check engine INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2143 of 4083

GI-1

GENERAL INFORMATION

C

DE

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

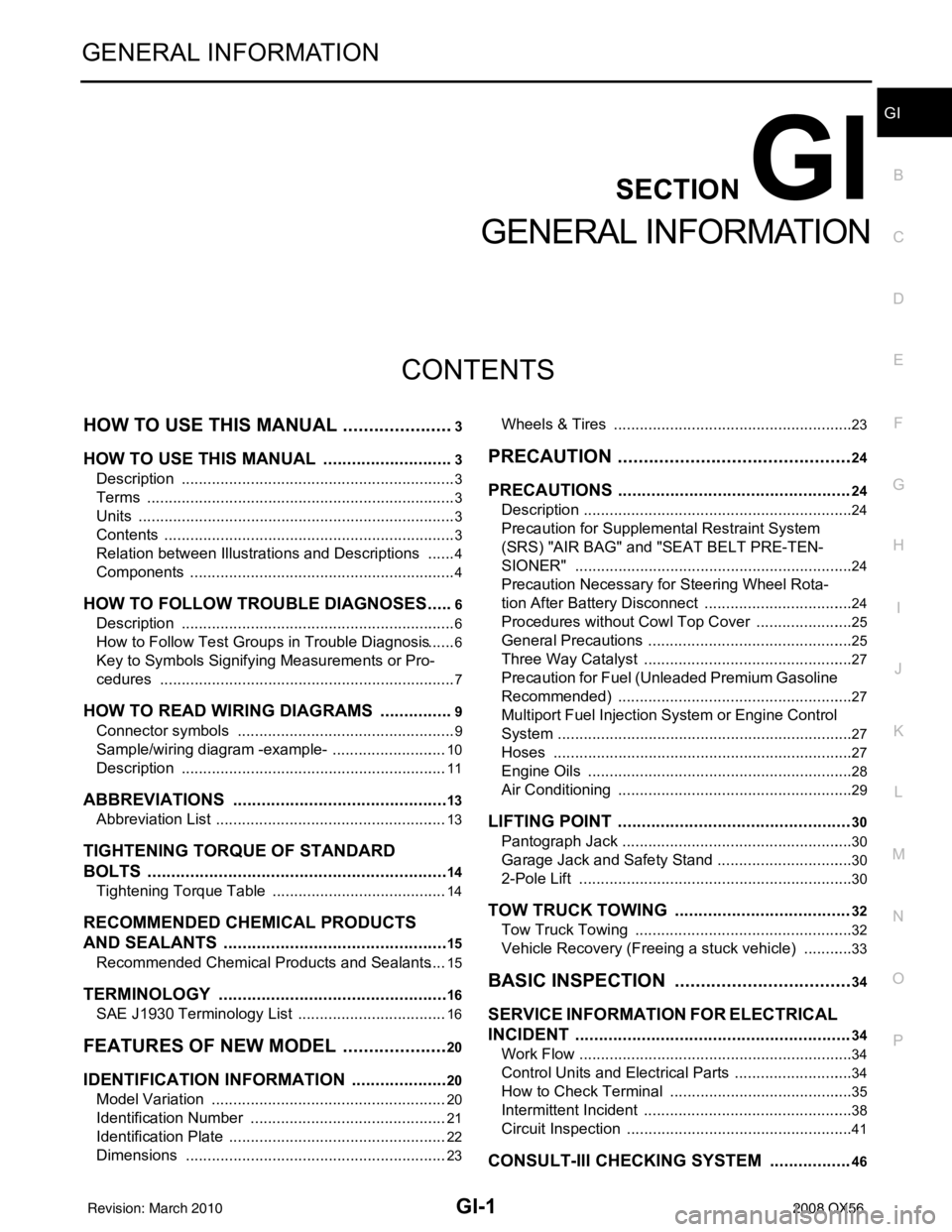

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANU AL ......................3

HOW TO USE THIS MANUAL ....................... .....3

Description .......................................................... ......3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Components ..............................................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures ............................................................... ......

7

HOW TO READ WIRING DIAGRAMS ................9

Connector symbols ............................................. ......9

Sample/wiring diagram -example- ...........................10

Description ..............................................................11

ABBREVIATIONS .......................................... ....13

Abbreviation List .................................................. ....13

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

14

Tightening Torque Table .........................................14

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ............................................ ....

