engine INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2594 of 4083

OIL COOLERLU-13

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

Installation is in the reverse order of removal, paying attention to the following:

• Confirm that no foreign objects are adhering to the sealing sur-

faces of the oil cooler or oil pan.

• Tighten the connecting bolt after aligning the stopper on the oil pan side with protrusion of the oil cooler.

INSPECTION AFTER INSTALLATION

1. Check levels and add engine oil and engine coolant. Refer to LU-8, "Inspection" and CO-10, "Inspection".

2. Start the engine, and check for leaks of engine oil and engine coolant.

3. Stop the engine and wait for 10 minutes.

4. Check engine oil level and engine coolant level again.

KBIA2500E

Revision: March 2010 2008 QX56

Page 2595 of 4083

LU-14

< ON-VEHICLE REPAIR >

OIL PUMP

OIL PUMP

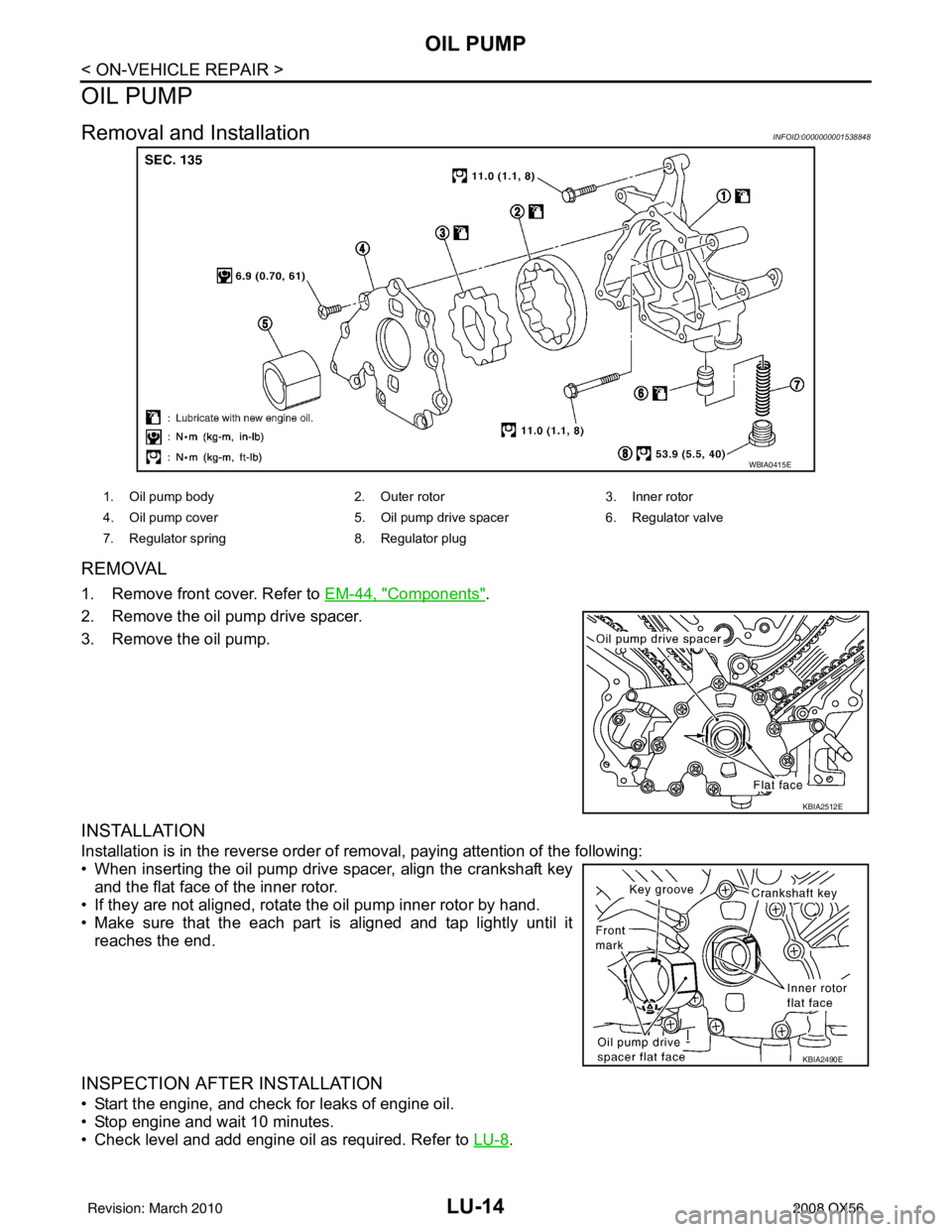

Removal and InstallationINFOID:0000000001538848

REMOVAL

1. Remove front cover. Refer to EM-44, "Components".

2. Remove the oil pump drive spacer.

3. Remove the oil pump.

INSTALLATION

Installation is in the reverse order of removal, paying attention of the following:

• When inserting the oil pump drive spacer, align the crankshaft key and the flat face of the inner rotor.

• If they are not aligned, rotate the oil pump inner rotor by hand.

• Make sure that the each part is aligned and tap lightly until it

reaches the end.

INSPECTION AFTER INSTALLATION

• Start the engine, and check for leaks of engine oil.

• Stop engine and wait 10 minutes.

• Check level and add engine oil as required. Refer to LU-8

.

WBIA0415E

1. Oil pump body2. Outer rotor 3. Inner rotor

4. Oil pump cover 5. Oil pump drive spacer 6. Regulator valve

7. Regulator spring 8. Regulator plug

KBIA2512E

KBIA2490E

Revision: March 2010 2008 QX56

Page 2597 of 4083

LU-16

< DISASSEMBLY AND ASSEMBLY >

OIL PUMP

2. Measure the inner diameter of oil pump body to brazed portion(position 6) using suitable tool.

