INFINITI QX56 2009 Factory Service Manual

QX56 2009

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57031/w960_57031-0.png

INFINITI QX56 2009 Factory Service Manual

Page 624 of 4171

BRM-28

< SERVICE INFORMATION >

BODY REPAIR

Passenger Compartment

LIIA1509E

Revision: December 20092009 QX56

Page 625 of 4171

BODY REPAIRBRM-29

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

MEASUREMENT

LIIA1510E

Revision: December 20092009 QX56

Page 626 of 4171

BRM-30

< SERVICE INFORMATION >

BODY REPAIR

LIIA1105E

Revision: December 20092009 QX56

Page 627 of 4171

BODY REPAIRBRM-31

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

MEASUREMENT POINTS

LIIA1103E

Revision: December 20092009 QX56

Page 628 of 4171

BRM-32

< SERVICE INFORMATION >

BODY REPAIR

AWIIA1090GB

Revision: December 20092009 QX56

Page 629 of 4171

BODY REPAIRBRM-33

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

Rear Body

LIIA1106E

Revision: December 20092009 QX56

Page 630 of 4171

BRM-34

< SERVICE INFORMATION >

BODY REPAIR

MEASUREMENT

LIIA1511E

Revision: December 20092009 QX56

Page 631 of 4171

BODY REPAIRBRM-35

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

MEASUREMENT POINTS

Precaution in Repairing High Strength SteelINFOID:0000000003776125

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

High strength steel (hss)

used in nissan vehicles

LIIA1107E

Revision: December 20092009 QX56

Page 632 of 4171

BRM-36

< SERVICE INFORMATION >

BODY REPAIR

SP130 is the most commonly used HSS.

SP150 HSS is used only on parts that require much more strength.

Read the following precautions when repairing HSS:

