service INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1915 of 4083

![INFINITI QX56 2008 Factory Service Manual EM-112

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

Va l v e S e a t

Unit: mm (in)

Valve Spring

CYLINDER BLOCK

ItemsStandardOversize [0.2 (0.008)] (ser INFINITI QX56 2008 Factory Service Manual EM-112

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

Va l v e S e a t

Unit: mm (in)

Valve Spring

CYLINDER BLOCK

ItemsStandardOversize [0.2 (0.008)] (ser](/img/42/57030/w960_57030-1914.png)

EM-112

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

Va l v e S e a t

Unit: mm (in)

Valve Spring

CYLINDER BLOCK

ItemsStandardOversize [0.2 (0.008)] (service)

Va l v e g u i d e Outside diameter

10.023 - 10.034 (0.3946 - 0.3950) 10.223 - 10.234 (0.4025 - 0.4029)

Inside diameter (Finished size) 6.000 - 6.018 (0.2362 - 0.2369) —

Cylinder head valve guide hole diameter 9.975 - 9.996 (0.3927 - 0.3935) 10.175 - 10.196 (0.4006 - 0.4014)

Interference fit of valve guide 0.027 - 0.059 (0.0011 - 0.0023)

Items StandardLimit

Stem to guide clearance Intake

0.020 - 0.053 (0.0008 - 0.0021) 0.08 (0.0031)

Exhaust 0.030 - 0.063 (0.0012 - 0.0025) 0.09 (0.0035)

Projection length “L” Intake

12.6 - 12.8 (0.496 - 0.504)

Exhaust 12.5 - 12.9 (0.492 - 0.508)

KBIA2555E

Items StandardOversize [0.5 (0.020)] (Service)

Cylinder head seat recess diameter (D) Intake 38.000 - 38.016 (1.4961 - 1.4967) 38.500 - 38.516 (1.5157 - 1.5164)

Exhaust 32.200 - 32.216 (1.2677 - 1.2683) 32.700 - 32.716 (1.2874 - 1.2880)

Valve seat interference fit Intake

0.081 - 0.113 (0.0032 - 0.0044)

Exhaust 0.064 - 0.096 (0.0025 - 0.0038)

Valve seat diameter (d) Intake 38.097 - 38.113 (1.4999 - 1.5005) 38.597 - 38.613 (1.5196 - 1.5202)

Exhaust 32.280 - 32.296 (1.2709 - 1.2715) 32.780 - 32.796 (1.2905 - 1.2912)

KBIA2541E

Free height mm (in)

50.58 (1.9913)

Pressure N (kg, lb) at height mm (in) Installation

165.8 - 187.0 (16.9 - 19.1, 37 - 42) at 37.0 (1.457)

Valve open 314.8 - 355.0 (32.1 - 36.2, 71 - 80) at 28.2 (1.110)

Out-of-square mm (in) Less than 2.2 (0.087)

Revision: March 2010 2008 QX56

Page 1916 of 4083

SERVICE DATA AND SPECIFICATIONS (SDS)EM-113

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Unit: mm (in)

