glove box INFINITI QX56 2009 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3318 of 4171

![INFINITI QX56 2009 Factory User Guide SEC-8

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

• Intelligent Key has 2 IDs (for Intelligent Key and for

NATS). It can perform the door lock/u INFINITI QX56 2009 Factory User Guide SEC-8

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

• Intelligent Key has 2 IDs (for Intelligent Key and for

NATS). It can perform the door lock/u](/img/42/57031/w960_57031-3317.png)

SEC-8

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

• Intelligent Key has 2 IDs (for Intelligent Key and for

NATS). It can perform the door lock/unlock operation and

the engine start operation when the registered Intelligent Key is carried.

• When the Intelligent Key battery is discharged, it can be used as emergency back-up by inserting the

mechanical key set in the Intelligent Key to the ignition key cylinder. At that time, perform the NATS ID verifi-

cation. If it is used when the Intelligent Key is carried, perform the Intelligent Key ID verification.

• If the ID is successfully verified, and when the igniti on knob switch is pressed, steering lock will be released

and initiating the engine will be possible.

• The door lock/unlock operation can be performed when the Intelligent Key battery is discharged, by operat-

ing the driver door key cylinder using the mechanical key set in the Intelligent Key.

• Up to 4 Intelligent Keys can be registered (including the standard Intelligent Key) on request from the owner. NOTE:

• Refer to DLK-21, "

INTELLIGENT KEY : System Description" for any functions other than engine start func-

tion of Intelligent Key system.

PRECAUTIONS FOR INTELLIGENT KEY SYSTEM

• For vehicles equipped with the Intelligent Key system , the transponder [the chip for NATS ID verifi-

cation] is integrated into the Inte lligent Key. Therefore, the Intellig ent Key alone is capable of provid-

ing security clearance for the engine to start. Also, when the mechanical key alone is inserted into

the key cylinder, performs the NATS ID verification to allow the engine to start. For vehicles without

Intelligent Key system, the transponder is integrated into the mechanical key which must be inserted

into the key cylinder to perform the NATS ID verification to allow the engine to start.

OPERATION WHEN INTELLIGENT KEY IS CARRIED

1. When the ignition knob switch is ON, the Intelligent Key unit transmits the request signal to the Intelligent

Key.

2. The Intelligent Key receives the request signal and transmits the Intelligent Key ID signal to the Intelligent Key unit.

3. The Intelligent Key unit receives the Intelligent Key ID signal and verifies it with the registered ID.

4. Intelligent Key unit transmits the steering lock/unlock signal to steering lock solenoid if the verification results are OK. For detail of key warning message operation, refer to DLK-38, "

System Description".

5. Release of the steering lock.

6. BCM transmits the starter request signal via CAN communication to IPDM E/R and turns the starter relay in IPDM E/R ON if BCM judges that the engine start condition is satisfied.

7. IPDM E/R turns the starter control relay ON when receiving the starter request signal.

8. When shift position is in P or N position, battery power is supplied through the starter relay and operate the starter motor and to start the cranking.

CAUTION:

If a malfunction is detected in the Intelligent Key system, the “KEY” warning message will be dis-

played in the combination meter. At th at time, the engine cannot be started.

OPERATION RANGE

Engine can be started when Intelligent Key is inside the vehicle. However, sometimes engine might not start

when Intelligent Key is on instrument panel or in glove box.

OPERATION WHEN MECHANICAL KEY IS USED

When the Intelligent Key battery is discharged, performs the NATS ID verification between the integrated tran-

sponder and BCM by inserting the mechanical key into the key cylinder, and then the engine can be started.

For details relating to starting the engine using mechanical key, refer to SEC-11, "

System Description".

STEERING LOCK OPERATION

Steering is locked by steering lock solenoid when ignition switch is in the LOCK position (the ignition knob is

released) and key switch is OFF (key is removed from ignition key cylinder).

Revision: December 20092009 QX56

Page 3483 of 4171

SR-10

< ON-VEHICLE REPAIR >

FRONT PASSENGER AIR BAG MODULE

FRONT PASSENGER AIR BAG MODULE

Removal and InstallationINFOID:0000000003775159

The passenger air bag module originally installed in the vehicle uses direct-connect style harness connectors.

Service replacement passenger air bag modules use tab-locking style harness connectors. If the passenger

air bag module is replaced or if the direct-connect harness connectors are damaged, the vehicle wiring har-

ness must be modified to allow connection of the service replacement passenger air bag module. Follow the

wiring harness modification procedure within this section.

REMOVAL

CAUTION:

• Do not attempt to repair or replace damaged di rect-connect front passenger air bag module connec-

tors. If a direct-connect harness connector is damaged, the front passenger air bag must be

replaced and the wiri ng harness modified.

• Before servicing SRS, turn the ig nition switch off, disconnect both battery terminals and wait at least

three minutes.

• Always work from the side of or under front passenger air bag module.

