fuel pressure INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2922 of 4171

PG

HARNESSPG-51

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

C3 F7 GR/3

: Ignition coil No. 4 (with power

transistor) F1 F60 GR/2 : Neutral-4LO switch

C3 F8 GR/3 : Ignition coil No. 6 (with power

transistor)

D5 F61 G/2: Intake valve timing control solenoid valve

(bank 1)

E2 F9 G/10 : A/T assembly D5 F62 B/3: Intake valve timing control position sensor

(bank 1)

C3 F10 — : Engine ground C4 F63 G/2: Intake valve timing control solenoid valve

(bank 2)

D3 F11 B/3 : Crankshaft position sensor (POS) C4 F64 B/3 : Intake valve timing control position sensor

(bank 2)

E1 F12 G/4 : Heated oxygen sensor 2 (bank2) E3 F65 GR/4 : Air fuel ratio (A/F) sensor 1 (bank1)

F2 F13 G/4 : Heated oxygen sensor 2 (bank1) C2 F68 GR/2 : Water valve

B2 F14 W/24 : To E5 Engine control sub-harness

D4 F15 GR/2 : EVAP canister purge volume control

solenoid valve C3 F101 B/6 : To F26

E5 F16 — : Engine ground C3 F102 B/2 : Knock sensor (bank 1)

C4 F18 GR/2 : Fuel injector No. 2 C3 F103 GR/2 : Engine coolant temperature sensor

D4 F20 GR/2 : Fuel injector No. 4 C3 F104 B/2 : Knock sensor (bank 2)

F4 F21 GR/2 : Condenser-1

D3 F22 GR/2 : Fuel injector No. 6

D4 F23 B/3 : Camshaft position sensor (phase)

D4 F26 B/6 : To F101

E3 F27 /1 : Starter motor

E3 F28 GR/1 : Starter motor

D4 F30 GR/2 : Fuel injector No. 1

D3 F31 GR/2 : Fuel injector No. 8

B2 F32 W/16 : To E2

C2 F33 W/16 : To E19

C2 F34 W/2 : To E39

B3 F39 /1 : Fusible link box (battery)

D4 F41 GR/2 : Fuel injector No. 3

D4 F42 GR/2 : Fuel injector No. 5

D3 F45 GR/2 : Fuel injector No. 7

B4 F46 B/3 : Power steering pressure sensor

E4 F47 GR/3 : Ignition coil No. 1 (with power

transistor)

E4 F48 GR/3 : Ignition coil No. 3 (with power

transistor)

E4 F49 GR/3 : Ignition coil No. 5 (with power

transistor)

D4 F50 W/6 : Electric throttle control actuator

E4 F51 GR/3 : Ignition coil No. 7 (with power

transistor)

D2 F52 GR/3 : Ignition coil No. 8 (with power

transistor)

E5 F53 B/6 : Mass air flow sensor

B2 F54 B/81 : ECM

F1 F55 B/2 : ATP switch

Revision: December 20092009 QX56

Page 2923 of 4171

PG-52

< COMPONENT DIAGNOSIS >

HARNESS

CHASSIS HARNESS

AWMIA0113GB

G2 C1 SMJ : To E41

B5 C2 B/7 : Trailer

A3 C3 GR/8 : To C101

C3 C4 GR/3: Evap control system pressure

sensor

D2 C5 GR/5 : Fuel level sensor unit and fuel pump

Revision: December 20092009 QX56

Page 3154 of 4171

RSU-6

< ON-VEHICLE MAINTENANCE >

REAR SUSPENSION ASSEMBLY

ON-VEHICLE MAINTENANCE

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000003772290

Check all of the component mountings for any excessive looseness, or back lash. Check the components for

any excessive wear, damage, or abnormal conditions. Repair or replace the components as necessary.

SHOCK ABSORBER INSPECTION

Check the shock absorbers for any air l eaks or damage, and replace as necessary.

Check the hoses for any air leaks or damage, and replace as necessary.

