clutch INFINITI QX56 2009 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 2281 of 4171

REFRIGERATION SYSTEMHA-17

< FUNCTION DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

FUNCTION DIAGNOSIS

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000003775298

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is , through the compressor, the condenser with liquid tank,

through the front and rear evaporators, and back to the compressor. The refrigerant evaporation through the

evaporator coils are controlled by fr ont and rear externally equalized expansion valves, located inside the front

and rear evaporator cases.

Refrigerant System ProtectionINFOID:0000000003775299

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rise s above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnet ic compressor clutch when pressure on the high

pressure side detected by refrigerant pressu re sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below

about 120 kPa (1.22 kg/cm

2, 17.4 psi).

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system incr eases to an abnormal level [more than 2,990 kPa (30.5 kg/

Revision: December 20092009 QX56

Page 2296 of 4171

HA-32

< ON-VEHICLE REPAIR >

COMPRESSOR

Replace the O-rings of the low-pressure flexible hose and high-pressure flexible hose with new

ones, apply compressor oil to the O-rings when installing them.

After recharging the A/C system with refrigerant, check for leaks.

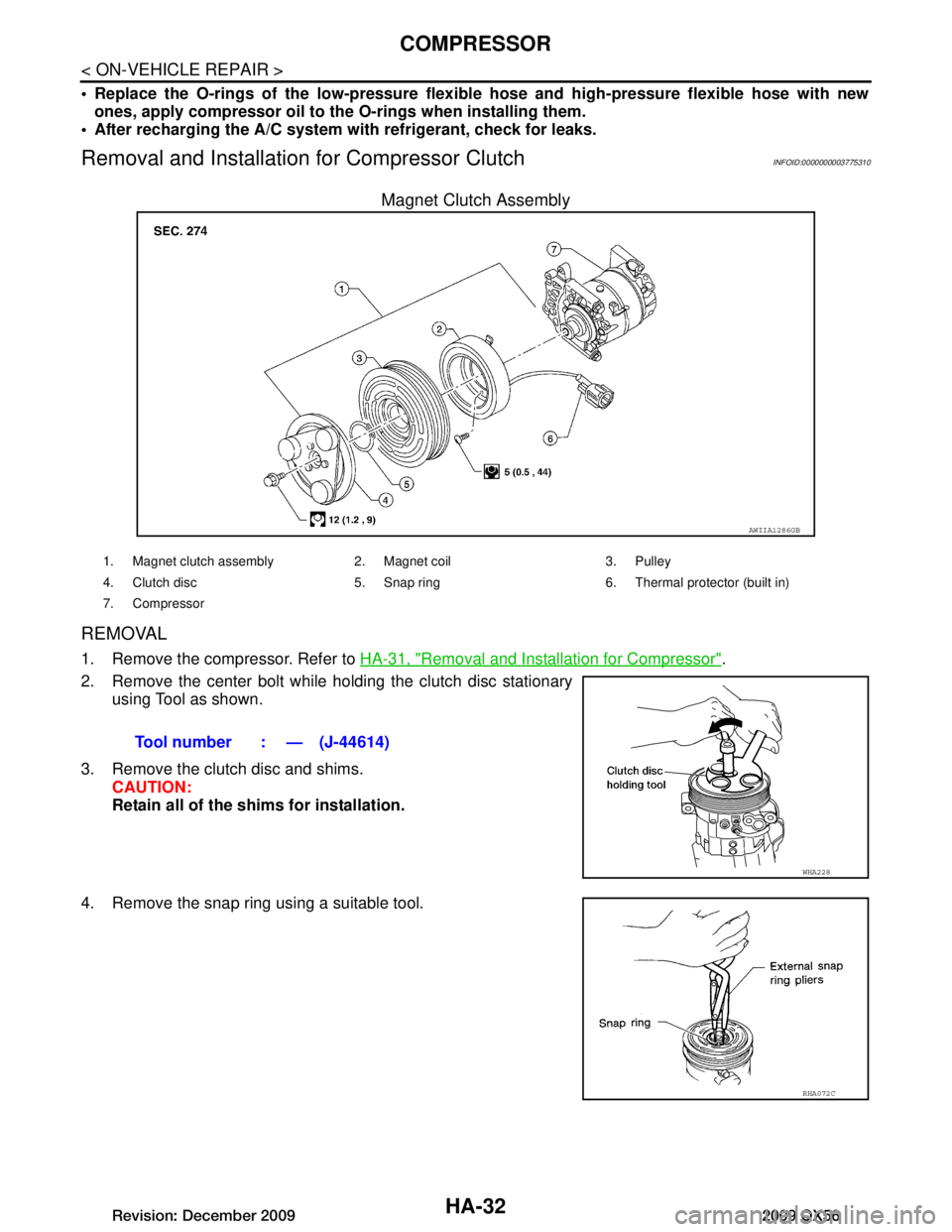

Removal and Installation for Compressor ClutchINFOID:0000000003775310

