relay INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2235 of 4171

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-41

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Circuit InspectionINFOID:0000000003771216

DESCRIPTION

• In general, testing electrical circuits is an easy task if it is approached in a logical and organized method. Before beginning it is important to have all available information on the system to be tested. Also, get a thor-

ough understanding of system operation. Then you will be able to use the appropriate equipment and follow

the correct test procedure.

• You may have to simulate vehicle vibrations while te sting electrical components. Gently shake the wiring

harness or electrical component to do this.

NOTE:

Refer to GI-35, "

How to Check Terminal" to probe or check terminal.

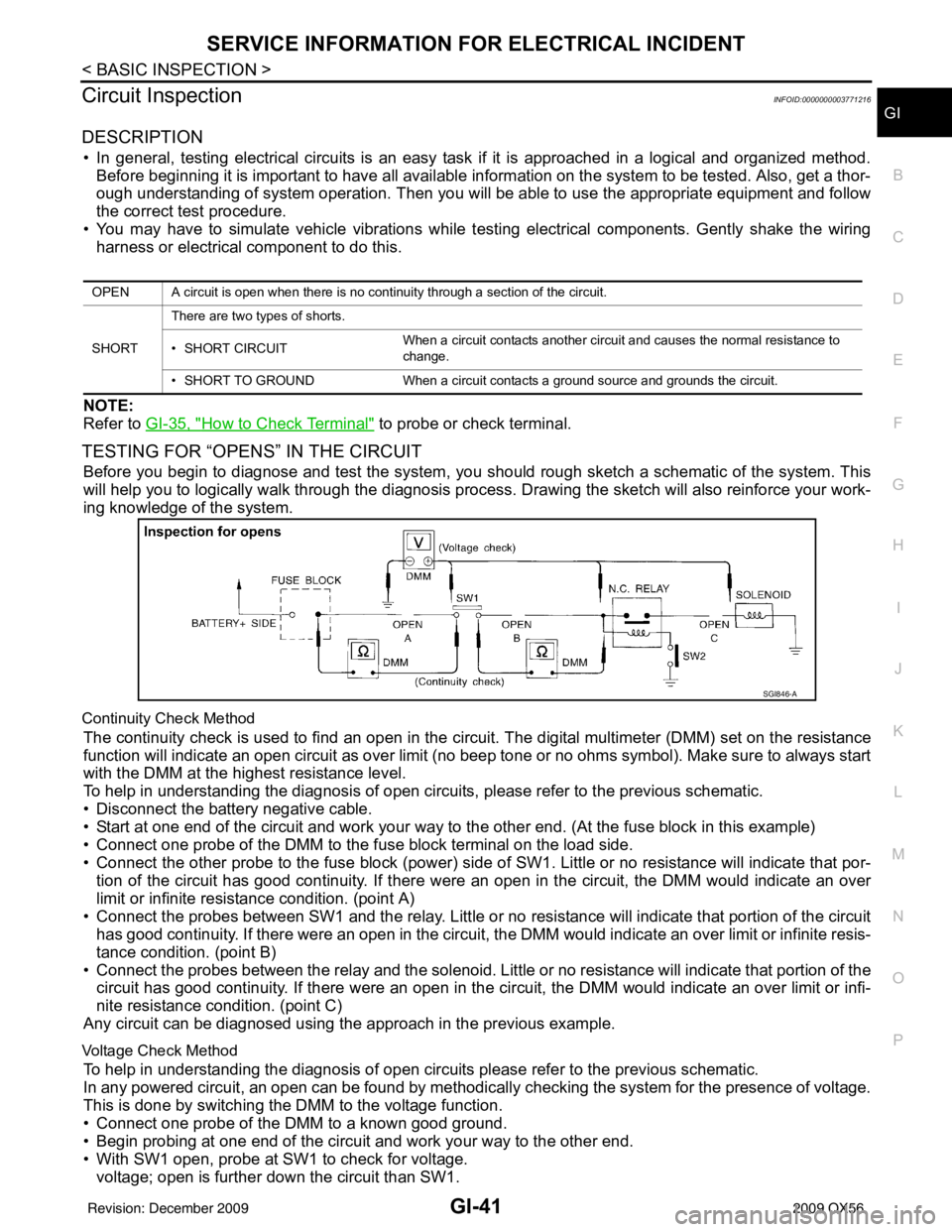

TESTING FOR “OPENS” IN THE CIRCUIT

Before you begin to diagnose and test the system, you should rough sketch a schematic of the system. This

will help you to logically walk through the diagnosis process. Drawing the sketch will also reinforce your work-

ing knowledge of the system.

