wiring diagram INFINITI QX56 2008 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 943 of 4083

![INFINITI QX56 2008 Factory Owners Manual DLK-150

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

Wiring Diagram — POWER DOOR LOCK SYSTEM —

INFOID:0000000001539053

AAKWA0114GB

Revision: March 2010 2008 QX56 INFINITI QX56 2008 Factory Owners Manual DLK-150

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

Wiring Diagram — POWER DOOR LOCK SYSTEM —

INFOID:0000000001539053

AAKWA0114GB

Revision: March 2010 2008 QX56](/img/42/57030/w960_57030-942.png)

DLK-150

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

BCM (BODY CONTROL MODULE)

Wiring Diagram — POWER DOOR LOCK SYSTEM —

INFOID:0000000001539053

AAKWA0114GB

Revision: March 2010 2008 QX56

Page 962 of 4083

![INFINITI QX56 2008 Factory Owners Manual INTELLIGENT KEY UNITDLK-169

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Wiring Diagram — INTELLIGENT KEY SYSTEM —INFOID:0000000001539059

ALKWA0069GB

Revision: INFINITI QX56 2008 Factory Owners Manual INTELLIGENT KEY UNITDLK-169

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Wiring Diagram — INTELLIGENT KEY SYSTEM —INFOID:0000000001539059

ALKWA0069GB

Revision:](/img/42/57030/w960_57030-961.png)

INTELLIGENT KEY UNITDLK-169

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Wiring Diagram — INTELLIGENT KEY SYSTEM —INFOID:0000000001539059

ALKWA0069GB

Revision: March 2010 2008 QX56

Page 982 of 4083

![INFINITI QX56 2008 Factory Owners Manual BACK DOOR CONTROL UNITDLK-189

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Wiring Diagram—AUTOMATIC BACK DOOR SYSTEM—INFOID:0000000001539062

AWKWA0019GB

Revis INFINITI QX56 2008 Factory Owners Manual BACK DOOR CONTROL UNITDLK-189

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Wiring Diagram—AUTOMATIC BACK DOOR SYSTEM—INFOID:0000000001539062

AWKWA0019GB

Revis](/img/42/57030/w960_57030-981.png)

BACK DOOR CONTROL UNITDLK-189

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

DLK

N

O P

Wiring Diagram—AUTOMATIC BACK DOOR SYSTEM—INFOID:0000000001539062

AWKWA0019GB

Revision: March 2010 2008 QX56

Page 1032 of 4083

DLN-2

P1820 ENGINE SPEED SIGNAL ......................52

Description ........................................................... ...52

DTC Logic ...............................................................52

Diagnosis Procedure ..............................................52

P1822 CLUTCH PRESSURE SOLENOID .........53

Description ..............................................................53

DTC Logic ...............................................................53

Diagnosis Procedure ..............................................53

Component Inspection ............................................55

P1823 2-4 SOLENOID .......................................57

Description ........................................................... ...57

DTC Logic ...............................................................57

Diagnosis Procedure ..............................................57

Component Inspection ............................................60

P1824 TRANSFER MOTOR ..............................61

Description ..............................................................61

DTC Logic ...............................................................61

Diagnosis Procedure ..............................................61

Component Inspection ............................................65

P1826 TRANSFER FLUID TEMPERATURE ....67

Description ........................................................... ...67

DTC Logic ...............................................................67

Diagnosis Procedure ..............................................67

Component Inspection ............................................68

P1827 CLUTCH PRESSURE SWITCH .............70

Description ........................................................... ...70

DTC Logic ...............................................................70

Diagnosis Procedure ..............................................70

Component Inspection ............................................71

P1828 LINE PRESSURE SWITCH ....................73

Description ........................................................... ...73

DTC Logic ...............................................................73

Diagnosis Procedure ..............................................73

Component Inspection ............................................75

P1829 THROTTLE POSITION SIGNAL (ECM)

...

