steering wheel adjustment INFINITI QX56 2009 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2184 of 4171

FSU-14

< REMOVAL AND INSTALLATION >

COIL SPRING AND SHOCK ABSORBER

REMOVAL AND INSTALLATION

COIL SPRING AND SHOCK ABSORBER

Removal and InstallationINFOID:0000000003772274

REMOVAL

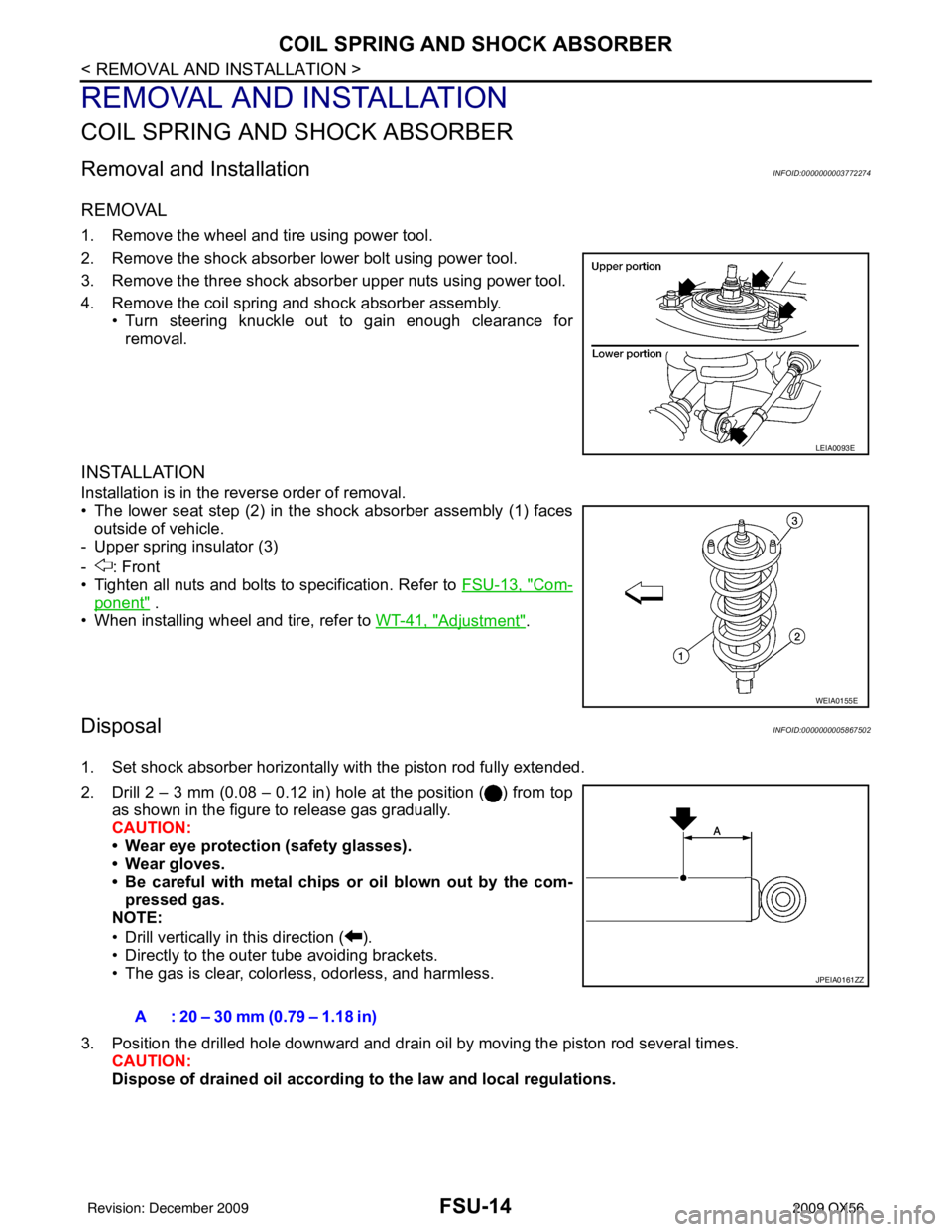

1. Remove the wheel and tire using power tool.

2. Remove the shock absorber lower bolt using power tool.

3. Remove the three shock absorber upper nuts using power tool.

4. Remove the coil spring and shock absorber assembly.• Turn steering knuckle out to gain enough clearance forremoval.

INSTALLATION

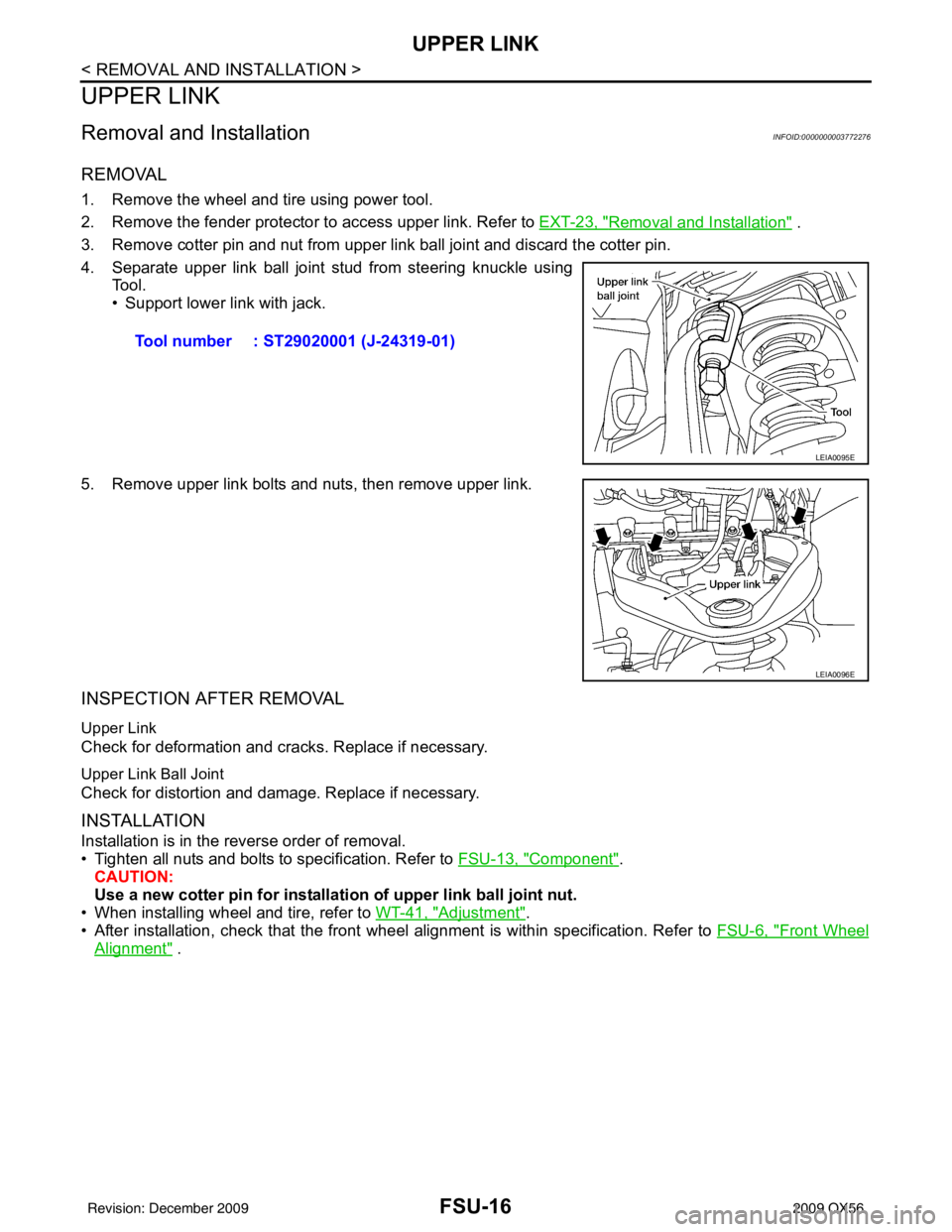

Installation is in the reverse order of removal.

• The lower seat step (2) in the shock absorber assembly (1) faces

outside of vehicle.

- Upper spring insulator (3)

- : Front

• Tighten all nuts and bolts to specification. Refer to FSU-13, "

Com-

ponent" .

• When installing wheel and tire, refer to WT-41, "

Adjustment".

DisposalINFOID:0000000005867502

1. Set shock absorber horizontally with the piston rod fully extended.

2. Drill 2 – 3 mm (0.08 – 0.12 in) hole at the position ( ) from top

as shown in the figure to release gas gradually.

CAUTION:

• Wear eye protection (safety glasses).

• Wear gloves.

• Be careful with metal chips or oil blown out by the com-pressed gas.

NOTE:

• Drill vertically in this direction ( ).

• Directly to the outer tube avoiding brackets.

• The gas is clear, colorless, odorless, and harmless.

3. Position the drilled hole downward and drain oil by moving the piston rod several times. CAUTION:

Dispose of drained oil according to the law and local regulations.

LEIA0093E

WEIA0155E

A : 20 – 30 mm (0.79 – 1.18 in)

JPEIA0161ZZ

Revision: December 20092009 QX56

Page 2186 of 4171

FSU-16

< REMOVAL AND INSTALLATION >

UPPER LINK

UPPER LINK

Removal and InstallationINFOID:0000000003772276

REMOVAL

1. Remove the wheel and tire using power tool.

2. Remove the fender protector to access upper link. Refer to EXT-23, "

Removal and Installation" .