PISTON, PISTON RING AND PISTON PIN

Available Piston

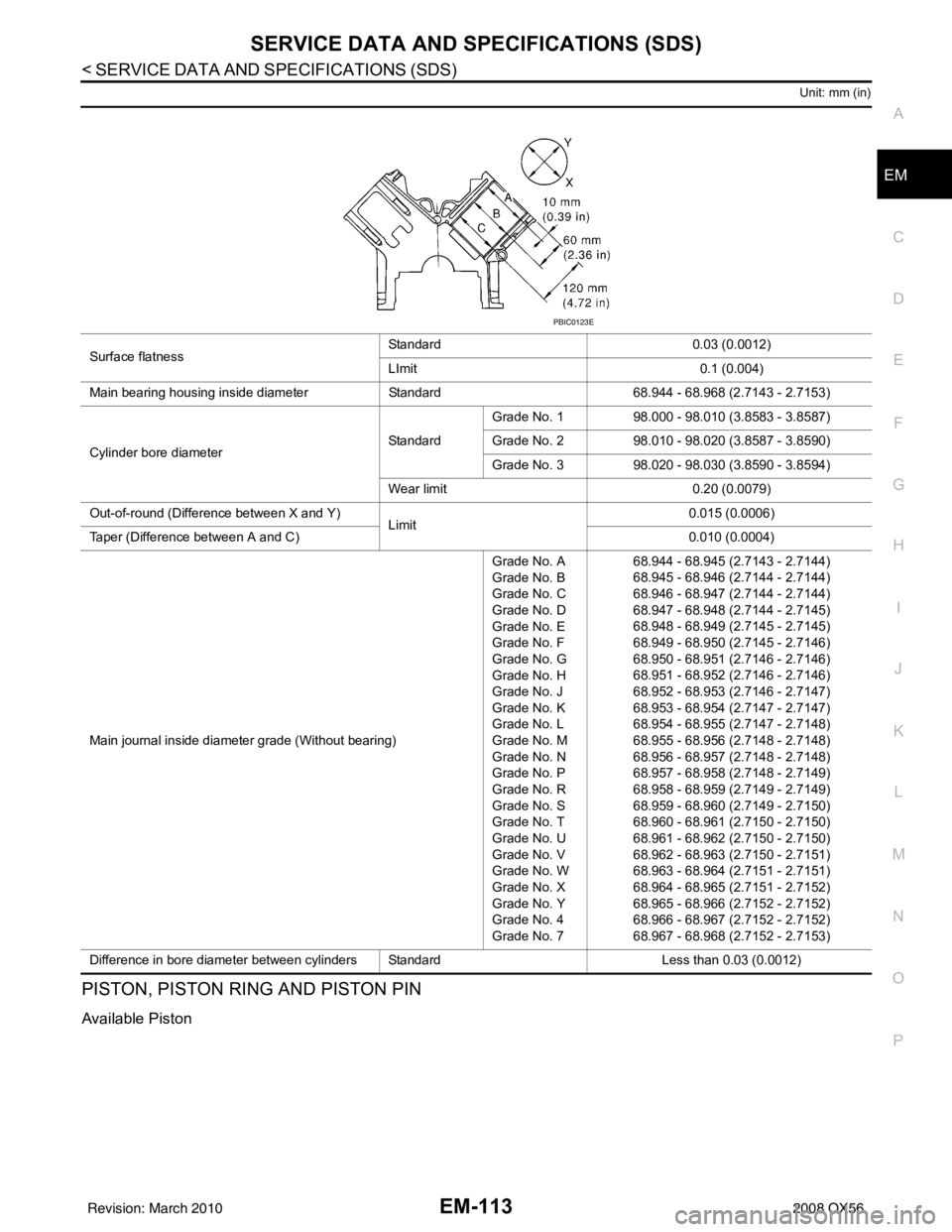

Surface flatness

Standard

0.03 (0.0012)

LImit 0.1 (0.004)

Main bearing housing inside diameter Standard68.944 - 68.968 (2.7143 - 2.7153)

Cylinder bore diameter StandardGrade No. 1

98.000 - 98.010 (3.8583 - 3.8587)

Grade No. 2 98.010 - 98.020 (3.8587 - 3.8590)

Grade No. 3 98.020 - 98.030 (3.8590 - 3.8594)

Wear limit 0.20 (0.0079)

Out-of-round (Difference between X and Y) Limit 0.015 (0.0006)

Taper (Difference between A and C) 0.010 (0.0004)

Main journal inside diameter grade (Without bearing) Grade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 4

Grade No. 768.944 - 68.945 (2.7143 - 2.7144)

68.945 - 68.946 (2.7144 - 2.7144)

68.946 - 68.947 (2.7144 - 2.7144)

68.947 - 68.948 (2.7144 - 2.7145)

68.948 - 68.949 (2.7145 - 2.7145)

68.949 - 68.950 (2.7145 - 2.7146)

68.950 - 68.951 (2.7146 - 2.7146)

68.951 - 68.952 (2.7146 - 2.7146)

68.952 - 68.953 (2.7146 - 2.7147)

68.953 - 68.954 (2.7147 - 2.7147)

68.954 - 68.955 (2.7147 - 2.7148)

68.955 - 68.956 (2.7148 - 2.7148)

68.956 - 68.957 (2.7148 - 2.7148)

68.957 - 68.958 (2.7148 - 2.7149)

68.958 - 68.959 (2.7149 - 2.7149)

68.959 - 68.960 (2.7149 - 2.7150)

68.960 - 68.961 (2.7150 - 2.7150)

68.961 - 68.962 (2.7150 - 2.7150)

68.962 - 68.963 (2.7150 - 2.7151)

68.963 - 68.964 (2.7151 - 2.7151)

68.964 - 68.965 (2.7151 - 2.7152)

68.965 - 68.966 (2.7152 - 2.7152)

68.966 - 68.967 (2.7152 - 2.7152)

68.967 - 68.968 (2.7152 - 2.7153)

Difference in bore diameter between cylinders Standard Less than 0.03 (0.0012)

PBIC0123E

Revision: March 2010 2008 QX56

Page 1917 of 4083

EM -114

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

Piston Ring

Unit: mm (in)

Piston Pin

Unit: mm (in)

CONNECTING ROD

Unit: mm (in)

