clutch INFINITI QX56 2008 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2059 of 4083

EXT-6

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the v ehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, chec k ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follo w the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to EXT-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-43980) is av ailable through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94× 5.31 in)/76884-71L01: 60 ×85 mm (2.36 ×3.35 in)/76884-71L02: 15 ×25

mm (0.59× 0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50 ×50 mm (1.97 ×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50× 50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movemen t does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59× 0.98 in) pad/68239-13E00: 5 mm (0.20 in ) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for inst rument panel applications.

Revision: March 2010 2008 QX56

Page 2158 of 4083

GI-16

< HOW TO USE THIS MANUAL >

TERMINOLOGY

TERMINOLOGY

SAE J1930 Terminology ListINFOID:0000000001539196

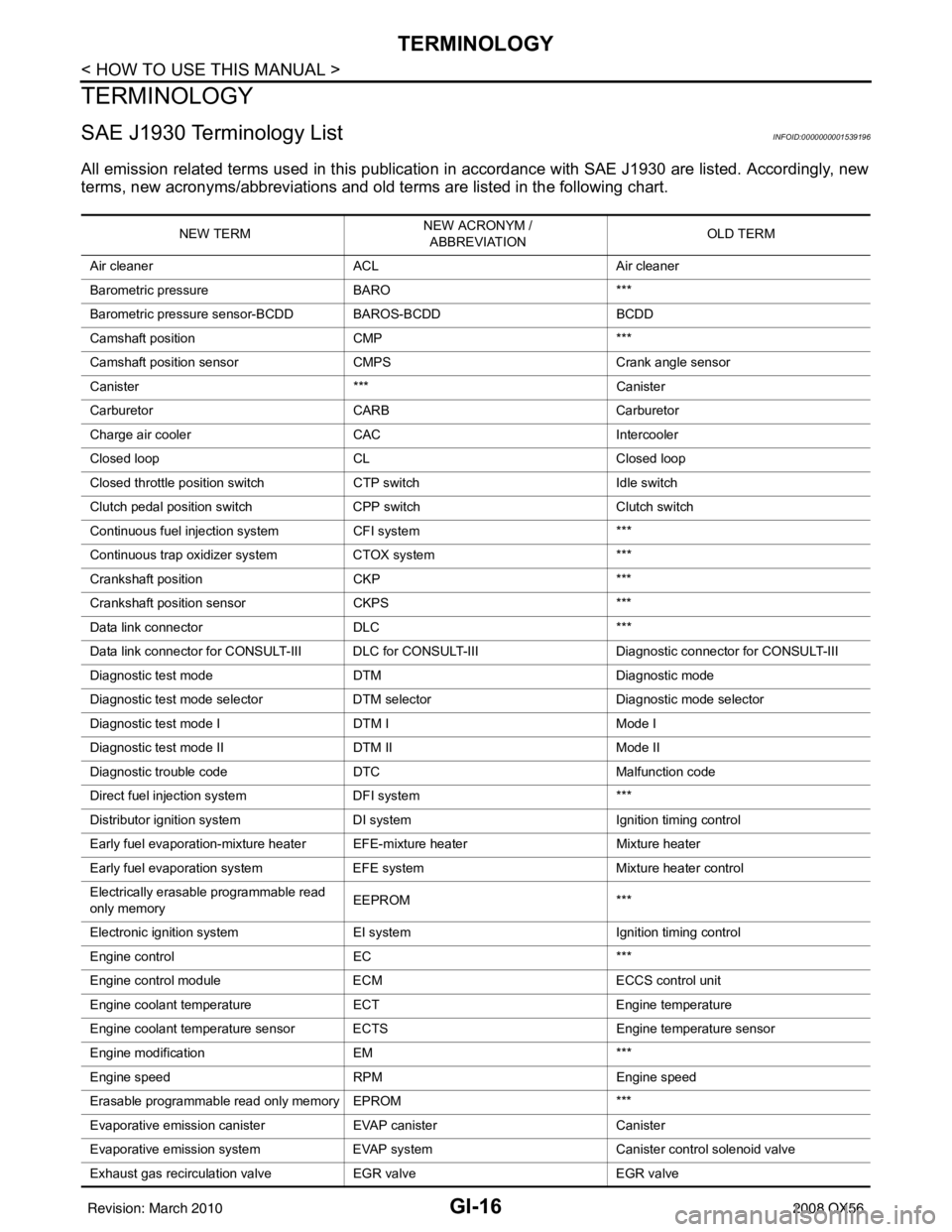

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATION OLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPSCrank angle sensor