15

Recommended Chemical Products and Sealants ....15

TERMINOLOGY .................................................16

SAE J1930 Terminology List ............................... ....16

FEATURES OF NEW MODEL .....................20

IDENTIFICATION INFORMATION .....................20

Model Variation ................................................... ....20

Identification Number ..............................................21

Identification Plate ...................................................22

Dimensions .............................................................23

Wheels & Tires .................................................... ....23

PRECAUTION ..............................................24

PRECAUTIONS .................................................24

Description ........................................................... ....24

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

24

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

24

Procedures without Cowl Top Cover .......................25

General Precautions ................................................25

Three Way Catalyst .................................................27

Precaution for Fuel (Unleaded Premium Gasoline

Recommended) .......................................................

27

Multiport Fuel Injection System or Engine Control

System .....................................................................

27

Hoses ......................................................................27

Engine Oils ..............................................................28

Air Conditioning .......................................................29

LIFTING POINT .................................................30

Pantograph Jack ......................................................30

Garage Jack and Safety Stand ................................30

2-Pole Lift ................................................................30

TOW TRUCK TOWING .....................................32

Tow Truck Towing ...................................................32

Vehicle Recovery (Freeing a stuck vehicle) ............33

BASIC INSPECTION ...................................34

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

34

Work Flow ............................................................ ....34

Control Units and Electrical Parts ............................34

How to Check Terminal ...........................................35

Intermittent Incident ............................................. ....38

Circuit Inspection .....................................................41

CONSULT-III CHECKING SYSTEM .................46

Revision: March 2010 2008 QX56

Page 2159 of 4083

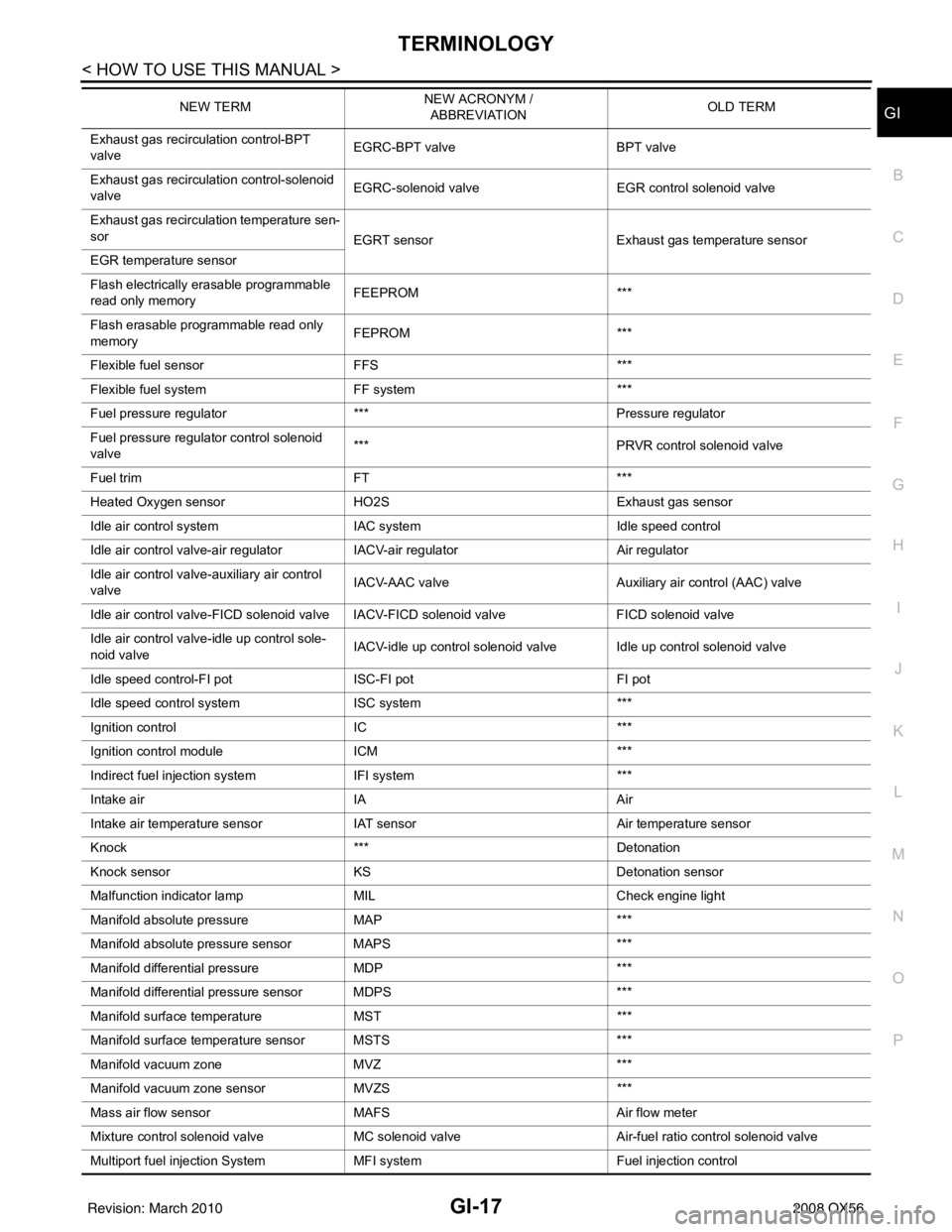

TERMINOLOGYGI-17

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Exhaust gas recirculation control-BPT

