coolant level INFINITI QX56 2009 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1904 of 4171

ENGINE ASSEMBLYEM-81

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

• When replacing an engine or tr

ansmission you must make sure the dowels are installed correctly

during re-assembly.

• Improper alignment caused by missing dowels m ay cause vibration, oil leaks or breakage of driv-

etrain components.

INSPECTION AFTER INSTALLATION

• Before starting the engine, check oil/fluid levels including engine coolant and engine oil. If the levels are lower than required quantity, fill to the specified level. Refer to MA-12, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to the fuel piping, check for fuel leakage at the connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down the engine, again check oil/fluid levels including engine oil and engine coolant. Refill to specified level if necessary.

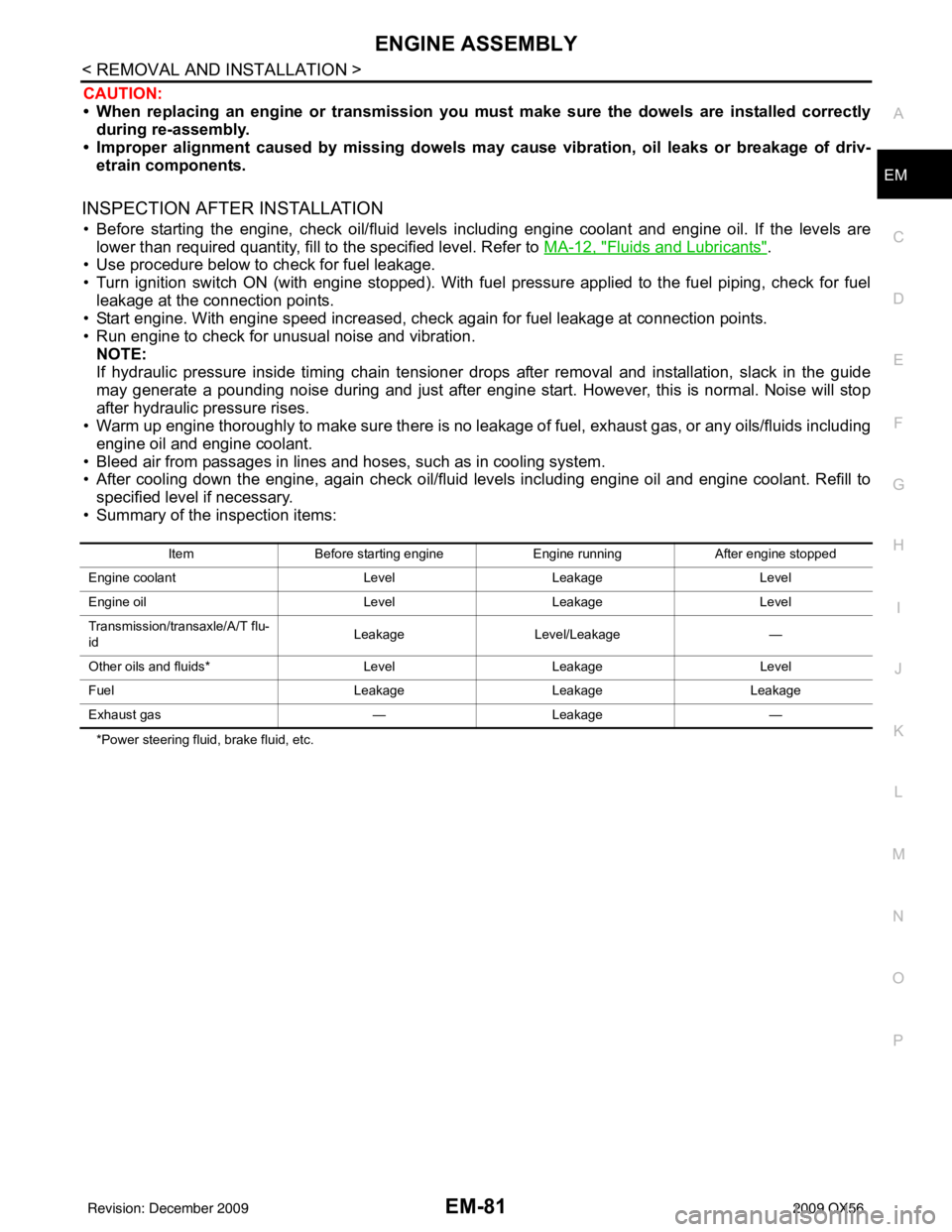

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/transaxle/A/T flu-

id Leakage

Level/Leakage —

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakage Leakage

Exhaust gas —Leakage —

Revision: December 20092009 QX56

Page 2091 of 4171

ADJUSTMENT AND INSPECTIONEXL-143

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

ON-VEHICLE REPAIR

ADJUSTMENT AND INSPECTION

HEADLAMP

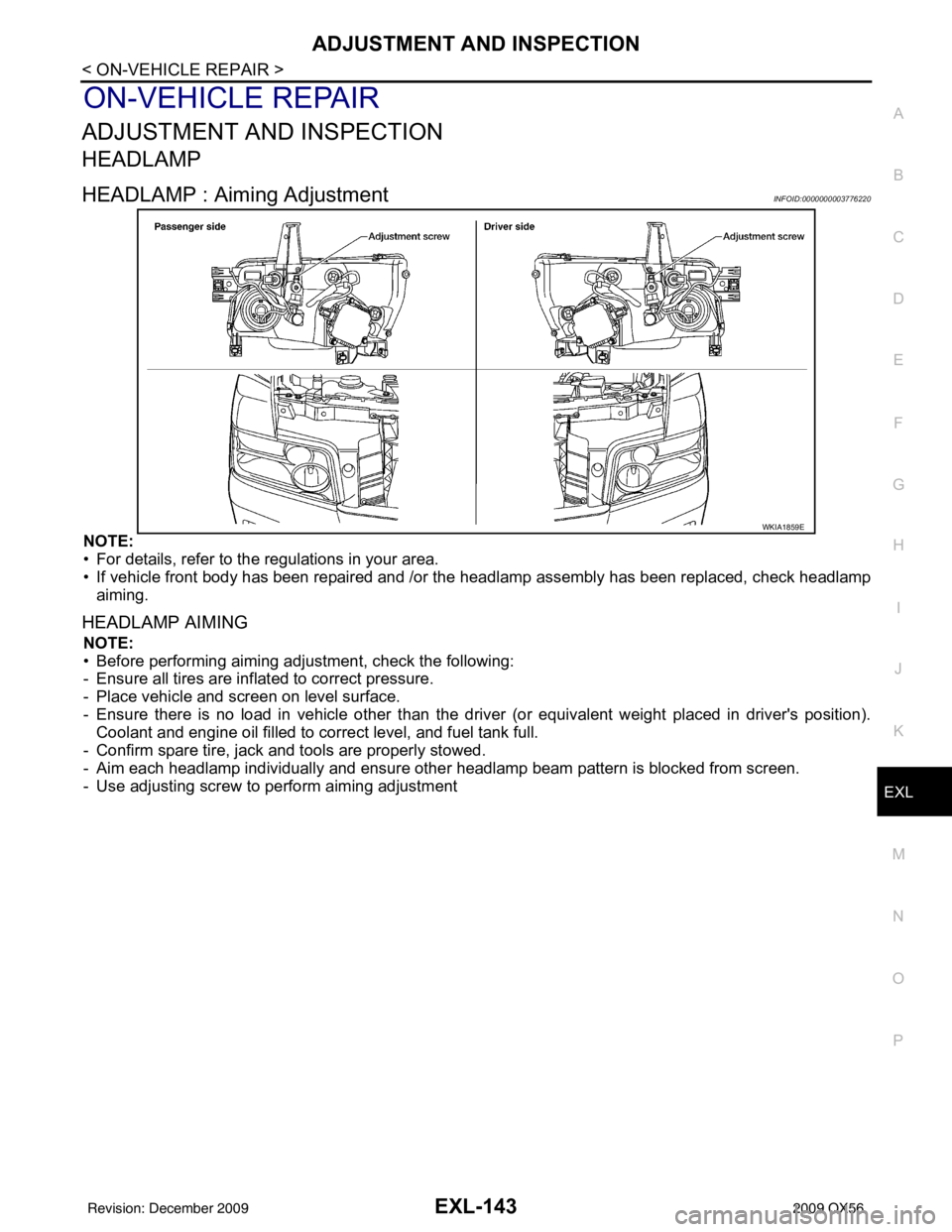

HEADLAMP : Aiming AdjustmentINFOID:0000000003776220

NOTE:

• For details, refer to the regulations in your area.

• If vehicle front body has been repaired and /or the headlamp assembly has been replaced, check headlamp

aiming.

HEADLAMP AIMING

NOTE:

• Before performing aiming adjustment, check the following:

- Ensure all tires are inflated to correct pressure.

- Place vehicle and screen on level surface.

- Ensure there is no load in vehicle other than the driver (or equivalent weight placed in driver's position). Coolant and engine oil filled to correct level, and fuel tank full.

- Confirm spare tire, jack and tools are properly stowed.

- Aim each headlamp individually and ensure other headlamp beam pattern is blocked from screen.