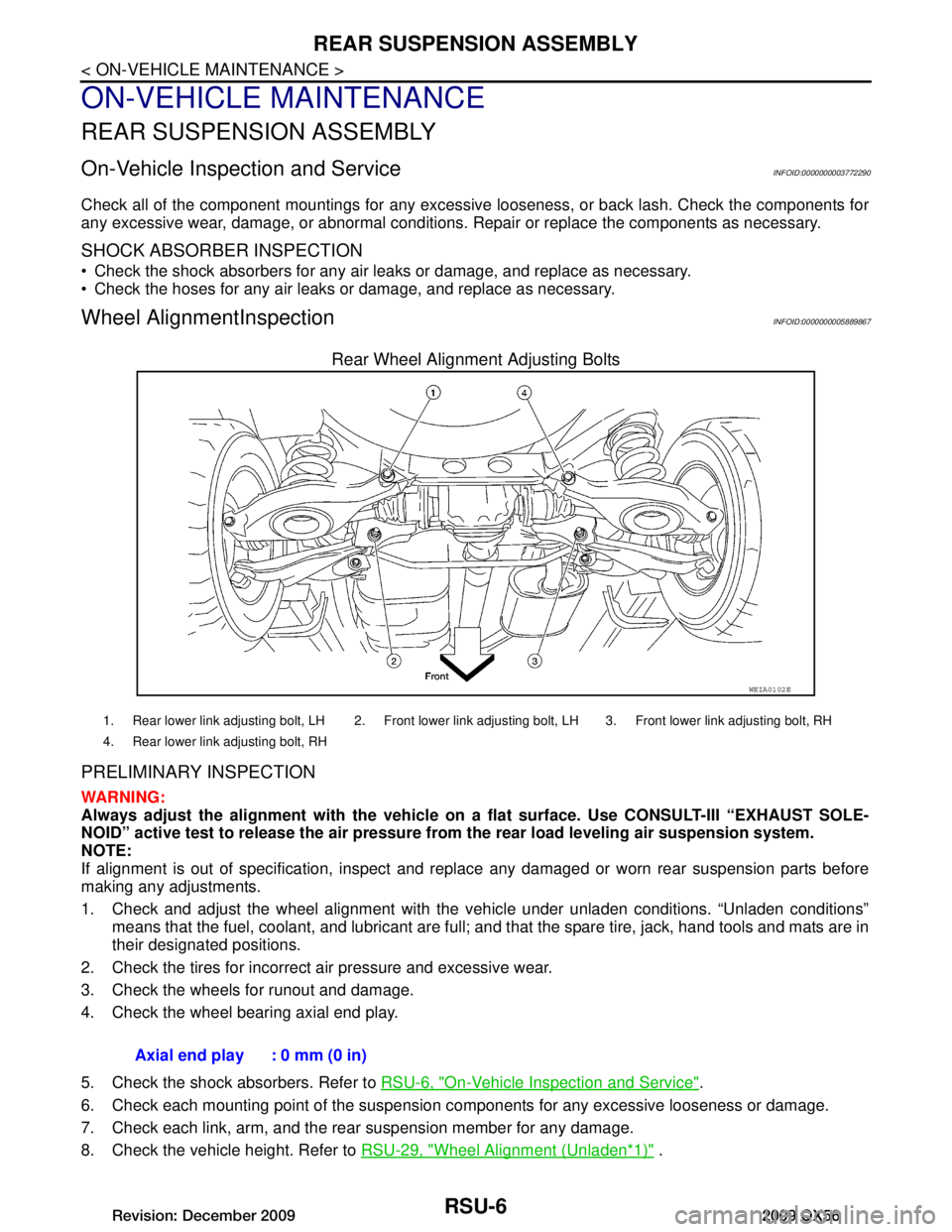

Wheel AlignmentInspectionINFOID:0000000005889867

Rear Wheel Alignment Adjusting Bolts

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignm ent with the vehicle on a flat su rface. Use CONSULT-III “EXHAUST SOLE-

NOID” active test to release the air pressure from the rear load leveling air suspension system.

NOTE:

If alignment is out of specificat ion, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for runout and damage.

4. Check the wheel bearing axial end play.

5. Check the shock absorbers. Refer to RSU-6, "On-Vehicle Inspection and Service"

.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer to RSU-29, "Wheel Alignment (Unladen

*1)" .

