air conditioning INFINITI QX56 2009 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2314 of 4171

HAC-1

VENTILATION, HEATER & AIR CONDITIONER

C

DE

F

G H

J

K L

M

SECTION HAC

A

B

HAC

N

O P

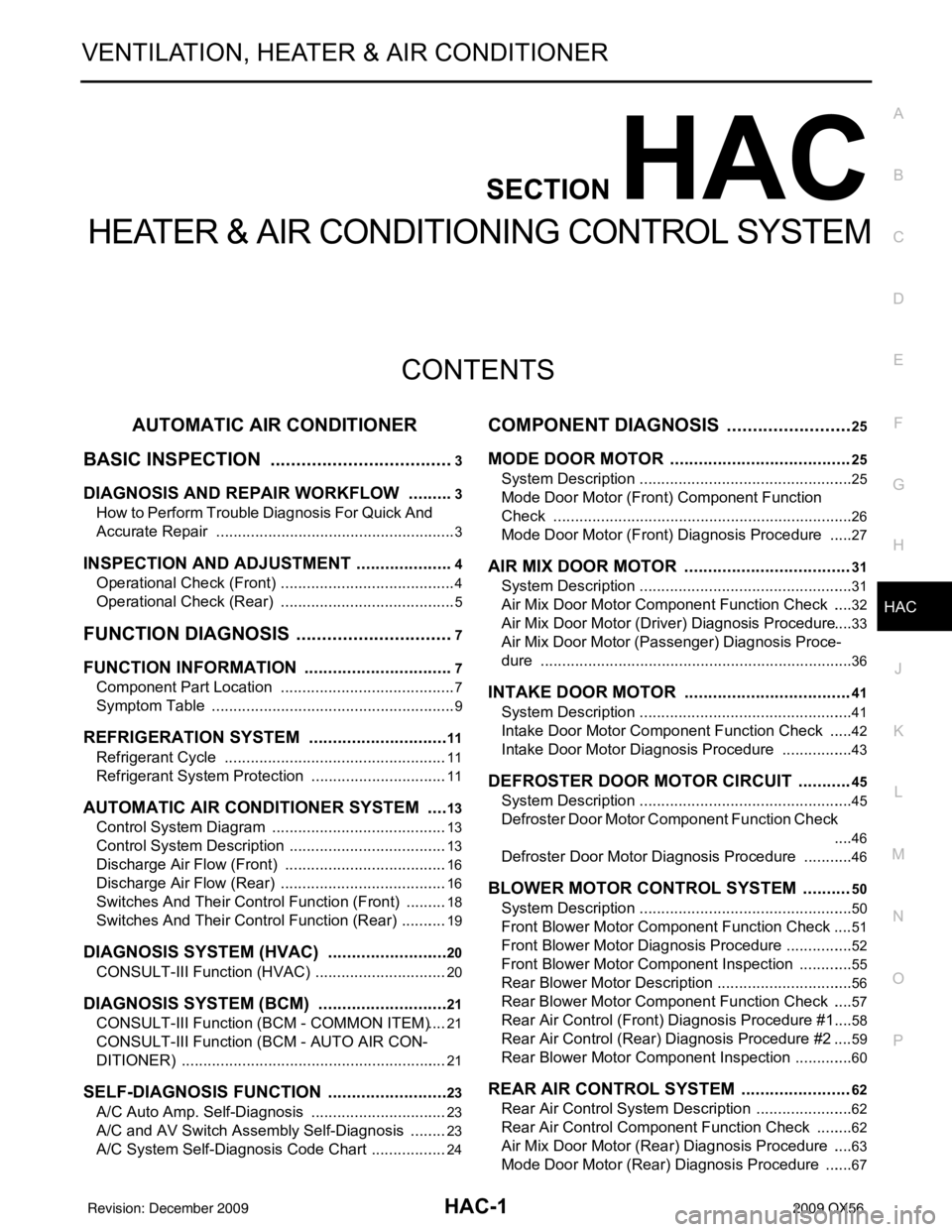

CONTENTS

HEATER & AIR CONDITIONING CONTROL SYSTEM

AUTOMATIC AIR CONDITIONER

BASIC INSPECTION ....... .............................

3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

How to Perform Trouble Diagnosis For Quick And

Accurate Repair ........................................................