Magnet Clutch Assembly

REMOVAL

1. Remove the compressor. Refer to HA-31, "Removal and Installation for Compressor".

2. Remove the center bolt while holding the clutch disc stationary using Tool as shown.

3. Remove the clutch disc and shims. CAUTION:

Retain all of the shims for installation.

4. Remove the snap ring using a suitable tool.

AWIIA1286GB

1. Magnet clutch assembly 2. Magnet coil 3. Pulley

4. Clutch disc 5. Snap ring 6. Thermal protector (built in)

7. Compressor

Tool number : — (J-44614)

WHA228

RHA072C

Revision: December 20092009 QX56

Page 2297 of 4171

COMPRESSORHA-33

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

5. Remove the pulley using suitable tool (A). CAUTION:

To prevent deformation of th e pulley groove, the puller

claws should be hooked un der the pulley groove and not

into the pulley groove.

6. Remove the three magnet coil screws using a suitable tool and remove the magnet coil.

INSPECTION

Clutch Disc

If the contact surface shows si gns of damage due to excessive heat,

replace clutch disc and pulley.

Pulley

Check the appearance of the pulley assembly. If contact surface of pulley shows signs of excessive grooving,

replace clutch disc and pulley. The contact surfaces of the pulley assembly should be cleaned with a suitable

solvent before reinstallation.

Coil

Check magnet coil for loose connections or any cracked insulation.

INSTALLATION

1. Install the magnet coil. CAUTION:

Be sure to align the magnet co il pin with the hole in the

compressor front head.