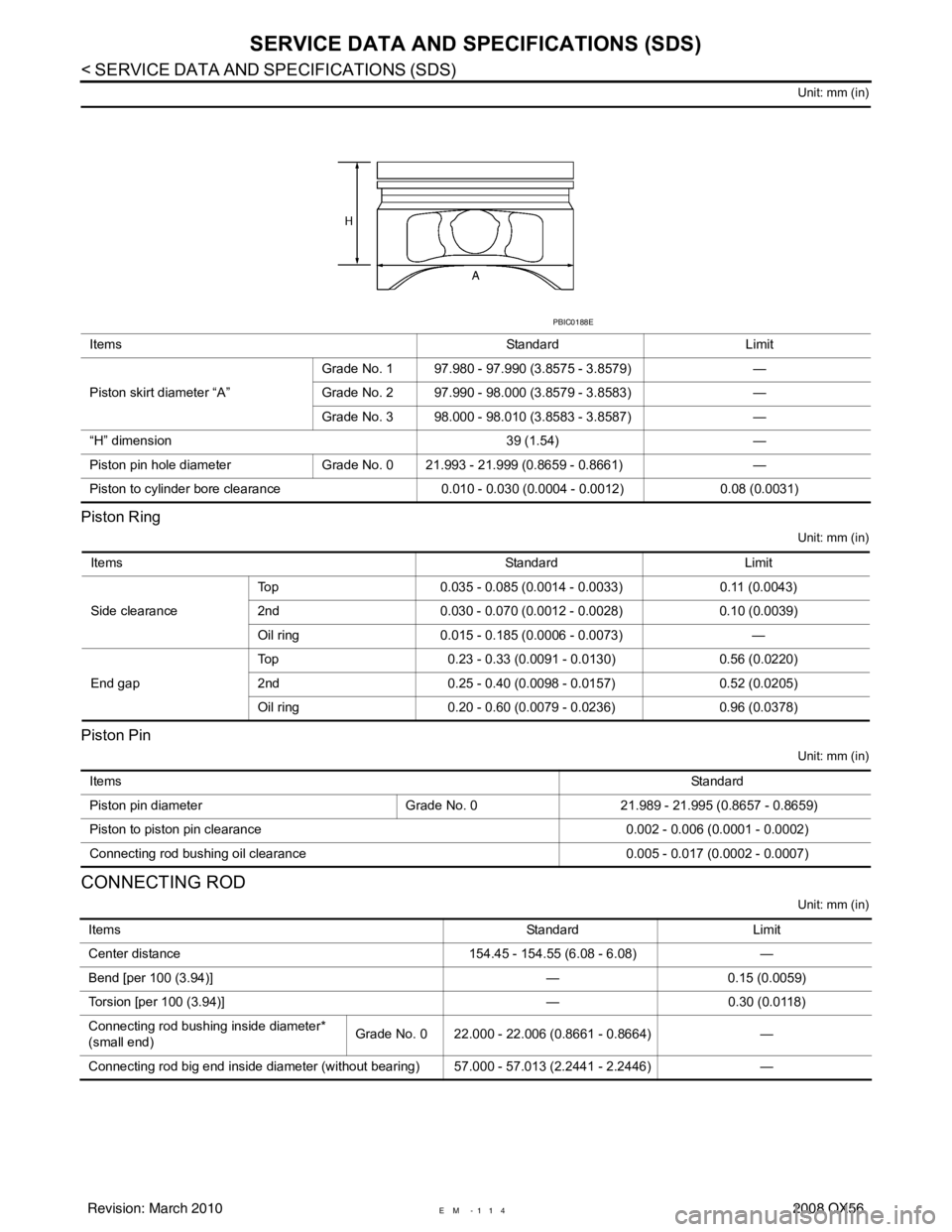

ItemsStandardLimit

Piston skirt diameter “A” Grade No. 1 97.980 - 97.990 (3.8575 - 3.8579)

—

Grade No. 2 97.990 - 98.000 (3.8579 - 3.8583) —

Grade No. 3 98.000 - 98.010 (3.8583 - 3.8587) —

“H” dimension 39 (1.54)—

Piston pin hole diameter Grade No. 0 21.993 - 21.999 (0.8659 - 0.8661) —

Piston to cylinder bore clearance 0.010 - 0.030 (0.0004 - 0.0012)0.08 (0.0031)

PBIC0188E

Items StandardLimit

Side clearance Top

0.035 - 0.085 (0.0014 - 0.0033) 0.11 (0.0043)

2nd 0.030 - 0.070 (0.0012 - 0.0028) 0.10 (0.0039)