valve EGRC-BPT valve

BPT valve

Exhaust gas recirculation control-solenoid

valve EGRC-solenoid valve

EGR control solenoid valve

Exhaust gas recirculation temperature sen-

sor EGRT sensorExhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memory FEEPROM

***

Flash erasable programmable read only

memory FEPROM

***

Flexible fuel sensor FFS***

Flexible fuel system FF system***

Fuel pressure regulato r*** Pressure regulator

Fuel pressure regulator control solenoid

valve ***

PRVR control solenoid valve

Fuel trim FT***

Heated Oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulato rIACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valve IACV-AAC valve

Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valve IACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system***

Ignition control IC***

Ignition control module ICM***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

Malfunction indicator lamp MIL Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold su rface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valveAir-fuel ratio control solenoid valve

Multiport fuel injection System MFI system Fuel injection control

NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

Revision: March 2010

2008 QX56

Page 2163 of 4083

IDENTIFICATION INFORMATIONGI-21

< FEATURES OF NEW MODEL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Identification NumberINFOID:0000000001559940

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

1. Emission control information label/ vacuum hose diagram 2. Tire placard 3. F.M.V.S.S./C.M.V.S.S. certification

label

4. Vehicle identification number plate 5. Air conditioner specification label

AWAIA0026GB

Position Character Qualifier Definition

1 5N3 Manufacturer 5N3: USA produced multi-purpose vehicle

2

3

4 A Engine type A: VK56DE

5 A0 Model code A0: Infiniti QX56

6

7 8 Body type 8: 4 door wagon

8D Gross vehicle

weight ratingD: 2WD, 4-wheel ABS, Class F

C: 4WD, 4-wheel ABS, Class F

9 * Check digit (0 to 9 or X) The code for the check digit is determined by a mathematical com-

putation.

10 8 Model year 2008

11 NManufacturing

plant

N: Canton Mississippi

12

XXXXXX Vehicle serial num-

ber Chassis number

13

14

15

16

17

Revision: March 2010

2008 QX56

Page 2167 of 4083

PRECAUTIONSGI-25

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Procedures without Cowl Top CoverINFOID:0000000001539208

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

General PrecautionsINFOID:0000000001539209

• Do not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any inflam-

mable or poisonous materials, such as gasoline, refrigerant gas,

etc. When working in a pit or ot her enclosed area, be sure to prop-

erly ventilate the area before working with hazardous materials.

Do not smoke while working on the vehicle.