3. Calculate the clearance using the following formula. • (Clearance) = (Inner diameter of oil pump body) - (Outer diameter of inner rotor)

Regulator Valve Clearance

Check regulator valve to oil pump cover clearance using the following formula.

• (Clearance) = D

1 (Valve hole diameter) - D2 (Outer Diameter of

valve)

CAUTION:

• Coat regulator valve with engine oil.

• Check that it falls smoothly into the regulator valve hole by its own weight.

ASSEMBLY

Installation is in the reverse order of removal.

NOTE:

Install the inner rotor and outer rotor with the punched marks on the

oil pump cover side.

PBIC0142E

Inner rotor to brazed portion of housing

clearance

: 0.045 - 0.091 mm (0.0018 - 0.0036 in)

Regulator valve to oil pump cover

: 0.040 - 0.097 mm (0.0016 - 0.0038 in)

PBIC0143E

PBIC0144E

Revision: March 2010 2008 QX56

Page 2598 of 4083

SERVICE DATA AND SPECIFICATIONS (SDS)LU-17

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DE

F

G H

I

J

K L

M A

LU

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and LimitINFOID:0000000001538850

OIL PRESSURE

Unit: kPa (kg/cm2

, psi)

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in)

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (US qt, Imp qt)

Engine speed

rpm Approximate discharge oil pressure

Idle speed 2,000 More than 98 (1.0, 14)

More than 294 (3.0, 43)

Body to outer rotor ra dial clearance 0.114 - 0.200 (0.0045 - 0.0079)

Inner rotor to outer rotor tip clearance Below 0.180 (0.0071)

Body to inner rotor side clearance 0.030 - 0.070 (0.0012 - 0.0028)

Body to outer rotor side clearance 0.030 - 0.090 (0.0012 - 0.0035)

Inner rotor to brazed portion of housing clearance 0.045 - 0.091 (0.0018 - 0.0036)

Regulator valve to oil pump cover clearance0.040 - 0.097 (0.0016 - 0.0038)

Drain and refillWith oil filter change 6.5 (6 7/8, 5 3/4)

Without oil filter change

6.2 (6 1/2, 5 1/2)

Dry engine (engine overhaul) 7.6 (8, 6-3/4)

Revision: March 2010 2008 QX56

Page 2599 of 4083

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K L

M B

MA

SECTION MA

N

O A

CONTENTS

MAINTENANCE

PREPARATION ....