- Use adjusting screw to perform aiming adjustment

WKIA1859E

Revision: December 20092009 QX56

Page 2093 of 4171

ADJUSTMENT AND INSPECTIONEXL-145

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

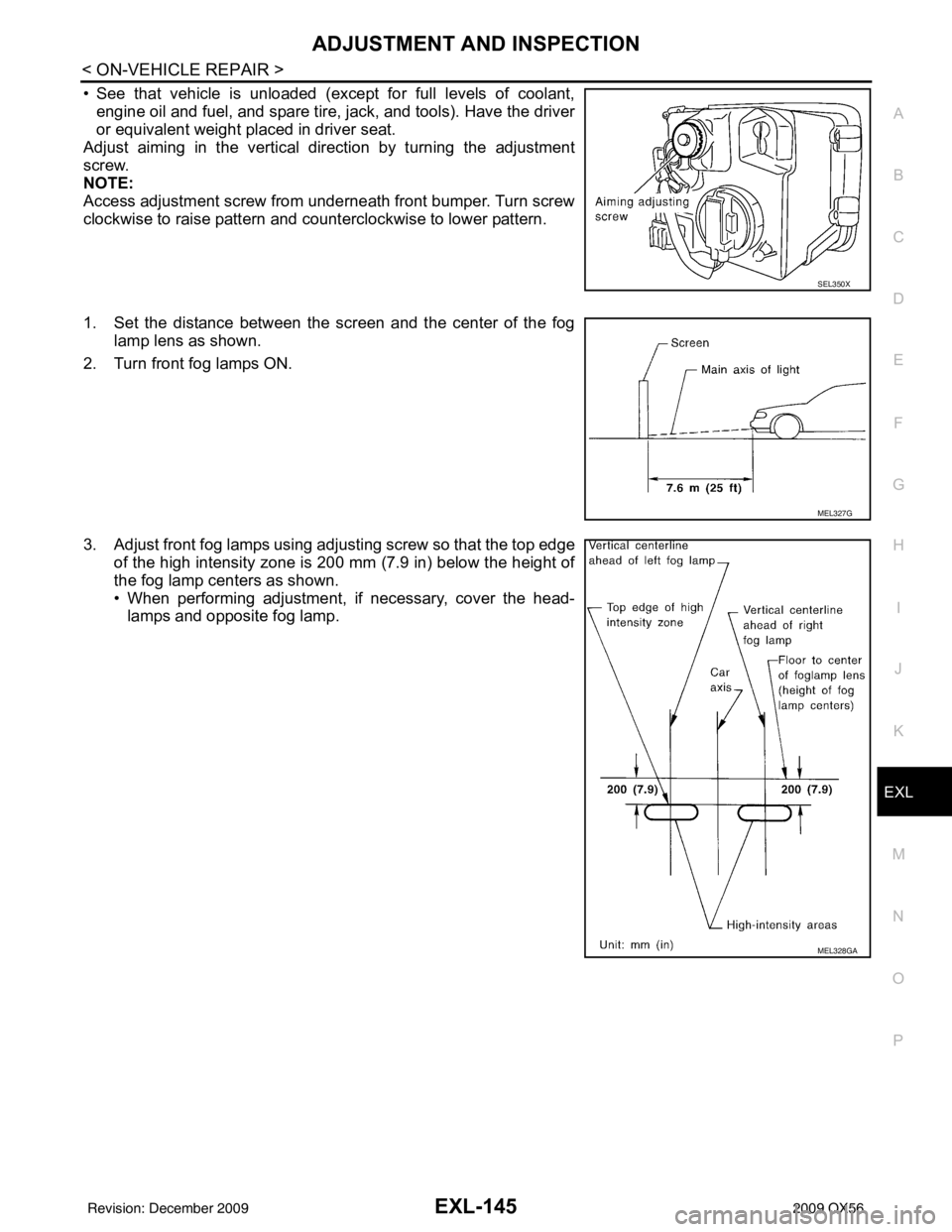

• See that vehicle is unloaded (except for full levels of coolant, engine oil and fuel, and spare tire, jack, and tools). Have the driver

or equivalent weight placed in driver seat.

Adjust aiming in the vertical direction by turning the adjustment

screw.

NOTE:

Access adjustment screw from underneath front bumper. Turn screw

clockwise to raise pattern and c ounterclockwise to lower pattern.

1. Set the distance between the screen and the center of the fog lamp lens as shown.

2. Turn front fog lamps ON.

3. Adjust front fog lamps using adjusting screw so that the top edge of the high intensity zone is 200 mm (7.9 in) below the height of

the fog lamp centers as shown.

• When performing adjustment, if necessary, cover the head-lamps and opposite fog lamp.

SEL350X

MEL327G

MEL328GA

Revision: December 20092009 QX56

Page 2173 of 4171

PRECAUTIONSFSU-3

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

PrecautionINFOID:0000000003772265

• When installing the rubber bushings, the final tightening must be done under unladen condition and with the

tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Lock nuts are not reusable. Always use new lock nuts for installation. New lock nuts are pre-oiled, do not

apply any additional lubrication.