WEIA0102E

1. Rear lower link adjusting bolt, LH 2. Front lower link adjusting bolt, LH 3. Front lower link adjusting bolt, RH

4. Rear lower link adjusting bolt, RH

Axial end play : 0 mm (0 in)

Revision: December 20092009 QX56

Page 3411 of 4171

![INFINITI QX56 2009 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-101

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

41 Y/B Hood switch Input —Hood closed OFF

0V

Ho INFINITI QX56 2009 Factory Service Manual IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-101

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

41 Y/B Hood switch Input —Hood closed OFF

0V

Ho](/img/42/57031/w960_57031-3410.png)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

SEC-101

< ECU DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

41 Y/B Hood switch Input —Hood closed OFF

0V

Hood open ON Battery voltage

42 GR Oil pressure switch Input — Engine running

Battery voltage

Engine stopped 0V

43 L/Y Wiper auto stop signal Input ON or

START Wiper switch OFF, LO, INT Battery voltage

44 BR Daytime light relay

control Input ONDaytime light system active

0V

Daytime light system inactive Battery voltage

45 G/W Horn relay control Input ON When door locks are operated

using keyfob or Intelligent Key

(OFF

→ ON)* Battery voltage

→ 0V

46 GR Fuel pump relay con-

trol

Input —Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

47 O Throttle control motor

relay control

Input —Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

48 B/R Starter relay (inhibit

switch) InputON or

START Selector lever in "P" or "N"

0V

Selector lever any other posi-

tion Battery voltage

49 R/L Trailer tow relay Output ON Lighting

switch must

be in the 1st

positionOFF

0V

ON Battery voltage

50 W/R Front fog lamp (LH) Output ON or

START Lighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switch OFF

0V

ON Battery voltage

51 W/R Front fog lamp (RH) Output ON or

START Lighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switch OFF

0V

ON Battery voltage

52 L LH low beam head-

lamp Output — Lighting switch in 2nd position Battery voltage

54 R/Y RH low beam head-

lamp Output — Lighting switch in 2nd position Battery voltage

55 G LH high beam head-

lamp Output —Lighting switch in 2nd position

and placed in HIGH or PASS

position Battery voltage

56 L/W RH high beam head-

lamp Output —Lighting switch in 2nd position

and placed in HIGH or PASS

position Battery voltage

57 R/L Parking, license, and

tail lamp

Output ONLighting

swi

t

ch 1st po-

sition OFF

0V

ON Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value(Approx.)

Igni-

tion

switch Operation or condition

Revision: December 20092009 QX56

Page 3639 of 4171

STR-10

< COMPONENT DIAGNOSIS >

B TERMINAL CIRCUIT

COMPONENT DIAGNOSIS

B TERMINAL CIRCUIT

DescriptionINFOID:0000000003771792

Terminal "2" (B) is constantly supplied with battery power.

Diagnosis ProcedureINFOID:0000000003771793

CAUTION:

Perform diagnosis under the condition that the engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is depleted.

1.CHECK TERMINAL 2 POWER SUPPLY VOLTAGE

1. Turn ignition switch OFF.

2. Make sure that starter motor connector F27 terminal 2 connection is clean and tight.

3. Check voltage between starter motor connector F27 terminal 2

and ground.

Is there battery voltage present?

YES >> GO TO 2

NO >> Check harness between battery and starter motor for open circuit.

2.CHECK BATTERY CABLE (VOLTAGE DROP TEST)

1. Shift the transmission into park or neutral.

2. Check voltage between battery positive terminal and starter motor connector F27 terminal 2 while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> GO TO 3

NO >> Check harness between the battery and the starter motor for high resistance.

3.CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor case and battery negative ter-

minal while cranking the engine.

Is the voltage drop less than 0.2V?

YES >> Terminal 2 circuit is OK. Further inspection necessary. Refer to STR-5, "

Work Flow".

NO >> Check the starter motor case to engine mounting for high resistance.

(+) (-)Condition Voltage

Connector Terminal

F27 2 Ground While cranking the

engine Battery voltage

AWBIA0122GB

(+)

(-)Condition Voltage

Connector Terminal

F27 2 Battery (+)

terminal While cranking the

engine Less than 0.2V

AWBIA0123GB

(+)

(-)Condition Voltage

Starter motor case Battery (-) terminal

While cranking the

engine Less than 0.2V

AWBIA0124GB

Revision: December 20092009 QX56

Page 3640 of 4171

S CONNECTOR CIRCUITSTR-11

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

S CONNECTOR CIRCUIT

DescriptionINFOID:0000000003771794

Terminal "1" (S) is the power supply for the starter mo

tor magnetic switch. Terminal 1 is supplied with power

when the ignition switch is turned to the START position while the selector lever is in the P or N position.

Diagnosis ProcedureINFOID:0000000003771795

CAUTION:

Perform diagnosis under the cond ition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possi ble) until the fuel pressure is released.

1.CHECK STARTER MOTOR MAGNETIC SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector F28.