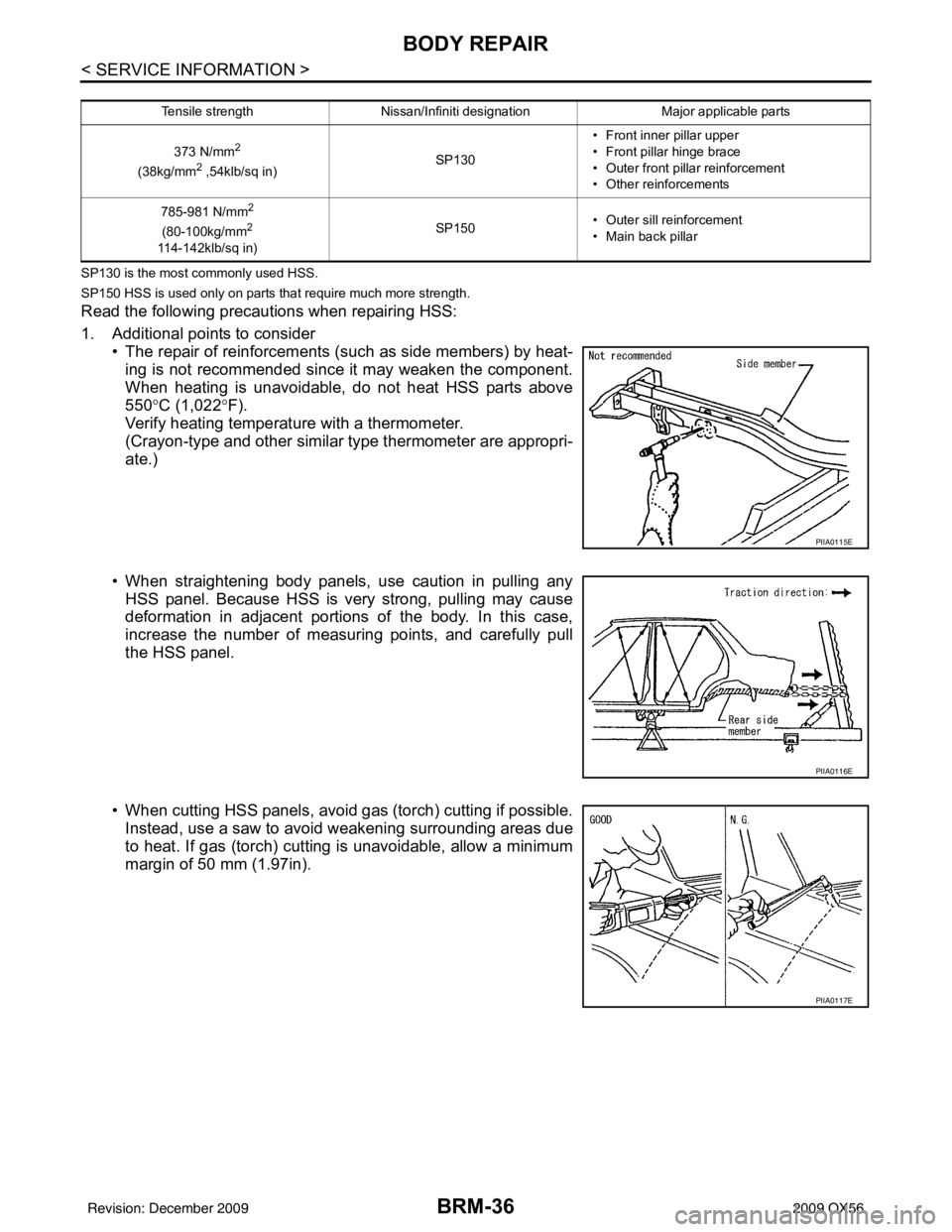

1. Additional points to consider• The repair of reinforcements (such as side members) by heat-ing is not recommended since it may weaken the component.

When heating is unavoidable, do not heat HSS parts above

550° C (1,022° F).

Verify heating temperature with a thermometer.

(Crayon-type and other similar type thermometer are appropri-

ate.)