AWIIA1285ZZ

WHA212

WHA183

WHA213

Revision: December 20092009 QX56

Page 2298 of 4171

HA-34

< ON-VEHICLE REPAIR >

COMPRESSOR

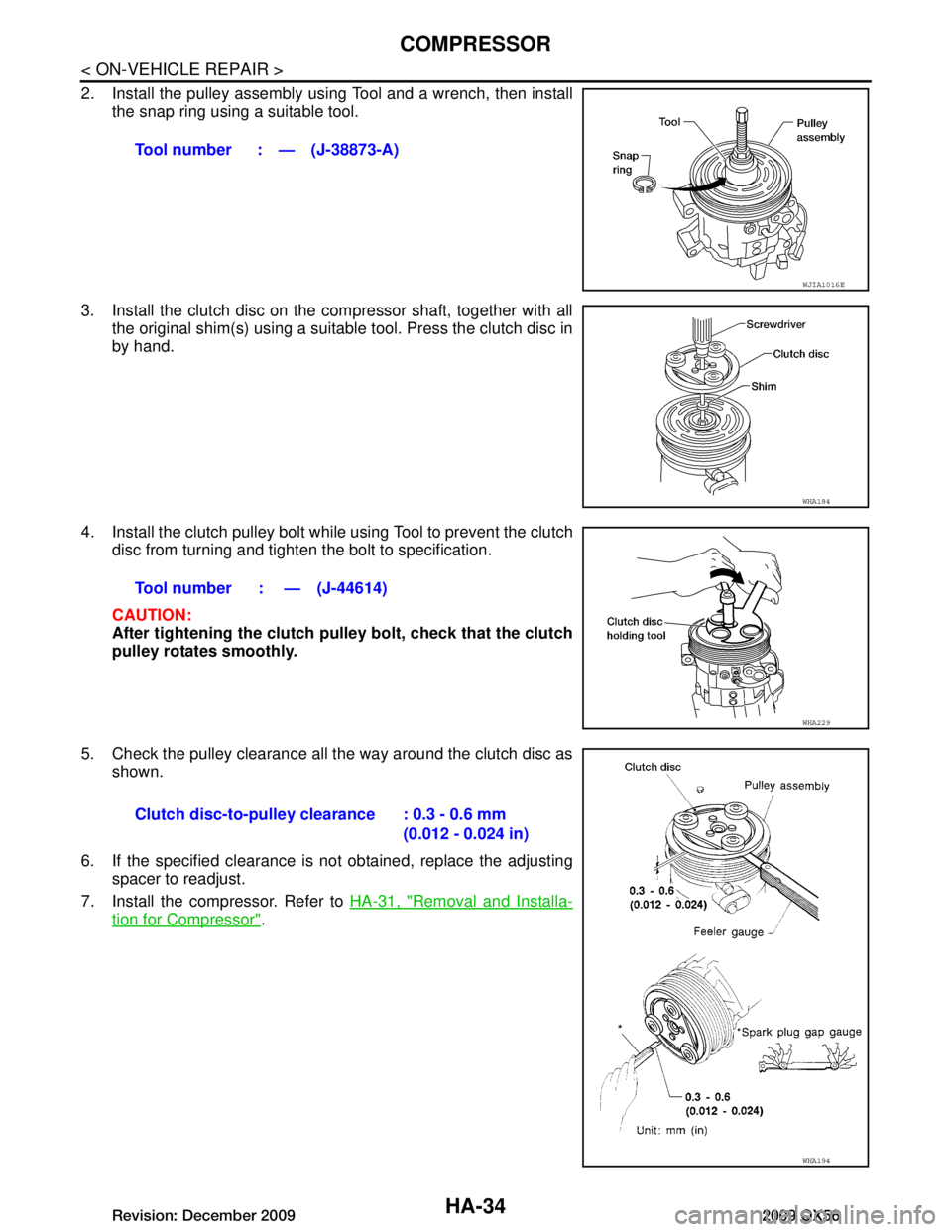

2. Install the pulley assembly using Tool and a wrench, then installthe snap ring using a suitable tool.

3. Install the clutch disc on the compressor shaft, together with all the original shim(s) using a suitabl e tool. Press the clutch disc in

by hand.

4. Install the clutch pulley bolt while using Tool to prevent the clutch

disc from turning and tighten the bolt to specification.

CAUTION:

After tightening the clutch pu lley bolt, check that the clutch

pulley rotates smoothly.

5. Check the pulley clearance all the way around the clutch disc as shown.

6. If the specified clearance is not obtained, replace the adjusting spacer to readjust.

7. Install the compressor. Refer to HA-31, "Removal and Installa-

tion for Compressor".

