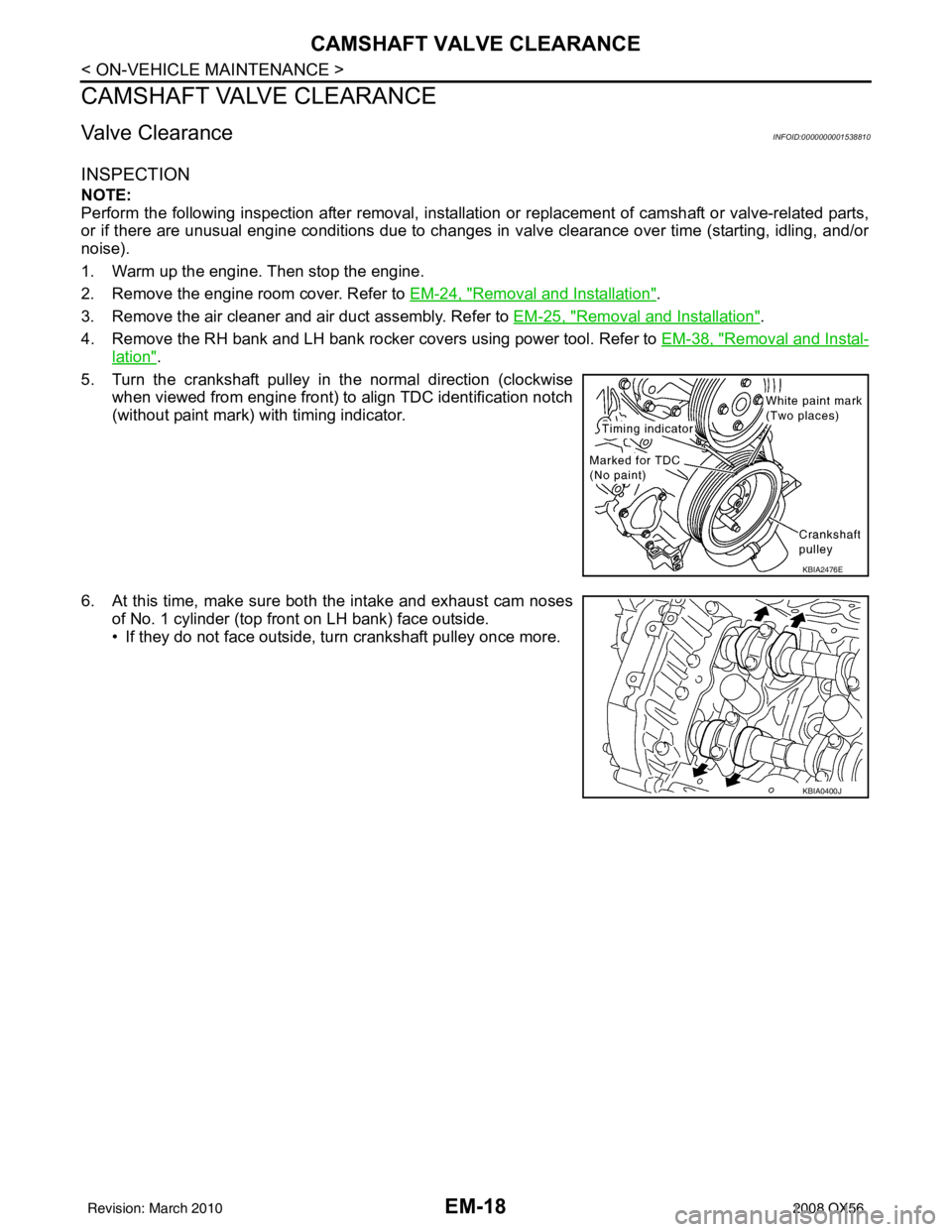

5. Install the compression tester with Tool into the spark plug hole.

6. With the accelerator pedal fully depressed, turn the ignition switch to “START” for cranking. When the gauge pointer stabi-

lizes, read the compression pressure and engine rpm. Perform

these steps to check each cylinder.

Unit: kPa (kg/cm2, psi) /rpm

CAUTION:

Always use a fully charged battery to obtain specified engine speed.

• If the engine speed is out of the specified range, check the battery liquid for proper gravity. Check the engine speed again with normal battery gravity.

• If the compression pressure is below the minimum value, check the valve clearances and parts associ-

ated with the combustion chamber (valve, valve seat , piston, piston ring, cylinder bore, cylinder head,

cylinder head gasket). After checking, measure the compression pressure again.

• If some cylinders have low compression pressure, pour a small amount of engine oil into the spark plug hole of the cylinder to re-check it for compression.

- If the added engine oil improves the compression, t he piston rings may be worn out or damaged. Check

the piston rings and replace if necessary.

- If the compression pressure remains at a low level despite the addition of engine oil, the valves may be malfunctioning. Check the valves for damage. Replace the valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, the gaskets may be leaking, or a valve in adjacent cylinders

may be damaged. Inspect and repair as required.

7. Install the components in the reverse order of removal.

8. Start the engine and confirm that it runs smoothly.

9. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-75, "

Description".

