fuses INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 60 of 4171

ADP-46

< COMPONENT DIAGNOSIS >

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

BCM

BCM : Diagnosis ProcedureINFOID:0000000004055989

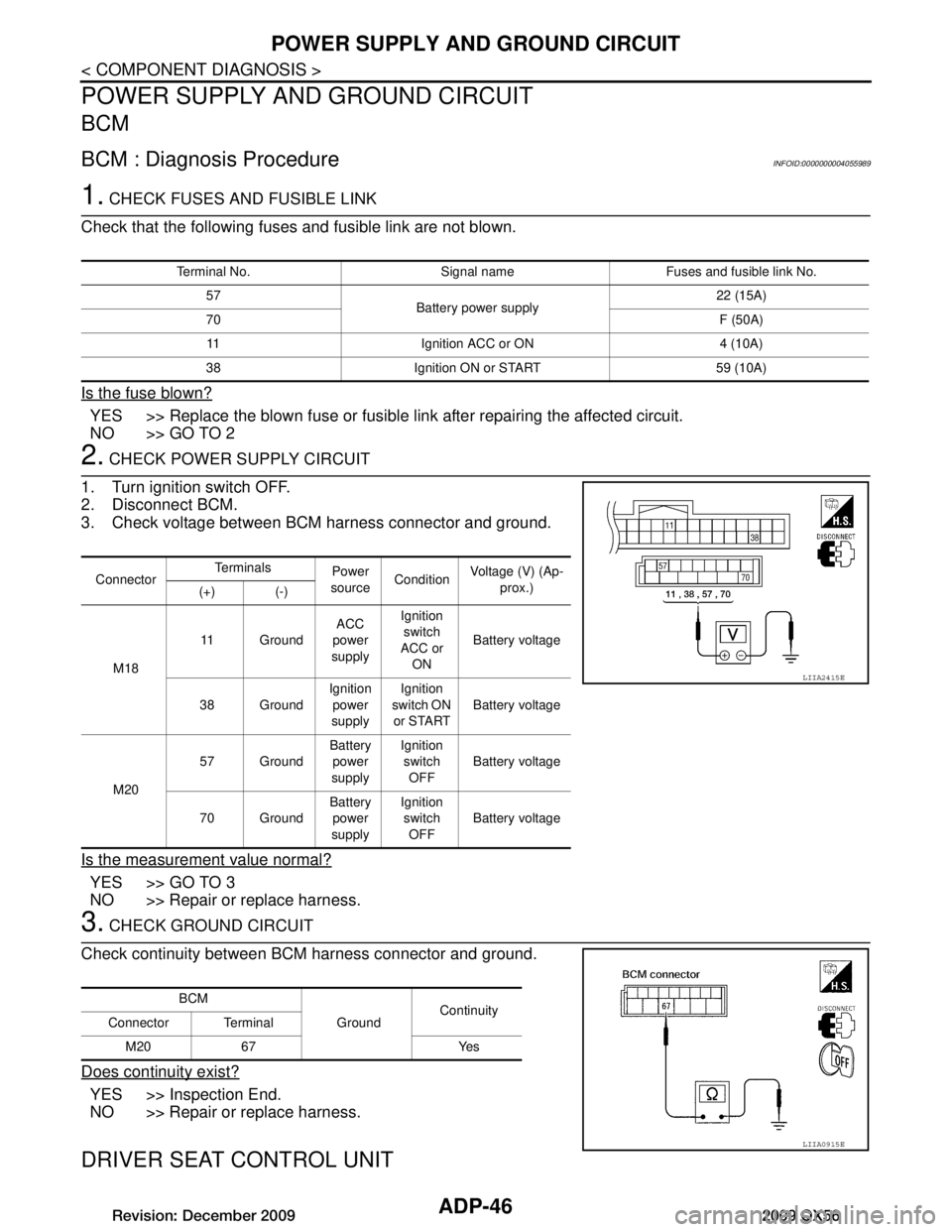

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

DRIVER SEAT CONTROL UNIT

Terminal No. Signal name Fuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

Connector Te r m i n a l s

Power

source Condition

Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch

OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch OFF Battery voltage

LIIA2415E

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Revision: December 20092009 QX56

Page 254 of 4171

![INFINITI QX56 2009 Factory Service Manual AV-68

< COMPONENT DIAGNOSIS >[AUDIO SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

AV CONTROL UNIT

AV CONTROL UNIT : Diagnosis ProcedureINFOID:0000000003776847

1.CHECK FUSES

C INFINITI QX56 2009 Factory Service Manual AV-68

< COMPONENT DIAGNOSIS >[AUDIO SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

AV CONTROL UNIT

AV CONTROL UNIT : Diagnosis ProcedureINFOID:0000000003776847

1.CHECK FUSES

C](/img/42/57031/w960_57031-253.png)

AV-68

< COMPONENT DIAGNOSIS >[AUDIO SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

AV CONTROL UNIT

AV CONTROL UNIT : Diagnosis ProcedureINFOID:0000000003776847

1.CHECK FUSES

Check that the following AV control unit fuses are not blown.