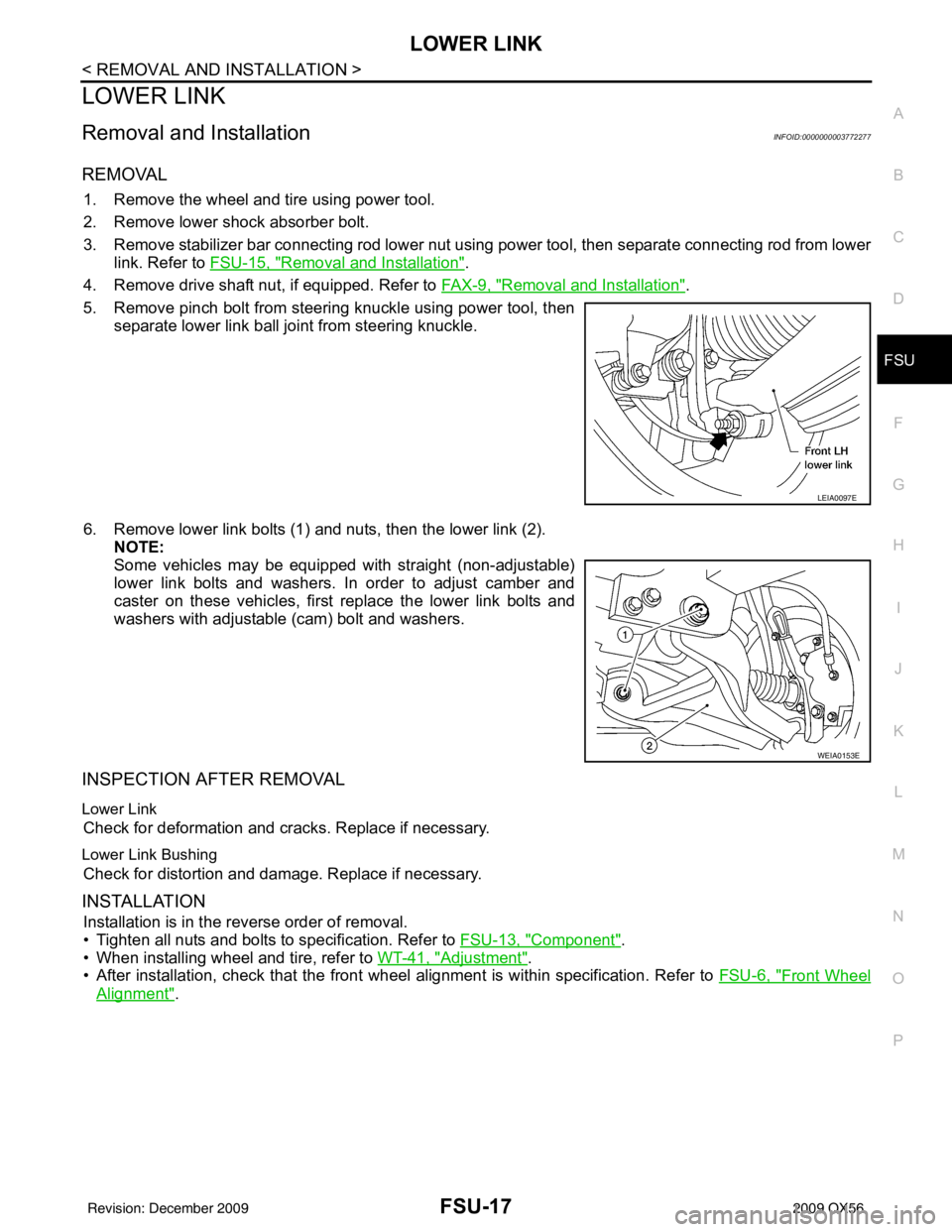

3. Remove cotter pin and nut from upper link ball joint and discard the cotter pin.

4. Separate upper link ball joint stud from steering knuckle using Tool.

• Support lower link with jack.

5. Remove upper link bolts and nuts, then remove upper link.

INSPECTION AFTER REMOVAL

Upper Link

Check for deformation and cracks. Replace if necessary.

Upper Link Ball Joint

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten all nuts and bolts to specification. Refer to FSU-13, "

Component".

CAUTION:

Use a new cotter pin for installation of upper link ball joint nut.

• When installing wheel and tire, refer to WT-41, "

Adjustment".

• After installation, check that the front wheel alignment is within specification. Refer to FSU-6, "

Front Wheel

Alignment" .

Tool number : ST29020001 (J-24319-01)

LEIA0095E

LEIA0096E

Revision: December 20092009 QX56

Page 2187 of 4171

LOWER LINKFSU-17

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

LOWER LINK

Removal and InstallationINFOID:0000000003772277

REMOVAL

1. Remove the wheel and tire using power tool.

2. Remove lower shock absorber bolt.

3. Remove stabilizer bar connecting rod lower nut using power tool, then separate connecting rod from lower

link. Refer to FSU-15, "

Removal and Installation".

4. Remove drive shaft nut, if equipped. Refer to FA X - 9 , "

Removal and Installation".