3. Shift transmission into park or neutral.

4. Check voltage between starter motor harness connector F28 terminal 1 and ground with the ignition switch in START.

Is battery voltage present?

YES >> Magnetic switch circuit is OK. Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> GO TO 2

2.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check the IPDM E/R harness connector E120 and starter motor harness connector F28 for damage, bent pins and loose connections.

Is the inspection result normal?

YES >> GO TO 3

NO >> Repair the terminal and connector.

3.CHECK HARNESS CONTI NUITY (OPEN CIRCUIT)

1. Disconnect IPDM E/R connector E120 and starter motor con- nector F28.

2. Check continuity between starter motor harness connector F28 (A) terminal 1 and IPDM E/R harness connector E120 (B) termi-

nal 19.

3. Check continuity between starter motor harness connector F28 (A) terminal 1 and ground.

Are the continuity test results as specified?

YES >> Further inspection necessary. Refer to STR-5, "Work Flow".

NO >> Repair the harness.

(+) (-)Condition Voltage

Connector Terminal

F28 1 Ground Ignition switch in

START Battery voltage

AWBIA0125GB

AB

Continuity

Connector Terminal Connector Terminal

F28 1E120 19 Yes

A —Con tin uit y

Connector Terminal

F28 1Ground No

AWBIA0126GB

Revision: December 20092009 QX56

Page 3674 of 4171

TM-26

< FUNCTION DIAGNOSIS >

A/T CONTROL SYSTEM

When shifting from the lock-up released state to the lock-up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In th is way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

The current output from the TCM to the torque converte r clutch solenoid is varied to gradually increase the

torque converter clutch solenoid pressure.

In this way, the lock-up apply pressure gradually rises and while the torque converter clutch piston is put into

half-clutched status, the torque converter clutch pi ston operating pressure is increased and the coupling is

completed smoothly.

Slip Lock-up Control

In the slip region, the torque converter clutch solenoid current is controlled with the TCM to put it into the

half-clutched state. This absorbs the engine tor que fluctuation and lock-up operates from low speed.

This raises the fuel efficiency for 4GR and 5GR at both low speed and when the accelerator has a low

degree of opening.

