check engine INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2291 of 4171

ELECTRICAL LEAK DETECTORHA-27

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

2. When checking for leaks, circle each fitting completely with the probe as shown.

3. Move the probe along each component at a speed of approxi- mately 25 - 50 mm (1 - 2 in)/second as shown.

CHECKING PROCEDURE

NOTE:

To prevent inaccurate or false readings, make sure t here is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in a calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn the engine OFF.

2. Connect the manifold gauge set (J-39183-C) to the A/C service ports. Refer to HA-20, "HFC-134a (R-

134a) Service Procedure".

3. Check if the A/C refrigerant pressu re is at least 345 kPa (3.52 kg/cm

2 , 50 psi) above a temperature of

16 °C (61 °F). If less than specification, recover/ev acuate and recharge the system with the specified

amount of refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

NOTE:

At temperatures below 16 °C (61 °F), leaks may not be detected sinc e the system may not reach 345 kPa

(3.52 kg/cm

2 , 50 psi) pressure.

4. Perform the leak test from the high-pressure side (f ront A/C compressor discharge “a” to evaporator inlet

“f” or rear piping connection “l”) to the low-pressure side (front A/C evaporator drain hose “g” to shaft seal

“k” and rear A/C evaporator drain hose “o” to piping connection “r”). Refer to HA-29, "Component"

. Clean

the component to be checked and carefully move the electronic refrigerant leak detector probe completely

around the following connections and components.

Check the compressor shaft seal

Check the high and low-pressure pipe and hose fitt ings, relief valve, and compressor shaft seal

Check the liquid tank

Check the refrigerant pressure sensor

Check all around the service valves. Check that the service valve caps are screwed tightly on the ser-

vice valves (to prevent leaks).

NOTE:

After removing manifold gauge set (J-39183-C) from t he service valves, wipe any residue from the ser-

vice valves to prevent any false readings by the electronic refrigerant leak detector (J-41995).

Evaporator

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in

the heater and cooling unit assembly. Wait a minimum of 10 minutes accumulation time (refer to the

manufacturer's recommended procedure for actual wait time) before inserting the electronic refrigerant

leak detector probe into the heater and cooling unit assembly drain hose.

NOTE:

SHA706E

SHA708EA

Revision: December 20092009 QX56

Page 2292 of 4171

HA-28

< ON-VEHICLE MAINTENANCE >

ELECTRICAL LEAK DETECTOR

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak is detected, verify at least once by blow ing compressed air into the area of the suspected leak,

then repeat the leak check.

6. Do not stop when one leak is found. Continue to c heck for additional leaks at all system components and

connections.

7. If no leaks are found, perform steps 8 - 11.

8. Start the engine.

9. Set the heater A/C controls as follows: NOTE:

For the automatic system, turn OF F the automatic controls and set the heater A/C controls manually.

a. A/C switch to ON

b. Air flow to VENT mode

c. Intake position to RECIRCULATION mode

d. Temperature to MAX cold

e. Blower fan speed to HIGH

10. Run the engine at 1,500 rpm for at least 2 minutes.

11. Turn the engine OFF and perform the leak check again following steps 4 through 6 above.

Refrigerant leaks should be checked immediately after turning

the engine OFF. Begin with the leak detector at the compressor.

The pressure on the high pressure side will gradually drop after

the refrigerant circulation stops and pressure on the low pres-

sure side will gradually rise, as shown in the graph. Some leaks

are more easily detected when the pressure is high.

12. Before connecting the recovery/recycling equipment to the vehicle, check the recovery/recycling equip-

ment gauges. No refrigerant pressure should be displayed. If pressure is displayed, recover the refriger-

ant from the equipment lines and then check the refrigerant purity.

13. Confirm refrigerant purity in supply tank using recovery/recycling equipment and refrigerant identifier

equipment (J-41810-NI).

14. Confirm the refrigerant purity in the vehicle's A/C system using recovery/recycling equipment and refriger-

ant identifier equipment (J-41810-NI).

15. Discharge the A/C system using recovery/recycling equipment. Repair the leaking fitting or component as

necessary.