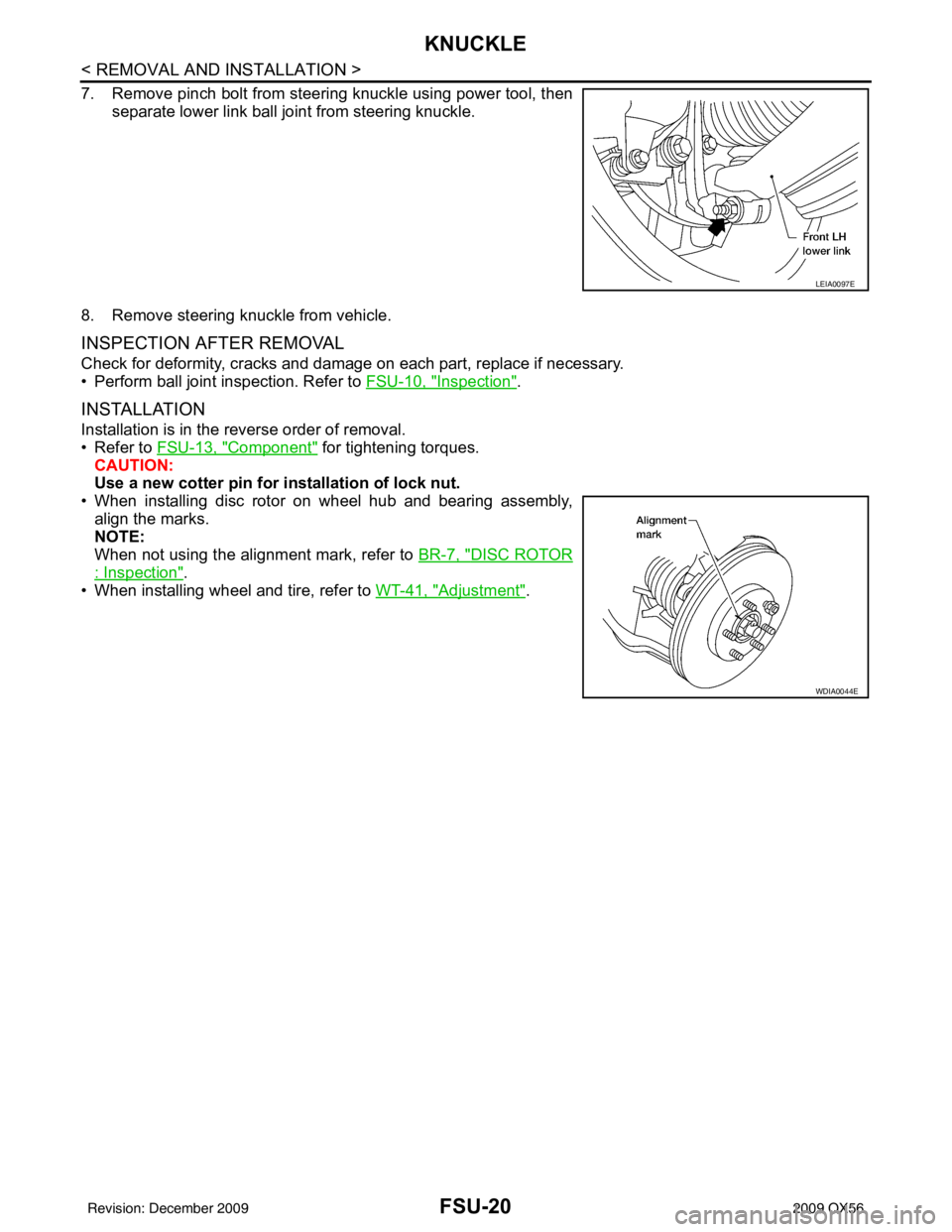

5. Remove pinch bolt from steering knuckle using power tool, then separate lower link ball joint from steering knuckle.

6. Remove lower link bolts (1) and nuts, then the lower link (2). NOTE:

Some vehicles may be equipped with straight (non-adjustable)

lower link bolts and washers. In order to adjust camber and

caster on these vehicles, first replace the lower link bolts and

washers with adjustable (cam) bolt and washers.

INSPECTION AFTER REMOVAL

Lower Link

Check for deformation and cracks. Replace if necessary.

Lower Link Bushing

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten all nuts and bolts to specification. Refer to FSU-13, "

Component".

• When installing wheel and tire, refer to WT-41, "

Adjustment".

• After installation, check that the front wheel alignment is within specification. Refer to FSU-6, "

Front Wheel

Alignment".

LEIA0097E

WEIA0153E

Revision: December 20092009 QX56

Page 2190 of 4171

FSU-20

< REMOVAL AND INSTALLATION >

KNUCKLE

7. Remove pinch bolt from steering knuckle using power tool, thenseparate lower link ball joint from steering knuckle.

8. Remove steering knuckle from vehicle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessary.

• Perform ball joint inspection. Refer to FSU-10, "

Inspection".

INSTALLATION

Installation is in the reverse order of removal.

• Refer to FSU-13, "

Component" for tightening torques.

CAUTION:

Use a new cotter pin for installation of lock nut.

• When installing disc rotor on wheel hub and bearing assembly, align the marks.

NOTE:

When not using the alignment mark, refer to BR-7, "

DISC ROTOR

: Inspection".

• When installing wheel and tire, refer to WT-41, "

Adjustment".