• Before jacking up the vehicle, apply wheel chocks or other tire blocks to the wheels to prevent t he vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

• When removing a heavy component such as the engine or tran-

saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

PIIB3706J

SGI285

SGI231

Revision: March 2010 2008 QX56

Page 2168 of 4083

GI-26

< PRECAUTION >

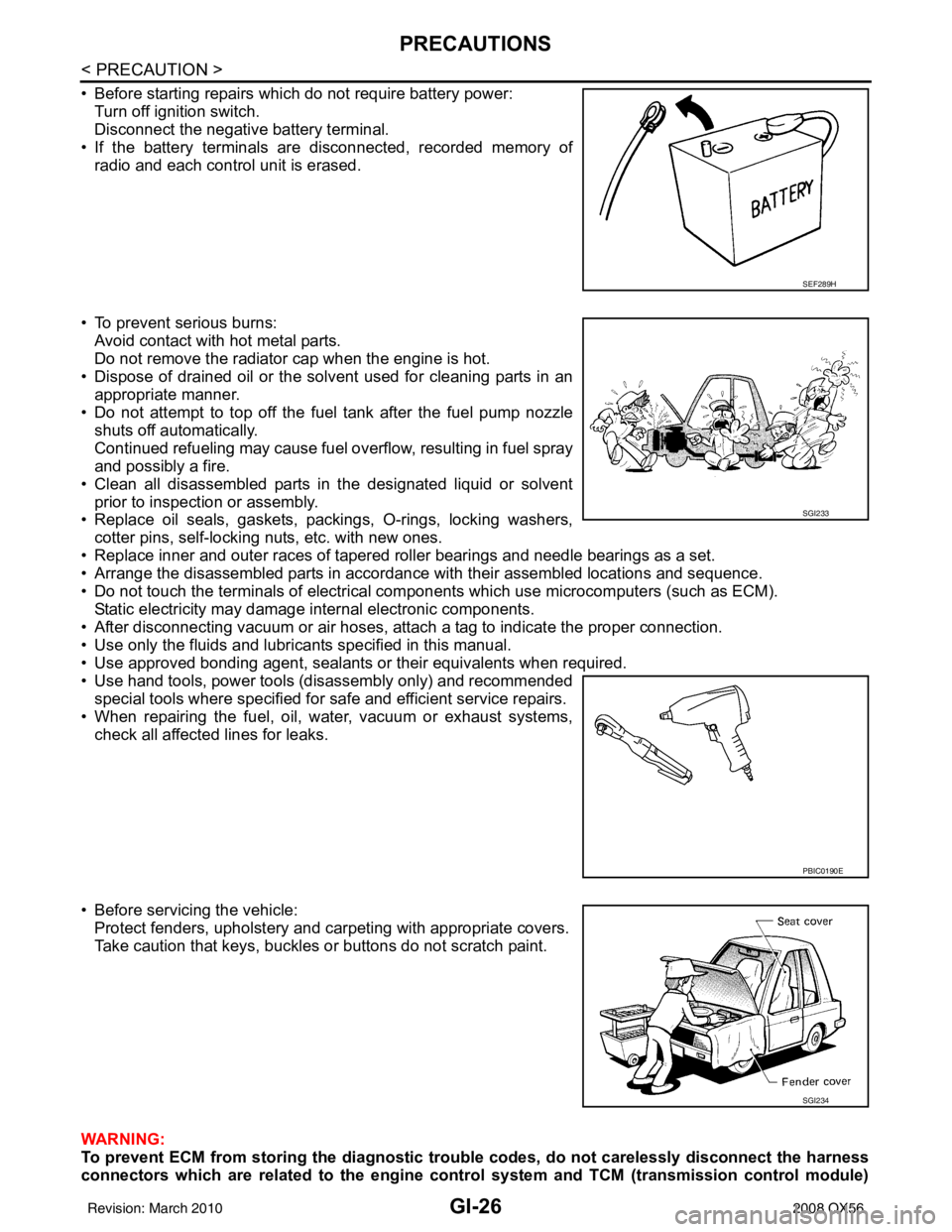

PRECAUTIONS

• Before starting repairs which do not require battery power:Turn off ignition switch.

Disconnect the negative battery terminal.

• If the battery terminals are disconnected, recorded memory of radio and each control unit is erased.

• To prevent serious burns: Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

• Dispose of drained oil or the solvent used for cleaning parts in an appropriate manner.

• Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

• Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

• Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

• Replace inner and outer races of tapered roller bearings and needle bearings as a set.

• Arrange the disassembled parts in accordance with their assembled locations and sequence.