16. Evacuate and recharge the A/C system and perform the leak test to confirm that there are no refrigerant

leaks.

17. Conduct the Operational Check to ens ure system works properly. Refer to HAC-109,

"Symptom Matrix Chart" and HAC-111, "Diagnostic Work Flow".

SHA839E

Revision: December 20092009 QX56

Page 2300 of 4171

HA-36

< ON-VEHICLE REPAIR >

LOW-PRESSURE FLEXIBLE HOSE

LOW-PRESSURE FLEXIBLE HOSE

Removal and Installation for Low-Pressure Flexible HoseINFOID:0000000003775311

REMOVAL

1. Remove the engine air cleaner and air ducts. Refer to EM-25, "Removal and Installation".

2. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

3. Remove the low-pressure flexible hose. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-ring of the low-pr essure flexible hose with a new one, then apply compressor oil to it

when installing it.

After charging refrigerant, check for leaks.

Revision: December 20092009 QX56

Page 2301 of 4171

LOW-PRESSURE PIPEHA-37

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

LOW-PRESSURE PIPE

Removal and Installation for Low-Pressure PipeINFOID:0000000003775312

REMOVAL

1. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Remove the cowl top and the cowl top extension. Refer to EXT-18, "Removal and Installation"

.

3. Remove the low-pressure pipe. CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-ring of the high/low-pressure pipe with a new one, then apply compressor oil to it

when installing it.

After charging refrigerant, check for leaks.

Removal and Installation for Rear High- and Low-Pressure A/C and Heater Core Pipes

INFOID:0000000003775313

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Drain the coolant from the engine cooling system. Refer to CO-11, "Changing Engine Coolant"

.

