transmission oil INFINITI QX56 2009 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3860 of 4171

TM-212

< ON-VEHICLE REPAIR >

REAR OIL SEAL

REAR OIL SEAL

Rear Oil SealINFOID:0000000004187482

REMOVAL AND INSTALLATION

Removal

1. Remove rear propeller shaft. Refer to DLN-196, "Removal and Installation".

2. Remove transfer from transmission (4WD models). Refer to DLN-141, "Removal and Installation"

.

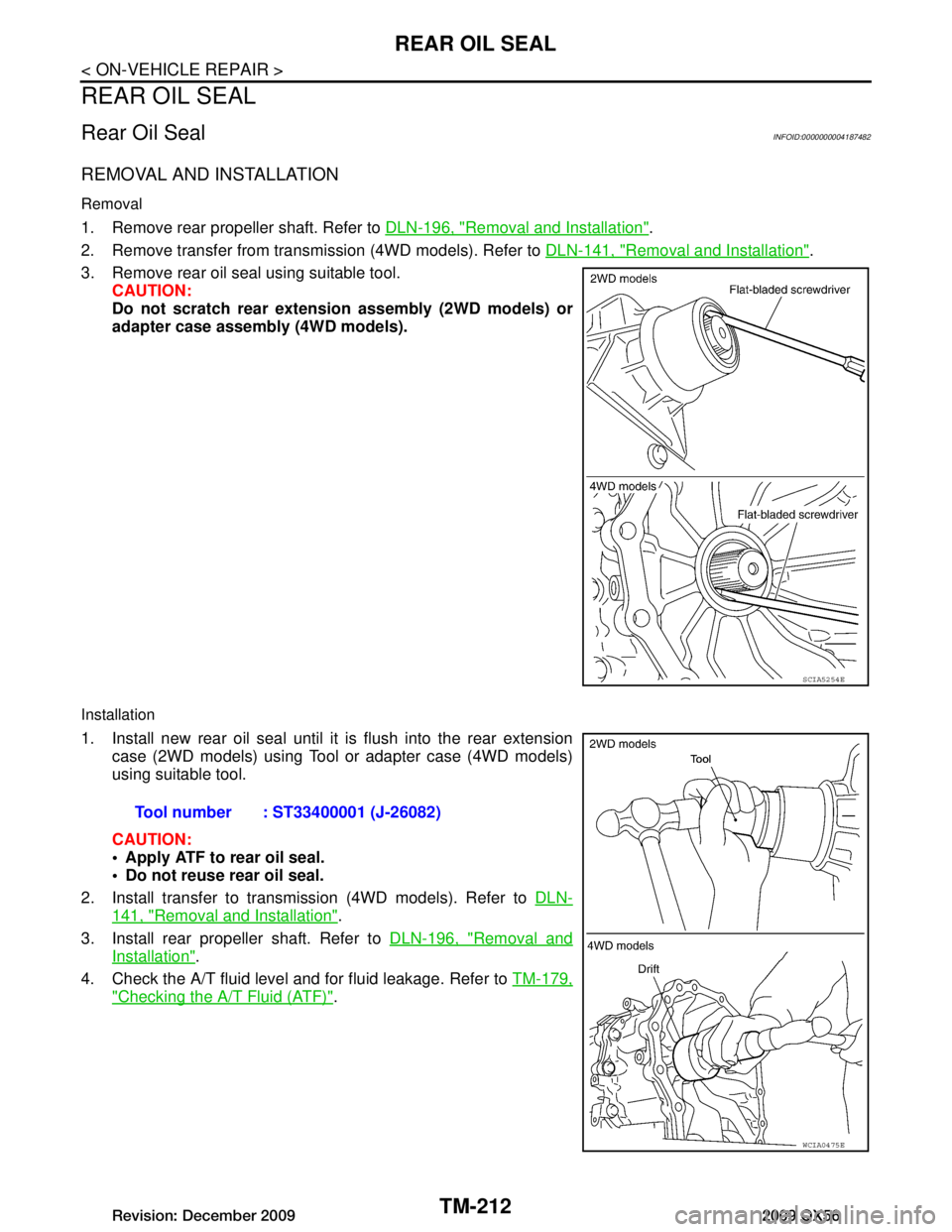

3. Remove rear oil seal using suitable tool. CAUTION:

Do not scratch rear extension assembly (2WD models) or

adapter case assembly (4WD models).

Installation

1. Install new rear oil seal until it is flush into the rear extension

case (2WD models) using Tool or adapter case (4WD models)

using suitable tool.

CAUTION:

Apply ATF to rear oil seal.

Do not reuse rear oil seal.

2. Install transfer to transmission (4WD models). Refer to DLN-

141, "Removal and Installation".

3. Install rear propeller shaft. Refer to DLN-196, "Removal and

Installation".

4. Check the A/T fluid level and for fluid leakage. Refer to TM-179,

"Checking the A/T Fluid (ATF)".

