Rax INFINITI QX56 2009 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1240 of 4171

![INFINITI QX56 2009 Factory User Guide

DLN-184

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2F1310]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooti INFINITI QX56 2009 Factory User Guide

DLN-184

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2F1310]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooti](/img/42/57031/w960_57031-1239.png)

DLN-184

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2F1310]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003772204

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

DLN-185, "On-Vehicle Service"DLN-185, "On-Vehicle Service"DLN-185, "On-Vehicle Service"

DLN-208, "NVH Troubleshooting Chart"RAX-5, "NVH Troubleshooting Chart"RSU-5, "NVH Troubleshooting Chart"WT-36, "NVH Troubleshooting Chart"WT-36, "NVH Troubleshooting Chart"FAX-9, "Removal and Installation"BR-6, "NVH Troubleshooting Chart"ST-12, "NVH Troubleshooting Chart"

Possible cause and suspected parts

Uneven rotation torque

Rotation imbalance

Excessive run out

Differential

Axle

Suspension

Tires

Road wheel

Drive shaft

Brakes

Steering

Symptom

Noise

×××××××××××

Shake ×××××××

Vibration ××××××××

Revision: December 20092009 QX56

Page 1250 of 4171

![INFINITI QX56 2009 Factory User Guide

DLN-194

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2S1410]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooti INFINITI QX56 2009 Factory User Guide

DLN-194

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2S1410]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooti](/img/42/57031/w960_57031-1249.png)

DLN-194

< SYMPTOM DIAGNOSIS >[PROPELLER SHAFT: 2S1410]

NOISE, VIBRATION, AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003772211

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

DLN-195, "On-Vehicle Service"DLN-195, "On-Vehicle Service"DLN-195, "On-Vehicle Service"

DLN-242, "NVH Troubleshooting Chart"RAX-5, "NVH Troubleshooting Chart"RSU-5, "NVH Troubleshooting Chart"WT-36, "NVH Troubleshooting Chart"WT-36, "NVH Troubleshooting Chart"

RAX-5, "NVH Troubleshooting Chart"

BR-6, "NVH Troubleshooting Chart"ST-12, "NVH Troubleshooting Chart"

Possible cause and suspected parts

Uneven rotation torque

Rotation imbalance

Excessive run out

Differential

Axle

Suspension

Tires

Road wheel

Drive shaft

Brakes

Steering

Symptom Noise

×××××××××××

Shake ×××××××

Vibration ××××××××

Revision: December 20092009 QX56

Page 1298 of 4171

![INFINITI QX56 2009 Factory User Guide

DLN-242

< SYMPTOM DIAGNOSIS >[REAR FINAL DRIVE: R230]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting INFINITI QX56 2009 Factory User Guide

DLN-242

< SYMPTOM DIAGNOSIS >[REAR FINAL DRIVE: R230]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting](/img/42/57031/w960_57031-1297.png)

DLN-242

< SYMPTOM DIAGNOSIS >[REAR FINAL DRIVE: R230]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000004193552

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

DLN-253, "Disassembly and Assembly"DLN-253, "Disassembly and Assembly"DLN-253, "Disassembly and Assembly"DLN-270, "Inspection and Adjustment"DLN-270, "Inspection and Adjustment"

MA-12, "Fluids and Lubricants"

DLN-194, "NVH Troubleshooting Chart"RAX-5, "NVH Troubleshooting Chart"RSU-5, "NVH Troubleshooting Chart"WT-36, "NVH Troubleshooting Chart"WT-36, "NVH Troubleshooting Chart"RAX-5, "NVH Troubleshooting Chart"BR-6, "NVH Troubleshooting Chart"ST-12, "NVH Troubleshooting Chart"