Canister *** Canister

Carburetor CARBCarburetor

Charge air cooler CACIntercooler

Closed loop CLClosed loop

Closed throttle position switch CTP switchIdle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP***

Crankshaft position sensor CKPS***

Data link connector DLC***

Data link connector for CONSULT-III DLC for CONSULT-IIIDiagnostic connector for CONSULT-III

Diagnostic test mode DTMDiagnostic mode

Diagnostic test mode selector DTM selectorDiagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM IIMode II

Diagnostic trouble code DTCMalfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memory EEPROM

***

Electronic ignition system EI systemIgnition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve

Revision: March 2010 2008 QX56

Page 2160 of 4083

GI-18

< HOW TO USE THIS MANUAL >

TERMINOLOGY

Nonvolatile random access memory NVRAM***

On board diagnostic system OBD system Self-diagnosis

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Transmission range switch *** Park/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain cont rol module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control sole-

noid valve PAIRC solenoid valve

AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI***

Simultaneous multiport fuel injection sys-

tem ***

Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVVThermal vacuum valve

Three way catalyst TWCCatalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OCCatalyst

Three way + oxidation catalytic converter

system TWC + OC system

***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

Lock-up solenoid

NEW TERM

NEW ACRONYM /

ABBREVIATION OLD TERM

Revision: March 2010

2008 QX56

Page 2206 of 4083

HA-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION HA

A

B

HA

N

O P

CONTENTS

HEATER & AIR CONDITIONING SYSTEM

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Working with HFC-134a (R-134a) ......4

Precaution for Procedure without Cowl Top Cover ......4

Contaminated Refrigerant .........................................4

General Refrigerant Precaution ................................5

Precaution for Leak Detection Dye ...........................5

A/C Identification Label .............................................5

Precaution for Refrigerant Connection ......................5

Precaution for Service of Compressor ................ ....10

Precaution for Service Equipment ....................... ....10

PREPARATION ...........................................13

PREPARATION .............................................. ....13

Special Service Tool ........................................... ....13

HFC-134a (R-134a) Service Tool and Equipment ....13

Commercial Service Tool ........................................16

FUNCTION DIAGNOSIS ..............................17

REFRIGERATION SYSTEM .......................... ....17

Refrigerant Cycle ................................................ ....17

Refrigerant System Protection ................................17

OIL .................................................................. ....19

Maintenance of Oil in Compressor ...................... ....19

ON-VEHICLE MAINTENANCE ....................20

REFRIGERATION SYSTEM .......................... ....20

HFC-134a (R-134a) Service Procedure ..................20

OIL .................................................................. ....22

Maintenance of Oil Quantity in Compressor ....... ....22

FLUORESCENT LEAK DETECTOR ................24

Checking of Refrigerant Leaks ................................24

Checking System for Leaks Using the Fluorescent

Dye Leak Detector ............................................... ....

24

Dye Injection ............................................................24

ELECTRICAL LEAK DETECTOR ....................26

Checking of Refrigerant Leaks ................................26

Electronic Refrigerant Leak Detector ................... ....26

ON-VEHICLE REPAIR .................................29

REFRIGERATION SYSTEM .............................29

Component .......................................................... ....29

COMPRESSOR .................................................31

Removal and Installation for Compressor ...............31

Removal and Installation for Compressor Clutch ....32

LOW-PRESSURE FLEXIBLE HOSE ................36

Removal and Installation for Low-Pressure Flexi-

ble Hose .............................................................. ....

36

LOW-PRESSURE PIPE ....................................37

Removal and Installation for Low-Pressure Pipe .....37

Removal and Installation for Rear High- and Low-

Pressure A/C and Heater Core Pipes ......................

37

Removal and Installation for Underfloor Rear

High- and Low-Pressure A/C and Heater Core

Pipes ........................................................................

38

HIGH-PRESSURE FLEXIBLE HOSE ...............40

Removal and Installation for High-Pressure Flexi-

ble Hose ..................................................................

40

HIGH-PRESSURE PIPE ....................................41

Removal and Installation for High-Pressure Pipe ....41

Removal and Installation for Rear High- and Low-

Pressure A/C and Heater Core Pipes .................. ....

41

Removal and Installation for Underfloor Rear

High- and Low-Pressure A/C and Heater Core

Pipes ........................................................................