Continuity Check Method

The continuity check is used to find an open in the circui t. The digital multimeter (DMM) set on the resistance

function will indicate an open circuit as over limit (no beep tone or no ohms symbol). Make sure to always start

with the DMM at the highest resistance level.

To help in understanding the diagnosis of open circui ts, please refer to the previous schematic.

• Disconnect the battery negative cable.

• Start at one end of the circuit and work your way to the other end. (At the fuse block in this example)

• Connect one probe of the DMM to the fuse block terminal on the load side.

• Connect the other probe to the fuse block (power) side of SW1. Little or no resistance will indicate that por-

tion of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over

limit or infinite resistance condition. (point A)

• Connect the probes between SW1 and the relay. Little or no resistance will indicate that portion of the circuit

has good continuity. If there were an open in the circuit, t he DMM would indicate an over limit or infinite resis-

tance condition. (point B)

• Connect the probes between the relay and the solenoid. Little or no resistance will indicate that portion of the

circuit has good continuity. If there were an open in the ci rcuit, the DMM would indicate an over limit or infi-

nite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the previous example.

Voltage Check Method

To help in understanding the diagnosis of open circuits please refer to the previous schematic.

In any powered circuit, an open can be found by methodica lly checking the system for the presence of voltage.

This is done by switching the DMM to the voltage function.

• Connect one probe of the DMM to a known good ground.

• Begin probing at one end of the circuit and work your way to the other end.

• With SW1 open, probe at SW1 to check for voltage. voltage; open is further down the circuit than SW1.

OPEN A circuit is open when there is no continuity through a section of the circuit.

SHORT There are two types of shorts.

• SHORT CIRCUIT

When a circuit contacts another circuit and causes the normal resistance to

change.

• SHORT TO GROUND When a circuit contacts a ground source and grounds the circuit.

SGI846-A

Revision: December 20092009 QX56

Page 2236 of 4171

GI-42

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

no voltage; open is between fuse block and SW1 (point A).

• Close SW1 and probe at relay. voltage; open is further down the circuit than the relay.

no voltage; open is between SW1 and relay (point B).

• Close the relay and probe at the solenoid. voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