LEIA0097E

WDIA0044E

Revision: December 20092009 QX56

Page 2679 of 4171

MA-6

< ON-VEHICLE MAINTENANCE >

GENERAL MAINTENANCE

ON-VEHICLE MAINTENANCE

GENERAL MAINTENANCE

General MaintenanceINFOID:0000000003776979

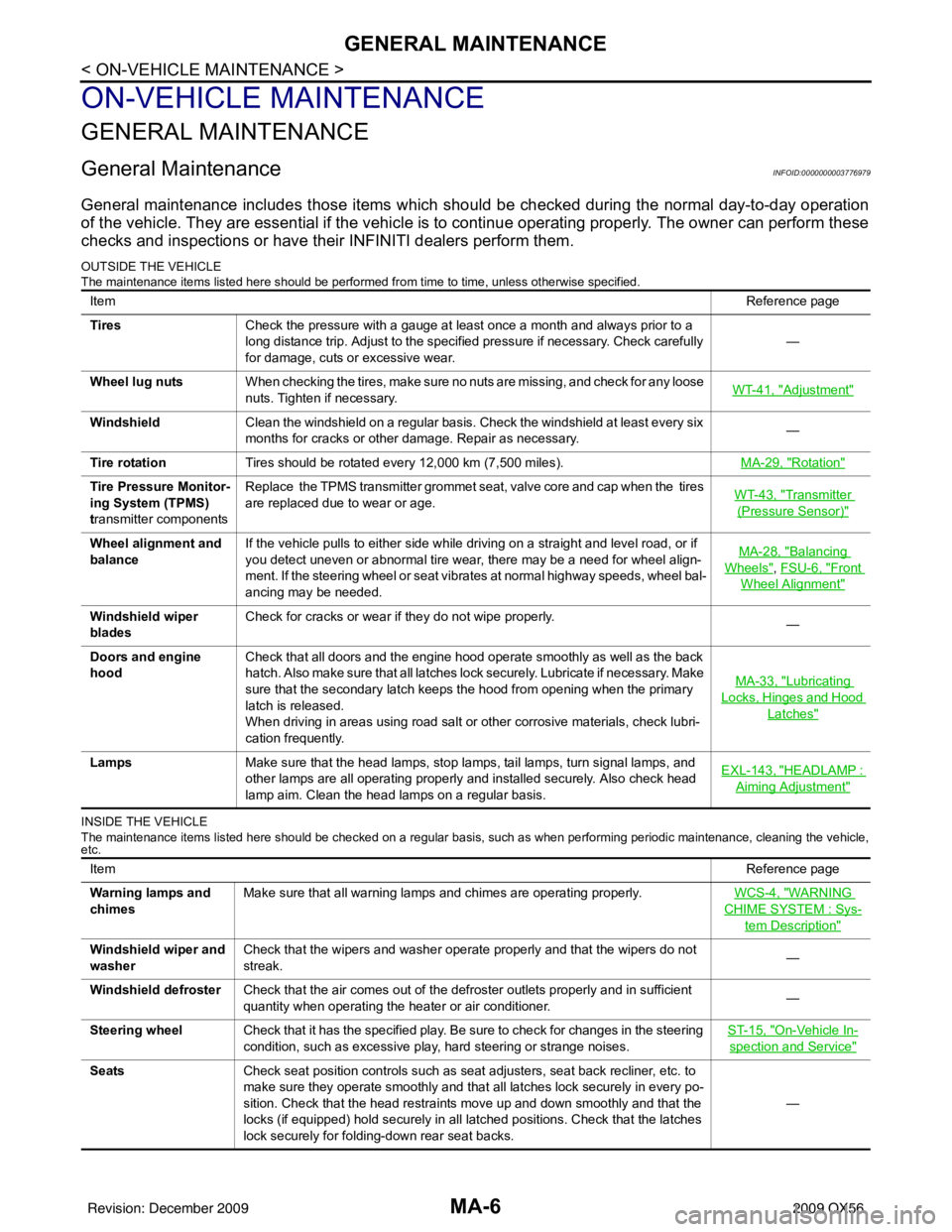

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owner can perform these

checks and inspections or have thei r INFINITI dealers perform them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge at least once a month and always prior to a

long distance trip. Adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear. —

Wheel lug nuts When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-41, "

Adjustment"

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Tire rotation Tires should be rotated every 12,000 km (7,500 miles). MA-29, "

Rotation"

Tire Pressure Monitor-

ing System (TPMS)

transmitter componentsReplace the TPMS transmitter grommet seat, valve core and cap when the tires

are replaced due to wear or age.

WT-43, "Transmitter

(Pressure Sensor)"

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel bal-

ancing may be needed. MA-28, "Balancing

Wheels", FSU-6, "Front

Wheel Alignment"

Windshield wiper

blades

Check for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-33, "

Lubricating

Locks, Hinges and Hood

Latches"

Lamps

Make sure that the head lamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head

lamp aim. Clean the head lamps on a regular basis. EXL-143, "HEADLAMP :

Aiming Adjustment"

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly.

WCS-4, "

WARNING

CHIME SYSTEM : Sys-

tem Description"

Windshield wiper and

washerCheck that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Be sure to check for changes in the steering

condition, such as excessive play, hard steering or strange noises. ST-15, "

On-Vehicle In-

spection and Service"

Seats

Check seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs. —

Revision: December 20092009 QX56

Page 2872 of 4171

PG

PG-1

ELECTRICAL & POWER CONTROL

C

DE

F

G H

I

J

K L

B

SECTION PG

A

O P

N

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

PRECAUTION .......

........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Power Generation Variable Voltage

Control System ..........................................................

3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

BASIC INSPECTION ....................................5

BATTERY ....................................................... .....5

How to Handle Battery ........................................ ......5

Work Flow ........................................................... ......7

INSPECTION AND ADJUSTMENT .....................8

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL ............................... ......

8

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL : Special Re-

pair Requirement ................................................. ......

8

COMPONENT DIAGNOSIS ..........................9

POWER SUPPLY ROUTING CIRCUIT .......... .....9

Wiring Diagram — Battery Power Supply — ....... ......9

Wiring Diagram — Accessory Power Supply — .....18

Wiring Diagram — Ignition Power Supply — ..........22

Fuse ........................................................................30

Fusible Link ......................................................... ....30

GROUND ...........................................................31

Ground Distribution ..................................................31

HARNESS .........................................................41

Harness Layout ................................................... ....41

ELECTRICAL UNITS LOCATION ....................64

Electrical Units Location ..........................................64

HARNESS CONNECTOR .................................67

Description ...............................................................67

STANDARDIZED RELAY .................................70

Description ...............................................................70

FUSE BLOCK - JUNCTION BOX (J/B) ............72

Terminal Arrangement .............................................72

FUSE, FUSIBLE LINK AND RELAY BOX ........73

Terminal Arrangement .............................................73

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) ................

75

IPDM E/R Terminal Arrangement ............................75

ON-VEHICLE REPAIR .................................76

BATTERY ..........................................................76

Removal and Installation ..................................... ....76

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

77

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

77

Battery ................................................................. ....77

Revision: December 20092009 QX56

Page 3423 of 4171

SN

SN-1

DRIVER INFORMATION & MULTIMEDIA

C

DE

F

G H

I

J

K L

M B

SECTION SN

A

O P

CONTENTS

SONAR SYSTEM

BASIC INSPECTION ....... .............................3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

INSPECTION AND ADJUSTMENT .....................5

Preliminary Check ............................................... ......5

FUNCTION DIAGNOSIS ...............................6

REAR SONAR SYSTEM ................................ .....6

System Diagram .................................................. ......6

System Description ...................................................6

Component Parts Location ........................................7

Component Description .............................................7

Self-Diagnosis Function ............................................7

FRONT AND REAR SONAR SYSTEM .......... ....10

System Diagram .................................................. ....10

System Description .................................................10

Component Parts Location ......................................11

Component Description ...........................................12

CONSULT-III Function (SONAR) ............................12

COMPONENT DIAGNOSIS .........................13

POWER SUPPLY AND GROUND CIRCUIT .. ....13

Diagnosis Procedure (With Rear Sonar System) ....13

Diagnosis Procedure (With Front and Rear Sonar

System) ............................................................... ....