43

Revision: March 2010 2008 QX56

Page 2215 of 4083

HA-10

< PRECAUTION >

PRECAUTIONS

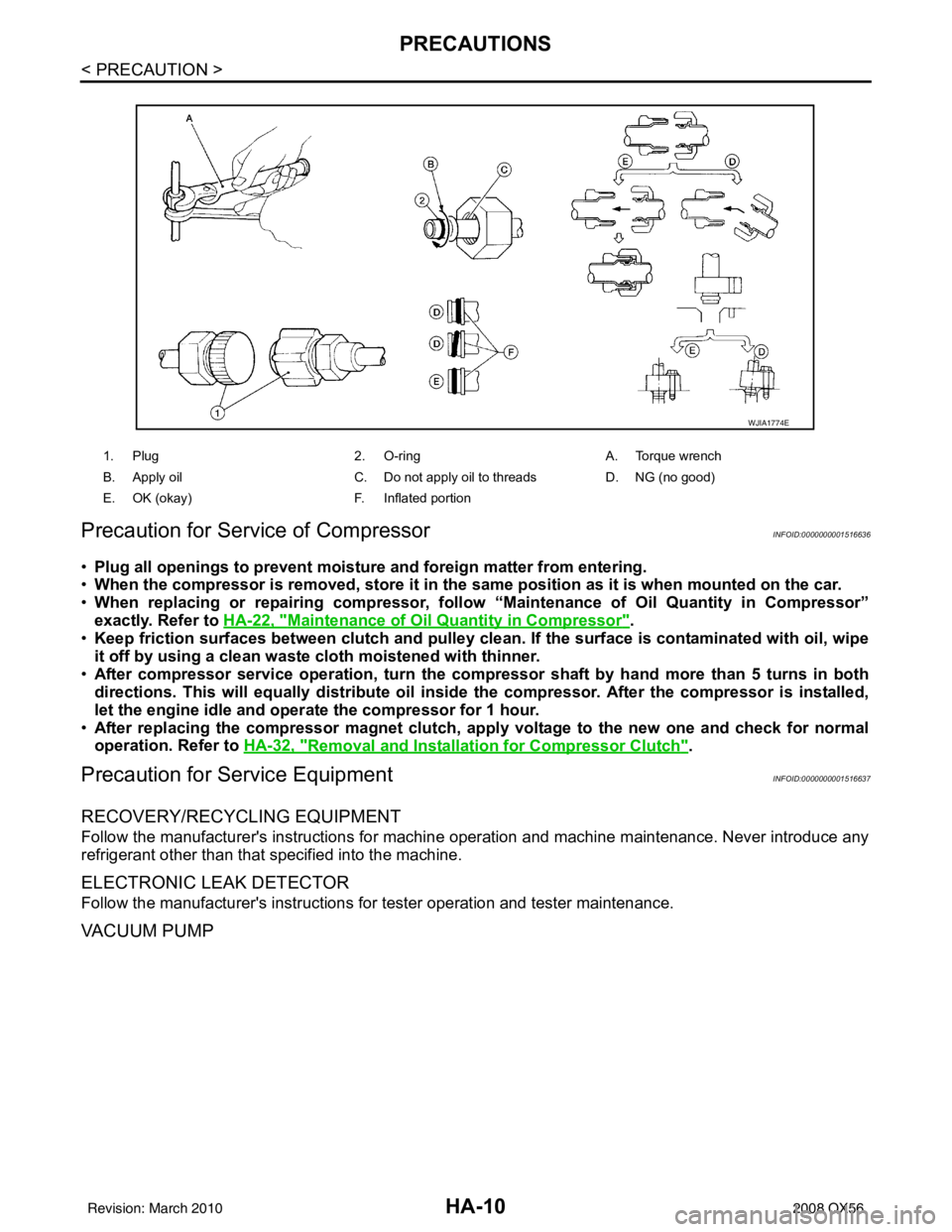

Precaution for Service of Compressor

INFOID:0000000001516636

• Plug all openings to prevent moisture and foreign matter from entering.

• When the compressor is removed, store it in th e same position as it is when mounted on the car.

• When replacing or repairing compressor, follow “Maintenance of Oil Quantity in Compressor”

exactly. Refer to HA-22, "

Maintenance of Oil Quantity in Compressor".

• Keep friction surfaces between clut ch and pulley clean. If the surface is contaminated with oil, wipe

it off by using a clean waste cloth moistened with thinner.