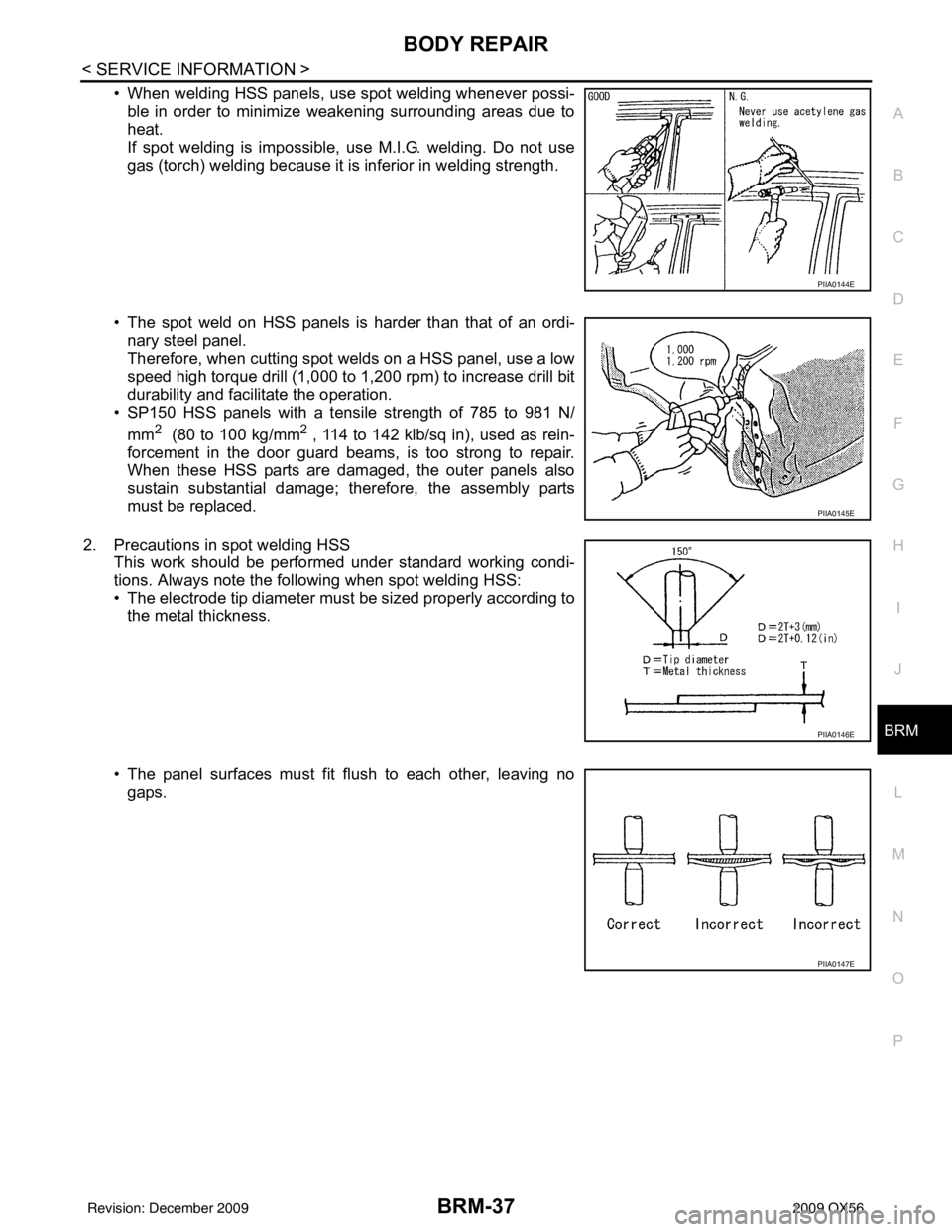

• When straightening body panels, use caution in pulling any HSS panel. Because HSS is very strong, pulling may cause

deformation in adjacent portions of the body. In this case,

increase the number of measuring points, and carefully pull

the HSS panel.

