change time INFINITI QX56 2009 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2553 of 4171

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: December 20092009 QX56

Page 2665 of 4171

LU-10

< ON-VEHICLE MAINTENANCE >

ENGINE OIL

Unit: (US qt, Imp qt)

CAUTION:

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

• Always use the oil level gauge to determine when the proper amount of engine oil is in the engine.

8. Warm up engine and check area around drain plug and oil filter for oil leakage.

9. Stop engine and wait for 10 minutes.

10. Check engine oil level. Refer to LU-8, "

Inspection".

Drain and refill With oil filter change

6.5 (6 7/8, 5-3/4)

Without oil filter change 6.2 (6-1/2, 5-1/2)

Dry engine (engine overhaul) 7.6 (8, 6-3/4)

Revision: December 20092009 QX56

Page 2679 of 4171

MA-6

< ON-VEHICLE MAINTENANCE >

GENERAL MAINTENANCE

ON-VEHICLE MAINTENANCE

GENERAL MAINTENANCE

General MaintenanceINFOID:0000000003776979

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owner can perform these

checks and inspections or have thei r INFINITI dealers perform them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge at least once a month and always prior to a

long distance trip. Adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear. —

Wheel lug nuts When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-41, "

Adjustment"

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Tire rotation Tires should be rotated every 12,000 km (7,500 miles). MA-29, "

Rotation"

Tire Pressure Monitor-

ing System (TPMS)

transmitter componentsReplace the TPMS transmitter grommet seat, valve core and cap when the tires

are replaced due to wear or age.

WT-43, "Transmitter

(Pressure Sensor)"

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel bal-

ancing may be needed. MA-28, "Balancing

Wheels", FSU-6, "Front

Wheel Alignment"

Windshield wiper

blades

Check for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-33, "

Lubricating

Locks, Hinges and Hood

Latches"

Lamps

Make sure that the head lamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head

lamp aim. Clean the head lamps on a regular basis. EXL-143, "HEADLAMP :

Aiming Adjustment"

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly.

WCS-4, "

WARNING

CHIME SYSTEM : Sys-

tem Description"

Windshield wiper and

washerCheck that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Be sure to check for changes in the steering

condition, such as excessive play, hard steering or strange noises. ST-15, "

On-Vehicle In-

spection and Service"