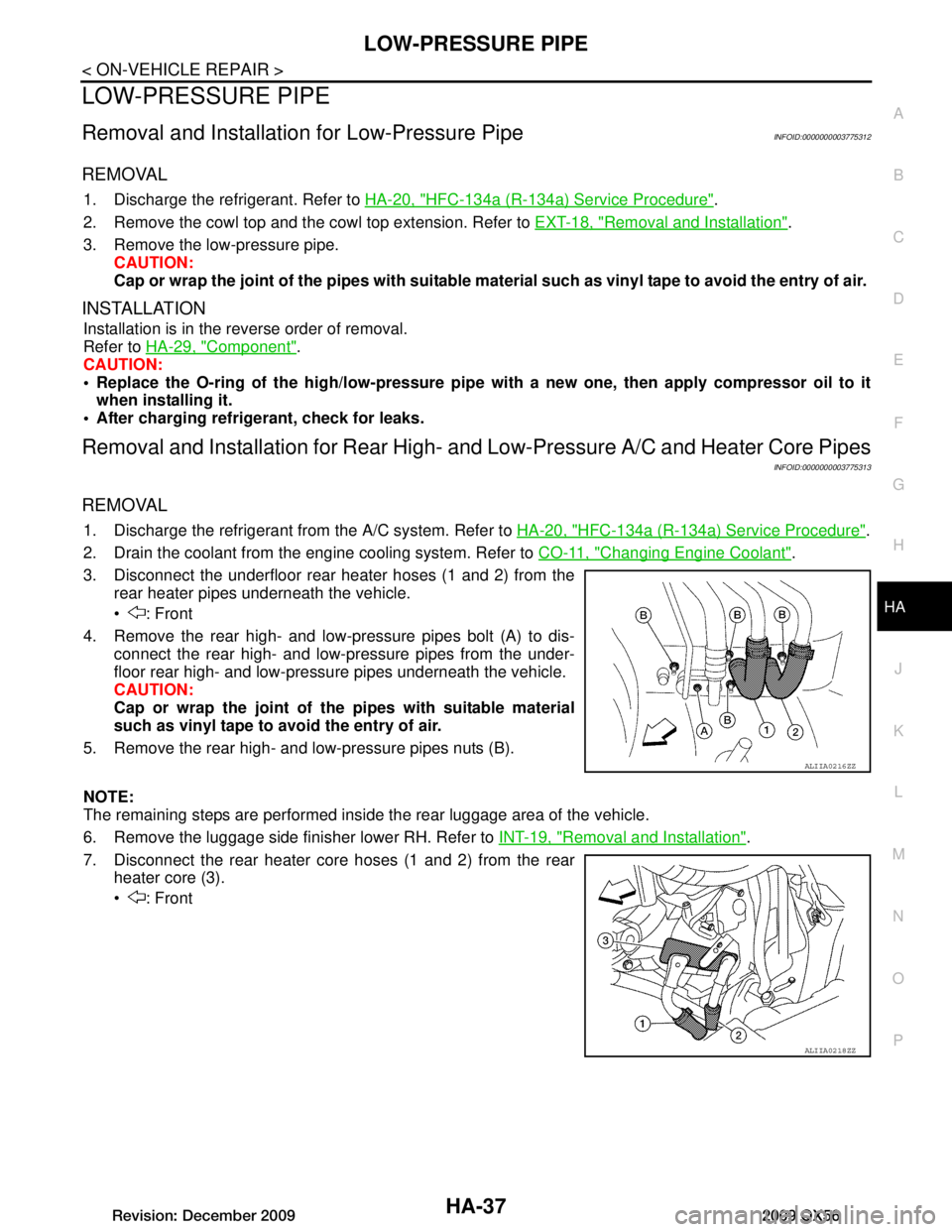

3. Disconnect the underfloor rear heater hoses (1 and 2) from the rear heater pipes underneath the vehicle.

: Front

4. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the under-

floor rear high- and low-pressu re pipes underneath the vehicle.

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

5. Remove the rear high- and low-pressure pipes nuts (B).

NOTE:

The remaining steps are performed inside the rear luggage area of the vehicle.

6. Remove the luggage side finisher lower RH. Refer to INT-19, "Removal and Installation"

.