Oil ring 0.015 - 0.185 (0.0006 - 0.0073) —

End gap Top

0.23 - 0.33 (0.0091 - 0.0130) 0.56 (0.0220)

2nd 0.25 - 0.40 (0.0098 - 0.0157) 0.52 (0.0205)

Oil ring 0.20 - 0.60 (0.0079 - 0.0236) 0.96 (0.0378)

Items Standard

Piston pin diameter Grade No. 0 21.989 - 21.995 (0.8657 - 0.8659)

Piston to piston pin clearance 0.002 - 0.006 (0.0001 - 0.0002)

Connecting rod bushing oil clearance 0.005 - 0.017 (0.0002 - 0.0007)

ItemsStandardLimit

Center distance 154.45 - 154.55 (6.08 - 6.08)—

Bend [per 100 (3.94)] —0.15 (0.0059)

Torsion [per 100 (3.94)] —0.30 (0.0118)

Connecting rod bushing inside diameter*

(small end) Grade No. 0 22.000 - 22.006 (0.8661 - 0.8664)

—

Connecting rod big end inside diameter (without bearing) 57.000 - 57.013 (2.2441 - 2.2446) —

Revision: March 20102008 QX56

Page 1918 of 4083

SERVICE DATA AND SPECIFICATIONS (SDS)EM-115

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

K L

M A

EM

NP

O

*: After installing in connecting rod

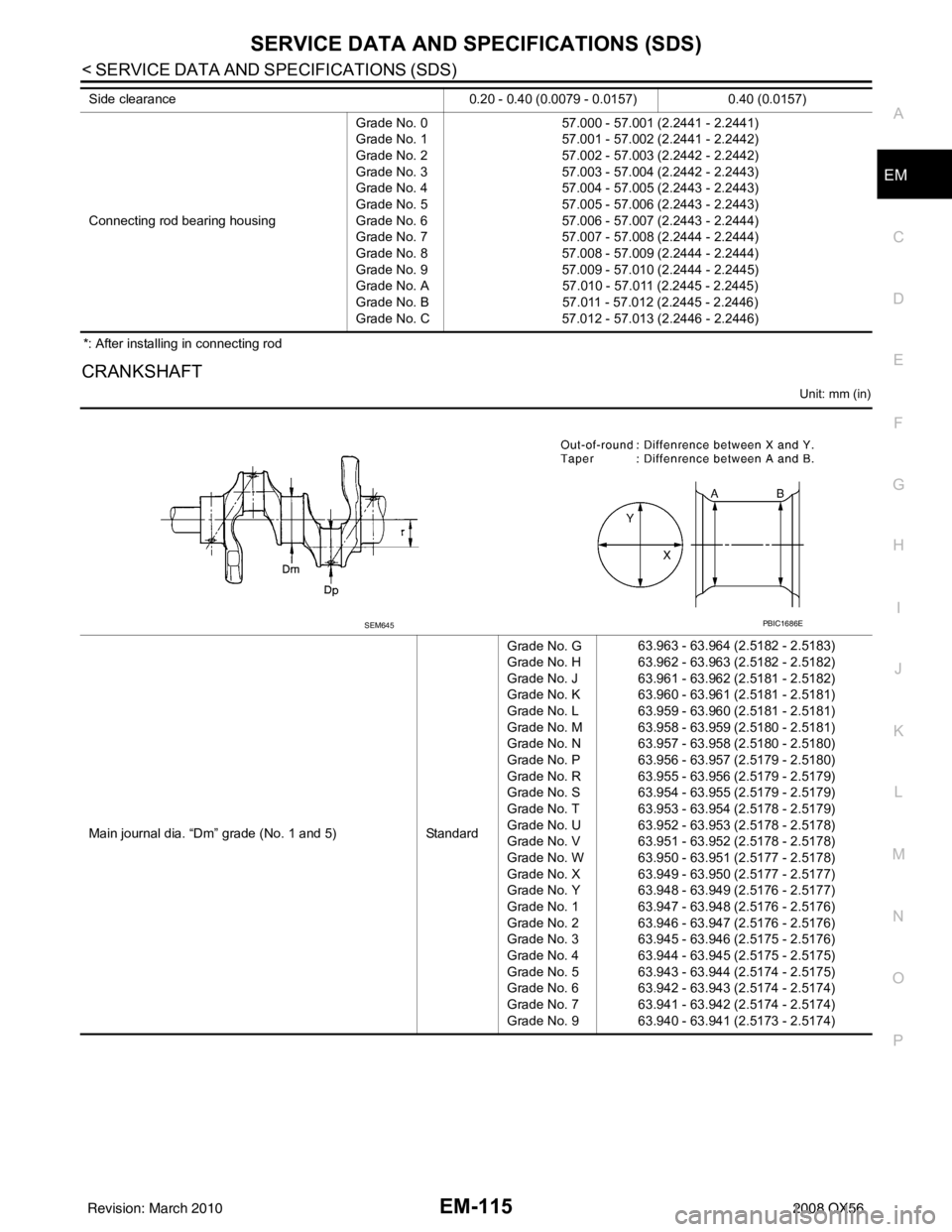

CRANKSHAFT

Unit: mm (in)