........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ...................................................4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

ON-VEHICLE MAINTENANCE .....................6

GENERAL MAINTE NANCE ........................... .....6

General Maintenance .......................................... ......6

PERIODIC MAINTENANCE ................................8

Introduction of Periodic Maintenance .................. ......8

Maintenance for Off-road Driving (4WD only) ...........8

Schedule 1 ................................................................8

Schedule 2 ..............................................................10

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

12

Fluids and Lubricants .......................................... ....12

Engine Oil Recommendation ..................................12

Anti-Freeze Coolant Mixture Ratio ..........................13

ENGINE MAINTENANCE ...................................14

Checking Drive Belts ........................................... ....14

Changing Engine Coolant .................................... ....14

Checking Fuel Line ..................................................17

Changing Fuel Filter ................................................17

Changing Engine Air Cleaner Filter .........................17

Changing Engine Oil ................................................18

Changing Oil Filter ...................................................18

Changing Spark Plugs .............................................20

Checking EVAP Vapor Line .....................................21

CHASSIS AND BODY MAINTENANCE ...........22

Changing In-cabin Microfilter ............................... ....22

Checking Exhaust System .......................................23

Checking Automatic Transmission Fluid (ATF) .......23

Changing Automatic Transmission Fluid (ATF) .......25

Changing Transfer Fluid ..........................................25

Checking Transfer Fluid ..........................................26

Checking Propeller Shaft .........................................26

Checking Final Drive Oil ..........................................26

Changing Final Drive Oil ..........................................27

Adjustment ...............................................................27

Tire Rotation ............................................................29

Checking Brake Fluid Level and Leaks ...................29

CheckingBrake Line and Cables .............................30

Checking Disc Brake ...............................................30

Checking Steering Gear and Linkage ......................30

Checking Power Steering Fluid and Line ................31

Checking Axle and Suspension Parts .....................31

Lubricating Locks, Hinges and Hood Latches .........33

Checking Seat Belts, Buckles, Retractors, An-

chors and Adjusters ............................................. ....

33

Revision: March 2010 2008 QX56

Page 2600 of 4083

MA-2

< PREPARATION >

PRECAUTIONS

PREPARATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006054111

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004900832

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 2602 of 4083

MA-4

< PREPARATION >

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000006054112

The actual shapes of the Kent-Moore tools may differ from those of the special service tools illustrated here.

Commercial Service ToolINFOID:0000000001606162

Tool number

(Kent-Moore No.)

Tool name Description

ST25051001

(J-25695-1)

Oil pressure gauge Measuring oil pressure

Maximum measuring range:

2,452 kPa (25 kg/cm

2, 356 psi)

ST25052000

(J-25695-2)

Hose Adapting oil pressure gauge to cylinder block

KV10115801

(J-38956)

Oil filter cap wrench Removing and installing oil filter

a: 64.3 mm (2.531 in)

KV991J0010

(J-23688)

Engine coolant refractometer Checking concentration of ethylene glycol in

engine coolant

KV991J0070

(J-45695)

Coolant refill tool Filling cooling system

—

(J-24460-92)

Radiator pressure test adapter set Adapting radiator pressure tester to reservoir

filler neck.