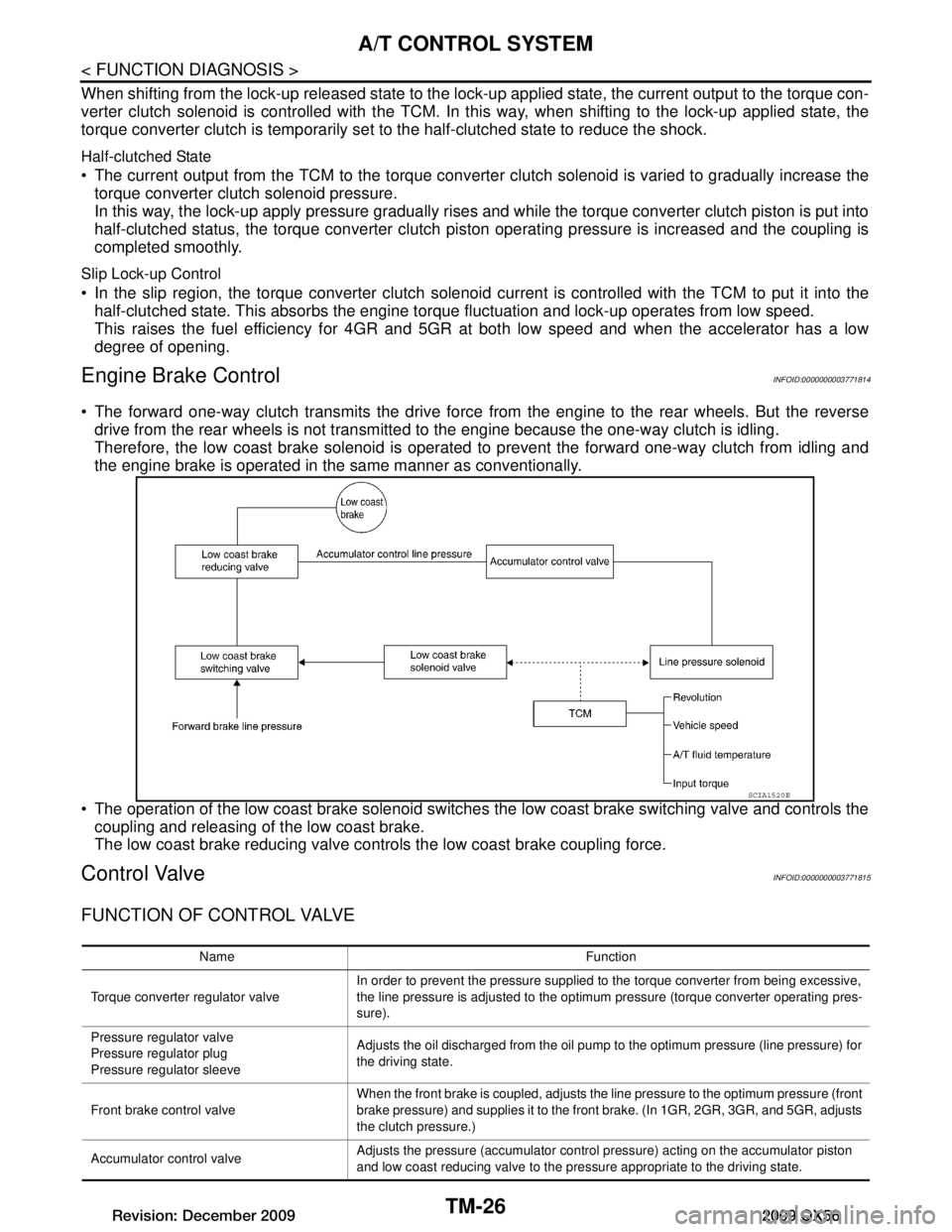

Engine Brake ControlINFOID:0000000003771814

The forward one-way clutch transmits the drive force from the engine to the rear wheels. But the reverse

drive from the rear wheels is not transmitted to the engine because the one-way clutch is idling.

Therefore, the low coast brake solenoid is operated to prevent the forward one-way clutch from idling and

the engine brake is operated in the same manner as conventionally.

The operation of the low coast brake solenoid switches the low coast brake switching valve and controls the

coupling and releasing of the low coast brake.

The low coast brake reducing valve contro ls the low coast brake coupling force.

Control ValveINFOID:0000000003771815

FUNCTION OF CONTROL VALVE

SCIA1520E

Name Function

Torque converter regulator valve In order to prevent the pressure supplied to the torque converter from being excessive,

the line pressure is adjusted to the optimum pressure (torque converter operating pres-

sure).

Pressure regu lator valve

Pressure regulator plug

Pressure regu lator sleeve Adjusts the oil discharged from the oil pump to the optimum pressure (line pressure) for

the driving state.

Front brake control valve When the front brake is coupled, adjusts the line pressure to the optimum pressure (front

brake pressure) and supplies it to the front brake. (In 1GR, 2GR, 3GR, and 5GR, adjusts

the clutch pressure.)

Accumulator control valve Adjusts the pressure (accumulator control pressure) acting on the accumulator piston

and low coast reducing valve to the pressure appropriate to the driving state.

Revision: December 20092009 QX56

Page 3989 of 4171

WCS-12

< FUNCTION DIAGNOSIS >

DIAGNOSIS SYSTEM (METER)

DIAGNOSIS SYSTEM (METER)