Seats

Check seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs. —

Revision: December 20092009 QX56

Page 2691 of 4171

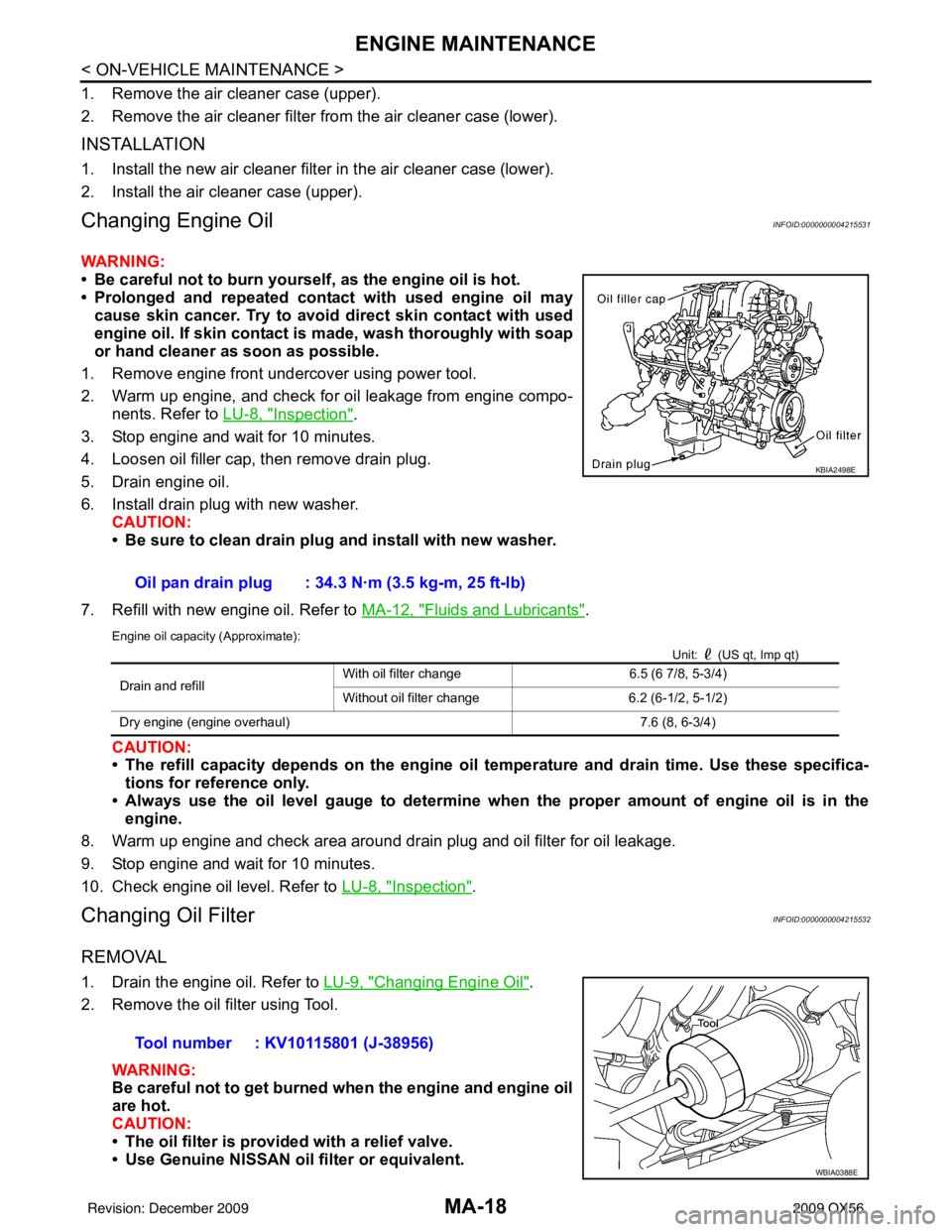

MA-18

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

1. Remove the air cleaner case (upper).

2. Remove the air cleaner filter from the air cleaner case (lower).

INSTALLATION

1. Install the new air cleaner filter in the air cleaner case (lower).

2. Install the air cleaner case (upper).

Changing Engine OilINFOID:0000000004215531

WARNING:

• Be careful not to burn yourself, as the engine oil is hot.

• Prolonged and repeated contact with used engine oil may

cause skin cancer. Try to avoid di rect skin contact with used

engine oil. If skin contact is made, wash thoroughly with soap

or hand cleaner as soon as possible.

1. Remove engine front undercover using power tool.

2. Warm up engine, and check for oil leakage from engine compo- nents. Refer to LU-8, "

Inspection".

3. Stop engine and wait for 10 minutes.

4. Loosen oil filler cap, then remove drain plug.

5. Drain engine oil.

6. Install drain plug with new washer. CAUTION:

• Be sure to clean drain plug and install with new washer.

7. Refill with new engine oil. Refer to MA-12, "

Fluids and Lubricants".

Engine oil capacity (Approximate):

Unit: (US qt, Imp qt)

CAUTION:

• The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

• Always use the oil level gauge to determine when the proper amount of engine oil is in the engine.

8. Warm up engine and check area around drain plug and oil filter for oil leakage.

9. Stop engine and wait for 10 minutes.

10. Check engine oil level. Refer to LU-8, "

Inspection".

Changing Oil FilterINFOID:0000000004215532

REMOVAL

1. Drain the engine oil. Refer to LU-9, "Changing Engine Oil".

2. Remove the oil filter using Tool.

WARNING:

Be careful not to get burned when the engine and engine oil

are hot.

CAUTION:

• The oil filter is provided with a relief valve.