Side clearance

0.20 - 0.40 (0.0079 - 0.0157)0.40 (0.0157)

Connecting rod bearing housing Grade No. 0

Grade No. 1

Grade No. 2

Grade No. 3

Grade No. 4

Grade No. 5

Grade No. 6

Grade No. 7

Grade No. 8

Grade No. 9

Grade No. A

Grade No. B

Grade No. C57.000 - 57.001 (2.2441 - 2.2441)

57.001 - 57.002 (2.2441 - 2.2442)

57.002 - 57.003 (2.2442 - 2.2442)

57.003 - 57.004 (2.2442 - 2.2443)

57.004 - 57.005 (2.2443 - 2.2443)

57.005 - 57.006 (2.2443 - 2.2443)

57.006 - 57.007 (2.2443 - 2.2444)

57.007 - 57.008 (2.2444 - 2.2444)

57.008 - 57.009 (2.2444 - 2.2444)

57.009 - 57.010 (2.2444 - 2.2445)

57.010 - 57.011 (2.2445 - 2.2445)

57.011 - 57.012 (2.2445 - 2.2446)

57.012 - 57.013 (2.2446 - 2.2446)

Main journal dia. “Dm” grade (No. 1 and 5) StandardGrade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 1

Grade No. 2

Grade No. 3

Grade No. 4

Grade No. 5

Grade No. 6

Grade No. 7

Grade No. 9 63.963 - 63.964 (2.5182 - 2.5183)

63.962 - 63.963 (2.5182 - 2.5182)

63.961 - 63.962 (2.5181 - 2.5182)

63.960 - 63.961 (2.5181 - 2.5181)

63.959 - 63.960 (2.5181 - 2.5181)

63.958 - 63.959 (2.5180 - 2.5181)

63.957 - 63.958 (2.5180 - 2.5180)

63.956 - 63.957 (2.5179 - 2.5180)

63.955 - 63.956 (2.5179 - 2.5179)

63.954 - 63.955 (2.5179 - 2.5179)

63.953 - 63.954 (2.5178 - 2.5179)

63.952 - 63.953 (2.5178 - 2.5178)

63.951 - 63.952 (2.5178 - 2.5178)

63.950 - 63.951 (2.5177 - 2.5178)

63.949 - 63.950 (2.5177 - 2.5177)

63.948 - 63.949 (2.5176 - 2.5177)

63.947 - 63.948 (2.5176 - 2.5176)

63.946 - 63.947 (2.5176 - 2.5176)

63.945 - 63.946 (2.5175 - 2.5176)

63.944 - 63.945 (2.5175 - 2.5175)

63.943 - 63.944 (2.5174 - 2.5175)

63.942 - 63.943 (2.5174 - 2.5174)

63.941 - 63.942 (2.5174 - 2.5174)

63.940 - 63.941 (2.5173 - 2.5174)

SEM645PBIC1686E

Revision: March 2010

2008 QX56

Page 1919 of 4083

EM-116

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

*: Total indicator reading

MAIN BEARING

Unit: mm (in)

Main journal dia. “Dm” grade (No. 2, 3 and 4)StandardGrade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 1

Grade No. 2 63.963 - 63.964 (2.5182 - 2.5183)

63.962 - 63.963 (2.5182 - 2.5182)

63.961 - 63.962 (2.5181 - 2.5182)

63.960 - 63.961 (2.5181 - 2.5181)

63.959 - 63.960 (2.5181 - 2.5181)

63.958 - 63.959 (2.5180 - 2.5181)

63.957 - 63.958 (2.5180 - 2.5180)

63.956 - 63.957 (2.5179 - 2.5180)

63.955 - 63.956 (2.5179 - 2.5179)

63.954 - 63.955 (2.5179 - 2.5179)

63.953 - 63.954 (2.5178 - 2.5179)

63.952 - 63.953 (2.5178 - 2.5178)

63.951 - 63.952 (2.5178 - 2.5178)

63.950 - 63.951 (2.5177 - 2.5178)

63.949 - 63.950 (2.5177 - 2.5177)

63.948 - 63.949 (2.5176 - 2.5177)

63.947 - 63.948 (2.5176 - 2.5176)

63.946 - 63.947 (2.5176 - 2.5176)