Tool number : — (J-38873-A)

WJIA1016E

WHA184

Tool number : — (J-44614)

WHA229

Clutch disc-to-pulley clearance : 0.3 - 0.6 mm

(0.012 - 0.024 in)

WHA194

Revision: December 20092009 QX56

Page 2299 of 4171

COMPRESSORHA-35

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Revision: December 20092009 QX56

Page 2315 of 4171

HAC-2

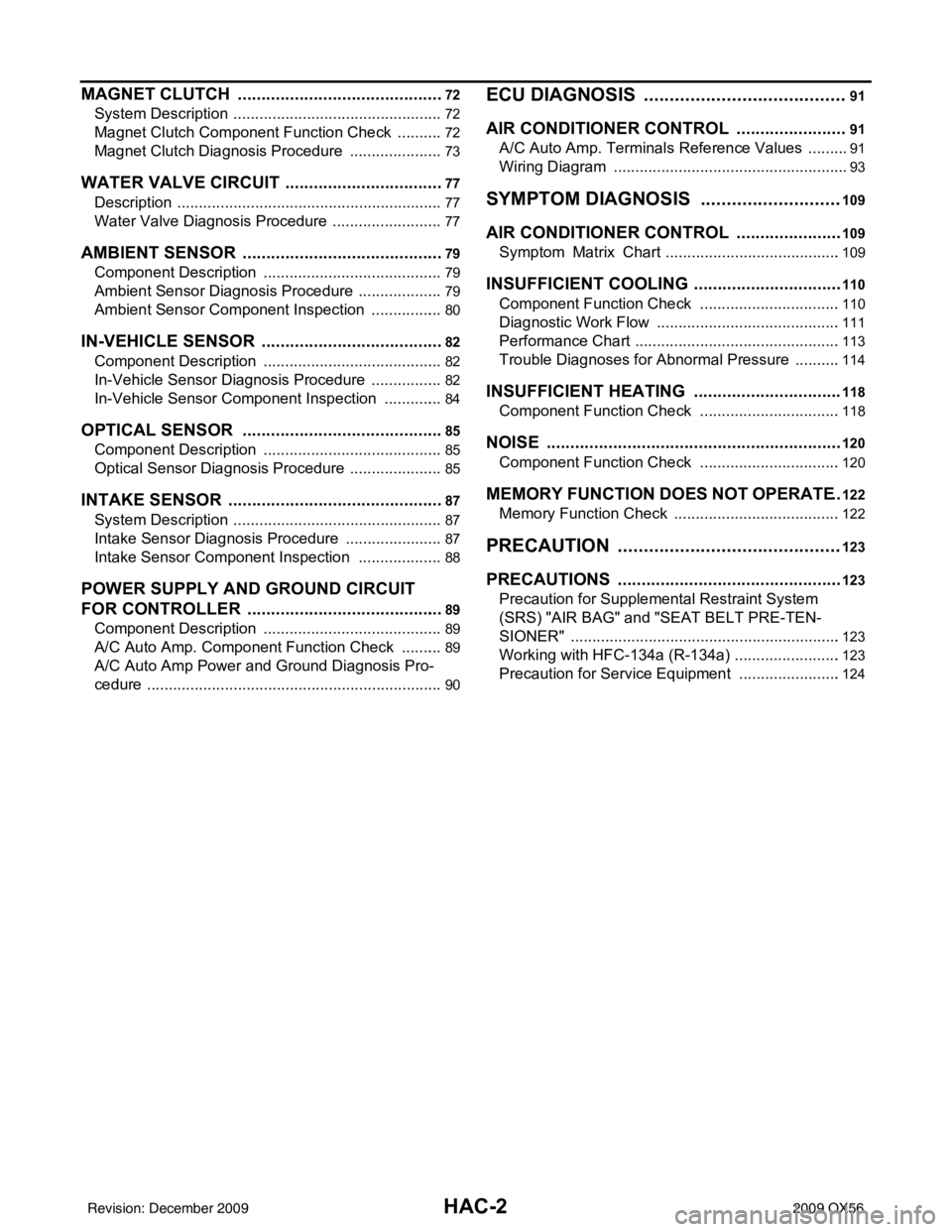

MAGNET CLUTCH ............................................72

System Description .............................................. ...72

Magnet Clutch Component Function Check ........ ...72

Magnet Clutch Diagnosis Procedure ................... ...73

WATER VALVE CIRCUIT ..................................77

Description ........................................................... ...77

Water Valve Diagnosis Procedure ..........................77

AMBIENT SENSOR ...........................................79

Component Description ....................................... ...79

Ambient Sensor Diagnosis Procedure ....................79

Ambient Sensor Component Inspection .................80

IN-VEHICLE SENSOR .......................................82

Component Description ....................................... ...82

In-Vehicle Sensor Diagnosis Procedure .................82

In-Vehicle Sensor Component Inspection ..............84

OPTICAL SENSOR ...........................................85

Component Description ..........................................85

Optical Sensor Diagnosis Procedure ......................85

INTAKE SENSOR ..............................................87

System Description .............................................. ...87

Intake Sensor Diagnosis Procedure .......................87

Intake Sensor Component Inspection ................. ...88

POWER SUPPLY AND GROUND CIRCUIT

FOR CONTROLLER ..........................................

89

Component Description ....................................... ...89

A/C Auto Amp. Component Function Check ..........89

A/C Auto Amp Power and Ground Diagnosis Pro-

cedure .....................................................................

90

ECU DIAGNOSIS .......................................91

AIR CONDITIONER CONTROL ..................... ...91

A/C Auto Amp. Terminals Reference Values ..........91

Wiring Diagram .................................................... ...93

SYMPTOM DIAGNOSIS ...........................109

AIR CONDITIONER CONTROL ..................... ..109

Symptom Matrix Chart ........................................ .109

INSUFFICIENT COOLING ................................110

Component Function Check ................................ .110

Diagnostic Work Flow ...........................................111