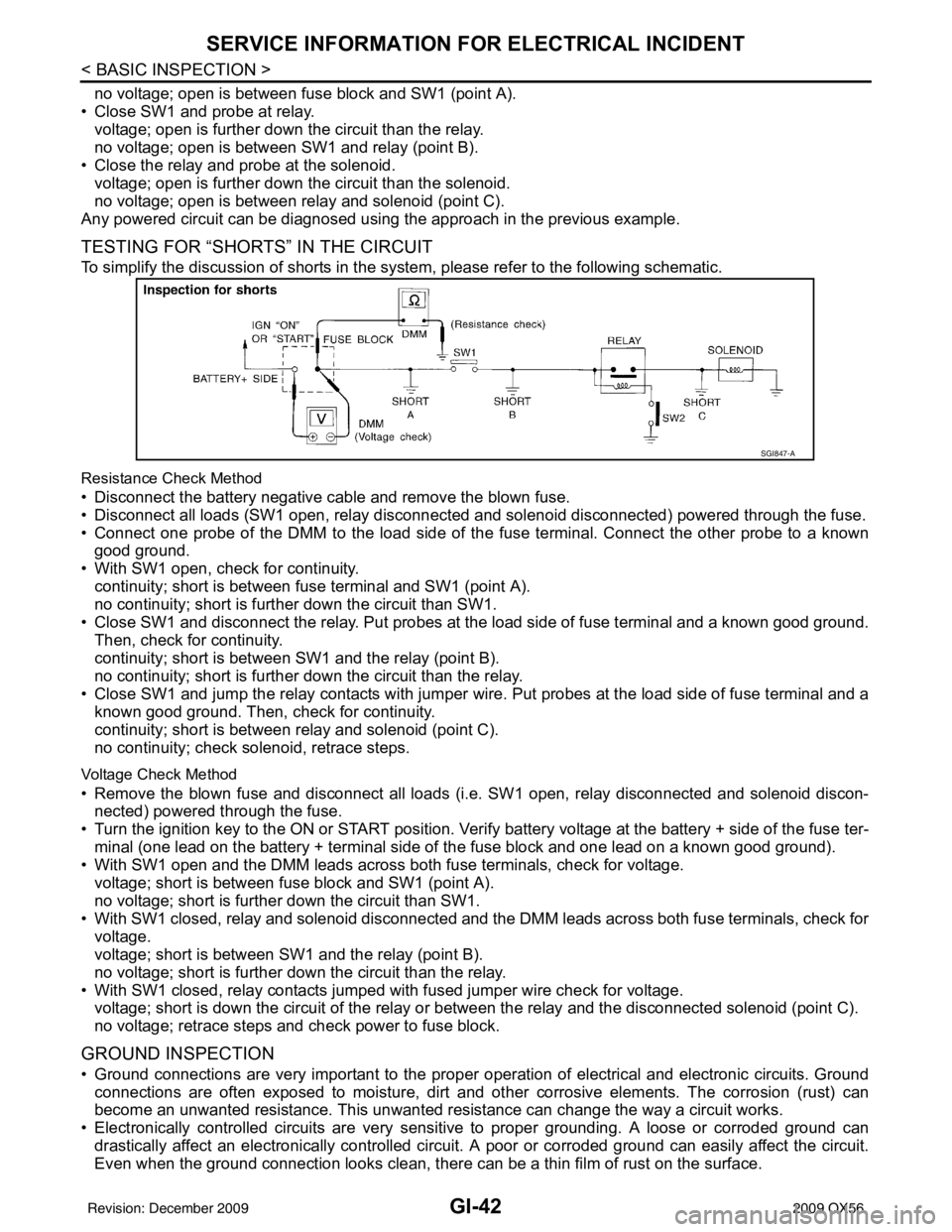

TESTING FOR “SHORTS” IN THE CIRCUIT

To simplify the discussion of shorts in the system, please refer to the following schematic.

Resistance Check Method

• Disconnect the battery negative cable and remove the blown fuse.

• Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

• Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known good ground.

• With SW1 open, check for continuity. continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

• Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

• Close SW1 and jump the relay contacts with jumper wire. Put probes at the load side of fuse terminal and a known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

Voltage Check Method

• Remove the blown fuse and disconnect all loads (i.e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

• Turn the ignition key to the ON or START position. Verify battery voltage at the battery + side of the fuse ter- minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

• With SW1 open and the DMM leads across both fuse terminals, check for voltage. voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

• With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

• With SW1 closed, relay contacts jumped with fused jumper wire check for voltage. voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

GROUND INSPECTION

• Ground connections are very important to the proper operation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

• Electronically controlled circuits are very sens itive to proper grounding. A loose or corroded ground can

drastically affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit.

Even when the ground connection looks clean, there c an be a thin film of rust on the surface.

SGI847-A

Revision: December 20092009 QX56

Page 2281 of 4171

REFRIGERATION SYSTEMHA-17

< FUNCTION DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

FUNCTION DIAGNOSIS

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000003775298

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is , through the compressor, the condenser with liquid tank,

through the front and rear evaporators, and back to the compressor. The refrigerant evaporation through the

evaporator coils are controlled by fr ont and rear externally equalized expansion valves, located inside the front

and rear evaporator cases.

Refrigerant System ProtectionINFOID:0000000003775299

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rise s above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnet ic compressor clutch when pressure on the high

pressure side detected by refrigerant pressu re sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below

about 120 kPa (1.22 kg/cm

2, 17.4 psi).