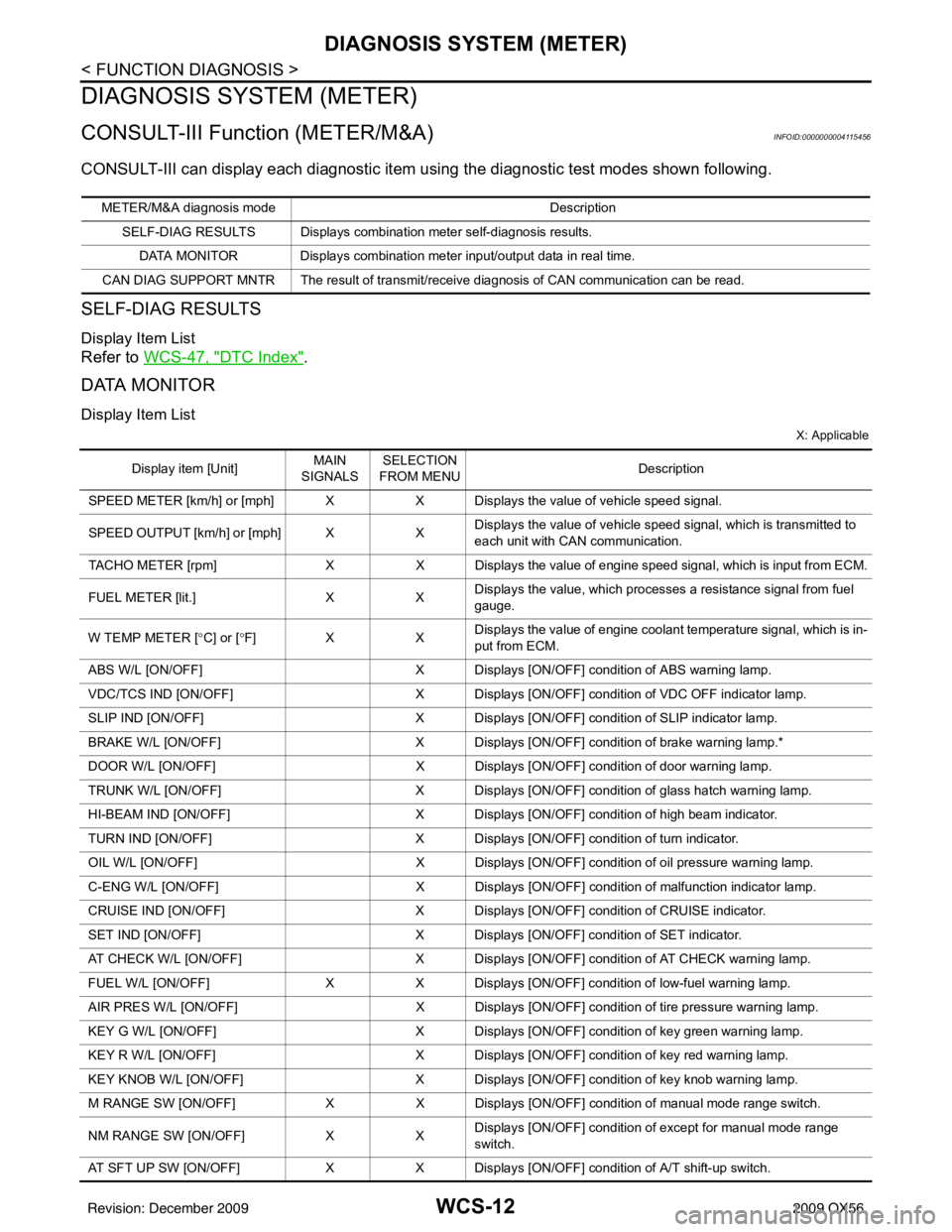

CONSULT-III Function (METER/M&A)INFOID:0000000004115456

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

SELF-DIAG RESULTS

Display Item List

Refer to WCS-47, "DTC Index".

DATA MONITOR

Display Item List

X: Applicable

METER/M&A diagnosis mode Description

SELF-DIAG RESULTS Displays combination meter self-diagnosis results. DATA MONITOR Displays combination meter input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

Display item [Unit] MAIN

SIGNALS SELECTION

FROM MENU Description

SPEED METER [km/h] or [mph] X X Displays the value of vehicle speed signal.

SPEED OUTPUT [km/h] or [mph] X XDisplays the value of vehicle speed signal, which is transmitted to

each unit with

CAN communication.

TACHO METER [rpm] XX Displays the value of engine speed signal, which is input from ECM.

FUEL METER [lit.] XXDisplays the value, which processes a resistance signal from fuel

gauge.

W TEMP METER [ °C] or [° F] X XDisplays the value of engine coolant temperature signal, which is in-

put from ECM.

ABS W/L [ON/OFF] X Displays [ON/OFF] condition of ABS warning lamp.

VDC/TCS IND [ON/OFF] X Displays [ON/OFF] condition of VDC OFF indicator lamp.

SLIP IND [ON/OFF] X Displays [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L [ON/OFF] X Displays [ON/OFF] condition of brake warning lamp.*

DOOR W/L [ON/OFF] X Displays [ON/OFF] condition of door warning lamp.

TRUNK W/L [ON/OFF] X Displays [ON/OFF] condition of glass hatch warning lamp.

HI-BEAM IND [ON/OFF] X Displays [ON/OFF] condition of high beam indicator.

TURN IND [ON/OFF] X Displays [ON/OFF] conditio n of turn indicator.

OIL W/L [ON/OFF] X Displays [ON/OFF] condition of oil pressure warning lamp.

C-ENG W/L [ON/OFF] X Displays [ON/OFF] condition of malfunction indicator lamp.

CRUISE IND [ON/OFF] X Displays [ON/OFF] condition of CRUISE indicator.