Performance Chart ................................................113

Trouble Diagnoses for Abnormal Pressure ...........114

INSUFFICIENT HEATING ................................118

Component Function Check .................................118

NOISE ...............................................................120

Component Function Check ................................ .120

MEMORY FUNCTION DOES NOT OPERATE ..122

Memory Function Check ...................................... .122

PRECAUTION ...........................................123

PRECAUTIONS .............................................. ..123

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

123

Working with HFC-134a (R-134a) ........................ .123

Precaution for Service Equipment ........................124

Revision: December 20092009 QX56

Page 2317 of 4171

![INFINITI QX56 2009 Factory Repair Manual HAC-4

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational Check (Front)INFOID:0000000003775325

The purpose of the operational check is to

c INFINITI QX56 2009 Factory Repair Manual HAC-4

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational Check (Front)INFOID:0000000003775325

The purpose of the operational check is to

c](/img/42/57031/w960_57031-2316.png)

HAC-4

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONER]

INSPECTION AND ADJUSTMENT

INSPECTION AND ADJUSTMENT

Operational Check (Front)INFOID:0000000003775325

The purpose of the operational check is to

confirm that the system operates properly.

CHECKING MEMORY FUNCTION

1. Set the temperature to 32 ° (90 °F).

2. Press the OFF switch.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Press the AUTO switch.

6. Confirm that the set temperature remains at previous temperature.

7. Press the OFF switch.

If NG, go to trouble diagnosis procedure for HAC-122, "

Memory Function Check".

If OK, continue with next check.

CHECKING BLOWER

1. Press the blower speed control switch (+) once, blower should operate on low speed. The fan display should have one bar lit (on display).

2. Press the blower speed control switch (+) again, and continue checking blower speed and fan display until

all speeds are checked.

3. Leave blower on maximum speed.

If NG, go to trouble diagnosis procedure for HAC-52, "

Front Blower Motor Diagnosis Procedure".

If OK, continue with next check.

CHECKING DISCHARGE AIR

1. Press MODE switch four times and the DEF switch.

2. Each position indicator should change shape (on display).

3. Confirm that discharge air comes out according to the air distribution table. Refer to HAC-16, "

Discharge

Air Flow (Front)".

Mode door position is checked in the next step.