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

REAR AXLE

REAR SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom Noise

××××××× ××××××

Revision: December 20092009 QX56

Page 1301 of 4171

![INFINITI QX56 2009 Factory User Guide

FRONT OIL SEALDLN-245

< ON-VEHICLE REPAIR > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

ON-VEHICLE REPAIR

FRONT OIL SEAL

Removal and InstallationINFOID:0000000005877760

REMOVAL

1. Remov INFINITI QX56 2009 Factory User Guide

FRONT OIL SEALDLN-245

< ON-VEHICLE REPAIR > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

ON-VEHICLE REPAIR

FRONT OIL SEAL

Removal and InstallationINFOID:0000000005877760

REMOVAL

1. Remov](/img/42/57031/w960_57031-1300.png)

FRONT OIL SEALDLN-245

< ON-VEHICLE REPAIR > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

ON-VEHICLE REPAIR

FRONT OIL SEAL

Removal and InstallationINFOID:0000000005877760

REMOVAL

1. Remove the drive shafts from the rear final drive assembly. Refer to RAX-9, "Removal and Installation".

2. Remove the side flanges and side oil seals. Refer to DLN-247, "Removal and Installation"

.

3. Remove the rear propeller shaft. Refer to DLN-196, "Removal and Installation"

.

4. Measure the total preload torque. Refer to DLN-253, "Disassembly and Assembly"

.

NOTE:

Record the total preload torque measurement.

5. Remove the drive pinion lock nut using suitable tool.

6. Put matching marks on the companion flange and drive pinion using paint. CAUTION:

Use paint to make the matching marks. Do not da mage the companion flange or drive pinion.

7. Remove the companion flange using suitable tool.

8. Remove the front oil seal using Tool.

INSTALLATION

SDIA1142E

SDIA1054E

Tool number : KV381054S0 (J-34286)

SDIA0485E

Revision: December 20092009 QX56

Page 1303 of 4171

![INFINITI QX56 2009 Factory User Guide

SIDE OIL SEALDLN-247

< ON-VEHICLE REPAIR > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

SIDE OIL SEAL

Removal and InstallationINFOID:0000000004193557

REMOVAL

1. Remove the drive shaft fr INFINITI QX56 2009 Factory User Guide

SIDE OIL SEALDLN-247

< ON-VEHICLE REPAIR > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

SIDE OIL SEAL

Removal and InstallationINFOID:0000000004193557

REMOVAL

1. Remove the drive shaft fr](/img/42/57031/w960_57031-1302.png)

SIDE OIL SEALDLN-247

< ON-VEHICLE REPAIR > [REAR FINAL DRIVE: R230]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

SIDE OIL SEAL

Removal and InstallationINFOID:0000000004193557

REMOVAL

1. Remove the drive shaft from the rear final drive assembly. Refer to RAX-9, "Removal and Installation".

2. Remove the side flange using Tools.

3. Remove the side oil seal using suitable tool. CAUTION:

Do not to damage gear carrier.

INSTALLATION

1. Apply multi-purpose grease to the lips of the new side oil seal.

Then drive the new side oil seal in evenly until it becomes flush

with the gear carrier using Tool.

CAUTION:

Do not reuse side oil seal.

Do not incline the new side oil seal when installing.

Apply multi-purpose grease to th e lips of the new side oil

seal.

2. Install the side flange using Tool.

a. Install the Tool to the side oil seal as shown.

b. Insert the side flange until the serrated part of the side flange has engaged the serrated part of the side gear and remove the

Tool.

c. Drive in the side flange using suitable tool. NOTE:

Installation is completed when the driving sound of the side

flange turns into a sound which seems to affect the whole rear

final drive assembly.

3. Installation of the remaining components is in the reverse order of removal. CAUTION:Tool numbers A: KV40104100 ( — )

B: ST36230000 (J-25840-A)

WDIA0115E

LDIA0109E

Tool number : KV38100200 (J-26233)

LDIA0111E

Tool number : KV38107900 (J-39352)

SDIA0822E

Revision: December 20092009 QX56

Page 1306 of 4171

![INFINITI QX56 2009 Factory User Guide

DLN-250

< REMOVAL AND INSTALLATION >[REAR FINAL DRIVE: R230]

REAR FINAL DRIVE

REMOVAL AND INSTALLATION

REAR FINAL DRIVE

Removal and InstallationINFOID:0000000005877761

REMOVAL

1. Remove the spare tir INFINITI QX56 2009 Factory User Guide

DLN-250

< REMOVAL AND INSTALLATION >[REAR FINAL DRIVE: R230]