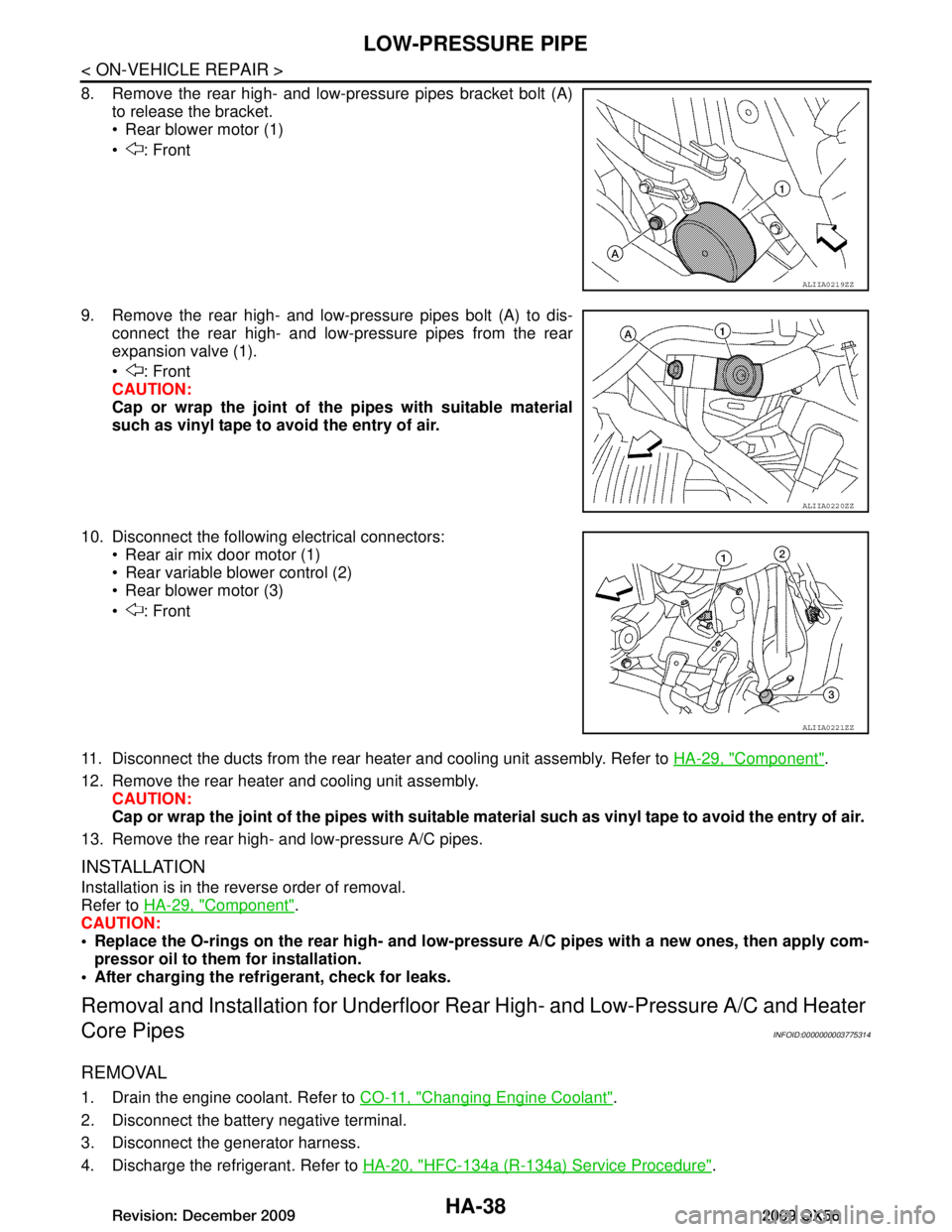

7. Disconnect the rear heater core hoses (1 and 2) from the rear heater core (3).

: Front

ALIIA0216ZZ

ALIIA0218ZZ

Revision: December 20092009 QX56

Page 2302 of 4171

HA-38

< ON-VEHICLE REPAIR >

LOW-PRESSURE PIPE

8. Remove the rear high- and low-pressure pipes bracket bolt (A)to release the bracket.

Rear blower motor (1)

: Front

9. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the rear

expansion valve (1).

: Front

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

10. Disconnect the following electrical connectors: Rear air mix door motor (1)

Rear variable blower control (2)

Rear blower motor (3)

: Front

11. Disconnect the ducts from the rear heater and cooling unit assembly. Refer to HA-29, "Component"

.

12. Remove the rear heater and cooling unit assembly. CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

13. Remove the rear high- and low-pressure A/C pipes.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-rings on the rear high- and low-pr essure A/C pipes with a new ones, then apply com-

pressor oil to them for installation.

After charging the refrigerant, check for leaks.

Removal and Installation for Underfloor Rear High- and Lo w-Pressure A/C and Heater

Core Pipes

INFOID:0000000003775314

REMOVAL

1. Drain the engine coolant. Refer to CO-11, "Changing Engine Coolant".

2. Disconnect the battery negative terminal.

3. Disconnect the generator harness.

4. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

ALIIA0219ZZ

ALIIA0220ZZ

ALIIA0221ZZ

Revision: December 20092009 QX56

Page 2304 of 4171

HA-40

< ON-VEHICLE REPAIR >

HIGH-PRESSURE FLEXIBLE HOSE

HIGH-PRESSURE FLEXIBLE HOSE

Removal and Installation for High-Pressure Flexible HoseINFOID:0000000003775315

REMOVAL

1. Remove the engine under cover.

2. Remove the front LH fender protector. Refer to EXT-23, "Removal and Installation"

.

3. Remove the engine air cleaner and air ducts. Refer to EM-25, "Removal and Installation"

.

4. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

5. Remove the high-pressure flexible hose. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-ring of the high-pr essure flexible hose with a new one, then apply compressor oil to it

when installing it.

After charging refrigerant, check for leaks.

Revision: December 20092009 QX56

Page 2305 of 4171

HIGH-PRESSURE PIPEHA-41

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

HIGH-PRESSURE PIPE

Removal and Installation for High-Pressure PipeINFOID:0000000003775316

REMOVAL

1. Remove the cowl top extension. Refer to EXT-18, "Removal and Installation".

2. Disconnect the battery negative termi nal and positive battery terminal.

3. Reposition the IPDM E/R aside.

4. Remove the front left wheel and tire assembly. Refer to MA-29, "Rotation"

.