• Use Genuine NISSAN oil filter or equivalent.Oil pan drain plug : 34.3 N·m (3.5 kg-m, 25 ft-lb)

KBIA2498E

Drain and refill

With oil filter change

6.5 (6 7/8, 5-3/4)

Without oil filter change 6.2 (6-1/2, 5-1/2)

Dry engine (engine overhaul) 7.6 (8, 6-3/4)

Tool number : KV10115801 (J-38956)

WBIA0388E

Revision: December 20092009 QX56

Page 2693 of 4171

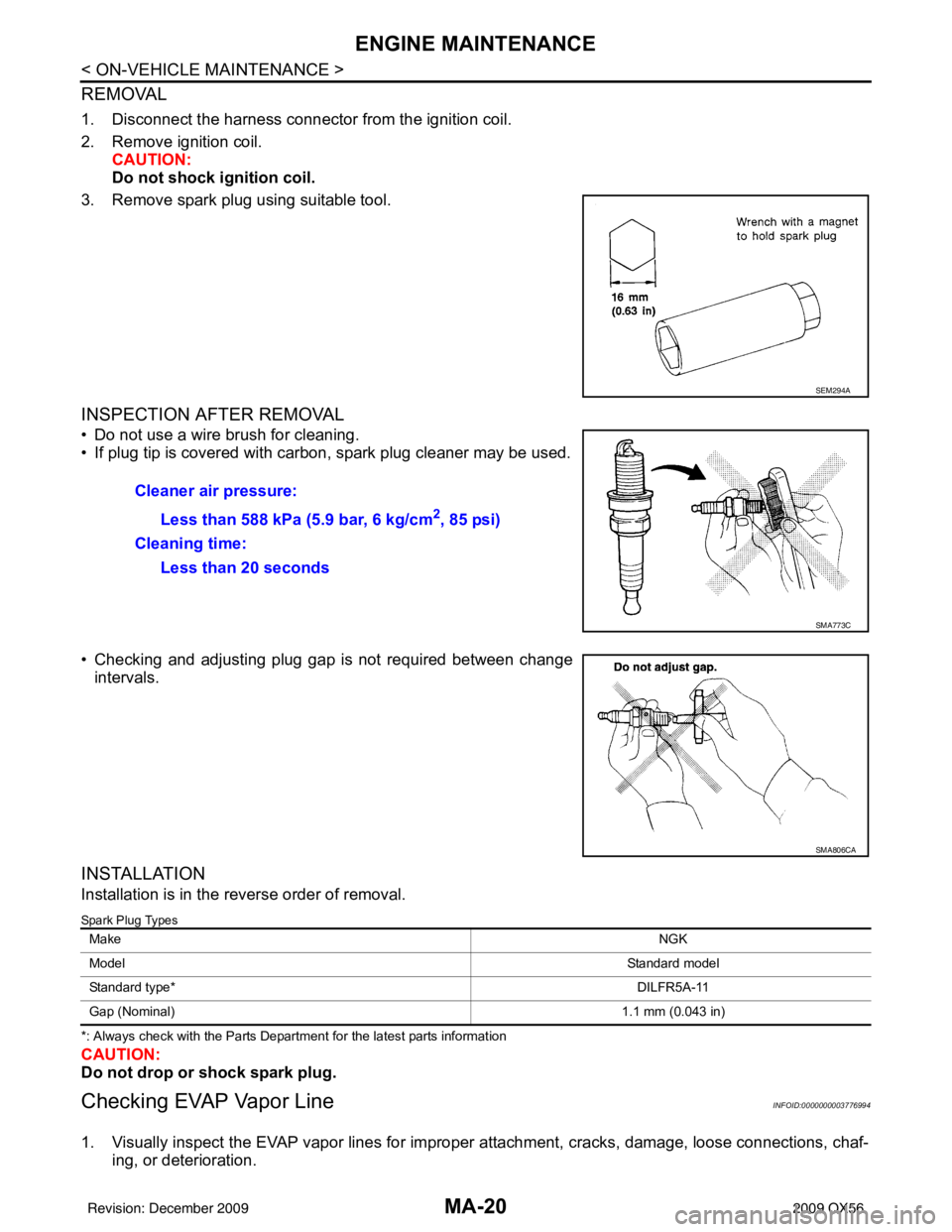

MA-20

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE

REMOVAL

1. Disconnect the harness connector from the ignition coil.

2. Remove ignition coil.CAUTION:

Do not shock ig nition coil.