REAR FINAL DRIVE

REMOVAL AND INSTALLATION

REAR FINAL DRIVE

Removal and InstallationINFOID:0000000005877761

REMOVAL

1. Remove the spare tir](/img/42/57031/w960_57031-1305.png)

DLN-250

< REMOVAL AND INSTALLATION >[REAR FINAL DRIVE: R230]

REAR FINAL DRIVE

REMOVAL AND INSTALLATION

REAR FINAL DRIVE

Removal and InstallationINFOID:0000000005877761

REMOVAL

1. Remove the spare tire.

2. Drain the differential gear oil. Refer to

DLN-244, "Changing Differential Gear Oil"

.

3. Remove the rear stabilizer bar. Refer to RSU-23, "Removal and Installation"

.

4. Remove the rear propeller shaft. Refer to DLN-196, "Removal and Installation"

.

5. Remove the rear drive shafts from the rear final drive assembly and support them using suitable wire. Refer to RAX-9, "Removal

and Installation".

6. Disconnect the breather hose from the rear final drive assembly.

1. Rear final drive assembly 2. Upper stopper 3. Washer

4. Lower stopper Vehicle front

WDIA0383E

LDIA0164E

Revision: December 20092009 QX56

Page 2832 of 4171

PARKING BRAKE CONTROLPB-7

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

PB

N

O P

ON-VEHICLE REPAIR

PARKING BRAKE CONTROL

ComponentINFOID:0000000003772471

Removal and InstallationINFOID:0000000003772472

REMOVAL

1. Remove lower instrument panel LH. Refer to IP-17, "Removal and Installation".

2. Remove center console. Refer to IP-20, "

Removal and Installation".

3. Remove floor trim. Refer to INT-16, "

Removal and Installation".

4. Remove adjusting nut and discard. CAUTION:

Do not reuse adjusting nut after removing it.

5. Remove the lock plate from the front cable.

6. Remove front cable retaining bolts and nut.

7. Disconnect return spring from equalizer.

8. Disconnect right and left rear cables from equalizer.

9. Remove rear wheel hub. Refer to RAX-7, "

Removal and Installa-

tion".