63.945 - 63.946 (2.5175 - 2.5176)

63.944 - 63.945 (2.5175 - 2.5175)

63.943 - 63.944 (2.5174 - 2.5175)

63.942 - 63.943 (2.5174 - 2.5174)

63.941 - 63.942 (2.5174 - 2.5174)

63.940 - 63.941 (2.5173 - 2.5174)

Pin journal dia. “Dp” StandardGrade No. 0 53.968 - 53.974 (2.1247 - 2.1250)

Grade No. 1 53.962 - 53.968 (2.1245 - 2.1247)

Grade No. 2 53.956 - 53.962 (2.1243 - 2.1245)

Center distance “r” 45.96 - 46.04 (1.8094 - 1.8126)

Out-of-round (Difference between X and Y) Limit0.002 (0.0001)

Taper (Difference between A and B) 0.002 (0.0001)

Runout [TIR*] Less than 0.05 (0.002)

Crankshaft end play Standard

0.10 - 0.26 (0.0039 - 0.0102)

Limit 0.30 (0.0118)

Grade number* UPR/LWR Thickness Identification color Remarks

PBIC0189E

Revision: March 2010 2008 QX56

Page 1920 of 4083

SERVICE DATA AND SPECIFICATIONS (SDS)EM-117

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

K L

M A

EM

NP

O

*: Always check with the Parts Department for the latest parts information.

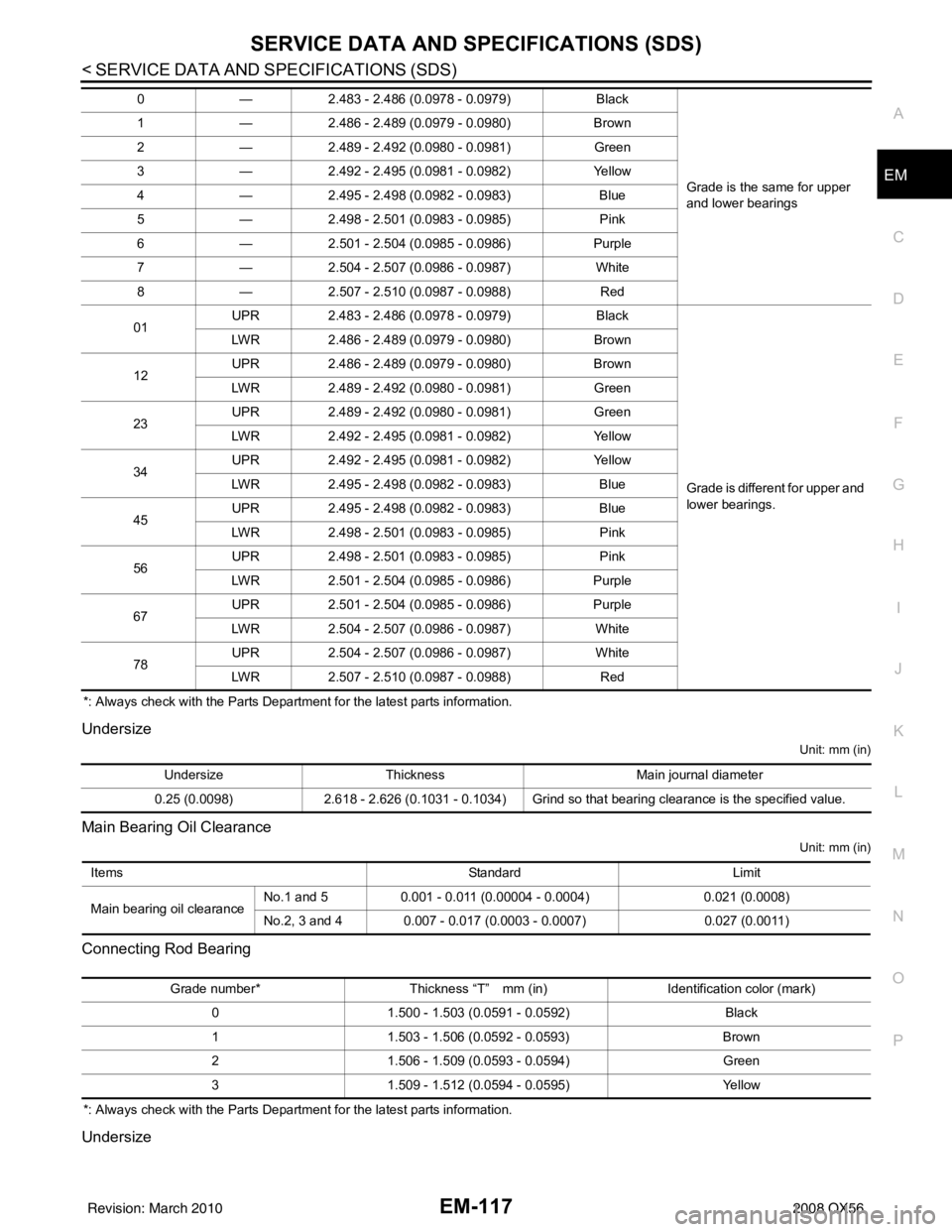

Undersize

Unit: mm (in)

Main Bearing Oil Clearance

Unit: mm (in)

Connecting Rod Bearing

*: Always check with the Parts Department for the latest parts information.