Are the fuses OK?

YES >> GO TO 2.

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.POWER SUPPLY CIRCUIT CHECK

1. Disconnect AV control unit connectors M42 and M45.

2. Check voltage between the AV control unit connectors M42 and M45 and ground.

Are the voltage results as specified?

YES >> GO TO 3.

NO >> • Check connector housings for disconnected or loose

terminals.

• Repair harness or connector.

3.GROUND CIRCUIT CHECK

Unit Terminals Signal name Fuse No.

AV c o n t r o l u n i t 19

Battery power 31

66

68

7 Ignition switch ACC or ON 4

69

79 Ignition switch ON or START 12

(+)

(-) OFF ACC ON

Connector Terminal

M42 7Ground0V

Battery

voltage Battery

voltage

19 Ground Battery

voltage Battery

voltage Battery

voltage

M45 66 Ground

Battery

voltage Battery

voltage Battery

voltage

68 Ground Battery

voltage Battery

voltage Battery

voltage

69 Ground 0V Battery

voltage Battery

voltage

79 Ground 0V 0V Battery

voltage

AWNIA1554ZZ

Revision: December 20092009 QX56

Page 256 of 4171

![INFINITI QX56 2009 Factory Service Manual AV-70

< COMPONENT DIAGNOSIS >[AUDIO SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

A/C AND AV SWITCH ASSEMBLY : Diagnosis Procedure

INFOID:0000000003776849

1.CHECK FUSE

Check that the A/C and AV switch assem INFINITI QX56 2009 Factory Service Manual AV-70

< COMPONENT DIAGNOSIS >[AUDIO SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

A/C AND AV SWITCH ASSEMBLY : Diagnosis Procedure

INFOID:0000000003776849

1.CHECK FUSE

Check that the A/C and AV switch assem](/img/42/57031/w960_57031-255.png)

AV-70

< COMPONENT DIAGNOSIS >[AUDIO SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

A/C AND AV SWITCH ASSEMBLY : Diagnosis Procedure

INFOID:0000000003776849

1.CHECK FUSE

Check that the A/C and AV switch assembly fuse is not blown.

Is the fuse OK?

YES >> GO TO 2.

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2.POWER SUPPLY CIRCUIT CHECK

1. Disconnect A/C and AV switch assembly connector M98.

2. Check voltage between the A/C and AV switch assembly con- nector M98 and ground.

Are the voltage results as specified?

YES >> GO TO 3.

NO >> • Check connector housings for disconnected or loose

terminals.

• Repair harness or connector.

3.GROUND CIRCUIT CHECK

1. Ignition OFF.

2. Check continuity between A/C and AV switch assembly harness connector M98 and ground.

Are the continuity results as specified?

YES >> Inspection End.

NO >> Repair A/C and AV switch assembly ground.

BOSE SPEAKER AMP

BOSE SPEAKER AMP : Diagnosis ProcedureINFOID:0000000003776850

1.CHECK FUSE

Check that the BOSE speaker amp. fuse is not blown.

Are the fuses OK?

YES >> GO TO 2.

NO >> Be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK POWER SUPPLY CIRCUIT

Unit Terminal Signal name Fuse No.

A/C and AV switch assembly 2Ignition switch ACC or ON 4

(+)

(-) OFF ACC ON

Connector Terminal

M98 2 Ground 0V Battery

voltage Battery

voltage

ALNIA0315GB

(+) (-) Continuity

Connector Terminal

M98 1 Ground Yes

ALNIA0316GB

Unit Terminal Signal name Fuse No.

BOSE speaker amp. 11Battery power 31

Revision: December 20092009 QX56

Page 258 of 4171

![INFINITI QX56 2009 Factory Service Manual AV-72

< COMPONENT DIAGNOSIS >[AUDIO SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between subwoofer harness connector B72

terminal 5 and ground.