3. Remove spark plug using suitable tool.

INSPECTION AFTER REMOVAL

• Do not use a wire brush for cleaning.

• If plug tip is covered with carbon, spark plug cleaner may be used.

• Checking and adjusting plug gap is not required between change intervals.

INSTALLATION

Installation is in the reverse order of removal.

Spark Plug Types

*: Always check with the Parts Department for the latest parts information

CAUTION:

Do not drop or shock spark plug.

Checking EVAP Vapor LineINFOID:0000000003776994

1. Visually inspect the EVAP vapor lines for improper attachment, cracks, damage, loose connections, chaf-

ing, or deterioration.

SEM294A

Cleaner air pressure:

Less than 588 kPa (5.9 bar, 6 kg/cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

SMA806CA

Make NGK

Model Standard model

Standard type* DILFR5A-11

Gap (Nominal) 1.1 mm (0.043 in)

Revision: December 20092009 QX56

Page 2784 of 4171

MWI-62

< ECU DIAGNOSIS >

COMBINATION METER

DTC Index

INFOID:0000000003776656

Function Specifications

Speedometer

Zero indication.

Tachometer

Fuel gauge

Engine coolant temperature gauge

Engine oil pressure gauge

Voltage gauge

A/T oil temperature gauge

Illumination control

Meter illumination Change to nighttime mode when communication is lost.

Segment LCD Odometer

Freeze current indication.

A/T position Display turns off.

Buzzer Buzzer turns off.

Warning lamp/indicator lamp ABS warning lamp

Lamp turns on when communication is lost.

Brake warning lamp

VDC OFF indicator lamp

SLIP indicator lamp

A/T CHECK warning lamp

Lamp turns off when communication is lost.

Oil pressure/coolant temperature

warning lamp

Light indicator

Malfunction indicator lamp

Master warning lamp

Air bag warning lamp

High beam indicator

Turn signal indicator lamp

CRUISE indicator lamp

Driver and passenger seat belt warn-

ing lamp

Lamp turns off when disconnected.

Charge warning lamp

Security indicator lamp

4WD indicator lamp

AT P i n d i c a t o r l a m p

CK SUSP warning lamp

Low tire pressure warning lamp

Lamp will flash every second for 1 minute and then stay on con-

tinuously thereafter.

CONSULT-III display

MalfunctionReference

page

CAN COMM CIRC

[U1000] Malfunction is detected in CAN communication.

CAUTION:

Even when there is no malfunction on CAN communication system, malfunction may be

misinterpreted when battery has low voltage (when maintaining 7 - 8 V for about 2 sec-

onds) or 10A fuse [No. 3, located in

the fuse block (J/B)] is disconnected. MWI-28

VEHICLE SPEED

CIRC

[B2205]Malfunction is detected when an erroneous speed signal is input.

CAUTION:

Even when there is no malfunction on speed signal system, malfunction may be misin-