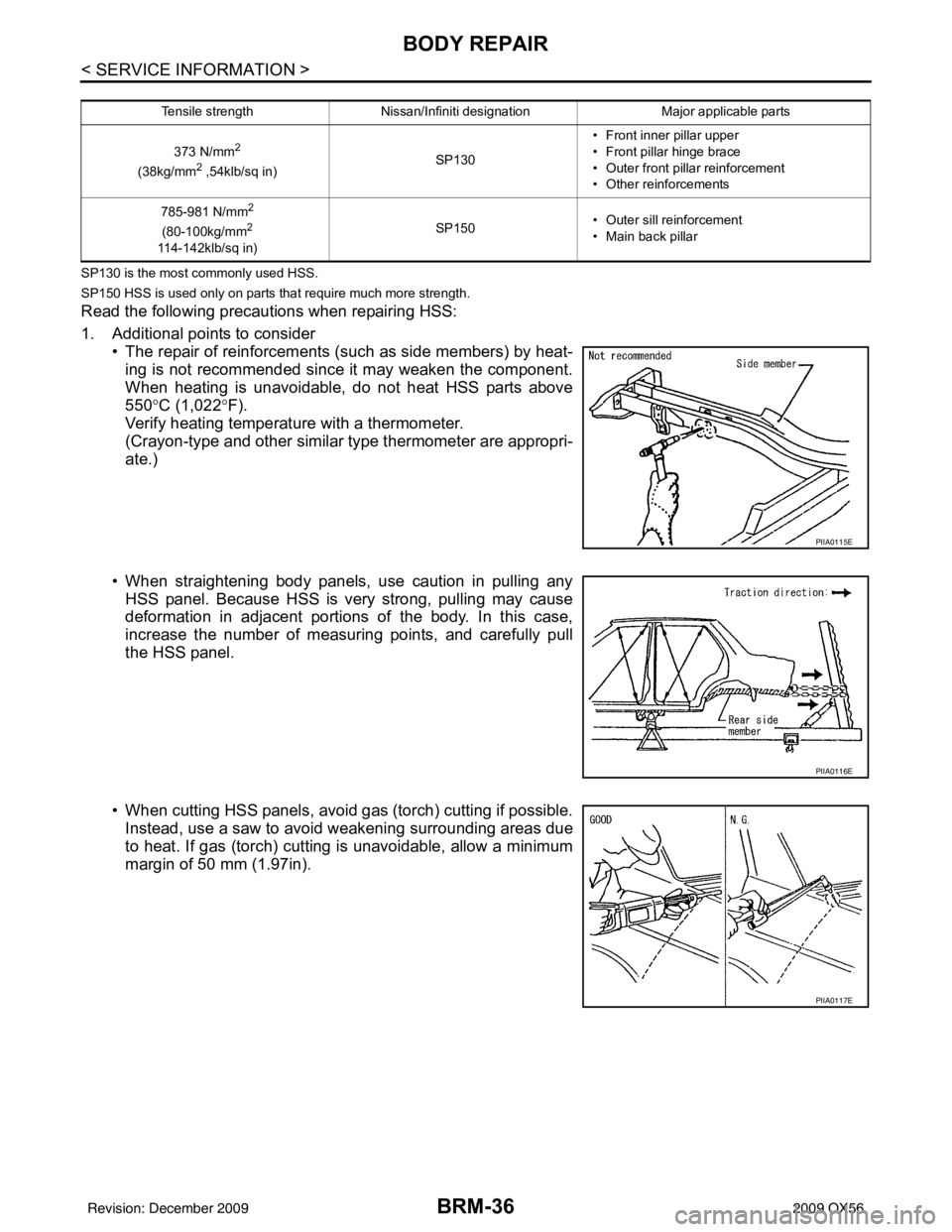

• When cutting HSS panels, avoid gas (torch) cutting if possible. Instead, use a saw to avoid weakening surrounding areas due

to heat. If gas (torch) cutting is unavoidable, allow a minimum

margin of 50 mm (1.97in).