S-NT050

S-NT559

NT375

WBIA0539E

LMA053

AWBIA0891ZZ

Revision: March 2010

2008 QX56

Page 2604 of 4083

MA-6

< ON-VEHICLE MAINTENANCE >

GENERAL MAINTENANCE

ON-VEHICLE MAINTENANCE

GENERAL MAINTENANCE

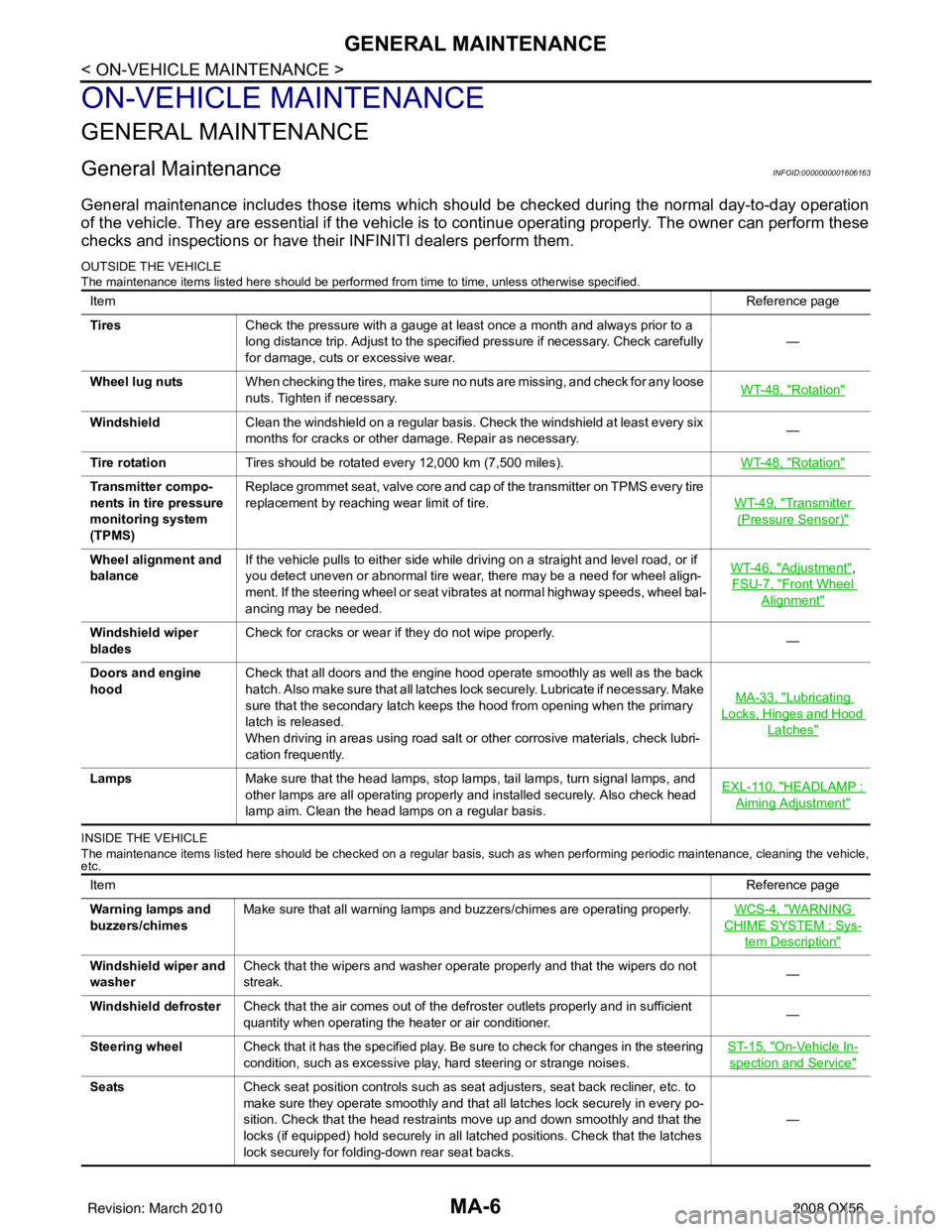

General MaintenanceINFOID:0000000001606163

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owner can perform these

checks and inspections or have thei r INFINITI dealers perform them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge at least once a month and always prior to a

long distance trip. Adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear. —

Wheel lug nuts When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-48, "

Rotation"

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Tire rotation Tires should be rotated every 12,000 km (7,500 miles). WT-48, "

Rotation"

Transmitter compo-

nents in tire pressure

monitoring system

(TPMS)Replace grommet seat, valve core and cap of the transmitter on TPMS every tire

replacement by reaching wear limit of tire.