13

SONAR SENSOR CIRCUIT INSPECTION ........15

Description .......................................................... ....15

Diagnosis Procedure (With Rear Sonar System) ....15

Diagnosis Procedure (With Front and Rear Sonar

System) ...................................................................

15

SONAR BUZZER CIRCUIT INSPECTION .........17

Description .......................................................... ....17

Diagnosis Procedure (With Rear Sonar System) ....17

Diagnosis Procedure (With Front and Rear Sonar

System) ...................................................................

17

Component Inspection ......................................... ....18

SONAR SYSTEM OFF SWITCH CIRCUIT IN-

SPECTION ........................................................

19

Description ........................................................... ....19

Diagnosis Procedure (With Rear Sonar System) ....19

Diagnosis Procedure (With Front and Rear Sonar

System) ............................................................... ....

19

Component Inspection .............................................20

ECU DIAGNOSIS .........................................21

SONAR CONTROL UNIT FOR REAR SONAR

SYSTEM ...................... ......................................

21

Reference Value .................................................. ....21

Wiring Diagram ........................................................23

DTC Index ...............................................................30

SONAR CONTROL UNIT FOR FRONT AND

REAR SONAR SYSTEM ...................................

31

Reference Value ......................................................31

Wiring Diagram ........................................................33

DTC Index ...............................................................44

SYMPTOM DIAGNOSIS ..............................45

SONAR SYSTEM SYMPTOMS ........................45

Symptom Table ................................................... ....45

PRECAUTION ..............................................46

PRECAUTION ...................................................46

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ....

46

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

46

PREPARATION ...........................................48

PREPARATION .................................................48

Commercial Service Tool .................................... ....48

Revision: December 20092009 QX56

Page 3481 of 4171

SR-8

< ON-VEHICLE REPAIR >

SPIRAL CABLE

5. While pressing tabs, pull lighting and turn signal switch towarddriver door and disconnect from base.

6. Remove the screws, release the clip, and remove the spiral cable.

CAUTION:

• Do not disassemble spiral cable.

• Do not apply lubricant to the spiral cable.

7. Remove the spiral cable connectors. CAUTION:

With the steering linkage di sconnected, the spiral cable

may snap by turning the steer ing wheel beyond the limited

number of turns. The spiral cable can be turned counter-

clockwise about 2.5 turns fr om the neutral position.

8. Remove the steering angle sensor. Refer to BRC-118, "

Removal

and Installation".

INSTALLATION

Installation is in the reverse order of removal.

• Align spiral cable correctly when installing steering wheel. Make

sure that the spiral cable is in the neutral position. The neutral

position is detected by turning left 2.5 revolutions from the right

end position and ending with the knob at the top.

• If equipped with VDC, refer to BRC-8, "

ADJUSTMENT OF STEER-

ING ANGLE SENSOR NEUTRAL POSITION : Special Repair

Requirement" for steering angle sensor adjustment.

• After the work is completed, perform self-diagnosis to make sure no malfunction is detected. Refer to SRC-13, "

SRS Operation

Check".

CAUTION:

LHIA0035E

LHIA0036E

SHIA0193E

WGIA0038E

Revision: December 20092009 QX56

Page 3609 of 4171

ST-18

< REMOVAL AND INSTALLATION >

STEERING WHEEL

REMOVAL AND INSTALLATION

STEERING WHEEL

Removal and InstallationINFOID:0000000004187593

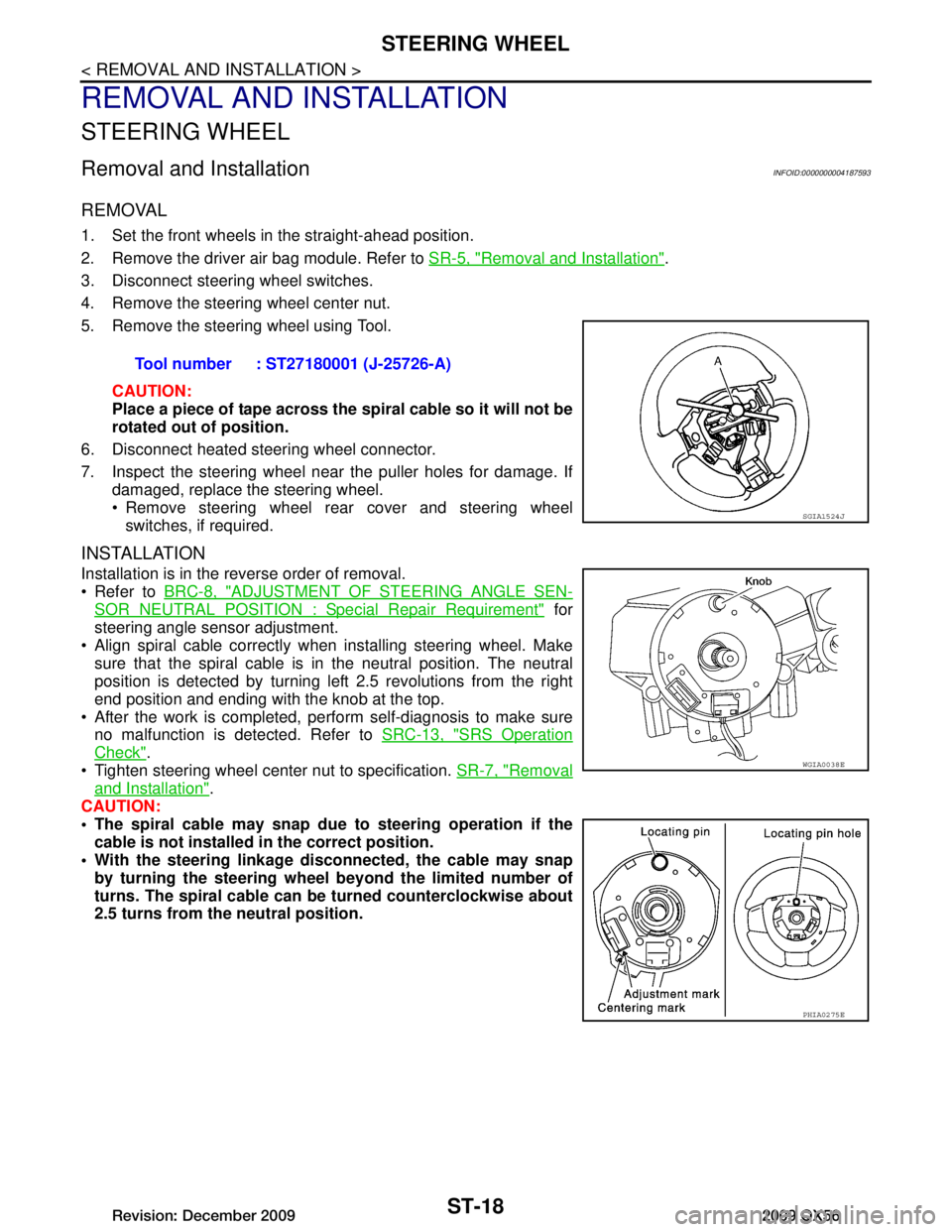

REMOVAL

1. Set the front wheels in the straight-ahead position.

2. Remove the driver air bag module. Refer to SR-5, "Removal and Installation"

.

3. Disconnect steering wheel switches.

4. Remove the steering wheel center nut.

5. Remove the steering wheel using Tool.

CAUTION:

Place a piece of tape across the sp iral cable so it will not be

rotated out of position.

6. Disconnect heated steering wheel connector.

7. Inspect the steering wheel near the puller holes for damage. If damaged, replace the steering wheel.

Remove steering wheel rear cover and steering wheelswitches, if required.

INSTALLATION

Installation is in the reverse order of removal.

Refer to BRC-8, "ADJUSTMENT OF STEERING ANGLE SEN-

SOR NEUTRAL POSITION : Special Repair Requirement" for

steering angle sensor adjustment.

Align spiral cable correctly when installing steering wheel. Make sure that the spiral cable is in the neutral position. The neutral

position is detected by turning left 2.5 revolutions from the right

end position and ending with the knob at the top.

After the work is completed, perform self-diagnosis to make sure no malfunction is detected. Refer to SRC-13, "SRS Operation

Check".

Tighten steering wheel center nut to specification. SR-7, "Removal

and Installation".

CAUTION:

The spiral cable may snap due to steering operation if the

cable is not installed in the correct position.

With the steering linkage di sconnected, the cable may snap

by turning the steering wheel beyond the limited number of

turns. The spiral cable can be turned counterclockwise about

2.5 turns from the neutral position. Tool number : ST27180001 (J-25726-A)