1. Disconnect both the negative and positive battery terminals, then wait at least three minutes.

2. Remove the glove box. Refer to IP-17, "

Exploded View".

3. Remove two nuts (through glove box opening) retaining front passenger air bag module to instrument panel crossmember.

4. Disconnect the air bag module electrical connectors. • For removal/installation of the direct-connect SRS connectors, refer to SRC-9, "

Direct-connect SRS

Component Connectors".

5. Remove the instrument panel assembly from the vehicle. Refer to IP-13, "

Removal and Installation".

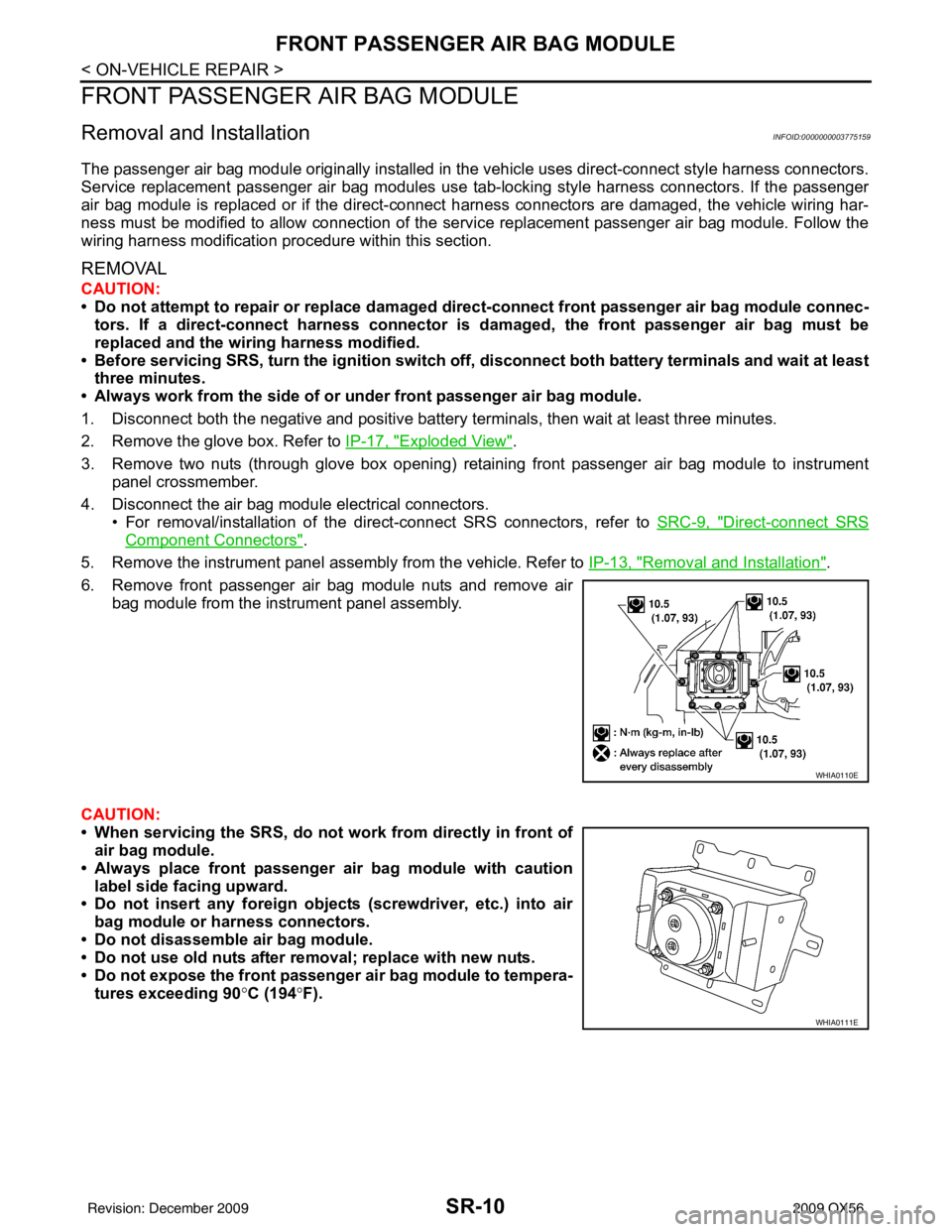

6. Remove front passenger air bag module nuts and remove air bag module from the instrument panel assembly.

CAUTION:

• When servicing the SRS, do not work from directly in front of

air bag module.

• Always place front passenger air bag module with caution label side facing upward.

• Do not insert any foreign object s (screwdriver, etc.) into air

bag module or harness connectors.

• Do not disassemble air bag module.

• Do not use old nuts after removal; replace with new nuts.

• Do not expose the front passenger air bag module to tempera- tures exceeding 90 °C (194 °F).