Revision: December 20092009 QX56

Page 2176 of 4171

FSU-6

< ON-VEHICLE MAINTENANCE >

ON-VEHICLE SERVICE

ON-VEHICLE MAINTENANCE

ON-VEHICLE SERVICE

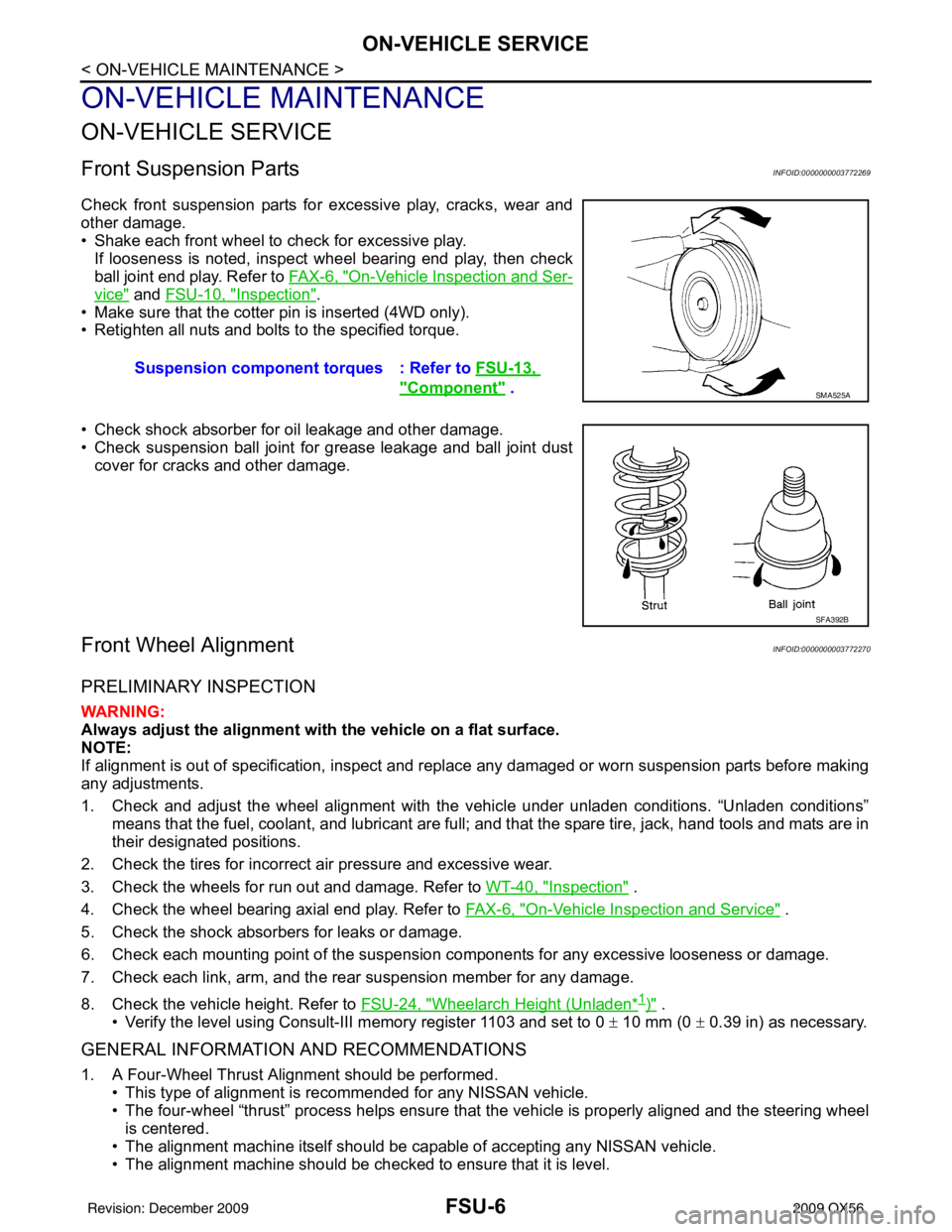

Front Suspension PartsINFOID:0000000003772269

Check front suspension parts for excessive play, cracks, wear and

other damage.

• Shake each front wheel to check for excessive play.If looseness is noted, inspect wheel bearing end play, then check

ball joint end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Ser-

vice" and FSU-10, "Inspection".

• Make sure that the cotter pin is inserted (4WD only).

• Retighten all nuts and bolts to the specified torque.

• Check shock absorber for oil leakage and other damage.

• Check suspension ball joint for grease leakage and ball joint dust cover for cracks and other damage.

Front Wheel AlignmentINFOID:0000000003772270

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specificat ion, inspect and replace any damaged or worn suspension parts before making

any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-40, "

Inspection" .

4. Check the wheel bearing axial end play. Refer to FA X - 6 , "

On-Vehicle Inspection and Service" .

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer to FSU-24, "

Wheelarch Height (Unladen*1)" .

• Verify the level using Consult-III memory register 1103 and set to 0 ± 10 mm (0 ± 0.39 in) as necessary.

