sensor INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2108 of 4171

EXT-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005852245

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005852246

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2119 of 4171

FRONT BUMPEREXT-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

FRONT BUMPER

Removal and InstallationINFOID:0000000003776104

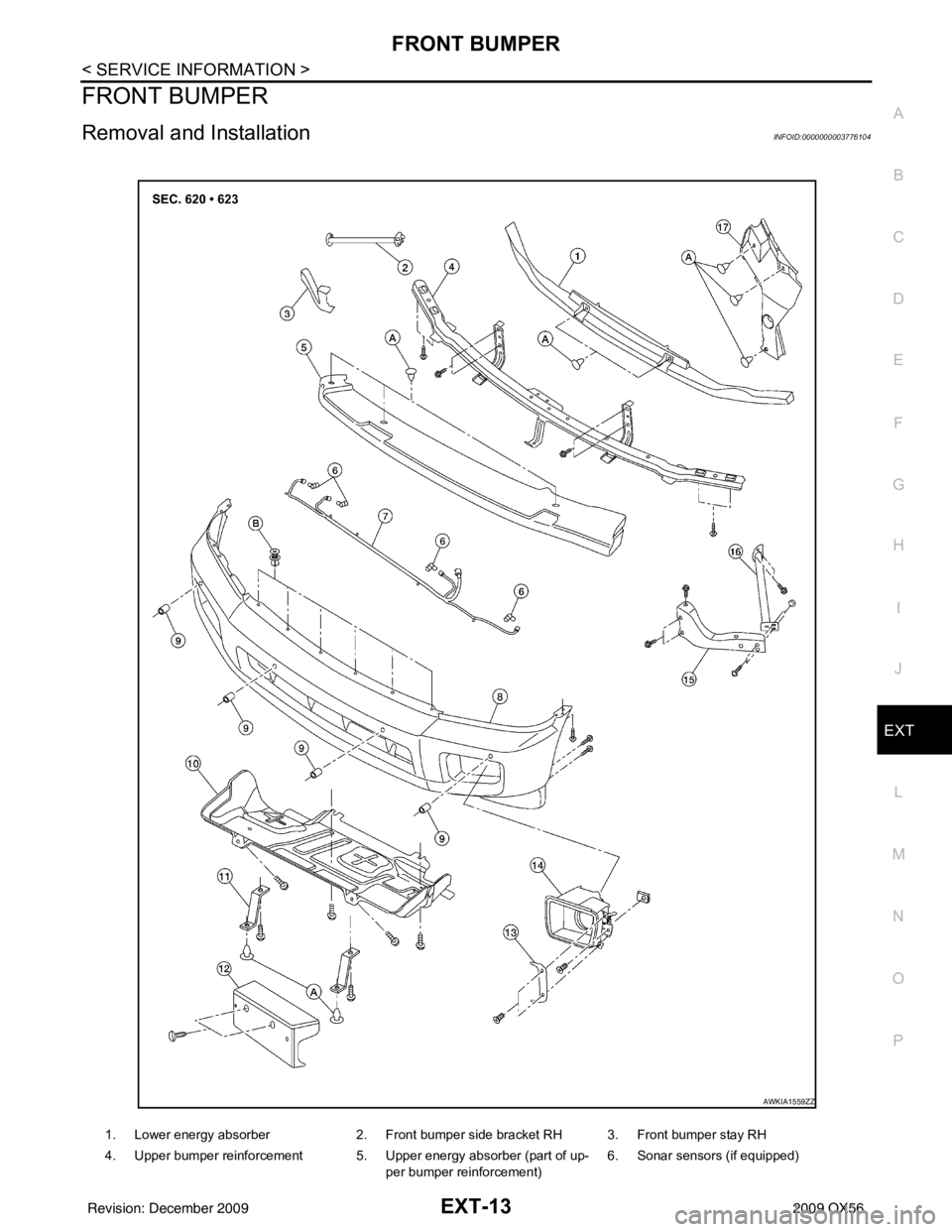

1. Lower energy absorber 2. Front bumper side bracket RH 3. Front bumper stay RH

4. Upper bumper reinforcement 5. Upper energy absorber (part of up- per bumper reinforcement) 6. Sonar sensors (if equipped)

AWKIA1559ZZ

Revision: December 20092009 QX56

Page 2120 of 4171

EXT-14

< SERVICE INFORMATION >

FRONT BUMPER

REMOVAL

1. Remove the side screws from the front fascia assembly.

2. Remove the screws from the front of fender protector. Refer to EXT-23

.