3

INSPECTION AND ADJUSTMENT ................ .....4

Operational Check (Front) ................................... ......4

Operational Check (Rear) .........................................5

FUNCTION DIAGNOSIS ...............................7

FUNCTION INFORMATION ........................... .....7

Component Part Location ................................... ......7

Symptom Table .........................................................9

REFRIGERATION SYSTEM ..............................11

Refrigerant Cycle ................................................ ....11

Refrigerant System Protection ................................11

AUTOMATIC AIR CONDITIONER SYSTEM . ....13

Control System Diagram ..................................... ....13

Control System Description .....................................13

Discharge Air Flow (Front) ......................................16

Discharge Air Flow (Rear) .......................................16

Switches And Their Control Function (Front) ..........18

Switches And Their Control Function (Rear) ...........19

DIAGNOSIS SYSTEM (HVAC) ..........................20

CONSULT-III Function (HVAC) ........................... ....20

DIAGNOSIS SYSTEM (BCM) ............................21

CONSULT-III Function (BCM - COMMON ITEM) ....21

CONSULT-III Function (BCM - AUTO AIR CON-

DITIONER) ..............................................................

21

SELF-DIAGNOSIS FUNCTION ..........................23

A/C Auto Amp. Self-Diagnosis ................................23

A/C and AV Switch Asse mbly Self-Diagnosis .........23

A/C System Self-Diagnosis Code Chart .............. ....24

COMPONENT DIAGNOSIS .........................25

MODE DOOR MOTOR ......................................25

System Description .............................................. ....25

Mode Door Motor (Front) Component Function

Check ......................................................................

26

Mode Door Motor (Front) Diagnosis Procedure ......27

AIR MIX DOOR MOTOR ...................................31

System Description ..................................................31

Air Mix Door Motor Component Function Check .....32

Air Mix Door Motor (Driver) Diagnosis Procedure ....33

Air Mix Door Motor (Passenger) Diagnosis Proce-

dure .........................................................................

36

INTAKE DOOR MOTOR ...................................41

System Description ..................................................41

Intake Door Motor Component Function Check ......42

Intake Door Motor Diagnosis Procedure .................43

DEFROSTER DOOR MOTOR CIRCUIT ...........45

System Description ..................................................45

Defroster Door Motor Component Function Check

....

46

Defroster Door Motor Diagnosis Procedure ............46

BLOWER MOTOR CONTROL SYSTEM ..........50

System Description ..................................................50

Front Blower Motor Component Function Check ....51

Front Blower Motor Diagnosis Procedure ................52

Front Blower Motor Component Inspection .............55

Rear Blower Motor Description ................................56

Rear Blower Motor Component Function Check .....57

Rear Air Control (Front) Diagnosis Procedure #1 ....58

Rear Air Control (Rear) Diagnosis Procedure #2 ....59

Rear Blower Motor Component Inspection ..............60

REAR AIR CONTROL SYSTEM .......................62

Rear Air Control System Description .......................62

Rear Air Control Component Function Check .........62

Air Mix Door Motor (Rear) Diagnosis Procedure .....63

Mode Door Motor (Rear) Diagnosis Procedure .......67

Revision: December 20092009 QX56

Page 2427 of 4171

![INFINITI QX56 2009 Factory User Guide HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Trouble INFINITI QX56 2009 Factory User Guide HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Trouble](/img/42/57031/w960_57031-2426.png)

HAC-114

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT COOLING

TEST READING

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Trouble Diagnoses fo

r Abnormal PressureINFOID:0000000003775395

Whenever system′s high and/or low side pressure is unusual, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the stan-

Vehicle location Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Recirculation (REC) switch (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68)

9.9 - 13.9 (50 - 57)

25 (77) 14.6 - 18.6 (58 - 65)

30 (86) 16.8 - 21.8 (62 - 71)

35 (95) 21.1 - 27.1 (70 - 81)

40 (104) 25.3 - 31.5 (78 - 89)

60 - 70 20 (68)

11.4 - 15.2 (53 - 59)

25 (77) 15.5 - 20.0 (60 - 68)

30 (86) 19.9 - 25.0 (68 - 77)

35 (95) 24.5 - 29.6 (76 - 85)

40 (104) 28.7 - 34.9 (84 - 95)

Ambient air High-pressure (Discharge side)

kPa (kg/cm

2 , psi) Low-pressure (Suction side)

kPa (kg/cm2 , psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

1020 - 1250

(10.4 - 12.7, 147.9 - 181.3) 160 - 190

(1.63 - 1.94, 23.2 - 27.6)

25 (77) 1236 - 1510

(12.6 - 15.4, 179.2 - 219) 206 - 245

(2.1 - 2.5, 29.9 - 35.6)

30 (86) 1569 - 1,922

(16.0 - 19.6, 227.6 - 278.8) 265 - 324

(2.7 - 3.3, 38.4 - 46.9)