5. Position aside the front floor insulator.

6. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

7. Remove the low pressure pipe. Refer to HA-37, "Removal and Installation for Low-Pressure Pipe"

.

8. Remove the high-pressure pipe. CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-ring of the high-pressure pipe with a new one, then apply compressor oil to it when

installing it.

After charging refrigerant, check for leaks.

Removal and Installation for Rear High- and Low-Pressure A/C and Heater Core Pipes

INFOID:0000000003775317

REMOVAL

1. Discharge the refrigerant from the A/C system. Refer to HA-20, "HFC-134a (R-134a) Service Procedure".

2. Drain the coolant from the engine cooling system. Refer to CO-11, "Changing Engine Coolant"

.

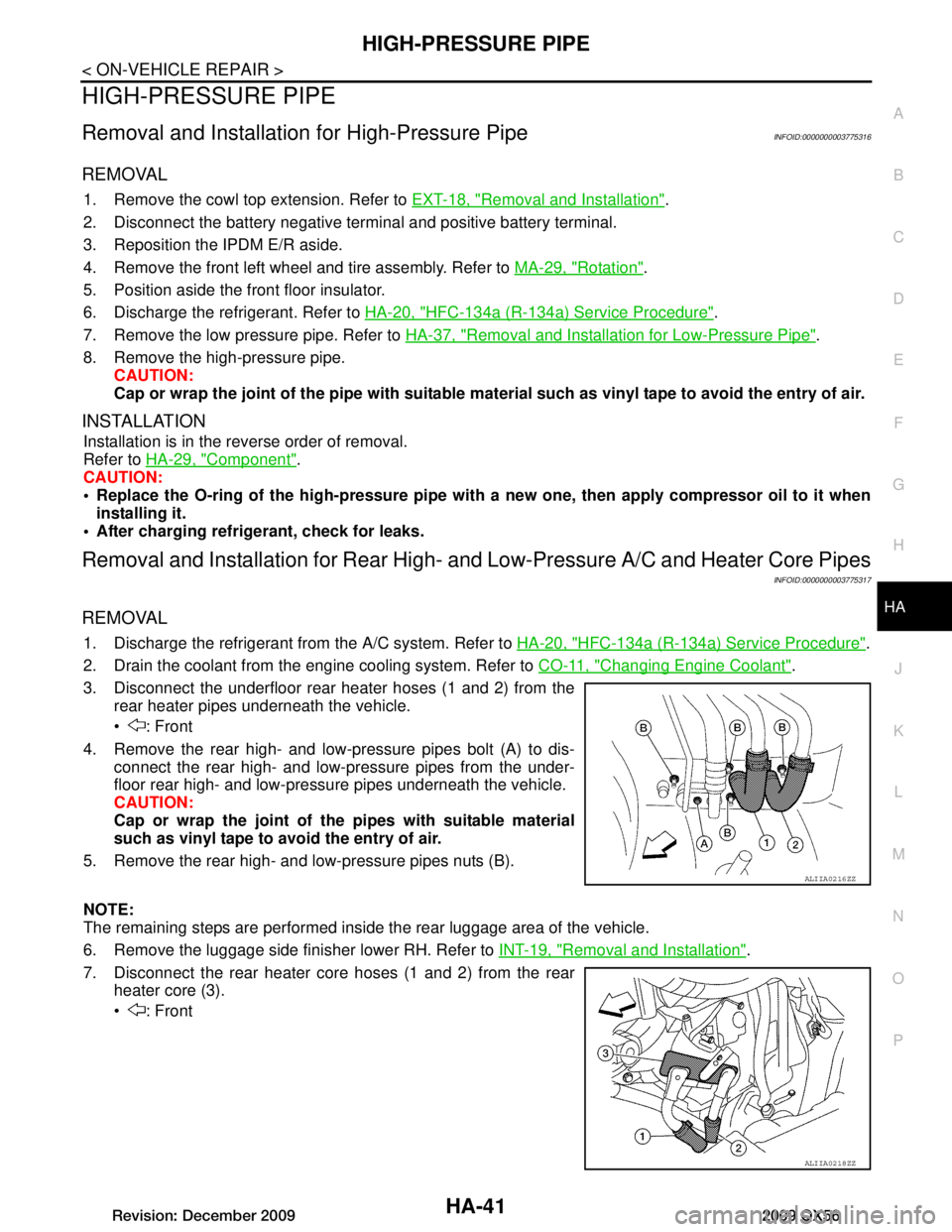

3. Disconnect the underfloor rear heater hoses (1 and 2) from the rear heater pipes underneath the vehicle.

: Front

4. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the under-

floor rear high- and low-pressu re pipes underneath the vehicle.