3. Remove the fog turn/fog lamp finisher and the fog turn/fog lamp. • Disconnect the harnesses.

4. Disconnect the sonar sensor, if equipped harness connector under the front fascia assembly.

5. Remove the fasteners, release the clips and remove the front fascia assembly.

6. Remove the plastic clips and remove the upper energy absorber.

7. Remove the upper bumper reinforcement.

8. Remove the plastic clips and remove the lower energy absorber.

9. Remove the front bumper stays and the front bumper side brackets, LH and RH.

10. Disconnect the sonar sensors, if equipped from the sonar sensor retainers, if equipped.

11. Remove the sonar sensors, if equipped and harness from the front fascia assembly. • Disconnect the sonar sensors, if equipped from the harness.

• Remove the sonar sensor retainers, if equipped from the front fascia assembly.

INSTALLATION

Installation is in the reverse order of removal.

7. Sonar sensor harness (if equipped) 8. Front fascia assembly 9. Sonar sensor retainers (if equipped)

10. Engine under cover 11. Front fascia bracket12. License plate bracket

13. Fog turn/fog lamp finisher LH/RH 14. Fog turn/fog lamp 15. Front bumper stay LH

16. Front bumper side bracket LH 17. Headlamp finisher (RH shown) A. Clip C103

B. Clip CS101

Revision: December 20092009 QX56

Page 2121 of 4171

REAR BUMPEREXT-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

REAR BUMPER

Removal and InstallationINFOID:0000000003776105

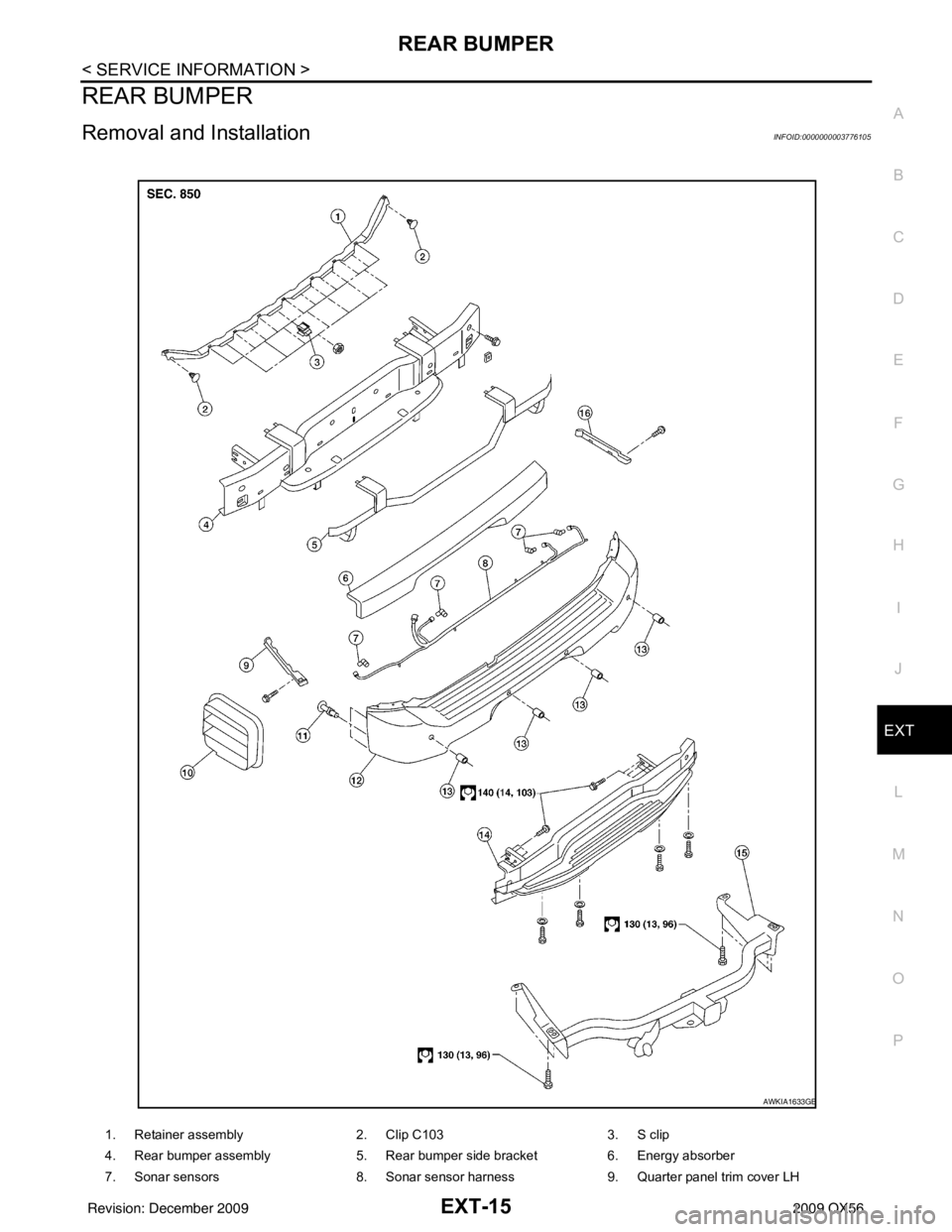

1. Retainer assembly 2. Clip C1033. S clip

4. Rear bumper assembly 5. Rear bumper side bracket6. Energy absorber

7. Sonar sensors 8. Sonar sensor harness9. Quarter panel trim cover LH

AWKIA1633GB