Undersize

0

—2.483 - 2.486 (0.0978 - 0.0979) Black

Grade is the same for upper

and lower bearings

1

—2.486 - 2.489 (0.0979 - 0.0980) Brown

2 —2.489 - 2.492 (0.0980 - 0.0981) Green

3 —2.492 - 2.495 (0.0981 - 0.0982) Yellow

4 —2.495 - 2.498 (0.0982 - 0.0983) Blue

5 —2.498 - 2.501 (0.0983 - 0.0985) Pink

6 —2.501 - 2.504 (0.0985 - 0.0986) Purple

7 —2.504 - 2.507 (0.0986 - 0.0987) White

8 —2.507 - 2.510 (0.0987 - 0.0988) Red

01 UPR

2.483 - 2.486 (0.0978 - 0.0979) Black

Grade is different for upper and

lower bearings.

LWR

2.486 - 2.489 (0.0979 - 0.0980) Brown

12 UPR

2.486 - 2.489 (0.0979 - 0.0980) Brown

LWR 2.489 - 2.492 (0.0980 - 0.0981) Green

23 UPR

2.489 - 2.492 (0.0980 - 0.0981) Green

LWR 2.492 - 2.495 (0.0981 - 0.0982) Yellow

34 UPR

2.492 - 2.495 (0.0981 - 0.0982) Yellow

LWR 2.495 - 2.498 (0.0982 - 0.0983) Blue

45 UPR

2.495 - 2.498 (0.0982 - 0.0983) Blue

LWR 2.498 - 2.501 (0.0983 - 0.0985) Pink

56 UPR

2.498 - 2.501 (0.0983 - 0.0985) Pink

LWR 2.501 - 2.504 (0.0985 - 0.0986) Purple

67 UPR

2.501 - 2.504 (0.0985 - 0.0986) Purple

LWR 2.504 - 2.507 (0.0986 - 0.0987) White

78 UPR

2.504 - 2.507 (0.0986 - 0.0987) White

LWR 2.507 - 2.510 (0.0987 - 0.0988) Red

UndersizeThickness Main journal diameter

0.25 (0.0098) 2.618 - 2.626 (0.1031 - 0.1034) Grind so that bearing clearance is the specified value.

Items StandardLimit

Main bearing oil clearance No.1 and 5

0.001 - 0.011 (0.00004 - 0.0004) 0.021 (0.0008)

No.2, 3 and 4 0.007 - 0.017 (0.0003 - 0.0007) 0.027 (0.0011)

Grade number*Thickness “T” mm (in) Identification color (mark)

0 1.500 - 1.503 (0.0591 - 0.0592) Black

1 1.503 - 1.506 (0.0592 - 0.0593) Brown

2 1.506 - 1.509 (0.0593 - 0.0594) Green

3 1.509 - 1.512 (0.0594 - 0.0595) Yellow

Revision: March 2010 2008 QX56

Page 1921 of 4083

EM-118

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

Connecting Rod Bearing Oil Clearance

Unit: mm (in)

UndersizeThicknessCrank pin journal diameter “Dp”

0.25 (0.0098) 1.627 - 1.635 (0.0641 - 0.0644) Grind so that bearing clearance is the specified value.

Items StandardLimit

Connecting rod bearing oil clearance 0.020 - 0.039 (0.0008 - 0.0015) 0.055 (0.0022)

Revision: March 2010 2008 QX56

Page 1922 of 4083

EX-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EX

A

EX

N

O P

CONTENTS

EXHAUST SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Liquid Gasket .....................................3