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system incr eases to an abnormal level [more than 2,990 kPa (30.5 kg/

Revision: December 20092009 QX56

Page 2324 of 4171

![INFINITI QX56 2009 Factory Service Manual REFRIGERATION SYSTEMHAC-11

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000004040375

REFRIGERANT FLOW

The refri INFINITI QX56 2009 Factory Service Manual REFRIGERATION SYSTEMHAC-11

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000004040375

REFRIGERANT FLOW

The refri](/img/42/57031/w960_57031-2323.png)

REFRIGERATION SYSTEMHAC-11

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000004040375

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the front and rear evaporators, and back to the compressor. The refrigerant evaporation through the

evaporator coils are controlled by front and rear externally equalized expansion valves, located inside the front

and rear evaporator cases.

Refrigerant System ProtectionINFOID:0000000004040376

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnetic compressor clutch when pressure on the high

pressure side detected by refrigerant pressu re sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below

about 120 kPa (1.22 kg/cm

2, 17.4 psi).

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system incr eases to an abnormal level [more than 2,990 kPa (30.5 kg/

Revision: December 20092009 QX56

Page 2329 of 4171

![INFINITI QX56 2009 Factory Service Manual HAC-16

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

AUTOMATIC AIR CONDITIONER SYSTEM

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate com-

pressor INFINITI QX56 2009 Factory Service Manual HAC-16

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

AUTOMATIC AIR CONDITIONER SYSTEM

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate com-

pressor](/img/42/57031/w960_57031-2328.png)

HAC-16

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

AUTOMATIC AIR CONDITIONER SYSTEM

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate com-

pressor.

Discharge Air Flow (Front)INFOID:0000000003775333

Discharge Air Flow (Rear)INFOID:0000000003775334

Mode door positionAir outlet/distribution

Vent Foot Defroster

95% 5% —

60% 40% —

—7 0% 3 0%

—6 0% 4 0%

—1 0% 9 0%

AWIIA0818ZZ

Revision: December 20092009 QX56

Page 2363 of 4171

![INFINITI QX56 2009 Factory Service Manual HAC-50

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000003775356

SYSTEM DESCRIPTION

Component Parts

Blower sp INFINITI QX56 2009 Factory Service Manual HAC-50

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000003775356

SYSTEM DESCRIPTION

Component Parts

Blower sp](/img/42/57031/w960_57031-2362.png)

HAC-50

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

BLOWER MOTOR CONTROL SYSTEM

System DescriptionINFOID:0000000003775356

SYSTEM DESCRIPTION

Component Parts

Blower speed control

system components are:• A/C auto amp.

• A/C and AV switch assembly

• Variable blower control

• Front blower motor relay

• Front blower motor

• In-vehicle sensor

• Ambient sensor

• Optical sensor

• Intake sensor

System Operation

Automatic Mode

In the automatic mode, the blower motor speed is calc ulated by the A/C auto amp. and variable blower control

based on input from the in-vehicle sensor, optical sens or, intake sensor and ambient sensor, and potentio tem-

perature control (PTC).

When the air flow is increased, the blower motor s peed is adjusted gradually to prevent a sudden increase in

air flow.

In addition to manual air flow control and the usual automat ic air flow control, starting air flow control, low

water temperature starting control and high passenger compartment temperature starting control are avail-

able.

Starting Blower Speed Control

Start up from cold soak condition (Automatic mode).

In a cold start up condition where the engine coolant temperature is below 50 °C (122° F), the blower will not

operate at blower speed 1 for a short period of time (up to 210 seconds). The exact start delay time varies

depending on the ambient and engine coolant temperatures.

In the most extreme case (very low ambient temper ature) the blower starting delay will be 210 seconds as

described above. After the coolant temperature reaches 50 °C (122° F), or the 210 seconds has elapsed, the

blower speed will increase to the objective blower speed.

Start up from usual operating or hot soak condition (Automatic mode).

The blower will begin operation momentarily after the AUTO switch is pushed. The blower speed will gradually

rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

AWIIA0173GB

Revision: December 20092009 QX56

Page 2366 of 4171

![INFINITI QX56 2009 Factory Service Manual BLOWER MOTOR CONTROL SYSTEMHAC-53

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Check 20A fuses [No. 24 and 27 (Located in the fuse and fusible link box)]. For INFINITI QX56 2009 Factory Service Manual BLOWER MOTOR CONTROL SYSTEMHAC-53

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Check 20A fuses [No. 24 and 27 (Located in the fuse and fusible link box)]. For](/img/42/57031/w960_57031-2365.png)

BLOWER MOTOR CONTROL SYSTEMHAC-53

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Check 20A fuses [No. 24 and 27 (Located in the fuse and fusible link box)]. For fuse layout. Refer to PG-72,

"Terminal Arrangement".