Revision: December 20092009 QX56

Page 2122 of 4171

EXT-16

< SERVICE INFORMATION >

REAR BUMPER

REMOVAL

1. Remove the rear combination lamps LH and RH. Refer to EXL-157, "Removal and Installation".

2. Remove the rear fascia assembly screws under the rear combination lamps LH and RH.

3. Remove the quarter panel trim covers LH and RH.

4. Disconnect the sonar sensor harness c onnector under the rear fascia assembly.

5. Release the retainer clips on both sides of the rear fascia assembly with a 1/4 turn and top S clips and remove the fascia assembly.

6. Detach the I-key antenna from the energy absorber.

7. Remove the energy absorber.

8. Remove the reinforcement assembly.

9. Remove the nuts and remove the retainer assembly. • Remove the S clips from the retainer assembly.

10. Disconnect the sonar sensors from the sonar sensor retainers.

11. Remove the sonar sensors and harness from the rear fascia assembly. • Disconnect the sonar sensors from the harness.

• Remove the sonar sensor retainers from the rear fascia assembly.

12. Remove the bolts on each side of the tow hitch and remove the tow hitch.

13. Remove the drafter duct from under the LH quarter panel.

INSTALLATION

Installation is in the reverse order of removal.

10. Drafter duct 11. Retainer clip 12. Rear fascia assembly

13. Sonar sensor retainer 14. Reinforcement assembly15. Tow hitch

16. Quarter panel trim cover RH

Revision: December 20092009 QX56

Page 2139 of 4171

FAX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005867499

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005867500

NOTE:

This Procedure is applied only to models with Intelli gent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56