WHIA0110E

WHIA0111E

Revision: December 20092009 QX56

Page 3946 of 4171

VTL-6

< ON-VEHICLE MAINTENANCE >

IN-CABIN MICROFILTER

ON-VEHICLE MAINTENANCE

IN-CABIN MICROFILTER

Removal and InstallationINFOID:0000000003775260

REPLACEMENT PROCEDURE

1. Remove the glove box assembly from the instrument panel. Refer to IP-17, "Removal and Installation".

2. Remove the screw and remove the in-cabin microfilter cover as shown.

3. Remove the two in-cabin microf ilters from the front heater and

cooling unit assembly housing.

4. Insert the first new in-cabin micr ofilter into the front heater and

cooling unit assembly housing and slide it over to the right.

Insert the second new in-cabin mi crofilter into the front heater

and cooling unit assembly housing as shown.

NOTE:

The in-cabin microfilters are marked with air flow arrows. The

end of the microfilter with the arro w should face the rear of the

vehicle. The arrows should point downward.

5. Install the in-cabin microfilter cover.

6. Install the glove box assembly in the instrument panel. Refer to IP-17, "

Removal and Installation".

7. Fill out the date information on the small replac ement label and attach it to the glove box lid.

LJIA0134E

LJIA0148E

LJIA0134E

Revision: December 20092009 QX56

Page 3951 of 4171

INTAKE SENSORVTL-11

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

INTAKE SENSOR

Removal and InstallationINFOID:0000000003775264

REMOVAL

1. Remove the instrument lower panel RH and glove box. Refer to IP-17, "Removal and Installation".

2. Disconnect the intake sensor electrical connector. NOTE:

The intake sensor is located on the top of the front heater and

cooling unit assembly next to the A/C evaporator cover.

3. Twist the intake sensor to remove the intake sensor from the front heater and cooling unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

LJIA0133E

Revision: December 20092009 QX56

Page 3952 of 4171

VTL-12

< ON-VEHICLE REPAIR >

BLOWER MOTOR

BLOWER MOTOR

ComponentINFOID:0000000003775265

Front Blower MotorRear Blower Motor

Removal and InstallationINFOID:0000000003775266

FRONT BLOWER MOTOR

Removal

1. Remove the instrument lower panel RH and glove box assembly. Refer to IP-17, "Removal and Installa-

tion".

2. Disconnect the front blower motor electrical connector.

3. Remove the three screws and remove the front blower motor.

4. Remove blower motor wheel as necessary to transfer to new blower motor.

Installation

LJIA0136E

1. Front heater and cooling unit assembly 2. Front blower motor 3. Front variable blower control

AWIIA0085ZZ

1. Rear blower motor2. Rear heater and cooling unit assembly 3. Rear variable blower control

Revision: December 20092009 QX56

Page 3954 of 4171

VTL-14

< ON-VEHICLE REPAIR >

IN-CABIN MICROFILTER

IN-CABIN MICROFILTER

Removal and InstallationINFOID:0000000003775267

REPLACEMENT PROCEDURE

1. Remove the glove box assembly from the instrument panel. Refer to IP-17, "Removal and Installation".

2. Remove the screw and remove the in-cabin microfilter cover.

3. Remove the in-cabin microfilters from the front heater and cool- ing unit assembly housing.

4. Insert the first new in-cabin micr ofilter into the front heater and

cooling unit assembly housing and slide it over to the right.

Insert the second new in-cabin mi crofilter into the front heater

and cooling unit assembly housing.

NOTE:

The in-cabin microfilters are marked with air flow arrows. The

end of the microfilter with the arro w should face the rear of the

vehicle. The arrows should point downward.

5. Install the in-cabin microfilter cover.

6. Install the glove box assembly in the instrument panel. Refer to IP-17, "

Removal and Installation".

7. Fill out the date information on the sm all replacement label and attach it to the inside of the glove box lid.

LJIA0134E

LJIA0148E

LJIA0134E

Revision: December 20092009 QX56

Page 3969 of 4171

VARIABLE BLOWER CONTROLVTL-29

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

Rear Variable Blower Control - Rear Heater and Cooling Unit Assembly

Removal and InstallationINFOID:0000000003775279

FRONT VARIABLE BLOWER CONTROL

Removal

1. Remove the glove box assembly. Refer to IP-17, "Removal and Installation".

2. Disconnect the variable blower control electrical connector.

3. Remove the two screws and remove the variable blower control.

Installation

Installation is in the reverse order of removal.

REAR VARIABLE BLOWER CONTROL

Removal

1. Remove the luggage side finisher lower RH. Refer to INT-19, "Removal and Installation".

2. Disconnect the rear blower motor resistor electrical connector.

3. Remove the two screws and remove the rear blower motor resistor.

Installation

Installation is in the reverse order of removal.

ALIIA0066ZZ

1. Air mix door motor 2. Heater core 3. Blower motor

4. Variable blower control 5. Rear heater and cooling unit assembly ⇐Front

Revision: December 20092009 QX56