• Do not touch the terminals of electrical com ponents which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

• After disconnecting vacuum or air hoses, atta ch a tag to indicate the proper connection.

• Use only the fluids and lubricants specified in this manual.

• Use approved bonding agent, sealants or their equivalents when required.

• Use hand tools, power tools (disassembly only) and recommended special tools where specified for safe and efficient service repairs.

• When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

• Before servicing the vehicle: Protect fenders, upholstery and carpeting with appropriate covers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic tro uble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

SEF289H

SGI233

PBIC0190E

SGI234

Revision: March 2010 2008 QX56

Page 2169 of 4083

PRECAUTIONSGI-27

< PRECAUTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and TM sections.

Three Way CatalystINFOID:0000000001539210

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

• Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

• When checking for ignition spark or measuring engine compression, make tests quickly and only when nec-

essary.

• Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to the

catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precaution for Fuel (Unlead ed Premium Gasoline Recommended)INFOID:0000000006211825

INFINITI recommends the use of unleaded premium gasoline with an octane rating of at least 91 AKI (Anti-

Knock Index) number (Research octane number 96).

If unleaded premium gasoline is not available, unleaded regular gasoline with an octane rating of at least 87

AKI number (Research octane number 91) can be us ed, but only under the following precautions:

• have the fuel tank filled only partially with unleaded regular gasoline, and fill up with unleaded premium gas- oline as soon as possible.

• avoid full throttle driving and abrupt acceleration.

However, for maximum vehicle performance, the u se of unleaded premium gasoline is recommended.

CAUTION:

Do not use leaded gasoline. Usin g leaded gasoline will damage the three way catalyst. Using a fuel

other than that specified could adversely affect the emission cont rol devices and systems, and could

also affect the warranty coverage validity.

Multiport Fuel Inje ction System or Engine Control SystemINFOID:0000000001539213

• Before connecting or disconnecting any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

• Before disconnecting pressurized fuel line from fuel pump to injec- tors, be sure to release fuel pressure.

• Be careful not to jar components such as ECM and mass air flow

sensor.

HosesINFOID:0000000001539214

HOSE REMOVAL AND INSTALLATION

• To prevent damage to rubber hose, do not pry off rubber hose withtapered tool or screwdriver.