WT-49, "

Transmitter

(Pressure Sensor)"

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel bal-

ancing may be needed. WT-46, "Adjustment",

FSU-7, "

Front Wheel

Alignment"

Windshield wiper

blades Check for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-33, "

Lubricating

Locks, Hinges and Hood

Latches"

Lamps

Make sure that the head lamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head

lamp aim. Clean the head lamps on a regular basis. EXL-110, "HEADLAMP :

Aiming Adjustment"

Item

Reference page

Warning lamps and

buzzers/chimes Make sure that all warning lamps and buzzers/chimes are operating properly.

WCS-4, "

WARNING

CHIME SYSTEM : Sys-

tem Description"

Windshield wiper and

washerCheck that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Be sure to check for changes in the steering

condition, such as excessive play, hard steering or strange noises. ST-15, "

On-Vehicle In-

spection and Service"

Seats

Check seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs. —

Revision: March 2010

2008 QX56

Page 2605 of 4083

GENERAL MAINTENANCEMA-7

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage. SB-11, "Seat Belt Inspec-

tion", MA-33, "Checking

Seat Belts, Buckles, Re-

tractors, Anchors and

Adjusters"

Accelerator pedal

Check the pedal for smooth operation. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Keep the floor

mats away from the pedal. BR-15, "

Inspection and

Adjustment", BR-10, "In-

spection"

Parking brake

Check that the parking brake control has the proper travel and make sure that

the vehicle is held securely on a fairly steep hill when only the parking brake is

applied. PB-5, "On-Vehicle Ser-

vice"

Automatic transmis-

sion “Park” mecha-

nismOn a fairly steep hill check that the vehicle is held securely with the shift selector

in the P position without applying the brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank.

—

Engine coolant level Check the coolant level when the engine is cold. —

Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections. —

Brake fluid level Make sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoirs MA-29

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level. —

Engine drive belt Make sure that no belt is frayed, worn, cracked or oily. MA-14

Engine oil levelCheck the level on the dipstick after parking the vehicle on a level spot and turn-

ing off the engine. —

Power steering fluid

level and lines Check the level on the reservoir with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.

MA-31

Automatic transmis-

sion fluid levelCheck the level on the dipstick after putting the shift selector in “P” with the en-

gine idling.

MA-23

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it. MA-23

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: March 2010

2008 QX56

Page 2606 of 4083

MA-8

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000001606164

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage or ti me intervals, whichever comes first.

Maintenance for Off-road Driving (4WD only)INFOID:0000000001606165

After driving the vehicle off-road through sand, mud, or water; more frequent maintenance may be required for

the following items:

Brake pads and rotors

Brake lines and hoses

Rear final drive oil, transmission fluid, and transfer fluid

Steering linkage

Drive shafts

Engine air cleaner filter

In-cabin microfilters

Schedule 1INFOID:0000000001606166

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or r eplace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if your driving habits frequently includes

one or more of the following driving conditions:

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures re-

maining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer or using a car-top carrier. Emission Control Sys-

tem Maintenance

MA-8

Chassis and Body

Maintenance

MA-8

Schedule 2Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown

in Schedule 1 apply to the driving habits.

Emission Control Sys-

tem MaintenanceMA-10Chassis and Body

Maintenance

MA-10

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.50

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Drive belts NOTE (1) MA-14

Air cleaner filterNOTE (2) [R]MA-17

EVAP vapor lines I*MA-21

Fuel lines I*MA-17

Fuel filter NOTE (3) —

Engine coolant NOTE (4) MA-14

Engine oilR R R R R R R R MA-18

Engine oil filterR R R R R R R R MA-18

Spark plugs (double PLATINUM-

TIPPED type)Replace every 105,000 miles (169,000 km).

MA-20

Intake and exhaust valve clear-

ance*NOTE (5)

EM-108

Revision: March 2010 2008 QX56