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

5. Remove the rear high- and low-pressure pipes nuts (B).

NOTE:

The remaining steps are performed inside the rear luggage area of the vehicle.

6. Remove the luggage side finisher lower RH. Refer to INT-19, "Removal and Installation"

.

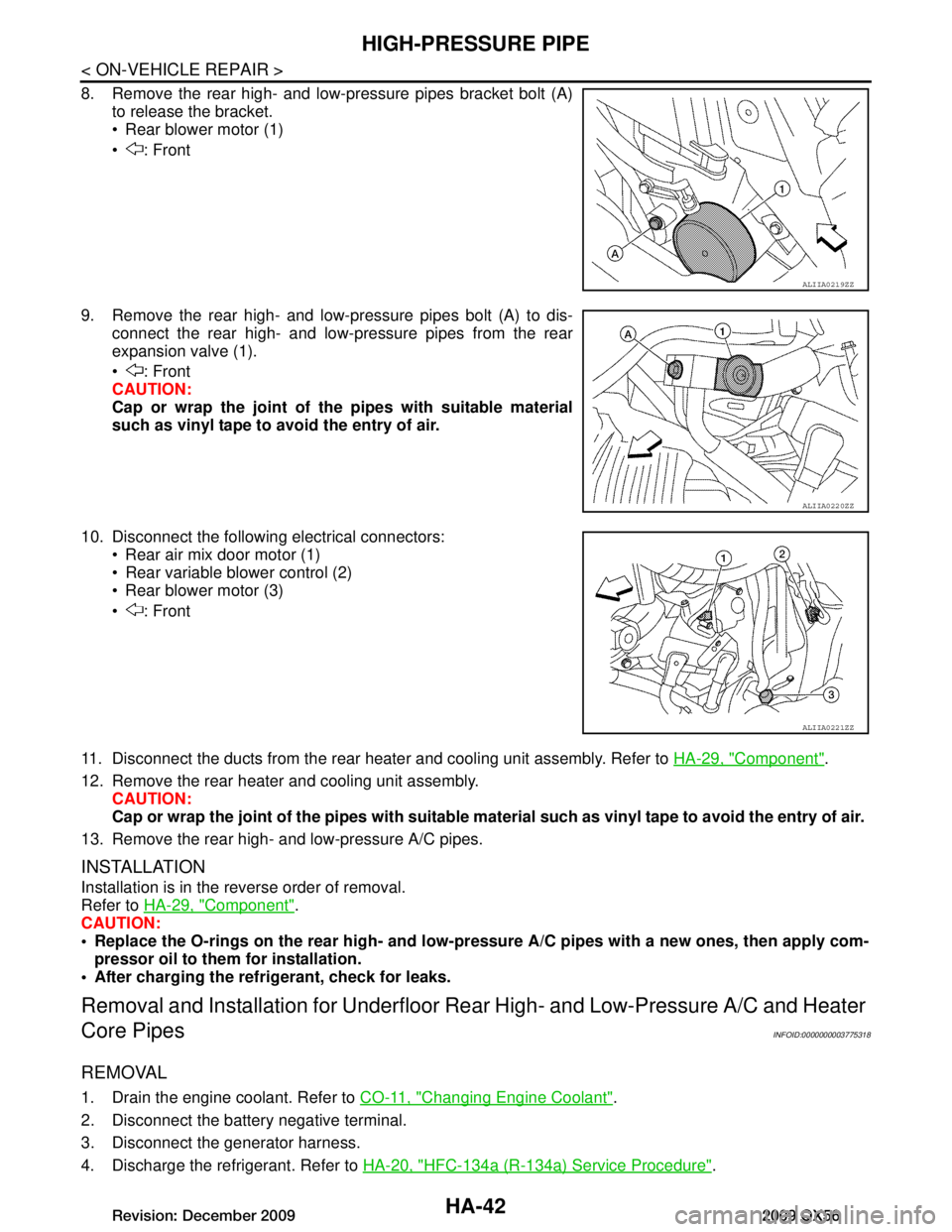

7. Disconnect the rear heater core hoses (1 and 2) from the rear heater core (3).

: Front

ALIIA0216ZZ

ALIIA0218ZZ

Revision: December 20092009 QX56

Page 2306 of 4171

HA-42

< ON-VEHICLE REPAIR >

HIGH-PRESSURE PIPE

8. Remove the rear high- and low-pressure pipes bracket bolt (A)to release the bracket.

Rear blower motor (1)

: Front

9. Remove the rear high- and low-pressure pipes bolt (A) to dis- connect the rear high- and low-pressure pipes from the rear

expansion valve (1).

: Front

CAUTION:

Cap or wrap the joint of the pipes with suitable material

such as vinyl tape to avoid the entry of air.

10. Disconnect the following electrical connectors: Rear air mix door motor (1)

Rear variable blower control (2)

Rear blower motor (3)

: Front

11. Disconnect the ducts from the rear heater and cooling unit assembly. Refer to HA-29, "Component"

.

12. Remove the rear heater and cooling unit assembly. CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

13. Remove the rear high- and low-pressure A/C pipes.

INSTALLATION

Installation is in the reverse order of removal.

Refer to HA-29, "Component"

.

CAUTION:

Replace the O-rings on the rear high- and low-pr essure A/C pipes with a new ones, then apply com-

pressor oil to them for installation.

After charging the refrigerant, check for leaks.

Removal and Installation for Underfloor Rear High- and Lo w-Pressure A/C and Heater

Core Pipes

INFOID:0000000003775318

REMOVAL

1. Drain the engine coolant. Refer to CO-11, "Changing Engine Coolant".

2. Disconnect the battery negative terminal.

3. Disconnect the generator harness.

4. Discharge the refrigerant. Refer to HA-20, "HFC-134a (R-134a) Service Procedure"