SGI787

SMA019D

Revision: March 2010 2008 QX56

Page 2176 of 4083

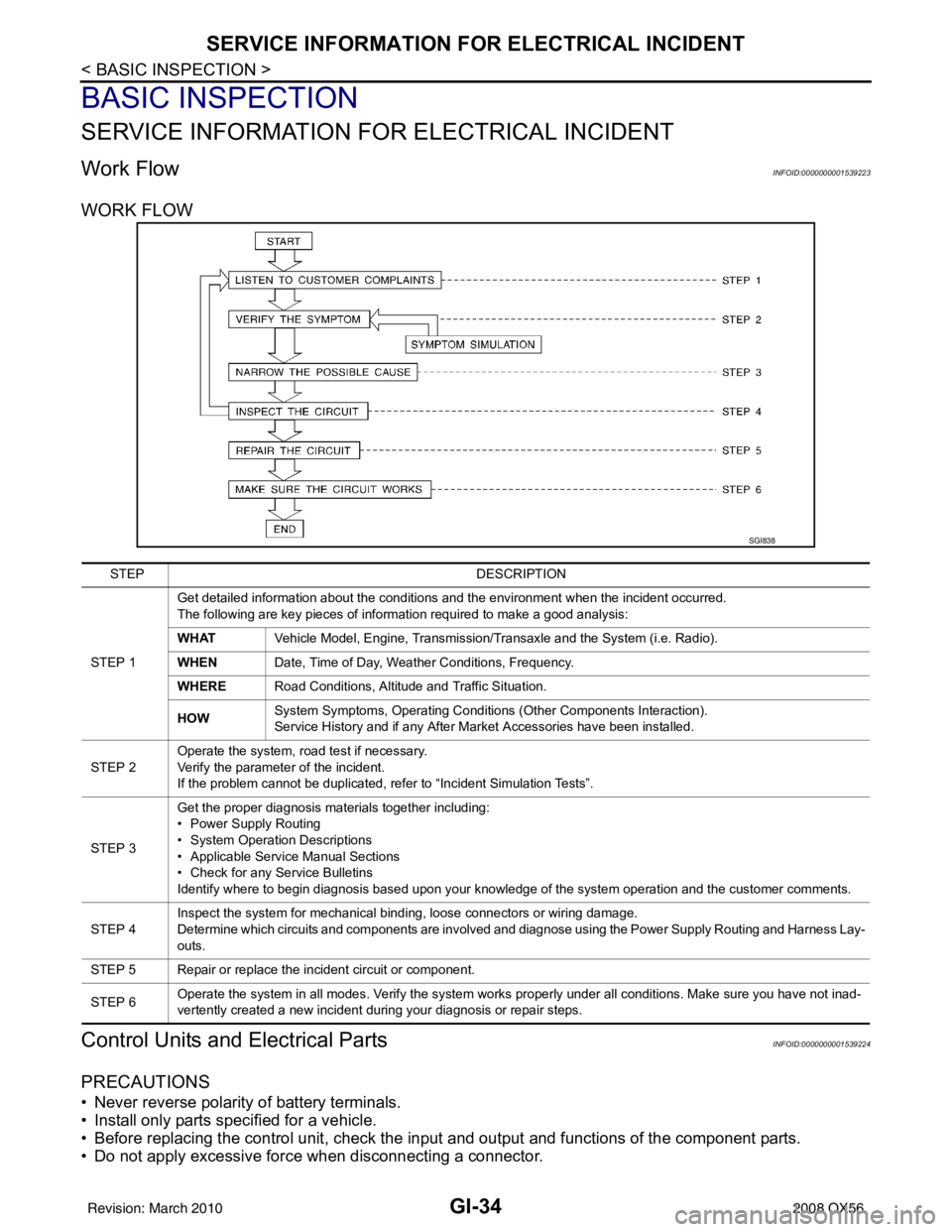

GI-34

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

BASIC INSPECTION

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Work FlowINFOID:0000000001539223

WORK FLOW

Control Units and Electrical PartsINFOID:0000000001539224

PRECAUTIONS

• Never reverse polarity of battery terminals.

• Install only parts specified for a vehicle.

• Before replacing the control unit, check the i nput and output and functions of the component parts.

• Do not apply excessive force when disconnecting a connector.

SGI838

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHAT

Vehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHEN Date, Time of Day, Weather Conditions, Frequency.

WHERE Road Conditions, Altitude and Traffic Situation.

HOW System Symptoms, Operating Conditions

(Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3 Get the proper diagnosis materials together including:

• Power Supply Routing

• System Operation Descriptions

• Applicable Service Manual Sections

• Check for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness Lay-

outs.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. Make sure you have not inad-

vertently created a new incident during your diagnosis or repair steps.

Revision: March 2010

2008 QX56

Page 2181 of 4083

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-39

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

lowing section illustrates ways to simulate the c onditions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold or hot start up

Get a thorough description of the incident from the customer . It is important for simulating the conditions of the

problem.