terpreted when battery has lo

w voltage (when maintaining 7 - 8 V for about 2 seconds). MWI-29

Revision: December 20092009 QX56

Page 2801 of 4171

MWI

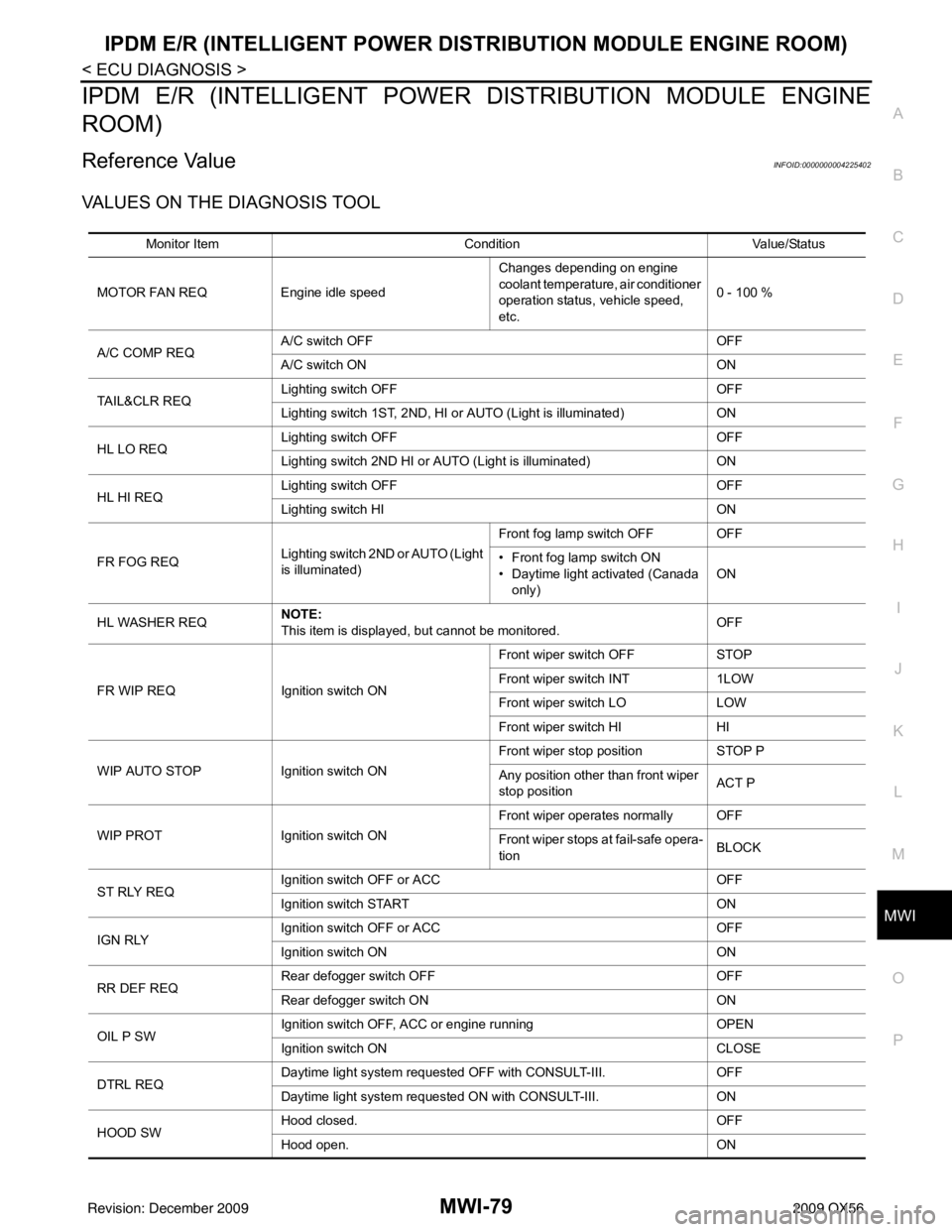

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

MWI-79

< ECU DIAGNOSIS >

C

D E

F

G H

I

J

K L

M B A

O P

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000004225402

VALUES ON THE DIAGNOSIS TOOL

Monitor Item ConditionValue/Status

MOTOR FAN REQ Engine idle speed Changes depending on engine

coolant temperature, air conditioner

operation status, vehicle speed,

etc.0 - 100 %

A/C COMP REQ A/C switch OFF

OFF

A/C switch ON ON

TA I L & C L R R E Q Lighting switch OFF

OFF

Lighting switch 1ST, 2ND, HI or AUTO (Light is illuminated) ON

HL LO REQ Lighting switch OFF

OFF

Lighting switch 2ND HI or AUTO (Light is illuminated) ON

HL HI REQ Lighting switch OFF

OFF

Lighting switch HI ON

FR FOG REQ Lighting switch 2ND or AUTO (Light

is illuminated) Front fog lamp switch OFF OFF

• Front fog lamp switch ON

• Daytime light activated (Canada

only) ON

HL WASHER REQ NOTE:

This item is displayed, but cannot be monitored.