76

Description ........................................................... ...76

DTC Logic ...............................................................76

Diagnosis Procedure ..............................................76

P1830 ABS OPERATION SIGNAL (ABS) ........77

Description ........................................................... ...77

DTC Logic ...............................................................77

Diagnosis Procedure ..............................................77

P1831 VDC OPERATION SIGNAL (ABS) ........78

Description ........................................................... ...78

DTC Logic ...............................................................78

Diagnosis Procedure ..............................................78

P1832 TCS OPERATION SIGNAL (ABS) .........79

Description ........................................................... ...79

DTC Logic ...............................................................79

Diagnosis Procedure ..............................................79

ECU DIAGNOSIS .......................................80

TRANSFER CONTROL UNIT ...........................80

Reference Value .................................................. ...80

Wiring Diagram .......................................................88

DTC Index ...............................................................95

SYMPTOM DIAGNOSIS ...........................100

4WD SYSTEM SYMPTOMS ........................... ..100

Symptom Table .................................................... .100

4WD SHIFT INDICATOR LAMP AND 4LO IN-

DICATOR LAMP DO NOT TURN ON ..............

101

Description ............................................................101

Diagnosis Procedure .............................................101

4WD WARNING LAMP DOES NOT TURN ON ..103

Description ........................................................... .103

Diagnosis Procedure .............................................103

4WD SHIFT INDICATOR LAMP OR 4LO INDI-

CATOR LAMP DO NOT CHANGE ...................

105

Description ........................................................... .105

Diagnosis Procedure .............................................105

ATP WARNING LAMP DOES NOT TURN ON ..107

Description ........................................................... .107

Diagnosis Procedure .............................................107

4WD SHIFT INDICATOR LAMP KEEPS

FLASHING ........................................................

109

Description ........................................................... .109

Diagnosis Procedure .............................................109

4WD WARNING LAMP FLASHES RAPIDLY ..110

Description ............................................................110

Diagnosis Procedure .............................................110

4WD WARNING LAMP FLASHES SLOWLY ..111

Description ............................................................111

Diagnosis Procedure .............................................111

HEAVY TIGHT-CORNER BRAKING SYMP-

TOM OCCURS ................................................ ..

112

Description ........................................................... .112

Diagnosis Procedure .............................................112

ATP SWITCH ....................................................114

Description ........................................................... .114

Diagnosis Procedure .............................................114

4WD SYSTEM DOES NOT OPERATE ............116

Description ........................................................... .116

Diagnosis Procedure .............................................116

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

117

NVH Troubleshooting Chart ..................................117

PRECAUTION ............... ............................118

Revision: March 2010 2008 QX56

Page 1118 of 4083

![INFINITI QX56 2008 Factory Owners Manual DLN-88

< ECU DIAGNOSIS >[ATX14B]

TRANSFER CONTROL UNIT

Wiring Diagram

INFOID:0000000001737180

AADWA0054GB

Revision: March 2010 2008 QX56 INFINITI QX56 2008 Factory Owners Manual DLN-88

< ECU DIAGNOSIS >[ATX14B]

TRANSFER CONTROL UNIT

Wiring Diagram

INFOID:0000000001737180

AADWA0054GB

Revision: March 2010 2008 QX56](/img/42/57030/w960_57030-1117.png)

DLN-88

< ECU DIAGNOSIS >[ATX14B]