Does continu INFINITI QX56 2009 Factory Service Manual AV-72

< COMPONENT DIAGNOSIS >[AUDIO SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between subwoofer harness connector B72

terminal 5 and ground.

Does continu](/img/42/57031/w960_57031-257.png)

AV-72

< COMPONENT DIAGNOSIS >[AUDIO SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between subwoofer harness connector B72

terminal 5 and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair harness or connector.

REAR VIEW CAMERA CONTROL UNIT

REAR VIEW CAMERA CONTRO L UNIT : Diagnosis ProcedureINFOID:0000000003776852

1.CHECK FUSE

Check that the following fuses of the rear view camera control unit are not blown.

Are the fuses OK?

YES >> GO TO 2.

NO >> Be sure to eliminate cause of malfunction before installing new fuse.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between rear view camera control unit harness con-

nector B73 and ground.

Are the voltage readings as specified?

YES >> GO TO 3.

NO >> Check harness between rear view camera control unit and fuse.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear view camera control unit connector.

3. Check continuity between rear view camera control unit harness connector B31 terminal 3 and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair harness or connector.

REAR VIEW CAMERA

(+) (-)Continuity

Connector Terminal

B72 5Ground Yes

ALNIA0368GB

Unit Terminals Signal name Fuse No.

Rear view camera control unit 1

Battery power 31

2 Ignition switch ACC or ON 4

Signal name Connector TerminalIgnition switch

position Value (Approx.)

Battery power supply B731OFF

Battery voltage

ACC power supply 2 ACC

ALLIA0244ZZ

(+)

(-) Continuity

Connector Terminal

B31 3 Ground Yes

ALLIA0245ZZ

Revision: December 20092009 QX56

Page 343 of 4171

![INFINITI QX56 2009 Factory Service Manual AV

NORMAL OPERATING CONDITIONAV-157

< SYMPTOM DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003776899

AUDIO SYSTEM

The majority of the au INFINITI QX56 2009 Factory Service Manual AV

NORMAL OPERATING CONDITIONAV-157

< SYMPTOM DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003776899

AUDIO SYSTEM

The majority of the au](/img/42/57031/w960_57031-342.png)

AV

NORMAL OPERATING CONDITIONAV-157

< SYMPTOM DIAGNOSIS > [AUDIO SYSTEM]

C

D

E

F

G H

I

J

K L

M B A

O P

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000003776899

AUDIO SYSTEM

The majority of the audio troubles are the result of outside causes (bad CD, electromagnetic interference,

etc.).

Noise

The following noise results from variations in field strength, such as fading noise and multi-path noise, or

external noise from trains and other sources. It is not a malfunction.

• Fading noise: This noise occurs because of variations in the field strength in a narrow range due to moun-

tains or buildings blocking the signal.

• Multi-path noise: This noise results from the waves sent directly from the broadcast station arriving at the antenna at a different time from the waves which reflect off mountains or buildings.

The vehicle itself can be a source of noise if noise prevention parts or electrical equipment is malfunctioning.

Check if noise is caused and/or changed by engine speed, ignition switch turned to each position, and opera-

tion of each piece of electrical equipment, and determine the cause.

NOTE:

The source of the noise can be found easily by listening to the noise while removing the fuses of electrical

components, one by one.

Type of Noise and Possible Cause

NAVIGATION SYSTEM

Basic Operation

Vehicle Mark

Occurrence condition Possible cause

Occurs only when engine is ON. A continuous growling noise occurs. The speed of

the noise varies with changes in the engine speed. • Ignition components

The occurrence of the noise is linked with the operation of the fuel pump. • Fuel pump condenser

Noise only occurs when various

electrical components are oper-

ating. A cracking or snapping sound occurs with the op-

eration of various switches.

• Relay malfunction, audio unit malfunction

The noise occurs when various motors are operat-

ing. • Motor case ground

•Motor

The noise occurs constantly, not just under certain conditions. • Rear defogger coil malfunction

• Open circuit in printed heater

• Poor ground of antenna feeder line

A cracking or snapping sound occurs while the vehicle is being driven, especially when

it is vibrating excessively. • Ground wire of body parts

• Ground due to improper part installation

• Wiring connections or a short circuit

Symptom

Cause Remedy

No image is shown. Display brightness adjustment is set fully to DARK

side. Adjust the display brightness.

No guide sound is heard.

Audio guide volume is too low or

too high. Volume control is set to OFF, MIN or MAX. Adjust the audio guide volume.

Audio guidance is not available while the vehicle is

driving on a dark pink route.