OFF

FR WIP REQ Ignition switch ON Front wiper switch OFF

STOP

Front wiper switch INT 1LOW

Front wiper switch LO LOW

Front wiper switch HI HI

WIP AUTO STOP Ignition switch ON Front wiper stop position

STOP P

Any position other than front wiper

stop position ACT P

WIP PROT Ignition switch ON Front wiper operates normally OFF

Front wiper stops at fail-safe opera-

tion

BLOCK

ST RLY REQ Ignition switch OFF or ACC

OFF

Ignition switch START ON

IGN RLY Ignition switch OFF or ACC

OFF

Ignition switch ON ON

RR DEF REQ Rear defogger switch OFF

OFF

Rear defogger switch ON ON

OIL P SW Ignition switch OFF, ACC or engine running

OPEN

Ignition switch ON CLOSE

DTRL REQ Daytime light system requested OFF with CONSULT-III.

OFF

Daytime light system reques ted ON with CONSULT-III. ON

HOOD SW Hood closed.

OFF

Hood open. ON

Revision: December 20092009 QX56

Page 2812 of 4171

MWI-90

< ECU DIAGNOSIS >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

If No CAN Communication Is Available With BCM

IGNITION RELAY MALFUNCTION DETECTION FUNCTION

• IPDM E/R monitors the voltage at the contact circuit and excitation coil circuit of the ignition relay inside it.

• IPDM E/R judges the ignition relay error if the voltage differs between the contact circuit and the excitation

coil circuit.

• If the ignition relay cannot turn OFF due to contact seizure, it activates the tail lamp relay for 10 minutes to alert the user to the ignition relay malfunction when the ignition switch is turned OFF.

NOTE:

The tail lamp turns OFF when the ignition switch is turned ON.

FRONT WIPER CONTROL

IPDM E/R detects front wiper stop posit ion by a front wiper auto stop signal.

When a front wiper auto stop signal is in the conditions listed below, IPDM E/R stops power supply to wiper

after repeating a front wiper 10 second activation and 20 second stop five times.

NOTE:

This operation status can be confirmed on the IPDM E/R “DATA MONITOR” that displays “Block” for the item

“WIP PROT” while the wiper is stopped.

STARTER MOTOR PROTECTION FUNCTION

IPDM E/R turns OFF the starter control relay to protect the starter motor when the starter control relay remains

active for 90 seconds.

Control part Fail-safe in operation

Cooling fan • Turns ON the cooling fan relay when the ignition switch is turned ON

• Turns OFF the cooling fan relay when the ignition switch is turned OFF

Control part

Fail-safe in operation

Headlamp • Turns ON the headlamp low relay when the ignition switch is turned ON

• Turns OFF the headlamp low relay when the ignition switch is turned OFF

• Headlamp high relay OFF

•Parking lamps

• License plate lamps

• Tail lamps • Turns ON the tail lamp relay when the ignition switch is turned ON

• Turns OFF the tail lamp relay when the ignition switch is turned OFF

Front wiper • The status just before activation of fail-safe control is maintained until the ignition

switch is turned OFF while the front wiper is operating at LO or HI speed.

• The wiper is operated at LO speed until the ignition switch is turned OFF if the fail- safe control is activated while the front wipe r is set in the INT mode and the front wiper

motor is operating.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C relay OFF

Front fog lamps Front fog lamp relay OFF

Ignition switch Ignition relayTail lamp relay

ON ON —

OFF OFF —

Ignition switchFront wiper switch Auto stop signal

ON OFF

Front wiper stop position signal cannot be

input 10 seconds.

ON The signal does not change for 10 seconds.