TRANSFER CONTROL UNIT

Wiring Diagram

INFOID:0000000001737180

AADWA0054GB

Revision: March 2010 2008 QX56

Page 1305 of 4083

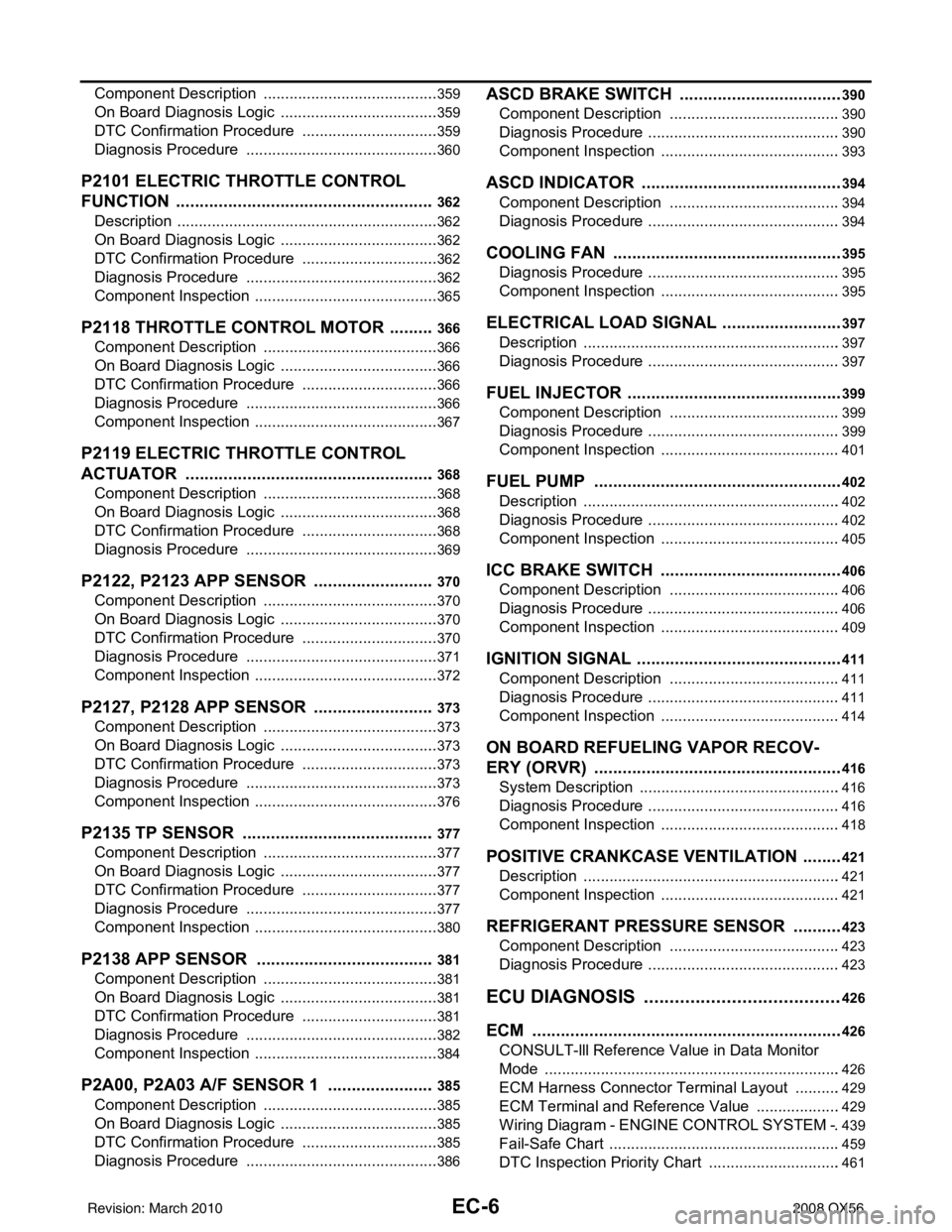

EC-6

Component Description .........................................359

On Board Diagnosis Logic .....................................359

DTC Confirmation Procedure ................................359

Diagnosis Procedure .............................................360

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION .......................................................

362

Description ........................................................... ..362

On Board Diagnosis Logic .....................................362

DTC Confirmation Procedure ................................362

Diagnosis Procedure .............................................362

Component Inspection ...........................................365

P2118 THROTTLE CONTROL MOTOR ..........366

Component Description ....................................... ..366

On Board Diagnosis Logic .....................................366

DTC Confirmation Procedure ................................366

Diagnosis Procedure .............................................366

Component Inspection ...........................................367

P2119 ELECTRIC THROTTLE CONTROL

ACTUATOR .....................................................