• After compressor service operation, turn the compressor shaft by ha nd more than 5 turns in both

directions. This will equally distribute oil inside the compressor. After the compressor is installed,

let the engine idle and oper ate the compressor for 1 hour.

• After replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation. Refer to HA-32, "

Removal and Installation for Compressor Clutch".

Precaution for Service EquipmentINFOID:0000000001516637

RECOVERY/RECYCLING EQUIPMENT

Follow the manufacturer's instructions for machi ne operation and machine maintenance. Never introduce any

refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Follow the manufacturer's instructions for tester operation and tester maintenance.

VACUUM PUMP

1. Plug 2. O-ring A. Torque wrench

B. Apply oil C. Do not apply oil to threads D. NG (no good)

E. OK (okay) F. Inflated portion

WJIA1774E

Revision: March 2010 2008 QX56

Page 2218 of 4083

PREPARATIONHA-13

< PREPARATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

PREPARATION

PREPARATION

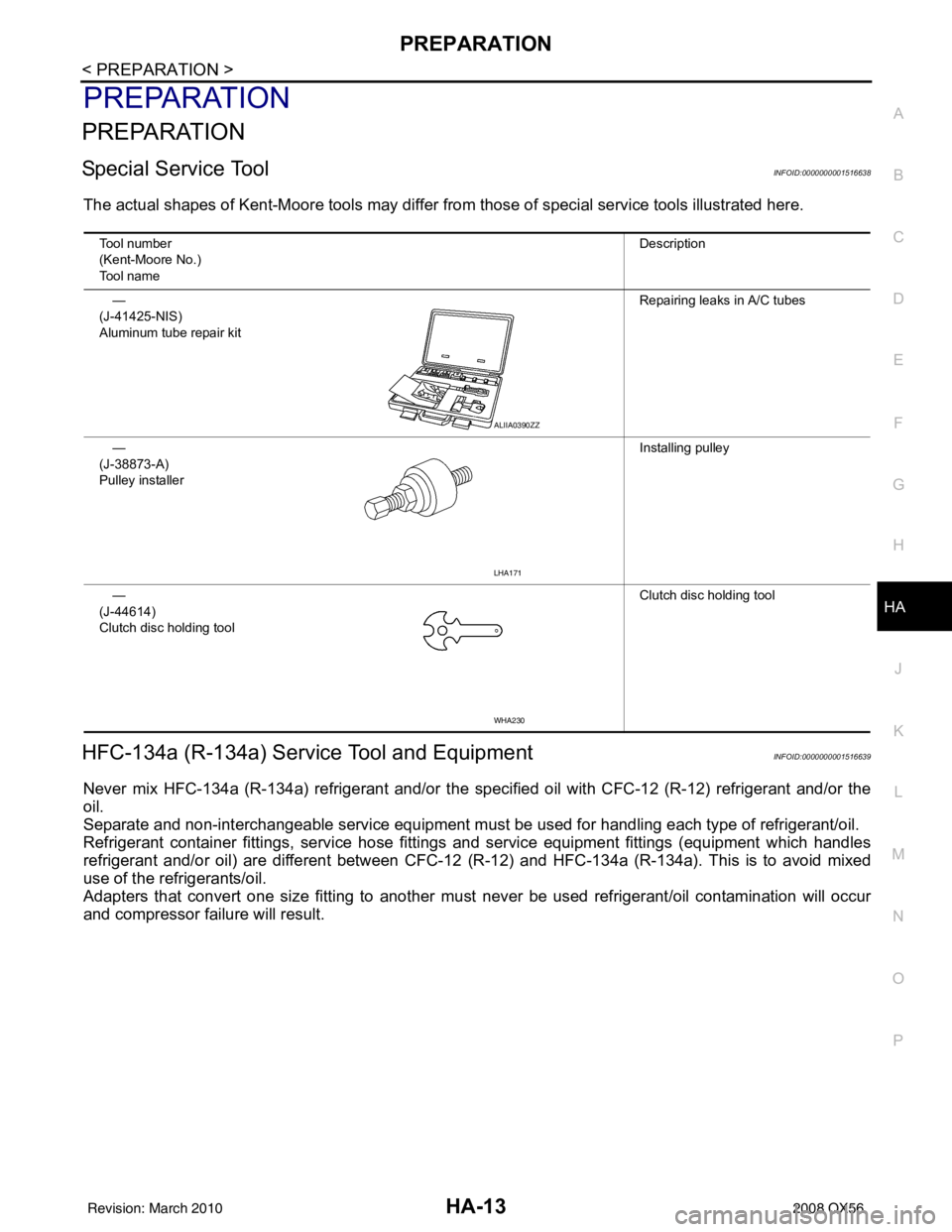

Special Service ToolINFOID:0000000001516638

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

HFC-134a (R-134a) Service Tool and EquipmentINFOID:0000000001516639

Never mix HFC-134a (R-134a) refrigerant and/or the specified oil with CFC-12 (R-12) refrigerant and/or the

oil.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/oil.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or oil) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid mixed

use of the refrigerants/oil.