35 (95) 1,697 - 2079

(17.3 - 21.2, 246.1 - 301.5) 304 - 363

(3.1 - 3.7, 44.1 - 52.6)

40 (104) 1971 - 2403

(20.1 - 24.5, 285.9 - 348.5) 373 - 451

(3.8 - 4.6, 54.0 - 65.4)

Revision: December 20092009 QX56

Page 2430 of 4171

![INFINITI QX56 2009 Factory User Guide INSUFFICIENT COOLINGHAC-117

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorre INFINITI QX56 2009 Factory User Guide INSUFFICIENT COOLINGHAC-117

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorre](/img/42/57031/w960_57031-2429.png)

INSUFFICIENT COOLINGHAC-117

< SYMPTOM DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

Low-pressure Side Becomes Negative

Gauge indication

Refrigerant cycleProbable causeCorrective action

Low-pressure side sometimes be-

comes negative. • Air conditioning system does

not function and does not cy-

clically cool the compart-

ment air.

• The system constantly func- tions for a certain period of

time after compressor is

stopped and restarted. Refrigerant does not discharge

cyclically.

↓

Moisture is frozen at expan-

sion valve outlet and inlet.

↓

Water is mixed with refrigerant.

• Drain water from refrigerant

or replace refrigerant.

• Replace liquid tank.

AC354A

Gauge indication Refrigerant cycleProbable causeCorrective action

Low-pressure side becomes nega-

tive. Liquid tank or front/rear side of

expansion valve′s pipe is frost-

ed or dewed. High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re- move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth- ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check oil for contamination.