1. Pedal assembly 2. Front cable3. Right rear cable

4. Left rear cable 5. Return spring6. Equalizer

7. Adjusting nut 8. Lock plate

WFIA0218E

WFIA0165E

Revision: December 20092009 QX56

Page 2834 of 4171

PARKING BRAKE SHOEPB-9

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

PB

N

O P

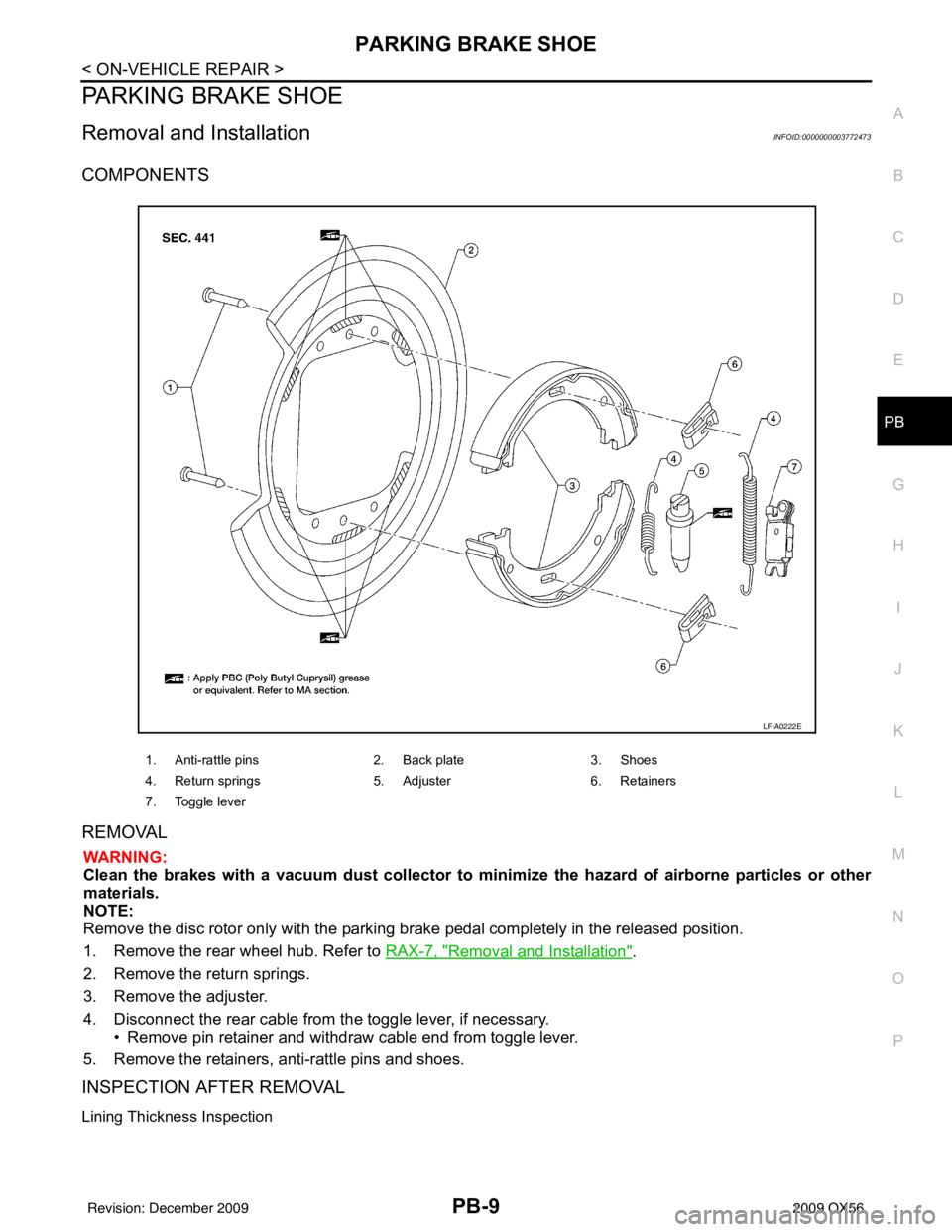

PARKING BRAKE SHOE

Removal and InstallationINFOID:0000000003772473

COMPONENTS

REMOVAL

WARNING:

Clean the brakes with a vacuum dust co llector to minimize the hazard of airborne particles or other

materials.

NOTE:

Remove the disc rotor only with the parking brake pedal completely in the released position.

1. Remove the rear wheel hub. Refer to RAX-7, "

Removal and Installation".

2. Remove the return springs.

3. Remove the adjuster.

4. Disconnect the rear cable from the toggle lever, if necessary.

• Remove pin retainer and withdraw cable end from toggle lever.

5. Remove the retainers, anti-rattle pins and shoes.

INSPECTION AFTER REMOVAL

Lining Thickness Inspection

1. Anti-rattle pins 2. Back plate3. Shoes

4. Return springs 5. Adjuster6. Retainers

7. Toggle lever

LFIA0222E

Revision: December 20092009 QX56

Page 3076 of 4171

RAX-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION RAX

A

B

RAX

N

O P

CONTENTS

REAR AXLE

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

2

Caution ......................................................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

5

NVH Troubleshooting Chart ................................ ......5

ON-VEHICLE MAINTENANCE .....................6

WHEEL HUB .... .............................................. .....6

On-Vehicle Inspection and Service ..................... .....6

REMOVAL AND INSTALLATION ................7

WHEEL HUB ......................................................7

Removal and Installation ..................................... .....7

REAR DRIVE SHAFT .........................................9

Component ...............................................................9

Removal and Installation ..........................................9

DISASSEMBLY AND ASSEMBLY ..............11

REAR DRIVE SHAFT ........................................11

Disassembly and Assembly ................................. ....11

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

16

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

16

Wheel Bearing ..................................................... ....16

Drive Shaft ...............................................................16

Boot Bands ..............................................................16

Revision: December 20092009 QX56

Page 3077 of 4171

RAX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005873184

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005873185

NOTE:

This Procedure is applied only to models with Intelli gent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56