System is not malfunctioning.

Screen is too dark.

Motion of the image is too slow. Temperature inside the vehicle is low.

Wait until the temperature inside the vehicle

reaches the proper temperature.

Small black or bright spots appear

on the screen. Symptom peculiar to a liquid crystal display (dis-

play unit). System is not malfunction.

Revision: December 20092009 QX56

Page 406 of 4171

![INFINITI QX56 2009 Factory Service Manual

BCS-32

< COMPONENT DIAGNOSIS >[BCM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000003776413

1. CHECK FUSES AND FUSIBLE LINK

Check that the following INFINITI QX56 2009 Factory Service Manual

BCS-32

< COMPONENT DIAGNOSIS >[BCM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000003776413

1. CHECK FUSES AND FUSIBLE LINK

Check that the following](/img/42/57031/w960_57031-405.png)

BCS-32

< COMPONENT DIAGNOSIS >[BCM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis ProcedureINFOID:0000000003776413

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM.

3. Check voltage between BCM harness connector and ground.

Is the measurement value normal?

YES >> GO TO 3

NO >> Repair or replace harness.

3. CHECK GROUND CIRCUIT

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES >> Inspection End.

NO >> Repair or replace harness.

Terminal No. Signal name Fuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

Connector Te r m i n a l s

Power

source Condition Voltage (V) (Ap-

prox.)

(+) (-)

M18 11 Ground

ACC

power

supply Ignition

switch

ACC or

ON Battery voltage

38 Ground Ignition

power

supply Ignition

switch ON or START Battery voltage

M20 57 Ground

Battery

power

supply Ignition

switch OFF Battery voltage

70 Ground Battery

power

supply Ignition

switch

OFF Battery voltage

LIIA2415E

BCM

GroundContinuity

Connector Terminal

M20 67 Yes

LIIA0915E

Revision: December 20092009 QX56

Page 778 of 4171

DEF-10

< COMPONENT DIAGNOSIS >

REAR WINDOW DEFOGGER RELAY

REAR WINDOW DEFOGGER RELAY

DescriptionINFOID:0000000003776339

Power is supplied to the rear window defogger with BCM control.

Component Function CheckINFOID:0000000003776340

1. CHECK REAR WINDOW DEFOGGER RELAY POWER SUPPLY CIRCUIT

Check that an operation noise of rear window defogger re lay (located in IPDM E/R) can be heard when turning

the rear window defogger switch ON.

Is the inspection result normal?

YES >> Rear window defogger relay power supply circuit is OK.

NO >> Refer to DEF-10, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000003776341

1.CHECK FUSES

Check if any of the following fuses in the IPDM E/R are blown.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2. CHECK REAR WINDOW DEFOGGER RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R connector and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R".

NO >> GO TO 3

3. CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to GI-38, "

Intermittent Incident"

Is the inspection result normal?

YES >> Check the following.

• Battery power supply circuit.

• IPDM E/R.

NO >> Repair or replace the malfunctioning parts.

COMPONENT PARTS AMPEREFUSE NO.

IPDM E/R 15A46

IPDM E/R 15A47

Te r m i n a l s

Condition of rear

window defogger

switch Voltage (V)

(Approx.)

(+)

(–)

IPDM E/R con-

nector Te r m i n a l

E124 60 Ground ON Battery voltage

OFF 0

LIIA2190E

Revision: December 20092009 QX56

Page 880 of 4171

![INFINITI QX56 2009 Factory Service Manual DLK-68

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

INTELLIGENT KEY UNIT

INTELLIGENT KEY UNIT

: Diagnosis ProcedureINFOID:00000 INFINITI QX56 2009 Factory Service Manual DLK-68

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

INTELLIGENT KEY UNIT

INTELLIGENT KEY UNIT

: Diagnosis ProcedureINFOID:00000](/img/42/57031/w960_57031-879.png)

DLK-68

< COMPONENT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

INTELLIGENT KEY UNIT

INTELLIGENT KEY UNIT

: Diagnosis ProcedureINFOID:0000000003775726

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect Intelligent Key unit connector.

3. Check voltage between Intelligent Key unit harness connector M70 terminals 6, 11 and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> Repair or replace Intelligent Key unit power supply circuit.

2.CHECK GROUND CIRCUIT

Check continuity between Intelligent Key unit harness connector

M70 terminal 12 and ground.

Is the inspection result normal?

YES >> Power supply and ground circuits are OK.

NO >> Repair or replace the Intelligent Key unit ground circuit.