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be ca pable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level. Suspension component

torques : Refer to FSU-13,

"Component" . SMA525A

SFA392B

Revision: December 20092009 QX56

Page 2194 of 4171

FSU-24

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

*2: Target value 37° 31 ′ (37.52 °)

*3: Target value 33 ° 59 ′ (33.98 °)

*4: Target value 37 ° 44 ′ (37.73 °)

*5: Target value 33 ° 29 ′ (33.48 °)

*6 Some vehicles may not be equipped with straight (non-adjustable) lower link bolts and washers. In order to adjust camber and caster

on these vehicles, first replace the lower link bolts and washers with adjustable (cam) bolts and washers

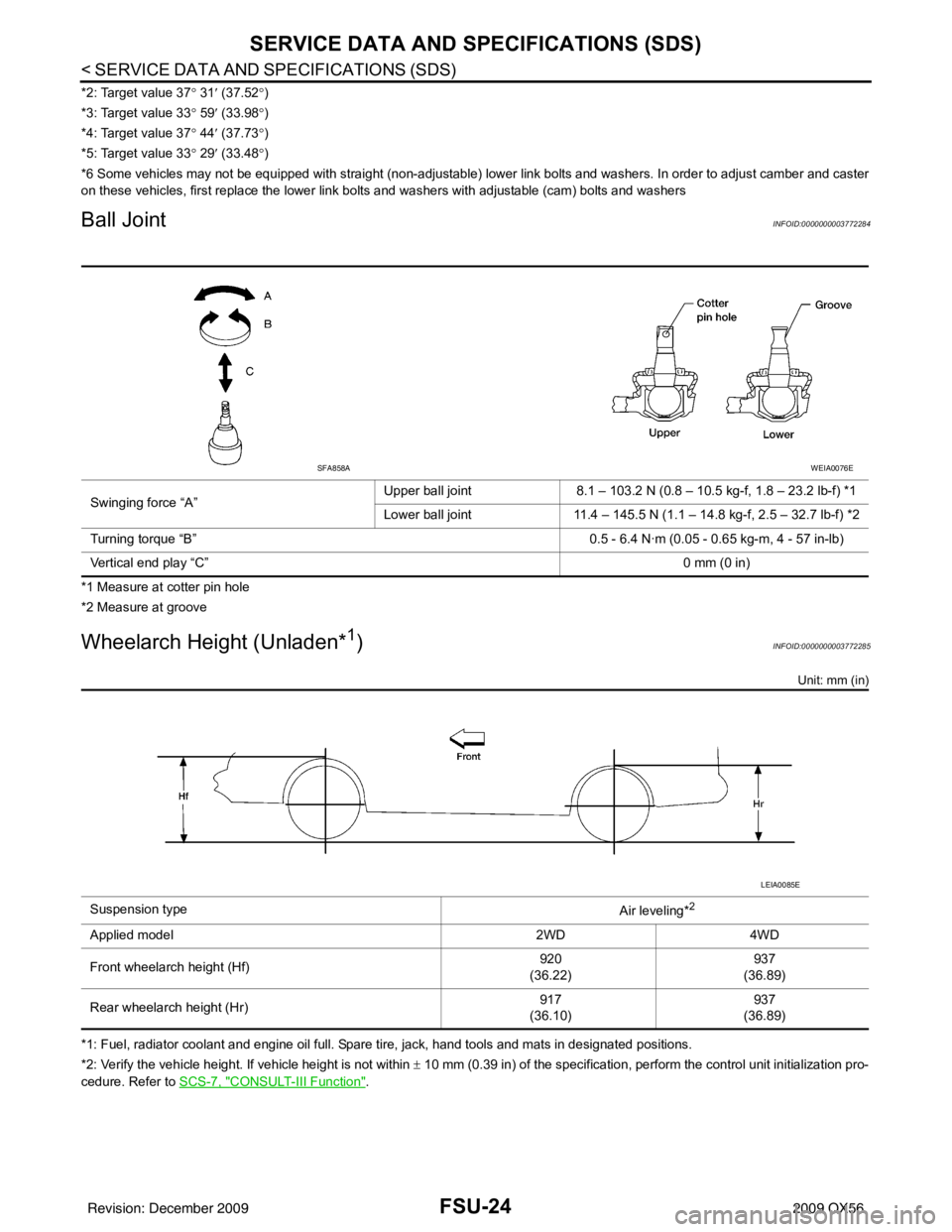

Ball JointINFOID:0000000003772284

*1 Measure at cotter pin hole

*2 Measure at groove

Wheelarch Height (Unladen*1)INFOID:0000000003772285

Unit: mm (in)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Verify the vehicle height. If vehicle height is not within ± 10 mm (0.39 in) of the specification, perform the control unit initialization pro-

cedure. Refer to SCS-7, "

CONSULT-III Function".