AC362A

Revision: December 20092009 QX56

Page 2685 of 4171

MA-12

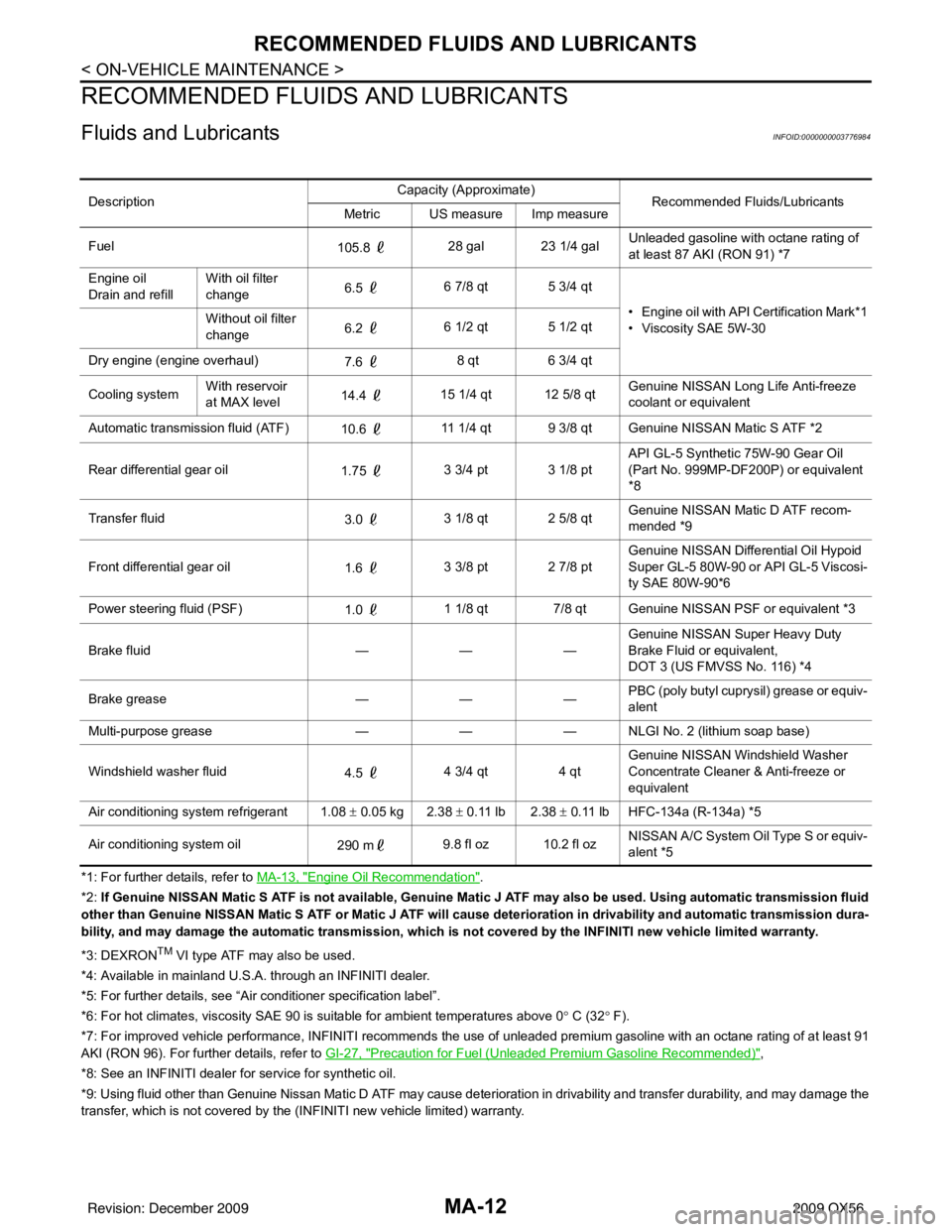

< ON-VEHICLE MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and LubricantsINFOID:0000000003776984

*1: For further details, refer to MA-13, "Engine Oil Recommendation".

*2: If Genuine NISSAN Matic S ATF is not available, Genuine Matic J ATF may also be used. Using automatic transmission fluid

other than Genuine NISSAN Matic S ATF or Matic J ATF will cause deterioration in drivability and automatic transmission dura-

bility, and may damage the automatic transmission, which is not covered by the INFINITI new vehicle limited warranty.

*3: DEXRON

TM VI type ATF may also be used.

*4: Available in mainland U.S.A. through an INFINITI dealer.

*5: For further details, see “Air conditioner specification label”.

*6: For hot climates, viscosity SAE 90 is suitable for ambient te mperatures above 0° C (32 ° F).

*7: For improved vehicle performance, INFINITI recommends the use of unleaded premium gasoline with an octane rating of at leas t 91

AKI (RON 96). For further details, refer to GI-27, "

Precaution for Fuel (Unleaded Premium Gasoline Recommended)",

*8: See an INFINITI dealer for service for synthetic oil.

*9: Using fluid other than Genuine Nissan Matic D ATF may cause deterioration in drivability and transfer durability, and may d amage the

transfer, which is not covered by the (INFINITI new vehicle limited) warranty. Description

Capacity (Approximate)

Recommended Fluids/Lubricants

Metric US measure Imp measure

Fuel 105.8 28 gal 23 1/4 gal Unleaded gasoline with octane rating of

at least 87 AKI (RON 91) *7

Engine oil

Drain and refill With oil filter

change

6.5

6 7/8 qt 5 3/4 qt

• Engine oil with API Certification Mark*1

• Viscosity SAE 5W-30

Without oil filter

change

6.2

6 1/2 qt 5 1/2 qt

Dry engine (engine overhaul) 7.6 8 qt

6 3/4 qt

Cooling system With reservoir

at MAX level

14.4

15 1/4 qt 12 5/8 qt Genuine NISSAN Long Life Anti-freeze

coolant or equivalent

Automatic transmission fluid (ATF) 10.6 11 1/4 qt 9 3/8 qt Genuine NISSAN Matic S ATF *2

Rear differential gear oil 1.75 3 3/4 pt 3 1/8 pt API GL-5 Synthetic 75W-90 Gear Oil

(Part No. 999MP-DF200P) or equivalent

*8

Transfer fluid 3.0 3 1/8 qt 2 5/8 qt Genuine NISSAN Matic D ATF recom-

mended *9

Front differential gear oil 1.6 3 3/8 pt 2 7/8 pt Genuine NISSAN Differential Oil Hypoid

Super GL-5 80W-90 or API GL-5 Viscosi-

ty SAE 80W-90*6

Power steering fluid (PSF) 1.0 1 1/8 qt 7/8 qt Genuine NISSAN PSF or equivalent *3

Brake fluid —— —Genuine NISSAN Super Heavy Duty

Brake Fluid or equivalent,

DOT 3 (US FMVSS No. 116) *4

Brake grease —— —PBC (poly butyl cuprysil) grease or equiv-

alent

Multi-purpose grease —— — NLGI No. 2 (lithium soap base)

Windshield washer fluid 4.5 4 3/4 qt

4 qtGenuine NISSAN Windshield Washer

Concentrate Cleaner & Anti-freeze or

equivalent

Air conditioning system refrigerant 1.08 ± 0.05 kg 2.38 ± 0.11 lb 2.38 ± 0.11 lb HFC-134a (R-134a) *5

Air conditioning system oil 290 m9.8 fl oz 10.2 fl oz NISSAN A/C System Oil Type S or equiv-

alent *5

Revision: December 20092009 QX56