368

Component Description ....................................... ..368

On Board Diagnosis Logic .....................................368

DTC Confirmation Procedure ................................368

Diagnosis Procedure .............................................369

P2122, P2123 APP SENSOR ..........................370

Component Description ....................................... ..370

On Board Diagnosis Logic .....................................370

DTC Confirmation Procedure ................................370

Diagnosis Procedure .............................................371

Component Inspection ...........................................372

P2127, P2128 APP SENSOR ..........................373

Component Description ....................................... ..373

On Board Diagnosis Logic .....................................373

DTC Confirmation Procedure ................................373

Diagnosis Procedure .............................................373

Component Inspection ...........................................376

P2135 TP SENSOR .........................................377

Component Description ....................................... ..377

On Board Diagnosis Logic .....................................377

DTC Confirmation Procedure ................................377

Diagnosis Procedure .............................................377

Component Inspection ...........................................380

P2138 APP SENSOR ......................................381

Component Description ....................................... ..381

On Board Diagnosis Logic .....................................381

DTC Confirmation Procedure ................................381

Diagnosis Procedure .............................................382

Component Inspection ...........................................384

P2A00, P2A03 A/F SENSOR 1 .......................385

Component Description ....................................... ..385

On Board Diagnosis Logic .....................................385

DTC Confirmation Procedure ................................385

Diagnosis Procedure .............................................386

ASCD BRAKE SWITCH ...................................390

Component Description ....................................... .390

Diagnosis Procedure .............................................390

Component Inspection ..........................................393

ASCD INDICATOR ...........................................394

Component Description ....................................... .394

Diagnosis Procedure .............................................394

COOLING FAN .................................................395

Diagnosis Procedure ............................................ .395

Component Inspection ..........................................395

ELECTRICAL LOAD SIGNAL ..........................397

Description ........................................................... .397

Diagnosis Procedure .............................................397

FUEL INJECTOR ..............................................399

Component Description ....................................... .399

Diagnosis Procedure .............................................399

Component Inspection ..........................................401

FUEL PUMP .....................................................402

Description ........................................................... .402

Diagnosis Procedure .............................................402

Component Inspection ..........................................405

ICC BRAKE SWITCH ..................................... ..406

Component Description ....................................... .406

Diagnosis Procedure .............................................406

Component Inspection ..........................................409

IGNITION SIGNAL ............................................411

Component Description ....................................... .411

Diagnosis Procedure .............................................411

Component Inspection ..........................................414

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) .....................................................

416

System Description .............................................. .416

Diagnosis Procedure .............................................416

Component Inspection ..........................................418

POSITIVE CRANKCASE VENTILATION .........421

Description ........................................................... .421

Component Inspection ..........................................421

REFRIGERANT PRESSURE SENSOR ...........423

Component Description ....................................... .423

Diagnosis Procedure .............................................423

ECU DIAGNOSIS ......................................426

ECM ................................................................ ..426

CONSULT-lll Reference Value in Data Monitor

Mode .................................................................... .

426

ECM Harness Connector Terminal Layout ...........429

ECM Terminal and Reference Value ....................429

Wiring Diagram - ENGINE CONTROL SYSTEM - .439

Fail-Safe Chart ......................................................459

DTC Inspection Priority Chart ...............................461

Revision: March 2010 2008 QX56

Page 1382 of 4083

![INFINITI QX56 2008 Factory Owners Manual POWER SUPPLY AND GROUND CIRCUITEC-83

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000001351355

1.INSPECTION START

Star INFINITI QX56 2008 Factory Owners Manual POWER SUPPLY AND GROUND CIRCUITEC-83

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000001351355

1.INSPECTION START

Star](/img/42/57030/w960_57030-1381.png)

POWER SUPPLY AND GROUND CIRCUITEC-83

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000001351355

1.INSPECTION START

Start engine.

Is engine running?

Ye s o r N o

Yes >> GO TO 8.

No >> GO TO 2.

2.CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF and then ON.

2. Check voltage between ECM terminal 109 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• 10A fuse

• Harness for open or short between ECM and fuse

>> Repair harness or connectors.

4.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body. Refer to EC-86, "

Ground Inspection" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace ground connections.

5.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 1, 115, 116 and ground. Refer to Wiring Diagram.

3. Also check harness for short to power. Voltage: Battery voltage

MBIB0015E

BBIA0354E

Continuity should exist.

Revision: March 2010

2008 QX56

Page 1384 of 4083

![INFINITI QX56 2008 Factory Owners Manual POWER SUPPLY AND GROUND CIRCUITEC-85

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK INFINITI QX56 2008 Factory Owners Manual POWER SUPPLY AND GROUND CIRCUITEC-85

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK](/img/42/57030/w960_57030-1383.png)

POWER SUPPLY AND GROUND CIRCUITEC-85

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 13.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

11 .CHECK ECM POWER SUPPLY CIRCUIT-VI

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector E119.

3. Check harness continuity between ECM terminal 111 and IPDM E/R terminal 7. Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 12.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

12.CHECK 20A FUSE

1. Disconnect 20A fuse from IPDM E/R.

2. Check 20A fuse.

OK or NG

OK >> GO TO 16.