Page 2144 of 4171

WHEEL HUBFAX-7

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

REMOVAL AND INSTALLATION

WHEEL HUB

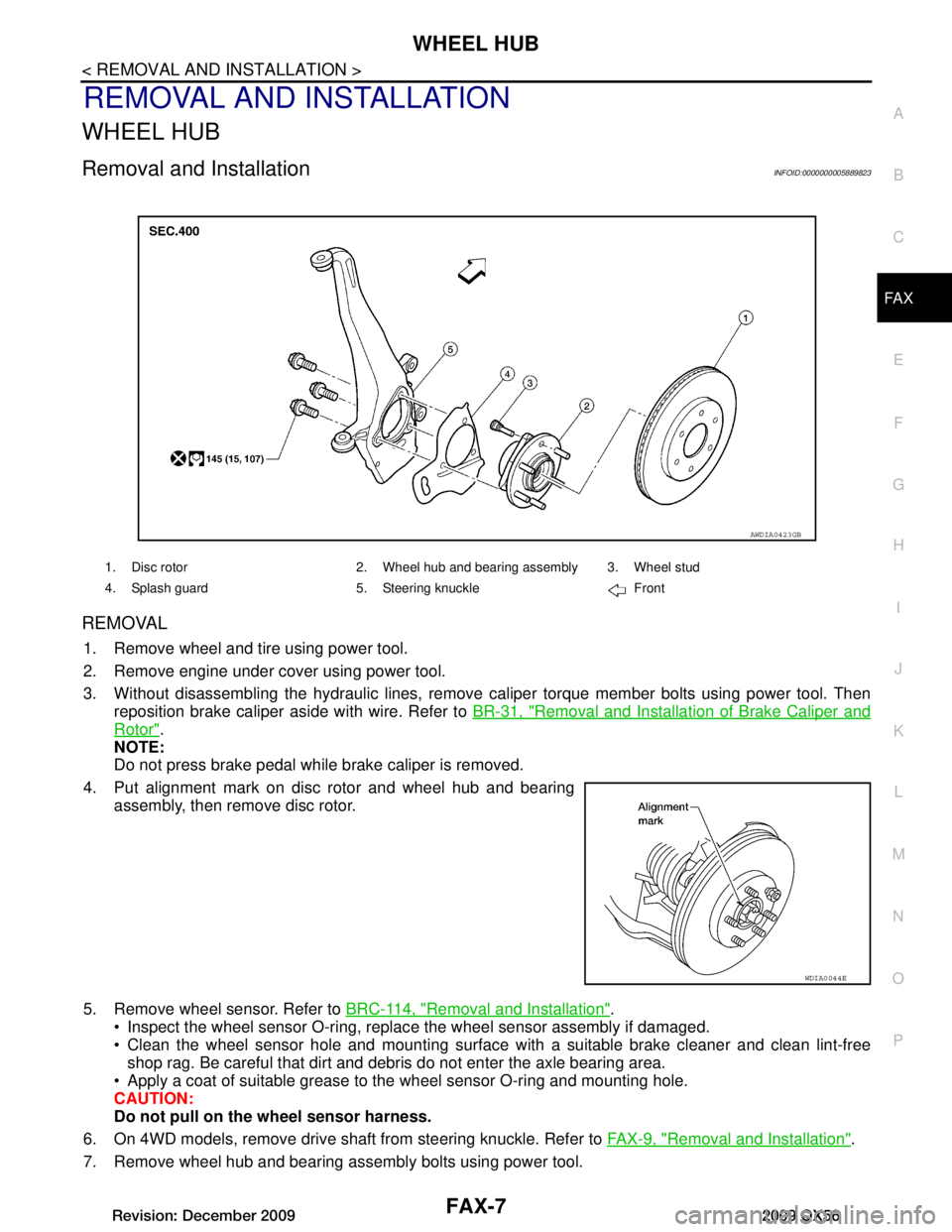

Removal and InstallationINFOID:0000000005889823

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Without disassembling the hydraulic lines, remove caliper torque member bolts using power tool. Then reposition brake caliper aside with wire. Refer to BR-31, "Removal and Installation of Brake Caliper and

Rotor".

NOTE:

Do not press brake pedal while brake caliper is removed.

4. Put alignment mark on disc rotor and wheel hub and bearing assembly, then remove disc rotor.

5. Remove wheel sensor. Refer to BRC-114, "Removal and Installation"

.

Inspect the wheel sensor O-ring, replac e the wheel sensor assembly if damaged.

Clean the wheel sensor hole and mounting surface with a suitable brake cleaner and clean lint-free shop rag. Be careful that dirt and debr is do not enter the axle bearing area.

Apply a coat of suitable grease to t he wheel sensor O-ring and mounting hole.

CAUTION:

Do not pull on th e wheel sensor harness.

6. On 4WD models, remove drive shaft from steering knuckle. Refer to FAX-9, "Removal and Installation"

.