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 7.

2.CHECK FRONT BLOWER MOTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front blower motor connector.

3. Turn ignition switch ON.

4. Press the A/C switch.

5. Press the front blower contro l "+" switch to maximum speed.

6. Check voltage between front blower motor harness connector

M62 terminal 2 and ground.

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 3.

3.CHECK FRONT BLOWER MOTOR RELAY (S WITCH SIDE) POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front blower motor relay.

3. Check voltage between front blower motor relay harness con- nector M107 terminal 5 and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair harness or connector.

4.CHECK FRONT BLOWER MOTOR RELAY

Turn ignition switch OFF.

Check front blower motor relay. Refer to HAC-55, "

Front Blower Motor Component Inspection".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace front blower motor relay.

5.CHECK FRONT BLOWER MOTOR RELA Y (SWITCH SIDE) CIRCUIT FOR OPEN

Check continuity between front bl ower motor relay harness connec-

tor M107 terminal 3 and front blower motor harness connector M62

terminal 2.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair harness or connector.

6.CHECK FRONT BLOWER MOTOR RELAY (COIL SIDE) POWER SUPPLY Fuses are good.

2 - Ground

: Battery voltage

WJIA1331E

5 - Ground: Battery voltage

WJIA1886E

3 - 2 : Continuity should exist.

WJIA1360E

Revision: December 20092009 QX56

Page 2367 of 4171

![INFINITI QX56 2009 Factory Service Manual HAC-54

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

1. Turn ignition switch ON.

2. Check voltage between front blower motor relay harness con-

nector M107 terminal 2 INFINITI QX56 2009 Factory Service Manual HAC-54

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

1. Turn ignition switch ON.

2. Check voltage between front blower motor relay harness con-

nector M107 terminal 2](/img/42/57031/w960_57031-2366.png)

HAC-54

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

1. Turn ignition switch ON.

2. Check voltage between front blower motor relay harness con-

nector M107 terminal 2 and ground.

Is the inspection result normal?

YES >> Repair front blower motor ground circuit or connector.

NO >> Repair harness or connector.

7.REPLACE FUSES

Replace fuses.

Does the fuse blow?

YES >> • If fuse blows without activating the front blower motor, repair short between fuse and front blower motor relay.

• If fuse blows activating the front blower motor, GO TO 8.

NO >> Inspection End.

8.CHECK FRONT BLOWER MOTOR POWER SUPPLY CIRCUIT FOR SHORT

1. Turn ignition switch OFF.

2. Disconnect front blower motor connector, front blower motor relay and variable blower control connector.

3. Check continuity between variable blower control harness con- nector M122 terminal 4 and ground.

Is the inspection result normal?

YES >> GO TO 9.

NO >> Repair harness or connector.

9.CHECK FRONT BLOWER MOTOR

Check front blower motor. Refer to HAC-55, "

Front Blower Motor Component Inspection".

Is the inspection result normal?

YES >> Replace variable blower control (front). Refer to VTL-29, "Removal and Installation".

NO >> Replace front blower motor. Refer to VTL-12, "

Removal and Installation".

10.CHECK FRONT BLOWER MOTOR

Check front blower motor. Refer to HAC-55, "

Front Blower Motor Component Inspection".

Is the inspection result normal?

YES >> GO TO 11.

NO >> Replace front blower motor. Refer to VTL-12, "

Removal and Installation".

11 .CHECK BLOWER MOTOR GROUND CIRCUIT

1. Disconnect variable blower control connector.

2. Check continuity between front blower motor harness connector M62 (B) terminal 1 and variable blower control harness connec-

tor M122 (A) terminal 2.

Is the inspection result normal?

YES >> GO TO 12.

NO >> Repair harness or connector. 2 - Ground

: Battery voltage

WJIA1363E

4 - Ground: Continuity should not exist.