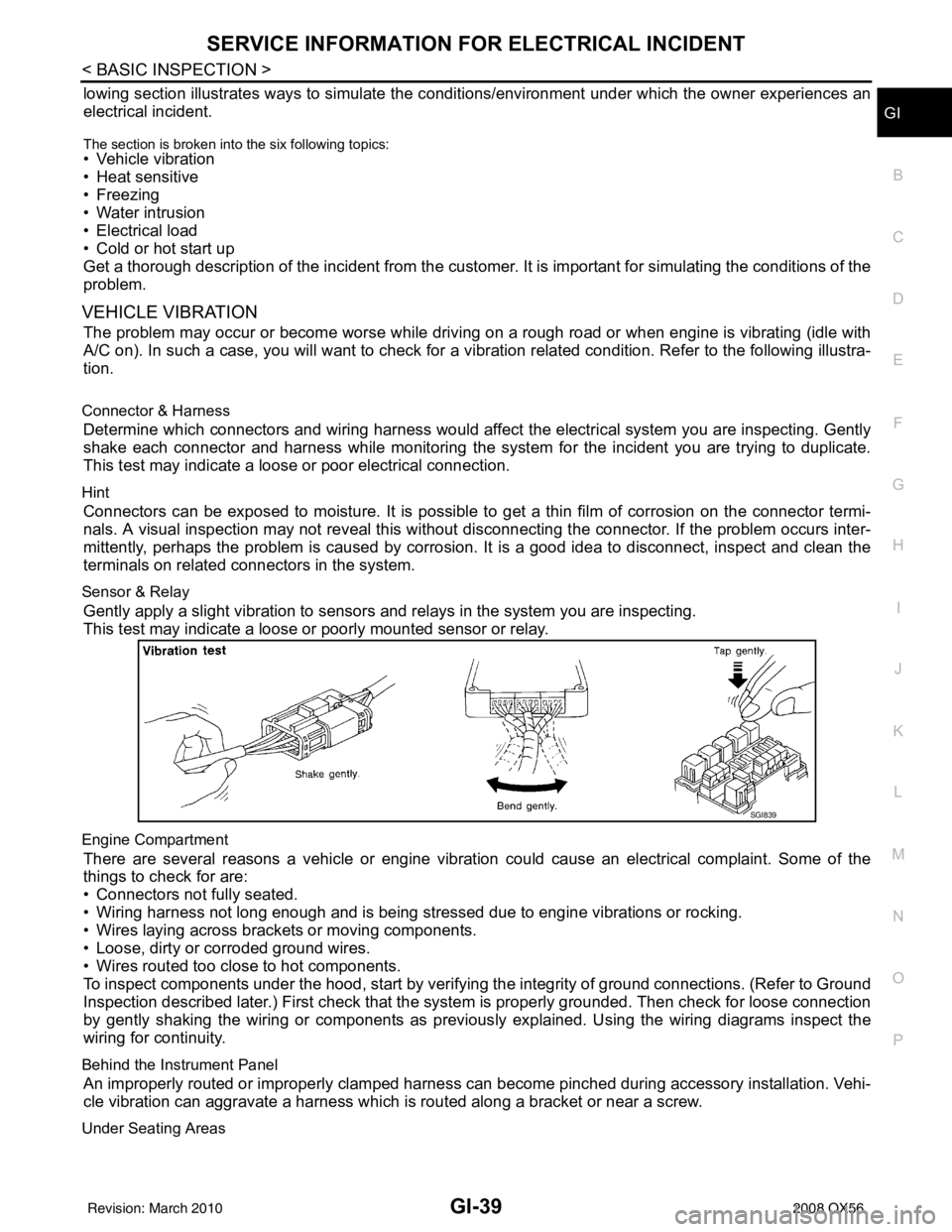

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vibration related condition. Refer to the following illustra-

tion.

Connector & Harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the syst em for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosi on. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

This test may indicate a loose or poorly mounted sensor or relay.

Engine Compartment

There are several reasons a vehicle or engine vibration could cause an electrical complaint. Some of the

things to check for are:

• Connectors not fully seated.

• Wiring harness not long enough and is being stressed due to engine vibrations or rocking.

• Wires laying across brackets or moving components.

• Loose, dirty or corroded ground wires.

• Wires routed too close to hot components.

To inspect components under the hood, start by verifyi ng the integrity of ground connections. (Refer to Ground

Inspection described later.) First check that the system is properly grounded. Then check for loose connection

by gently shaking the wiring or components as previous ly explained. Using the wiring diagrams inspect the

wiring for continuity.

Behind the Instrument Panel

An improperly routed or improperly clamped harness can become pinched during accessory installation. Vehi-

cle vibration can aggravate a harness which is routed along a bracket or near a screw.

Under Seating Areas

SGI839

Revision: March 2010 2008 QX56

Page 2188 of 4083

GI-46

< BASIC INSPECTION >

CONSULT-III CHECKING SYSTEM

CONSULT-III CHECKING SYSTEM

DescriptionINFOID:0000000001539228

• When CONSULT-III is connected with a data link connectorequipped on the vehicle side, it will communicate with the control

unit equipped in the vehicle and then enable various kinds of diag-

nostic tests.

• Refer to “CONSULT-III Operation Manual” for more information.