Tool number : EG15050500 (J-45402)

Standard

MinimumDeference limit be-

tween cylinders

1,520 (15.5, 220) / 200 1,324 (13.5, 192) / 200 98 (1.0, 14) / 200WBIA0605E

Revision: March 2010 2008 QX56

Page 1832 of 4083

INTAKE MANIFOLDEM-29

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

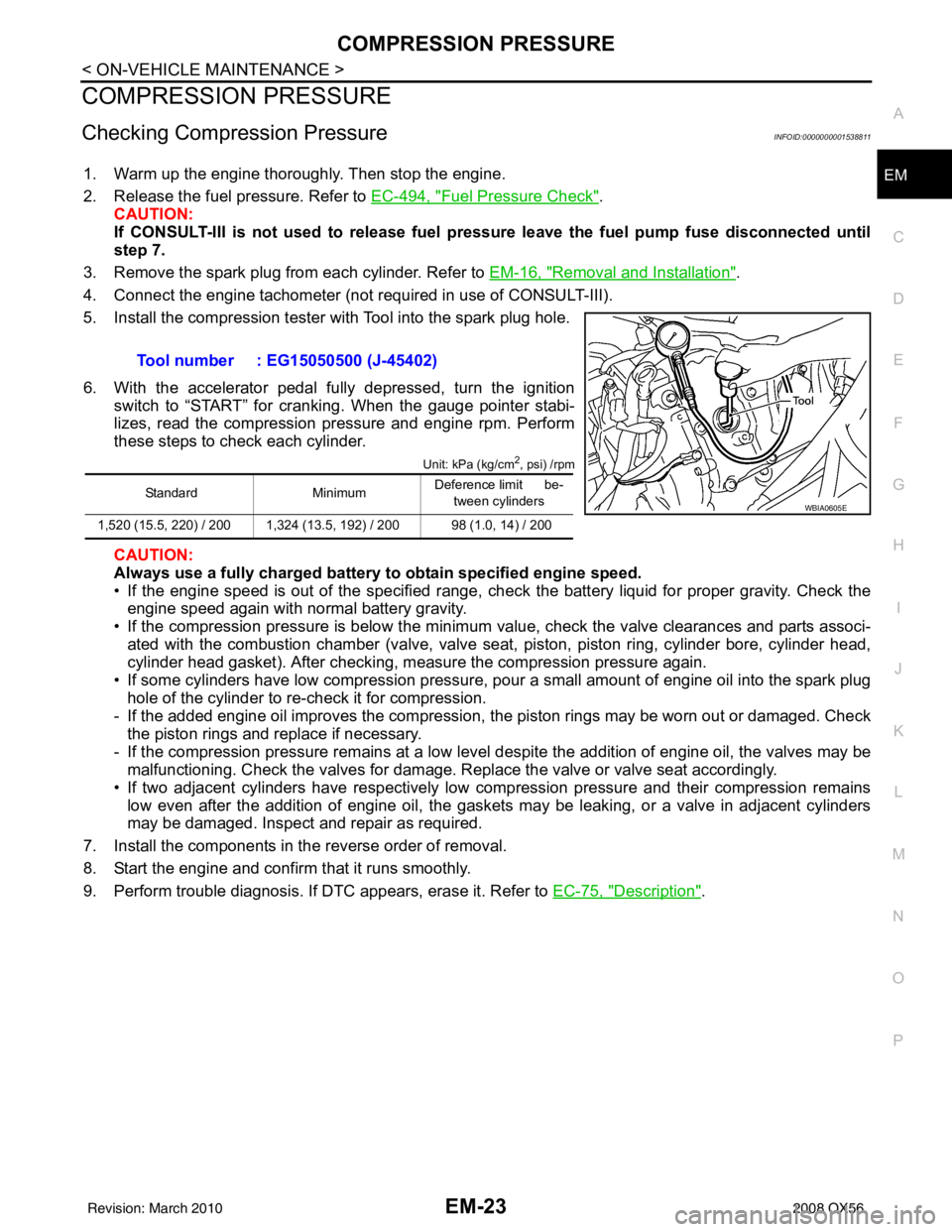

5. Install the quick connector cap on the quick connector joint (on

engine side only).

6. Install the fuel hose and tube to hose clamps.

7. Refill the engine coolant. Refer to CO-11, "

Changing Engine

Coolant".

INSPECTION AFTER INSTALLATION

• After installing fuel tubes, make sure there is no fuel leakage at connections in the following steps.

- Apply fuel pressure to fuel lines by turning ignition switch ON (with engine stopped). Then check for fuel leaks at connections.

- Start the engine and rev it up and check for fuel leaks at the connections.

• Perform procedures for “Throttle Valve Closed Position Learning” after finishing repairs. Refer to EC-18,

"Throttle Valve Closed Position Learning".

• If electric throttle control actuator is replaced, per form procedures for “Idle Air Volume Learning” after finish-

ing repairs. Refer to EC-18, "

Idle Air Volume Learning".

SBIA0354E

Revision: March 2010 2008 QX56

Page 1839 of 4083

EM-36

< ON-VEHICLE REPAIR >

OIL PAN AND OIL STRAINER

4. Install the oil pan drain plug.

5. Install engine assembly. Refer to EM-78, "

Removal and Installation".

• Do not fill the engine oil for at least 30 minutes after oil pan is installed.

INSPECTION AFTER INSTALLATION

1. Check engine oil level and add engine oil if necessary. Refer to LU-8, "Inspection".

2. Start the engine, and check for leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check engine oil level again.

Revision: March 2010 2008 QX56