Tensile strength Nissan/Infiniti designation Major applicable parts

373 N/mm

2

(38kg/mm2 ,54klb/sq in) SP130• Front inner pillar upper

• Front pillar hinge brace

• Outer front pillar reinforcement

• Other reinforcements

785-981 N/mm

2

(80-100kg/mm2

114-142klb/sq in) SP150

• Outer sill reinforcement

• Main back pillar

PIIA0115E

PIIA0116E

PIIA0117E

Revision: December 20092009 QX56

Page 633 of 4171

BODY REPAIRBRM-37

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

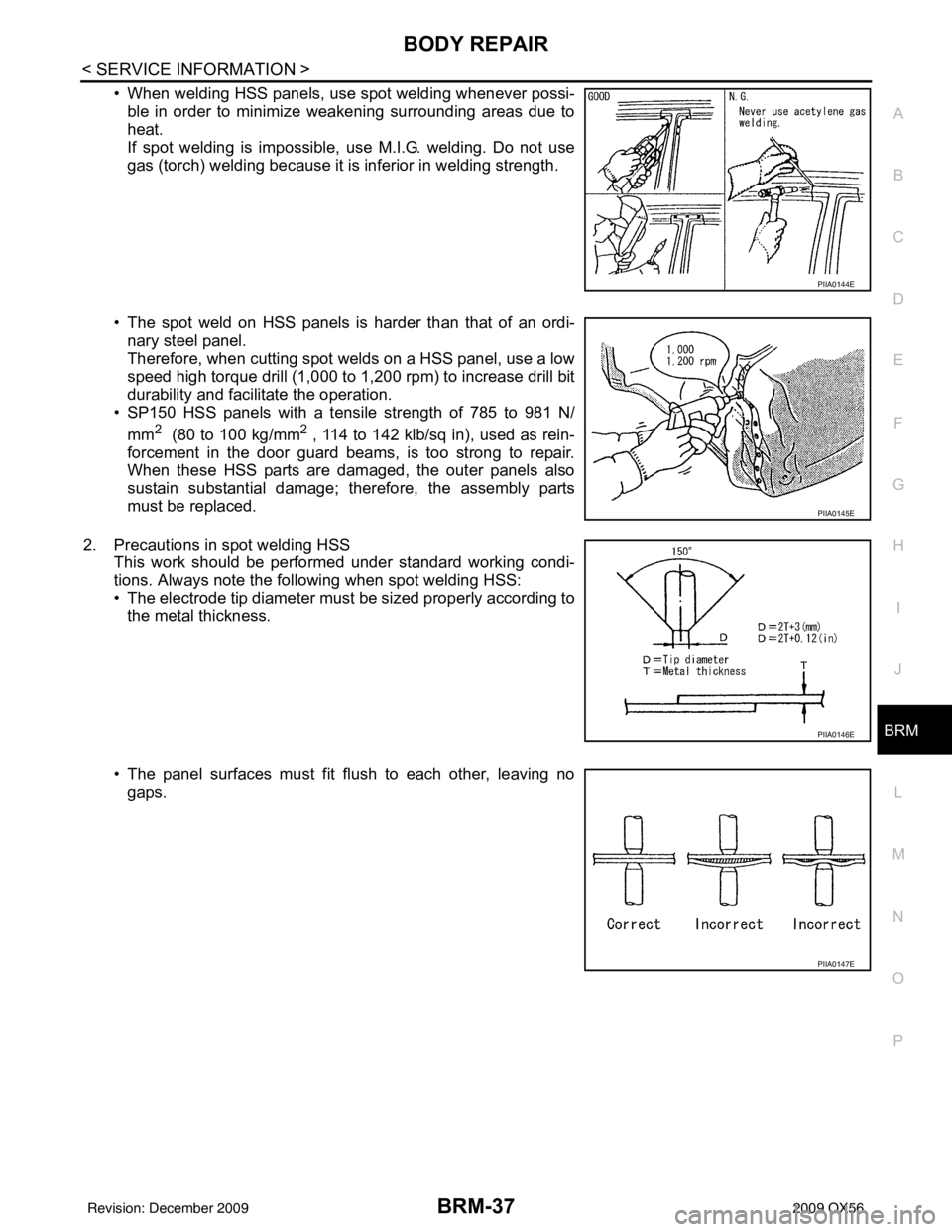

• When welding HSS panels, use spot welding whenever possi- ble in order to minimize weakening surrounding areas due to

heat.

If spot welding is impossible, use M.I.G. welding. Do not use

gas (torch) welding because it is inferior in welding strength.

• The spot weld on HSS panels is harder than that of an ordi- nary steel panel.

Therefore, when cutting spot welds on a HSS panel, use a low

speed high torque drill (1,000 to 1,200 rpm) to increase drill bit

durability and facilitate the operation.

• SP150 HSS panels with a tensile strength of 785 to 981 N/

mm

2 (80 to 100 kg/mm2 , 114 to 142 klb/sq in), used as rein-

forcement in the door guard beams, is too strong to repair.

When these HSS parts are damaged, the outer panels also

sustain substantial damage; therefore, the assembly parts

must be replaced.

2. Precautions in spot welding HSS This work should be performed under standard working condi-

tions. Always note the following when spot welding HSS:

• The electrode tip diameter must be sized properly according tothe metal thickness.

• The panel surfaces must fit flush to each other, leaving no gaps.

PIIA0144E

PIIA0145E

PIIA0146E

PIIA0147E

Revision: December 20092009 QX56