If NG, go to trouble diagnosis procedure for HAC-27, "

Mode Door Motor (Front) Diagnosis Procedure".

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or visual inspection) and intake door position is at

fresh when the DEF or D/F is selected.

CHECKING RECIRCULATION ( , ONLY)

1. Press recirculation ( ) switch one time. Recirculation indicator should illuminate.

2. Press recirculation ( ) switch one more time. Recirculation indicator should go off.

3. Listen for intake door position change (blower sound should change slightly).

If NG, go to trouble diagnosis procedure for HAC-43, "

Intake Door Motor Diagnosis Procedure".

If OK, continue the check.

NOTE:

Confirm that the compressor clutch is engaged (sound or vis ual inspection) and intake door position is at fresh

when the DEF or D/F is selected. REC ( ) is not allowed in DEF ( ) D/F ( ) or FOOT ( ).

CHECKING TEMPERATURE DECREASE

1. Rotate temperature control dial (drive or passenger) counterclockwise until 18° C (60°F) is displayed.

2. Check for cold air at appropriate discharge air outlets. Conditions : Engine running and at normal operating temperature

Revision: December 20092009 QX56

Page 2318 of 4171

![INFINITI QX56 2009 Factory Repair Manual INSPECTION AND ADJUSTMENTHAC-5

< BASIC INSPECTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnos INFINITI QX56 2009 Factory Repair Manual INSPECTION AND ADJUSTMENTHAC-5

< BASIC INSPECTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnos](/img/42/57031/w960_57031-2317.png)

INSPECTION AND ADJUSTMENTHAC-5

< BASIC INSPECTION > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnosis procedure for HAC-110,

"Component Function Check". If air mix door motor appears to be malfunctioning, go to HAC-32, "Air Mix Door

Motor Component Function Check".

If OK, continue the check.

CHECKING TEMPERATURE INCREASE

1. Rotate temperature control dial clockwise (drive or passenger) until 32 °C (90° F) is displayed.

2. Check for hot air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnosis procedure for HAC-118,

"Component Function Check". If air mix door motor appears to be malfunctioning, go to HAC-32, "Air Mix Door

Motor Component Function Check".

If OK, continue with next check.

CHECK A/C SWITCH

1. Press A/C switch when AUTO switch is ON, or in manual mode.

2. A/C switch indicator will turn ON. • Confirm that the compressor clutch engages (sound or visual inspection).

NOTE:

If current mode setting is DEF or D/F, compre ssor clutch will already be engaged and cannot be turned off.

If NG, go to trouble diagnosis procedure for HAC-73, "

Magnet Clutch Diagnosis Procedure".

If OK, continue with next check.

CHECKING AUTO MODE

1. Press AUTO switch.

2. Display should indicate AUTO.

• If ambient temperature is warm, and selected temperat ure is cool, confirm that the compressor clutch

engages (sound or visual inspection). (Discharge air and blower speed will depend on ambient, in-vehi-

cle, and set temperatures.)

If NG, go to trouble diagnosis procedure for HAC-90, "

A/C Auto Amp Power and Ground Diagnosis Proce-

dure", then if necessary, trouble diagnosis procedure for HAC-73, "Magnet Clutch Diagnosis Procedure".

If all operational checks are OK (symptom cannot be duplicated), go to malfunction Simulation Tests in HAC-

3, "How to Perform Trouble Diagnosis For Quick And Accurate Repair" and perform tests as outlined to simu-

late driving conditions environment. If symptom appears. Refer to HAC-109, "

SymptomMatrixChart", and

perform applicable troubl e diagnosis procedures.

Operational Check (Rear)INFOID:0000000003775326

The purpose of the operational check is to confirm that the system operates properly.