Swinging force “A”

Upper ball joint

8.1 – 103.2 N (0.8 – 10.5 kg-f, 1.8 – 23.2 lb-f) *1

Lower ball joint 11.4 – 145.5 N (1.1 – 14.8 kg-f, 2.5 – 32.7 lb-f) *2

Turning torque “B” 0.5 - 6.4 N·m (0.05 - 0.65 kg-m, 4 - 57 in-lb)

Vertical end play “C” 0 mm (0 in)

SFA858AWEIA0076E

Suspension type

Air leveling*2

Applied model2WD4WD

Front wheelarch height (Hf) 920

(36.22) 937

(36.89)

Rear wheelarch height (Hr) 917

(36.10) 937

(36.89)

LEIA0085E

Revision: December 20092009 QX56

Page 2431 of 4171

![INFINITI QX56 2009 Factory Owners Manual HAC-118

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000003775396

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFI INFINITI QX56 2009 Factory Owners Manual HAC-118

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000003775396

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFI](/img/42/57031/w960_57031-2430.png)

HAC-118

< SYMPTOM DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

INSUFFICIENT HEATING

INSUFFICIENT HEATING

Component Function CheckINFOID:0000000003775396

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPER

ATIONAL CHECK - TEMPERATURE INCREASE

1. Press the AUTO switch.

2. Turn the temperature control dial (driver) clockwise until 32 °C (90° F) is displayed.

3. Check for hot air at discharge air outlets.

Can this symptom be duplicated?

YES >> GO TO 2.

NO >> Perform complete system operational check. Refer to HAC-4, "

Operational Check (Front)".

2.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

3.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to HAC-23, "

A/C Auto Amp. Self-Diagnosis".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Refer to HAC-24, "

A/C System Self-Diagnosis Code Chart".

4.CHECK ENGINE COOLING SYSTEM

1. Check for proper engine coolant level. Refer to CO-10, "

Inspection".

2. Check hoses for leaks or kinks.

3. Check radiator cap. Refer to CO-10, "

Inspection".

4. Check for air in cooling system.

>> GO TO 5.

5.CHECK AIR MIX DOOR OPERATION

Check the operation of the air mix door.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Check the air mix door motor circuit. Refer to HAC-32, "

Air Mix Door Motor Component Function

Check".

6.CHECK AIR DUCTS

Check for disconnected or leaking air ducts.

Is the inspection result normal?

YES >> GO TO 7.

NO >> Repair all disconnected or leaking air ducts.

7.CHECK HEATER HOSE TEMPERATURES

1. Start engine and warm it up to normal operating temperature.

2. Touch both the inlet and outlet heater hoses.

Is the inspection result normal?

YES >> Hot inlet hose and a warm outlet hose: GO TO 8.

NO >> • Inlet hose cold: GO TO 11. • Both hoses warm: GO TO 9.

8.CHECK ENGINE COOLANT SYSTEM

Check engine control temperature sensor. Refer to EC-122, "

Component Inspection".

Revision: December 20092009 QX56

Page 2663 of 4171

LU-8

< ON-VEHICLE MAINTENANCE >

ENGINE OIL

ON-VEHICLE MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000003771270

OIL LEVEL

• Before starting the engine make sure the vehicle is parked on a flatand level surface, then check the oil level. If the engine is already

running, turn it off and allow 10 minutes before checking.

• Check that the oil level is within the low (L) and high (H) range as indicated on the dipstick.

• If the engine oil level is out of range, add oil as necessary. Refer to

MA-12, "

Fluids and Lubricants".

OIL APPEARANCE

• Check the engine oil for a white milky appearance or excessive contamination.