.

ALIIA0219ZZ

ALIIA0220ZZ

ALIIA0221ZZ

Revision: December 20092009 QX56

Page 2317 of 4171

![INFINITI QX56 2009 Factory Service Manual HAC-4

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational Check (Front)INFOID:0000000003775325

The purpose of the operational check is to

c INFINITI QX56 2009 Factory Service Manual HAC-4

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational Check (Front)INFOID:0000000003775325

The purpose of the operational check is to

c](/img/42/57031/w960_57031-2316.png)

HAC-4

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational Check (Front)INFOID:0000000003775325

The purpose of the operational check is to

confirm that the system operates properly.

CHECKING MEMORY FUNCTION

1. Set the temperature to 32 ° (90 °F).

2. Press the OFF switch.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous temperature.

7. Press the OFF switch.

If NG, go to trouble diagnosis procedure for HAC-122, "

Memory Function Check".

If OK, continue with next check.

CHECKING BLOWER

1. Press the blower speed control switch (+) once, blower should operate on low speed. The fan display should have one bar lit (on display).

2. Press the blower speed control switch (+) again, and continue checking blower speed and fan display until

all speeds are checked.

3. Leave blower on maximum speed.

If NG, go to trouble diagnosis procedure for HAC-52, "

Front Blower Motor Diagnosis Procedure".

If OK, continue with next check.

CHECKING DISCHARGE AIR

1. Press MODE switch four times and the DEF switch.

2. Each position indicator should change shape (on display).

3. Confirm that discharge air comes out according to the air distribution table. Refer to HAC-16, "

Discharge

Air Flow (Front)".

Mode door position is checked in the next step.

If NG, go to trouble diagnosis procedure for HAC-27, "

Mode Door Motor (Front) Diagnosis Procedure".

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and intake door position is at

fresh when the DEF or D/F is selected.