Adapters that convert one size fitting to another must never be used refrigerant/oil contamination will occur

and compressor failure will result.

Tool number

(Kent-Moore No.)

Tool name Description

—

(J-41425-NIS)

Aluminum tube repair kit Repairing leaks in A/C tubes

—

(J-38873-A)

Pulley installer Installing pulley

—

(J-44614)

Clutch disc holding tool Clutch disc holding tool

ALIIA0390ZZ

LHA171

WHA230

Revision: March 2010

2008 QX56

Page 2222 of 4083

REFRIGERATION SYSTEMHA-17

< FUNCTION DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

FUNCTION DIAGNOSIS

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000001516641

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the front and rear evaporators, and back to the compressor. The refrigerant evaporation through the

evaporator coils are controlled by front and rear externally equalized expansion valves, located inside the front

and rear evaporator cases.

Refrigerant System ProtectionINFOID:0000000001516642

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnetic compressor clutch when pressure on the high

pressure side detected by refrigerant pressu re sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below

about 120 kPa (1.22 kg/cm

2, 17.4 psi).

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system incr eases to an abnormal level [more than 2,990 kPa (30.5 kg/

Revision: March 2010 2008 QX56

Page 2237 of 4083

HA-32

< ON-VEHICLE REPAIR >

COMPRESSOR

• Replace the O-rings of the low-pressure flexible hose and high-pressure flexible hose with new

ones, apply compressor oil to the O-rings when installing them.

• After recharging the A/C system with refrigerant, check for leaks.

Removal and Installation for Compressor ClutchINFOID:0000000001516653

Magnet Clutch Assembly

REMOVAL

1. Remove the compressor. Refer to HA-31, "Removal and Installation for Compressor" .

2. Remove the center bolt while holding the clutch disc stationary using Tool as shown.

3. Remove the clutch disc and shims. CAUTION:

Retain all of the shims for installation.

4. Remove the snap ring using external snap ring pliers or suitable tool.

AWIIA1286GB

1. Magnet clutch assembly 2. Magnet coil 3. Pulley

4. Clutch disc 5. Snap ring 6. Thermal protector (built in)

7. Compressor

Tool number : — ( J-44614 )

WHA228

RHA072C

Revision: March 2010 2008 QX56

Page 2238 of 4083

COMPRESSORHA-33

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

5. Remove the pulley using suitable tool ( A ).

CAUTION:

To prevent deformation of the pulley groove, the puller claws should be hooked under the pulley

groove and not into the pulley groove.

6. Remove the three magnet coil screws using a suitable tool and remove the magnet coil.

INSPECTION

Clutch Disc

If the contact surface shows signs of damage due to excessive heat,

replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If contact surface of pulley shows signs of excessive grooving,

replace clutch disc and pulley. The contact surfaces of the pulley assembly should be cleaned with a suitable

solvent before reinstallation.

Coil

Check magnet coil for loose connections or any cracked insulation.

INSTALLATION

WJIA1017E

WHA212

WHA183

Revision: March 2010 2008 QX56

Page 2239 of 4083

HA-34

< ON-VEHICLE REPAIR >

COMPRESSOR

1. Install the magnet coil.CAUTION:

Be sure to align the magnet coil pin with the hole in the

compressor front head.

2. Install the pulley assembly using Tool and a wrench, then install the snap ring using snap ring pliers.

3. Install the clutch disc on the compressor shaft, together with the original shim(s). Press the clutch disc down by hand.

4. Install the clutch pulley bolt using Tool, to prevent the clutch disc from turning and tighten the bolt to specification.

CAUTION:

After tightening the clutch pu lley bolt, check that the clutch

pulley rotates smoothly.

WHA213

Tool number : — (J-38873-A)

WJIA1016E

WHA184

Tool number : — ( J-44614 )

WHA229

Revision: March 2010 2008 QX56