NG >> Replace 20A fuse.

13.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten ground three screws on the body. Refer to EC-86, "

Ground Inspection" .

OK or NG

OK >> GO TO 14.

NG >> Repair or replace ground connections.

14.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 1, 115, 116 and ground. Refer to Wiring Diagram.

3. Also check harness for short to power.

OK or NG

OK >> GO TO 16.

NG >> GO TO 15.

15.DETECT MALFUNCTIONING PART Continuity should exist.

Continuity should exist.

BBIA0354E

Continuity should exist.

Revision: March 2010

2008 QX56

Page 1391 of 4083

![INFINITI QX56 2008 Factory Owners Manual EC-92

< COMPONENT DIAGNOSIS >[VK56DE]

P0011, P0021 IVT CONTROL

Refer to EC-86, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK INTAKE VALVE TIMING CONT INFINITI QX56 2008 Factory Owners Manual EC-92

< COMPONENT DIAGNOSIS >[VK56DE]

P0011, P0021 IVT CONTROL

Refer to EC-86, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK INTAKE VALVE TIMING CONT](/img/42/57030/w960_57030-1390.png)

EC-92

< COMPONENT DIAGNOSIS >[VK56DE]

P0011, P0021 IVT CONTROL

Refer to EC-86, "Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.

3.CHECK INTAKE VALVE TIMING CONTROL PO SITION SENSOR POWER SUPPLY CIRCUIT

1. Disconnect intake valve timing control position sensor harness connector.

2. Turn ignition switch ON.

3. Check voltage between intake valve timing control position sen- sor terminal 3 and ground with CONSULT-III or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between intake valve timing control position sensor and ECM

• Harness for open or short between intake valve timing control position sensor and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.CHECK INTAKE VALVE TIMING CONTROL POSI TION SENSOR GROUND CIRCUIT FOR OPEN AND

SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between intake valve timing control position sensor terminal 1 and ground.

Refer to Wiring Diagram.

BBIA0354E

1. Intake valve timing control position

sensor (bank 2) 2. Intake valve timing control solenoid

valve (bank 2) 3. Drive belt

4. Radiator hose 5. Intake valve timing control solenoid

valve (bank 1) 6. Intake valve timing control position

sensor (bank 1)

Voltage: Battery voltage

BBIA0771E

SEF509Y

Revision: March 2010 2008 QX56

Page 1392 of 4083

![INFINITI QX56 2008 Factory Owners Manual P0011, P0021 IVT CONTROLEC-93

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Also check harness for short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING INFINITI QX56 2008 Factory Owners Manual P0011, P0021 IVT CONTROLEC-93

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Also check harness for short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING](/img/42/57030/w960_57030-1391.png)

P0011, P0021 IVT CONTROLEC-93

< COMPONENT DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

3. Also check harness for short to power.

OK or NG

OK >> GO TO 7.

NG >> GO TO 6.

6.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E2, F32

• Harness for open or short between intake valve timing control position sensor and ground

>> Repair open circuit or short to power in harness or connectors.

7.CHECK INTAKE VALVE TIMING CONTROL POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN

AND SHORT1. Disconnect ECM harness connector.

2. Check harness continuity between the following; ECM terminal 72 and intake valve timing control position sensor (Bank 1) terminal 2 or

ECM terminal 53 and intake valve timing contro l position sensor (Bank 2) terminal 2.

Refer to Wiring Diagram.

3. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK INTAKE VALVE TIMING CONTROL POSITION SENSOR

Refer to EC-95, "

Component Inspection".

OK or NG

OK >> GO TO 9.

NG >> Replace malfunctioning intake valve timing control position sensor. Refer to EC-501

.

9.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Reconnect ECM harness connector.

2. Disconnect intake valve timing control solenoid valve harness connector.

3. Turn ignition switch ON. Continuity should exist.

Continuity should exist.

1. Intake valve timing control position

sensor (bank 2) 2. Intake valve timing control solenoid

valve (bank 2) 3. Drive belt

4. Radiator hose 5. Intake valve timing control solenoid

valve (bank 1) 6. Intake valve timing control position

sensor (bank 1)

BBIA0771E

Revision: March 2010 2008 QX56