• If the engine oil is milky, it is highly probable that it is contaminated with engine coolant. Repair the broken

parts.

OIL LEAKAGE

Check for oil leakage around the following areas:

•Oil pan

• Oil pan drain plug

• Oil pressure switch

• Oil filter

• Oil cooler

• Intake valve timing control cover

• Intake valve timing control solenoid valve

• Front cover

• Mating surface between cylinder block and cylinder head

• Mating surface between cylinder head and rocker cover

• Crankshaft oil seal (front and rear)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• Put the A/T shift selector in the Park “P” position.

1. Check the engine oil level. Refer to LU-8, "

Inspection".

2. Remove engine front undercover using power tool.

3. Disconnect the oil pressure switch harness connector.

4. Remove the oil pressure switch (A).

SMA954C

WBIA0791E

Revision: December 20092009 QX56

Page 2668 of 4171

OIL COOLERLU-13

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

Relief Valve

Inspect relief valve for movement, cracks and breaks by

pushing the ball. If replacement is necessary, remove

the valve by prying it out using a suitable tool. Install a new valve in place by tapping it.

INSTALLATION

Installation is in the reverse order of removal, paying attention to the following:

• Confirm that no foreign objects are adhering to the sealing sur- faces of the oil cooler or oil pan.

• Tighten the connecting bolt after aligning the stopper on the oil pan side with protrusion of the oil cooler.

INSPECTION AFTER INSTALLATION

1. Check levels and add engine oil and engine coolant. Refer to LU-8, "Inspection" and CO-10, "Inspection".

2. Start the engine, and check for leaks of engine oil and engine coolant.

3. Stop the engine and wait for 10 minutes.

4. Check engine oil level and engine coolant level again.

KBIA2500E

Revision: December 20092009 QX56

Page 2674 of 4171

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K L

M B

MA

SECTION MA

N

O A

CONTENTS

MAINTENANCE

PRECAUTION .......

........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

ON-VEHICLE MAINTENANCE .....................6

GENERAL MAINTE NANCE ........................... .....6

General Maintenance .......................................... ......6

PERIODIC MAINTENANCE ................................8

Introduction of Periodic Maintenance .................. ......8

Maintenance for Off-road Driving (4WD only) ...........8

Schedule 1 ................................................................8

Schedule 2 ..............................................................10

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

12

Fluids and Lubricants .......................................... ....12

Engine Oil Recommendation ..................................13

ENGINE MAINTENANCE ...................................14

Checking Drive Belts ........................................... ....14

Changing Engine Coolant .......................................14

Checking Fuel Line .............................................. ....17

Changing Fuel Filter ................................................17

Changing Engine Air Cleaner Filter .........................17

Changing Engine Oil ................................................18

Changing Oil Filter ...................................................18

Changing Spark Plugs .............................................19

Checking EVAP Vapor Line .....................................20

CHASSIS AND BODY MAINTENANCE ...........22

Changing In-cabin Microfilter ............................... ....22

Checking Exhaust System .......................................22

Checking the A/T Fluid (ATF) ..................................23

Changing the A/T Fluid (ATF) ..................................24

Checking Transfer Fluid ..........................................25

Changing Transfer Fluid ..........................................26

Checking Propeller Shaft .........................................26

Checking Front Final Drive Oil .................................26

Changing Front Final Drive Oil ................................27

Checking Rear Final Drive Oil .................................27

Changing Rear Final Drive Oil .................................27

Balancing Wheels ....................................................28

Rotation ...................................................................29

Checking Brake Fluid Level and Leaks ...................30

Checking Brake Line and Cables ............................30

Checking Disc Brake ...............................................30

Checking Steering Gear and Linkage ......................31

Checking Power Steering Fluid and Line ................31

Checking Axle and Suspension Parts .....................32

Lubricating Locks, Hinges and Hood Latches .........33

Checking Seat Belts, Buckles, Retractors, An-

chors and Adjusters ............................................. ....

33

Revision: December 20092009 QX56