7. Remove wheel hub and bearing assembly bolts using power tool.

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle Front

AWDIA0423GB

WDIA0044E

Revision: December 20092009 QX56

Page 2146 of 4171

DRIVE SHAFTFAX-9

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

DRIVE SHAFT

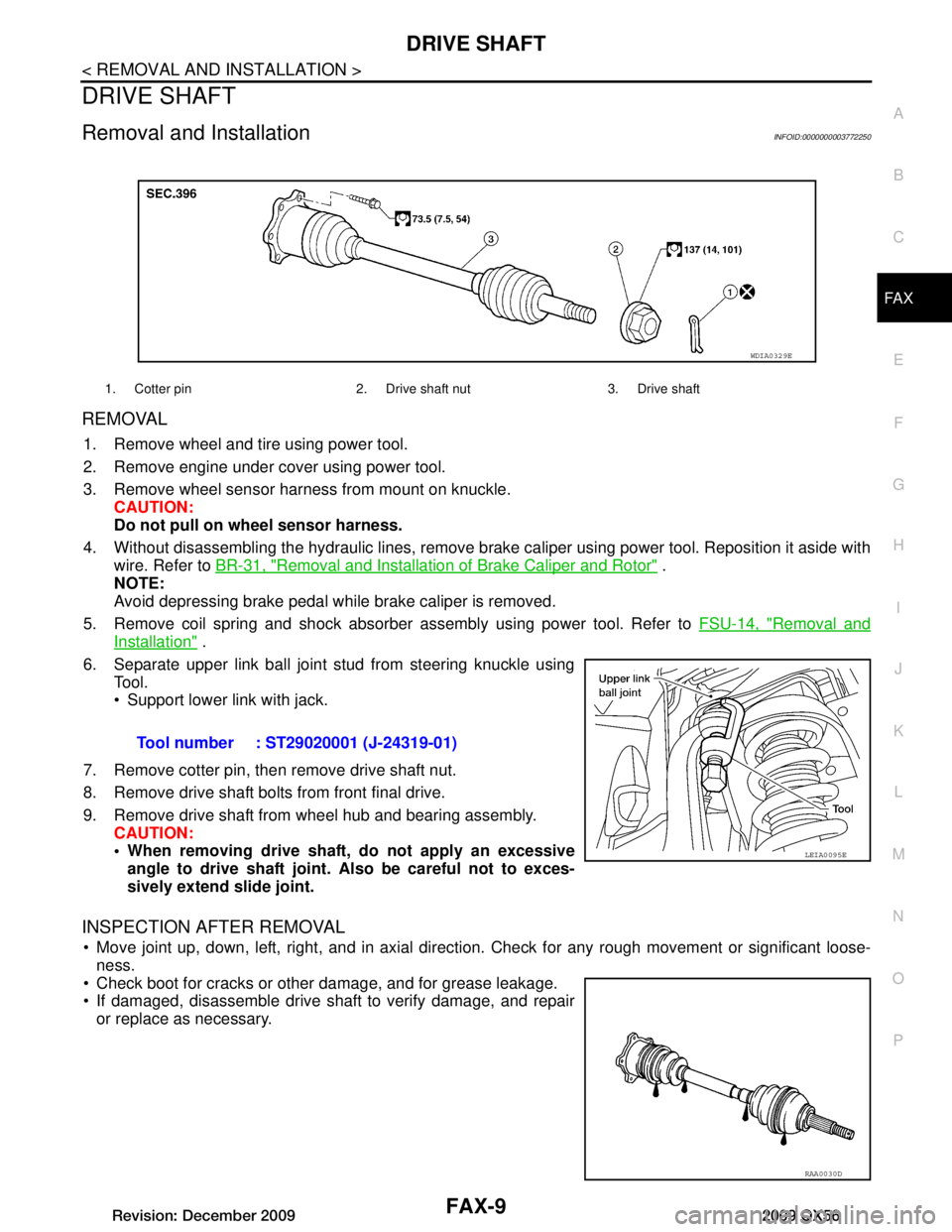

Removal and InstallationINFOID:0000000003772250

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Remove wheel sensor harness from mount on knuckle. CAUTION:

Do not pull on wheel sensor harness.

4. Without disassembling the hydraulic lines, remove brake caliper using power tool. Reposition it aside with wire. Refer to BR-31, "Removal and Installation of Brake Caliper and Rotor"

.

NOTE:

Avoid depressing brake pedal while brake caliper is removed.

5. Remove coil spring and shock absorber assembly using power tool. Refer to FSU-14, "Removal and

Installation" .

6. Separate upper link ball joint stud from steering knuckle using Tool.

Support lower link with jack.

7. Remove cotter pin, then remove drive shaft nut.

8. Remove drive shaft bolts from front final drive.

9. Remove drive shaft from wheel hub and bearing assembly. CAUTION:

When removing drive shaft, do not apply an excessiveangle to drive shaft joint. Also be careful not to exces-

sively extend slide joint.

INSPECTION AFTER REMOVAL

Move joint up, down, left, right, and in axial directi on. Check for any rough movement or significant loose-

ness.

Check boot for cracks or other damage, and for grease leakage.

If damaged, disassemble drive shaft to verify damage, and repair or replace as necessary.

1. Cotter pin 2. Drive shaft nut 3. Drive shaft

WDIA0329E

Tool number : ST29020001 (J-24319-01)

LEIA0095E

RAA0030D

Revision: December 20092009 QX56

Page 2154 of 4171

FL-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION FL

A

FL

N

O P

CONTENTS

FUEL SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

FUEL SYSTEM ....................................................4

General Precaution ............................................. ......4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

BASIC INSPECTION ....................................6

FUEL SYSTEM ............................................... .....6

Checking Fuel Line ............................................. ......6

REMOVAL AND INSTALLATION ................7

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY .........................

7

Removal and Installation ..................................... .....7

FUEL TANK ......................................................11

Removal and Installation ..................................... ....11

DISASSEMBLY AND ASSEMBLY ..............16

FUEL LEVEL SENSOR UNIT, FUEL FILTER

AND FUEL PUMP ASSEMBLY ........................

16

Disassembly and Assembly ................................. ....16

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

17

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

17

Standard and Limit .............................................. ....17

Revision: December 20092009 QX56

Page 2155 of 4171

FL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005851872

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005851873

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: December 20092009 QX56