AWIIA0177ZZ

1 - 2 : Continuity should exist.

AWIIA0179ZZ

Revision: December 20092009 QX56

Page 2368 of 4171

![INFINITI QX56 2009 Factory Service Manual BLOWER MOTOR CONTROL SYSTEMHAC-55

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

12.CHECK VARIABLE BLOWER CONTRO L POWER SUPPLY CIRCUIT FOR OPEN

1. Disconnect fr INFINITI QX56 2009 Factory Service Manual BLOWER MOTOR CONTROL SYSTEMHAC-55

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

12.CHECK VARIABLE BLOWER CONTRO L POWER SUPPLY CIRCUIT FOR OPEN

1. Disconnect fr](/img/42/57031/w960_57031-2367.png)

BLOWER MOTOR CONTROL SYSTEMHAC-55

< COMPONENT DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

12.CHECK VARIABLE BLOWER CONTRO L POWER SUPPLY CIRCUIT FOR OPEN

1. Disconnect front blower motor relay.

2. Check continuity between front blower motor relay harness con- nector M107 (A) terminals 3 and variable blower control harness

connector M122 (B) terminal 4.

Is the inspection result normal?

YES >> GO TO 13.

NO >> Repair harness or connector.

13.CHECK VARIABLE BLOWER CONTROL GROUND CIRCUIT

Check continuity between variable blower control harness connector

M122 terminal 1 and ground.

Is the inspection result normal?

YES >> GO TO 14.

NO >> Repair harness or connector.

14.CHECK VARIABLE BLOWER CONTROL SIGNAL CIRCUIT

1. Reconnect all disconnected component connectors.

2. Disconnect A/C auto amp. connector.

3. Turn ignition switch ON.

4. Press the blower (+) switch to maximum speed.

5. Check voltage between A/C auto amp. harness connector M49 terminal 13 and ground.

Is the inspection result normal?

YES >> Replace A/C auto amp. Refer to VTL-7, "Removal and

Installation".

NO >> GO TO 15.

15.CHECK VARIABLE BLOWER CONTROL SIGNAL CIRCUIT FOR OPEN

1. Disconnect variable blower control connector.

2. Check continuity between A/C auto amp. harness connector M49 (B) terminal 13 and variable blower control harness con-

nector M122 (A) terminal 3.

Is the inspection result normal?

YES >> Replace variable blower control. Refer to VTL-29,

"Removal and Installation".

NO >> Repair harness or connector.

Front Blower Motor Component InspectionINFOID:0000000003775359

COMPONENT INSPECTION

3 - 4 : Continuity should exist.

AWIIA0175ZZ

1 - Ground: Continuity should exist.

AWIIA0180ZZ

13 - Ground : Approx. 4.5V

AWIIA1129ZZ

13 - 3: Continuity should exist.

AWIIA0178ZZ

Revision: December 20092009 QX56

Page 2369 of 4171

![INFINITI QX56 2009 Factory Service Manual HAC-56

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

Check continuity between terminals by supplying 12 volts and

ground to coil side terminals of relay.

Front Blower INFINITI QX56 2009 Factory Service Manual HAC-56

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

Check continuity between terminals by supplying 12 volts and

ground to coil side terminals of relay.

Front Blower](/img/42/57031/w960_57031-2368.png)

HAC-56

< COMPONENT DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

BLOWER MOTOR CONTROL SYSTEM

Check continuity between terminals by supplying 12 volts and

ground to coil side terminals of relay.

Front Blower Motor

Confirm smooth rotation of the blower motor.

• Ensure that there are no foreign particles inside the blower unit.

• Apply 12 volts to terminal 2 and ground to terminal 1 and verify that

the motor operates freely and quietly.

Rear Blower Motor DescriptionINFOID:0000000003775360

SYSTEM DESCRIPTION

Component Parts

Rear blower speed control system components are:

• A/C auto amp.

• A/C and AV switch assembly

• Rear air control (front)

• Rear air control (rear)

• Variable blower control (rear)

• Rear blower motor

• Rear blower motor relay

WJIA1401E

WJIA1508E

Revision: December 20092009 QX56