Revision: December 20092009 QX56

Page 2821 of 4171

MWI

NORMAL OPERATING CONDITIONMWI-99

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

NORMAL OPERATING CONDITION

COMPASS

COMPASS : Description (Early Production)INFOID:0000000004244474

COMPASS

• The electronic compass is highly protected from changes in most magnetic fields. However, some large

changes in magnetic fields can affect it. Some exampl es are (but not limited to): high tension power lines,

large steel buildings, subways, steel bridges, automatic car washes, large piles of scrap metal, etc. While

this does not happen very often, it is possible.

• During normal operation, the Compass Mirror will cont inuously update the compass calibration to adjust for

gradual changes in the vehicle's magnetic "remnant" field. If the vehicle is subjected to high magnetic influ-

ences, the compass may appear to indicate false headings , become locked, or appear that it is unable to be

calibrated. If this occurs, perform the calibration procedure.

• If at any time the compass continually displays the incorrect direction or the reading is erratic or locked, ver-

ify the correct zone variance.

Symptom Chart

Symptom CauseSolution / Reference

The compass display reads "C".

• Compass is not calibrated.

• Incorrect zone variance setting.

• Large change in magnetic field (Steel bridges, subways, concentrations of

metal, car washes, etc.)

• Compass was calibrated incorrectly or

in the presence of a strong magnetic

field. Perform Calibration. Refer to

MWI-22,

"Description (Early Production)".

Compass shows the wrong direction.

Compass does not change direction ap-

pears "Locked".

Compass does not show all the directions,

one or more is missing.

The compass was calibrated but it "loses"

calibration.

On long trips the compass shows the

wrong direction.

Perform Zone Variatio

n Setting if correct

reading is desired in that location. Refer to

MWI-22, "

Description (Early Production)".

Revision: December 20092009 QX56

Page 2856 of 4171

![INFINITI QX56 2009 Factory Workshop Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-19

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER

DISTRIBUTION MODULE ENGINE INFINITI QX56 2009 Factory Workshop Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-19

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER

DISTRIBUTION MODULE ENGINE](/img/42/57031/w960_57031-2855.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-19

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER

DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000003776502

VALUES ON THE DIAGNOSIS TOOL

Monitor Item ConditionValue/Status

MOTOR FAN REQ Engine idle speed Changes depending on engine

coolant temperature, air conditioner

operation status, vehicle speed,

etc.0 - 100 %

A/C COMP REQ A/C switch OFF

OFF

A/C switch ON ON

TA I L & C L R R E Q Lighting switch OFF

OFF

Lighting switch 1ST, 2ND, HI or AUTO (Light is illuminated) ON

HL LO REQ Lighting switch OFF

OFF

Lighting switch 2ND HI or AUTO (Light is illuminated) ON

HL HI REQ Lighting switch OFF

OFF

Lighting switch HI ON

FR FOG REQ Lighting switch 2ND or AUTO (Light

is illuminated) Front fog lamp switch OFF OFF

• Front fog lamp switch ON

• Daytime light activated (Canada

only) ON

FR WIP REQ Ignition switch ON Front wiper switch OFF

STOP

Front wiper switch INT 1LOW

Front wiper switch LO LOW

Front wiper switch HI HI

WIP AUTO STOP Ignition switch ON Front wiper stop position

STOP P

Any position other than front wiper

stop position ACT P

WIP PROT Ignition switch ON Front wiper operates normally OFF

Front wiper stops at fail-safe opera-

tion

BLOCK

ST RLY REQ Ignition switch OFF or ACC

OFF

Ignition switch START ON

IGN RLY Ignition switch OFF or ACC

OFF

Ignition switch ON ON

RR DEF REQ Rear defogger switch OFF

OFF

Rear defogger switch ON ON

OIL P SW Ignition switch OFF, ACC or engine running

OPEN

Ignition switch ON CLOSE

DTRL REQ Daytime light system requested OFF with CONSULT-III.

OFF

Daytime light system reques ted ON with CONSULT-III. ON

HOOD SW Hood closed.

OFF

Hood open. ON

Revision: December 20092009 QX56