CHECKING REAR BLOWER MOTOR

1. Turn the ignition switch ON.

2. Rotate rear air control (front) blower control dial to low speed.

3. Rotate the blower control dial clockwise and continue checking blower speed until all speeds are checked.

4. Leave blower on maximum speed.

5. Press the REAR CTRL switch from the rear air control (front).

6. Rotate rear air control (rear) blower control dial to low speed.

7. Rotate the blower control dial clockwise and continue checking blower speed until all speeds are checked.

8. Leave blower on maximum speed.

If NG, go to trouble diagnosis procedure for HAC-57, "

Rear Blower Motor Component Function Check".

If OK, continue with next check.

CHECKING REAR DISCHARGE AIR

Conditions : Engine running and at normal operating temperature

Revision: December 20092009 QX56

Page 2323 of 4171

![INFINITI QX56 2009 Factory Repair Manual HAC-10

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

FUNCTION INFORMATION

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor.

HAC-46

Front blower mo INFINITI QX56 2009 Factory Repair Manual HAC-10

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

FUNCTION INFORMATION

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor.

HAC-46

Front blower mo](/img/42/57031/w960_57031-2322.png)

HAC-10

< FUNCTION DIAGNOSIS >[AUTOMATIC AIR CONDITIONER]

FUNCTION INFORMATION

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor.

HAC-46

Front blower motor operation is malfunction-

ing.Go to Trouble Diagnosis Procedure for Front Blower Motor.

HAC-51

Rear blower motor operation is malfunction-

ing.Go to Trouble Diagnosis Procedure for Rear Blower Motor.

HAC-57

Rear air discharge outlet does not change. Go to Trouble Diagnosis Procedure for Mode Door Motor (rear). HAC-62

Rear air temperature does not change. Go to Trouble Diagnosis Procedure for Air Mix Door Motor (rear).HAC-62

Magnet clutch does not engage.Go to Trouble Diagnosis Procedure for Magnet Clutch. HAC-72

Insufficient coolingGo to Trouble Diagnosis Procedure for Insufficient Cooling. HAC-110

Insufficient heatingGo to Trouble Diagnosis Procedure for Insufficient Heating. HAC-118

NoiseGo to Trouble Diagnosis Procedure for Noise. HAC-120

Self-diagnosis cannot be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis. HAC-89

Memory function does not operate.Go to Trouble Diagnosis Procedure for Memory Function. HAC-122

SymptomReference Page

Revision: December 20092009 QX56

Page 2324 of 4171

![INFINITI QX56 2009 Factory Repair Manual REFRIGERATION SYSTEMHAC-11

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000004040375

REFRIGERANT FLOW

The refri INFINITI QX56 2009 Factory Repair Manual REFRIGERATION SYSTEMHAC-11

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000004040375

REFRIGERANT FLOW

The refri](/img/42/57031/w960_57031-2323.png)

REFRIGERATION SYSTEMHAC-11

< FUNCTION DIAGNOSIS > [AUTOMATIC AIR CONDITIONER]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REFRIGERATION SYSTEM

Refrigerant CycleINFOID:0000000004040375

REFRIGERANT FLOW

The refrigerant flows in the standard pattern, that is, through the compressor, the condenser with liquid tank,

through the front and rear evaporators, and back to the compressor. The refrigerant evaporation through the

evaporator coils are controlled by front and rear externally equalized expansion valves, located inside the front

and rear evaporator cases.

Refrigerant System ProtectionINFOID:0000000004040376

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively hi gh or low pressures by the refrigerant pressure sen-

sor, located on the condenser. If the system pressure rises above or falls below the specifications, the refriger-

ant pressure sensor detects the pressure inside the refrigerant line and sends a voltage signal to the ECM.

The ECM de-energizes the A/C relay to disengage the magnetic compressor clutch when pressure on the high

pressure side detected by refrigerant pressu re sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi), or below

about 120 kPa (1.22 kg/cm

2, 17.4 psi).

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compressor.

When the pressure of refrigerant in the system incr eases to an abnormal level [more than 2,990 kPa (30.5 kg/

Revision: December 20092009 QX56