Function and System ApplicationINFOID:0000000001555032

1 : Hood release handle

2 : Data link connector

ALBIA0047ZZ

Diagnostic test mode Function

ENGINE

TRANSMISSION

ICC

*1

ABS

AIR BAG

IPDM E/R

BCM

METER/M&A

INTELLIGENT KEY

AUTO DRIVE POS.

REARVIEW CAMERA

AIR LEVELIZER MULTI AV

ALL MODE AWD/4WD

*2

HVAC

SONAR

Work support This mode enables a technician to adjust some devic-

es faster and more accurately by following the indica-

tions on CONSULT-III. x - xx - - x - xxxx - - - -

Self-diagnostic Self-diagnostic can be performed quickly. ----x-----------

Self-diagnostic re-

sults Self-diagnostic results can be read and erased quick-

ly.

xxxx - xxxxx - xxxxx

Trouble diagnostic

record Current self-diagnostic results and all trouble diag-

nostic records previously stored can be read.

--- - x--- - -------

Data monitor Input/Output data in the ECM can be read. xxxx - xxxxxxxxxxx

Data monitor (spec)Data monitor specification can be read. x---------------

CAN diagnosis The condition of CAN communication can be indicat-

ed by a topology.

xxxxxxxxxx - - xxx -

CAN diagnosis sup-

port monitor The communication condition of CAN communication

line can be read.

xxxx - xxxxx - - xxx -

Active test Diagnostic Test Mode in which CONSULT-III drives

some actuators apart from the ECMs and also shifts

some parameters in a specified range. x-xx-xx-xx-x- - - -

Function test This mode can show results of self-diagnosis of ECU

with either “OK” or “NG”. For engines, more practical

tests regarding sensors/switches and/or actuators

are available. xxxxx - - - x

-------

DTC & SRT confir-

mation The results of SRT (System Readiness Test) and the

self-diagnosis status/result can be confirmed.

x-x-----x-------

DTC work support The operating condition to confirm Diagnosis Trouble

Codes can be selected. xxx-----x-------

ECM/ECU part num-

ber ECM/ECU part number can be read.

xxxx - - x - xxxxx - xx

ECU discriminated

No. Classification number of a replacement ECU can be

read to prevent an incorrect ECU from being in-

stalled.

----x-----------

Revision: March 2010

2008 QX56

Page 2189 of 4083

CONSULT-III CHECKING SYSTEMGI-47

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

x : Applicable

*1: With intelligent cruise control

*2: With 4-wheel drive

*3: With security card installed

CONSULT-III Data Link Connector (DLC) CircuitINFOID:0000000001555031

INSPECTION PROCEDURE

If the CONSULT-III cannot diagnose the sys tem properly, check the following items.

NOTE:

The CAN and DDL2 circuits from DLC pins 6, 7 and 14 may be connected to more than one system. A short in

any circuit connected to a control unit in one system may affect CONSULT-III access to other systems.

Passenger AirbagDisplays the STATUS (readiness) of the front passen-

ger air bag. ----x-----------

AV COMM monitor The condition of AV communication can be indicated.------------x---

Configuration Sets control module parame

ters to match vehicle op-

tions. ------x---------

PIN read

*3This mode shows the BCM-specific 5-digit code. ------x---------

Control unit initial-

ization

*3All registered ignition key IDs in NATS components

can be initialized and new IDs can be registered. ------x---------

Diagnostic test

mode Function

ENGINE

TRANSMISSION

ICC

*1

ABS

AIR BAG

IPDM E/R BCM

METER/M&A

INTELLIGENT KEY

AUTO DRIVE POS.

REARVIEW CAMERA AIR LEVELIZER MULTI AV

ALL MODE AWD/4WD

*2

HVAC

SONAR

Symptom Check item

CONSULT-III cannot access

any system. • CONSULT-III DLC power supply circuit (Terminal 8) and ground circuit (Terminal 4)

CONSULT-III cannot access in-

dividual system. (Other sys-

tems can be accessed.) • Power supply and ground circuit for the control unit of the system (For detailed circuit, refer to wiring

diagram for each system.)

• Open or short circuit between the system and CONSULT-III DLC (For detailed circuit, refer to wiring diagram for each system.)

• Open or short circuit CAN communication line. Refer to LAN-14, "

Trouble Diagnosis Flow Chart".

Revision: March 2010 2008 QX56