BCM (BODY CONTROL MODULE)

BCM (BODY CONTROL MODULE) : Diagnosis ProcedureINFOID:0000000004190660

1. CHECK FUSES AND FUSIBLE LINK

Check that the following fuses and fusible link are not blown.

Is the fuse blown?

YES >> Replace the blown fuse or fusible link after repairing the affected circuit.

NO >> GO TO 2

2. CHECK POWER SUPPLY CIRCUIT

Connector Terminals Ignition switch position

M70 (+) (–) OFF

ON

6 Ground 0V Battery voltage

11 Battery voltage Battery voltage

WIIA1171E

12 - Ground : Continuity should exist.

WIIA1172E

Terminal No. Signal nameFuses and fusible link No.

57 Battery power supply 22 (15A)

70 F (50A)

11 Ignition ACC or ON 4 (10A)

38 Ignition ON or START 59 (10A)

Revision: December 20092009 QX56

Page 1079 of 4171

![INFINITI QX56 2009 Factory Service Manual

P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

DLN-23

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

10A fuses No. 26 located in fuse and fusible link box and No. 59 locate INFINITI QX56 2009 Factory Service Manual

P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

DLN-23

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

10A fuses No. 26 located in fuse and fusible link box and No. 59 locate](/img/42/57031/w960_57031-1078.png)

P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

DLN-23

< COMPONENT DIAGNOSIS > [ATX14B]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

10A fuses No. 26 located in fuse and fusible link box and No. 59 located in the fuse and relay box.

20A fuse No. 53 located in the IPDM E/R.

Harness for short or open between battery and tr ansfer control unit harness connector terminals

47.

Harness for short or open between battery and transfer control unit harness connector terminal

29.

Harness for short or open between battery and transfer shut off relay harness connector E69 terminal 1, and 5.

Harness for short or open between transfer shut off relay harness connector E69 terminal 2 and transfer control unit harness connector terminal 30.

Harness for short or open between transfer shut off relay harness connector E69 terminal 3 and transfer control unit harness connector terminals 16 and 22.

Battery and ignition switch.

Transfer shut off relay. Refer to DLN-23, "Component Inspection"

.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Disconnect transfer control unit harness connector.

3. Check continuity between transfer control unit harness connec- tor E142 terminals 3, 6, E143 terminal 45 and ground.

Also check harness for short to ground and short to power.

Are the inspection results normal?

YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to DLN-81, "Reference Value"

.

Are the inspection results normal?

YES >> GO TO 4.

NO >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

4.CHECK DTC

Perform the self-diagnosis, after driving a vehicle for a while.

Are the inspection results normal?

YES >> Inspection End.

NO >> Replace transfer control unit. Refer to DLN-130, "Removal and Installation"

.

Component InspectionINFOID:0000000003772083

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Remove transfer shut off relay. Refer to DLN-16, "Component Parts Location"

.

3. Apply 12V direct current between transfer shut off relay termi- nals 1 and 2.

4. Check continuity between relay terminals 3 and 5.

5. If inspection results are abnormal replace the transfer shut off relay.Continuity should exist.

SDIA2691E

Condition Continuity

12V direct current supply between terminals 1 and 2 Yes

OFF No

SCIA1245E

Revision: December 20092009 QX56

Page 1958 of 4171

EXL-10

< FUNCTION DIAGNOSIS >

DAYTIME LIGHT SYSTEM

Component Description

INFOID:0000000003776151

After starting the engine with the parking brake released and the lighting switch in the OFF or 1ST position, the

headlamp high beam automatically turns on at a reduced intensity. With the lighting switch in the 2nd position

or with autolamps ON, the headlamps function the same as conventional light systems.

OPERATION

The BCM monitors inputs from the parking brake switch and the combination switch to determine when to acti-

vate the daytime light system. The BCM sends a dayti me light request to the IPDM E/R via the CAN commu-

nication lines. The IPDM E/R grounds the daytime light relay which in turn, provides power to the ground side

of the LH high beam lamp. Power flows backward through the LH high beam lamp to the IPDM E/R, through

the high beam fuses, through the RH high beam lamp circuit to the RH high beam lamp and on to ground. The

high beam lamps are wired in series which causes them to illuminate at a reduced intensity.

1. IPDM E/R E119, E122, E123, E124 2. BCM M18, M20 (view with instrument

panel removed)3. Daytime running light relay E103

4. Combination switch M28 5. Combination meter M23, M24 6. Parking brake switch M11

Revision: December 20092009 QX56