SGIA1524J

WGIA0038E

PHIA0275E

Revision: December 20092009 QX56

Page 3652 of 4171

TM-4

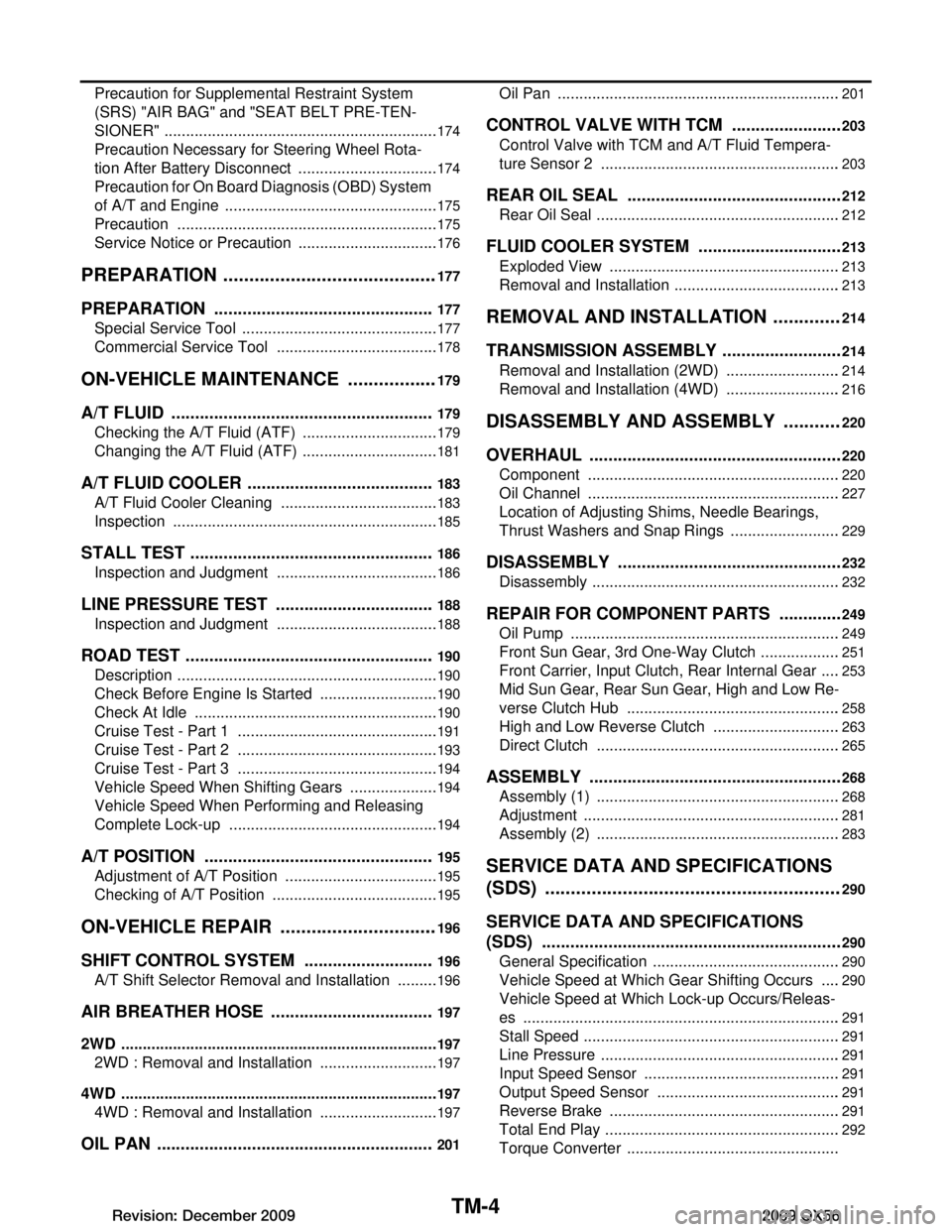

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................

174

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

174

Precaution for On Board Diagnosis (OBD) System

of A/T and Engine ..................................................

175

Precaution .............................................................175

Service Notice or Precaution .................................176

PREPARATION ..........................................177

PREPARATION .............................................. .177

Special Service Tool ............................................ ..177

Commercial Service Tool ......................................178

ON-VEHICLE MAINTENANCE ..................179

A/T FLUID ....................................................... .179

Checking the A/T Fluid (ATF) .............................. ..179

Changing the A/T Fluid (ATF) ................................181

A/T FLUID COOLER ........................................183

A/T Fluid Cooler Cleaning ................................... ..183

Inspection ..............................................................185

STALL TEST ....................................................186

Inspection and Judgment .................................... ..186

LINE PRESSURE TEST ..................................188

Inspection and Judgment .................................... ..188

ROAD TEST .....................................................190

Description ........................................................... ..190

Check Before Engine Is Started ............................190

Check At Idle .........................................................190

Cruise Test - Part 1 ...............................................191

Cruise Test - Part 2 ...............................................193

Cruise Test - Part 3 ...............................................194

Vehicle Speed When Shifting Gears .....................194

Vehicle Speed When Performing and Releasing

Complete Lock-up .................................................

194

A/T POSITION .................................................195

Adjustment of A/T Position .................................. ..195

Checking of A/T Position .......................................195

ON-VEHICLE REPAIR ............................. ..196

SHIFT CONTROL SYSTEM ........................... .196

A/T Shift Selector Removal and Installation ........ ..196

AIR BREATHER HOSE ...................................197

2WD ........................................................................ ..197

2WD : Removal and Installation ............................197

4WD ........................................................................ ..197

4WD : Removal and Installation ............................197

OIL PAN ...........................................................201

Oil Pan ................................................................. .201

CONTROL VALVE WITH TCM ........................203

Control Valve with TCM and A/T Fluid Tempera-

ture Sensor 2 ....................................................... .

203

REAR OIL SEAL ..............................................212

Rear Oil Seal ........................................................ .212

FLUID COOLER SYSTEM ...............................213

Exploded View ..................................................... .213

Removal and Installation .......................................213

REMOVAL AND INSTALLATION .............214

TRANSMISSION ASSEMBLY ........................ ..214

Removal and Installation (2WD) .......................... .214

Removal and Installation (4WD) ...........................216

DISASSEMBLY AND ASSEMBLY ...........220

OVERHAUL .................................................... ..220

Component .......................................................... .220

Oil Channel ...........................................................227

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ......................... .

229

DISASSEMBLY .............................................. ..232

Disassembly ......................................................... .232

REPAIR FOR COMPONENT PARTS ..............249

Oil Pump .............................................................. .249

Front Sun Gear, 3rd One-Way Clutch ...................251

Front Carrier, Input Clutch, Rear Internal Gear .....253

Mid Sun Gear, Rear Sun Gear, High and Low Re-

verse Clutch Hub ..................................................

258

High and Low Reverse Clutch ..............................263

Direct Clutch .........................................................265

ASSEMBLY .................................................... ..268

Assembly (1) ........................................................ .268

Adjustment ............................................................281

Assembly (2) .........................................................283

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ..........................................

290

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

290

General Specification ........................................... .290

Vehicle Speed at Which Gear Shifting Occurs .....290

Vehicle Speed at Which Lock-up Occurs/Releas-

es ..........................................................................

291

Stall Speed ............................................................291

Line Pressure ........................................................291

Input Speed Sensor ..............................................291

Output Speed Sensor ...........................................291

Reverse Brake ......................................................291

Total End Play .......................................................292

Torque Converter .................................................

Revision: December 20092009 QX56