SET IND [ON/OFF] X Displays [ON/OFF] condition of SET indicator.

AT CHECK W/L [ON/OFF] X Displays [ON/OFF] condition of AT CHECK warning lamp.

FUEL W/L [ON/OFF] XX Displays [ON/OFF] condition of low-fuel warning lamp.

AIR PRES W/L [ON/OFF] X Displays [ON/OFF] condition of tire pressure warning lamp.

KEY G W/L [ON/OFF] X Displays [ON/OFF] condition of key green warning lamp.

KEY R W/L [ON/OFF] X Displays [ON/OFF] condition of key red warning lamp.

KEY KNOB W/L [ON/OFF] X Displays [ON/OFF] condition of key knob warning lamp.

M RANGE SW [ON/OFF] XX Displays [ON/OFF] condition of manual mode range switch.

NM RANGE SW [ON/OFF] XXDisplays [ON/OFF] condition of except for manual mode range

switch.

AT SFT UP SW [ON/OFF] XX Displays [ON/OFF] condition of A/T shift-up switch.

Revision: December 20092009 QX56

Page 4024 of 4171

WCS

COMBINATION METERWCS-47

< ECU DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

DTC IndexINFOID:0000000004115463

Function Specifications

Speedometer

Zero indication.

Tachometer

Fuel gauge

Engine coolant temperature gauge

Engine oil pressure gauge

Voltage gauge

A/T oil temperature gauge

Illumination control

Meter illumination Change to nighttime mode when communication is lost.

Segment LCD Odometer

Freeze current indication.

A/T position Display turns off.

Buzzer Buzzer turns off.

Warning lamp/indicator lamp ABS warning lamp

Lamp turns on when communication is lost.

Brake warning lamp

VDC OFF indicator lamp

SLIP indicator lamp

A/T CHECK warning lamp

Lamp turns off when communication is lost.

Oil pressure/coolant temperature

warning lamp

Light indicator

Malfunction indicator lamp

Master warning lamp

Air bag warning lamp

High beam indicator

Turn signal indicator lamp

CRUISE indicator lamp

Driver and passenger seat belt warn-

ing lamp

Lamp turns off when disconnected.

Charge warning lamp

Security indicator lamp

4WD indicator lamp

ATP indicator lamp

CK SUSP warning lamp

Low tire pressu

re warning lamp Lamp will flash every second for 1 minute and then stay on con-

tinuously thereafter.

CONSULT-III display

MalfunctionReference

page

CAN COMM CIRC

[U1000] Malfunction is detected in CAN communication.

CAUTION:

Even when there is no ma

lfunction on CAN communication system, malfunction may be

misinterpreted when battery has low voltag e (when maintaining 7 - 8 V for about 2 sec-

onds) or 10A fuse [No. 19, located in the fuse block (J/B)] is disconnected. MWI-28