CHECKING RECIRCULATION ( , ONLY)

1. Press recirculation ( ) switch one time. Recirculation indicator should illuminate.

2. Press recirculation ( ) switch one more time. Recirculation indicator should go off.

3. Listen for intake door position change (blower sound should change slightly).

If NG, go to trouble diagnosis procedure for HAC-43, "

Intake Door Motor Diagnosis Procedure".

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or vis ual inspection) and intake door position is at fresh

when the DEF or D/F is selected. REC ( ) is not allowed in DEF ( ) D/F ( ) or FOOT ( ).

CHECKING TEMPERATURE DECREASE

1. Rotate temperature control dial (drive or passenger) counterclockwise until 18° C (60°F) is displayed.

2. Check for cold air at appropriate discharge air outlets. Conditions : Engine running and at normal operating temperature

Revision: December 20092009 QX56

Page 2318 of 4171

![INFINITI QX56 2009 Factory Service Manual INSPECTION AND ADJUSTMENTHAC-5

< BASIC INSPECTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnos INFINITI QX56 2009 Factory Service Manual INSPECTION AND ADJUSTMENTHAC-5

< BASIC INSPECTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnos](/img/42/57031/w960_57031-2317.png)

INSPECTION AND ADJUSTMENTHAC-5

< BASIC INSPECTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnosis procedure for HAC-110,

"Component Function Check". If air mix door motor appears to be malfunctioning, go to HAC-32, "Air Mix Door

Motor Component Function Check".

If OK, continue the check.

CHECKING TEMPERATURE INCREASE

1. Rotate temperature control dial clockwise (drive or passenger) until 32 °C (90° F) is displayed.

2. Check for hot air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnosis procedure for HAC-118,

"Component Function Check". If air mix door motor appears to be malfunctioning, go to HAC-32, "Air Mix Door

Motor Component Function Check".

If OK, continue with next check.

CHECK A/C SWITCH

1. Press A/C switch when AUTO switch is ON, or in manual mode.

2. A/C switch indicator will turn ON. • Confirm that the compressor clutch engages (sound or visual inspection).

NOTE:

If current mode setting is DEF or D/F, compre ssor clutch will already be engaged and cannot be turned off.

If NG, go to trouble diagnosis procedure for HAC-73, "

Magnet Clutch Diagnosis Procedure".

If OK, continue with next check.

CHECKING AUTO MODE

1. Press AUTO switch.

2. Display should indicate AUTO.

• If ambient temperature is warm, and selected temperat ure is cool, confirm that the compressor clutch

engages (sound or visual inspection). (Discharge air and blower speed will depend on ambient, in-vehi-

cle, and set temperatures.)

If NG, go to trouble diagnosis procedure for HAC-90, "

A/C Auto Amp Power and Ground Diagnosis Proce-

dure", then if necessary, trouble diagnosis procedure for HAC-73, "Magnet Clutch Diagnosis Procedure".

If all operational checks are OK (symptom cannot be duplicated), go to malfunction Simulation Tests in HAC-

3, "How to Perform Trouble Diagnosis For Quick And Accurate Repair" and perform tests as outlined to simu-

late driving conditions environment. If symptom appears. Refer to HAC-109, "

SymptomMatrixChart", and

perform applicable troubl e diagnosis procedures.

Operational Check (Rear)INFOID:0000000003775326

The purpose of the operational check is to confirm that the system operates properly.

CHECKING REAR BLOWER MOTOR

1. Turn the ignition switch ON.

2. Rotate rear air control (front) blower control dial to low speed.

3. Rotate the blower control dial clockwise and continue checking blower speed until all speeds are checked.

4. Leave blower on maximum speed.

5. Press the REAR CTRL switch from the rear air control (front).

6. Rotate rear air control (rear) blower control dial to low speed.

7. Rotate the blower control dial clockwise and continue checking blower speed until all speeds are checked.

8. Leave blower on maximum speed.

If NG, go to trouble diagnosis procedure for HAC-57, "

Rear Blower Motor Component Function Check".

If OK, continue with next check.

CHECKING REAR DISCHARGE AIR

Conditions : Engine running and at normal operating temperature

Revision: December 20092009 QX56