PREPARATION ............................................4

PREPARATION ..................................................4

Special Service Tool ............................................ .....4

Commercial Service Tool .........................................4

ON-VEHICLE MAINTENANCE .....................5

EXHAUST SYSTEM ...........................................5

Checking Exhaust System ................................... .....5

ON-VEHICLE REPAIR ..................................6

EXHAUST SYSTEM ...........................................6

Removal and Installation ..................................... .....6

Revision: March 2010 2008 QX56

Page 1923 of 4083

EX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004857579

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004857585

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 1925 of 4083

EX-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

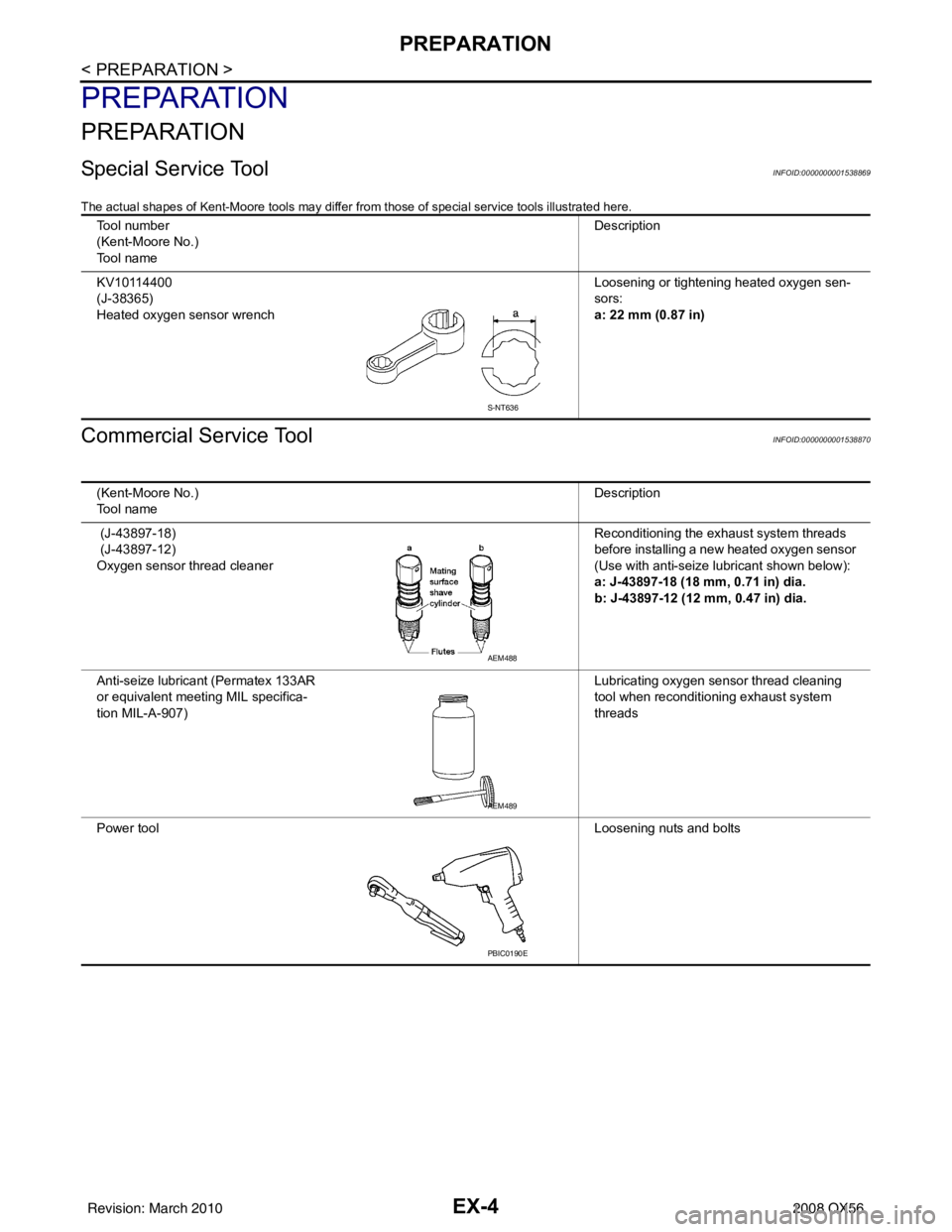

Special Service ToolINFOID:0000000001538869

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000001538870

Tool number

(Kent-Moore No.)

Tool name Description

KV10114400

(J-38365)

Heated oxygen sensor wrench Loosening or tightening heated oxygen sen-

sors:

a: 22 mm (0.87 in)

S-NT636

(Kent-Moore No.)

Tool name

Description

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleaner Reconditioning the exhaust system threads

before installing a new heated oxygen sensor

(Use with anti-seize lubricant shown below):

a: J-43897-18 (18 mm, 0.71 in) dia.

b: J-43897-12 (12 mm, 0.47 in) dia.

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL specifica-

tion MIL-A-907) Lubricating oxygen sensor thread cleaning

tool when reconditioning exhaust system

threads

Power tool Loosening nuts and bolts

AEM488

AEM489

PBIC0190E

Revision: March 2010 2008 QX56