VEHICLE SPEED

CIRC

[B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunction may be misin-

terpreted when battery has low voltage (whe

n maintaining 7 - 8 V for about 2 seconds). MWI-29

Revision: December 20092009 QX56

Page 4146 of 4171

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

WW-59

< ECU DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

WW

N

O P

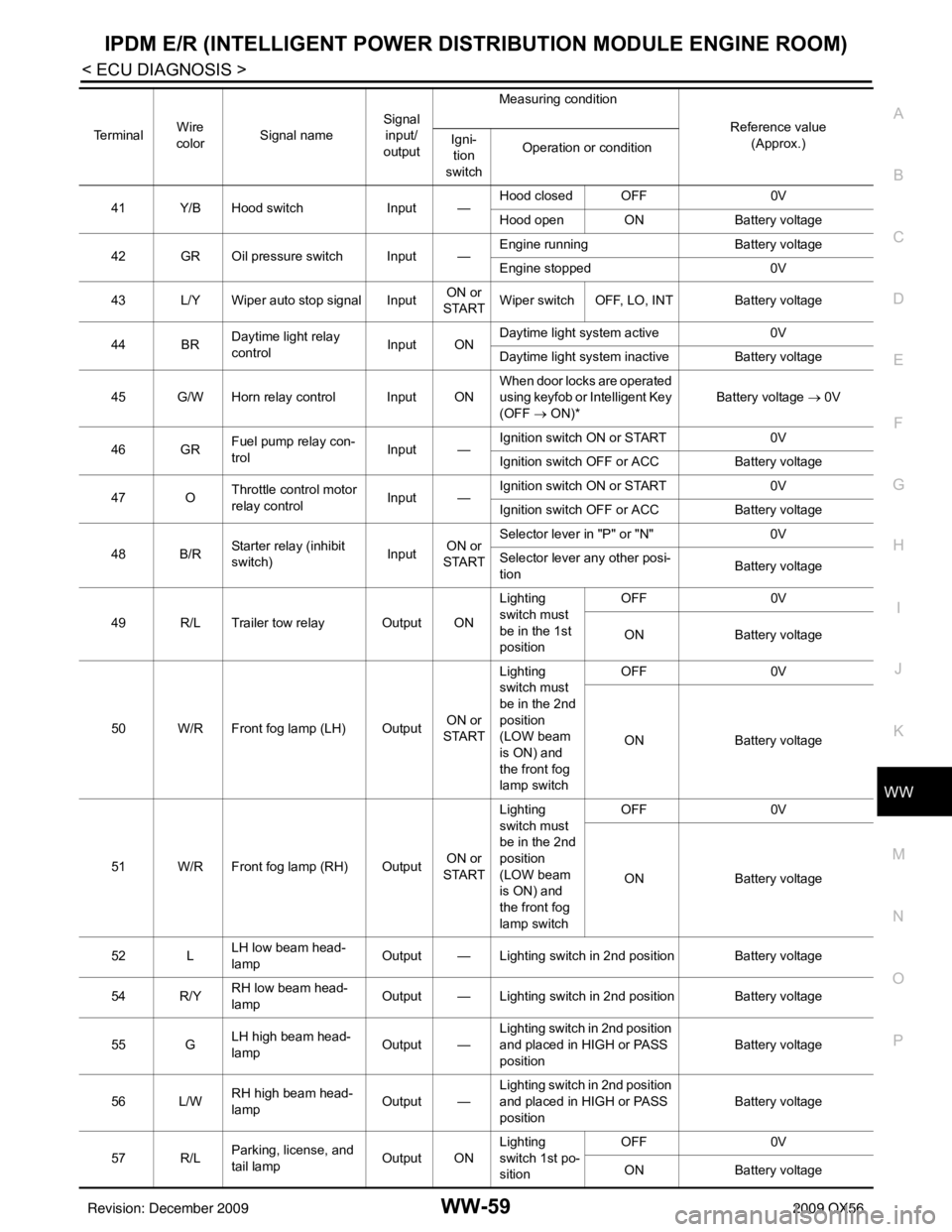

41 Y/B Hood switch Input —Hood closed OFF

0V

Hood open ON Battery voltage

42 GR Oil pressure switch Input — Engine running

Battery voltage

Engine stopped 0V

43 L/Y Wiper auto stop signal Input ON or

START Wiper switch OFF, LO, INT Battery voltage

44 BR Daytime light relay

control Input ONDaytime light system active

0V

Daytime light system inactive Battery voltage

45 G/W Horn relay control Input ON When door locks are operated

using keyfob or Intelligent Key

(OFF

→ ON)* Battery voltage

→ 0V

46 GR Fuel pump relay con-

trol

Input —Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

47 O Throttle control motor

relay control

Input —Ignition switch ON or START

0V

Ignition switch OFF or ACC Battery voltage

48 B/R Starter relay (inhibit

switch) InputON or

START Selector lever in "P" or "N"

0V

Selector lever any other posi-

tion Battery voltage

49 R/L Trailer tow relay Output ON Lighting

switch must

be in the 1st

positionOFF

0V

ON Battery voltage

50 W/R Front fog lamp (LH) Output ON or

START Lighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switch OFF

0V

ON Battery voltage

51 W/R Front fog lamp (RH) Output ON or

START Lighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switch OFF

0V

ON Battery voltage

52 L LH low beam head-

lamp Output — Lighting switch in 2nd position Battery voltage

54 R/Y RH low beam head-

lamp Output — Lighting switch in 2nd position Battery voltage

55 G LH high beam head-

lamp Output —Lighting switch in 2nd position

and placed in HIGH or PASS

position Battery voltage

56 L/W RH high beam head-

lamp Output —Lighting switch in 2nd position

and placed in HIGH or PASS

position Battery voltage

57 R/L Parking, license, and

tail lamp

Output ONLighting

swi

t

ch 1st po-

sition OFF

0V

ON Battery voltage

Te r m i n a l

Wire

color Signal name Signal

input/

output Measuring condition

Reference value(Approx.)

Igni-

tion

switch Operation or condition

Revision: December 20092009 QX56