SCIA5254E

Tool number : ST33400001 (J-26082)

WCIA0475E

Revision: December 20092009 QX56

Page 3864 of 4171

TM-216

< REMOVAL AND INSTALLATION >

TRANSMISSION ASSEMBLY

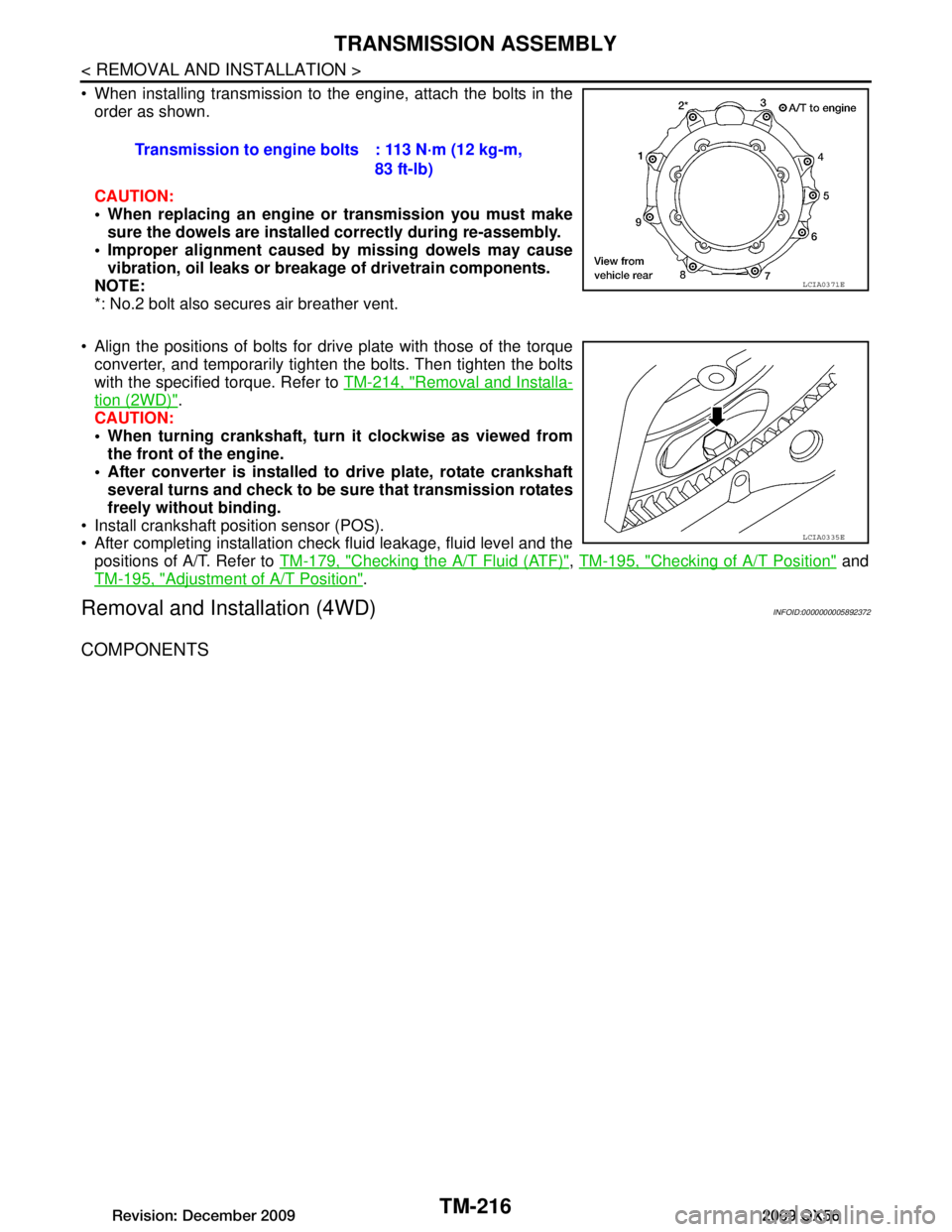

When installing transmission to the engine, attach the bolts in theorder as shown.

CAUTION:

When replacing an engine or transmission you must make

sure the dowels are installe d correctly during re-assembly.

Improper alignment caused by missing dowels may cause

vibration, oil leaks or breakage of drivetrain components.

NOTE:

*: No.2 bolt also secures air breather vent.

Align the positions of bolts for drive plate with those of the torque converter, and temporarily tight en the bolts. Then tighten the bolts

with the specified torque. Refer to TM-214, "Removal and Installa-

tion (2WD)".

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

After converter is installed to drive plate, rotate crankshaft several turns and check to be su re that transmission rotates

freely without binding.

Install crankshaft position sensor (POS).

After completing installation check fluid leakage, fluid level and the positions of A/T. Refer to TM-179, "Checking the A/T Fluid (ATF)"

, TM-195, "Checking of A/T Position" and

TM-195, "Adjustment of A/T Position"

.

Removal and Installation (4WD)INFOID:0000000005892372

COMPONENTS

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

Revision: December 20092009 QX56

Page 3867 of 4171

TRANSMISSION ASSEMBLYTM-219

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

INSPECTION

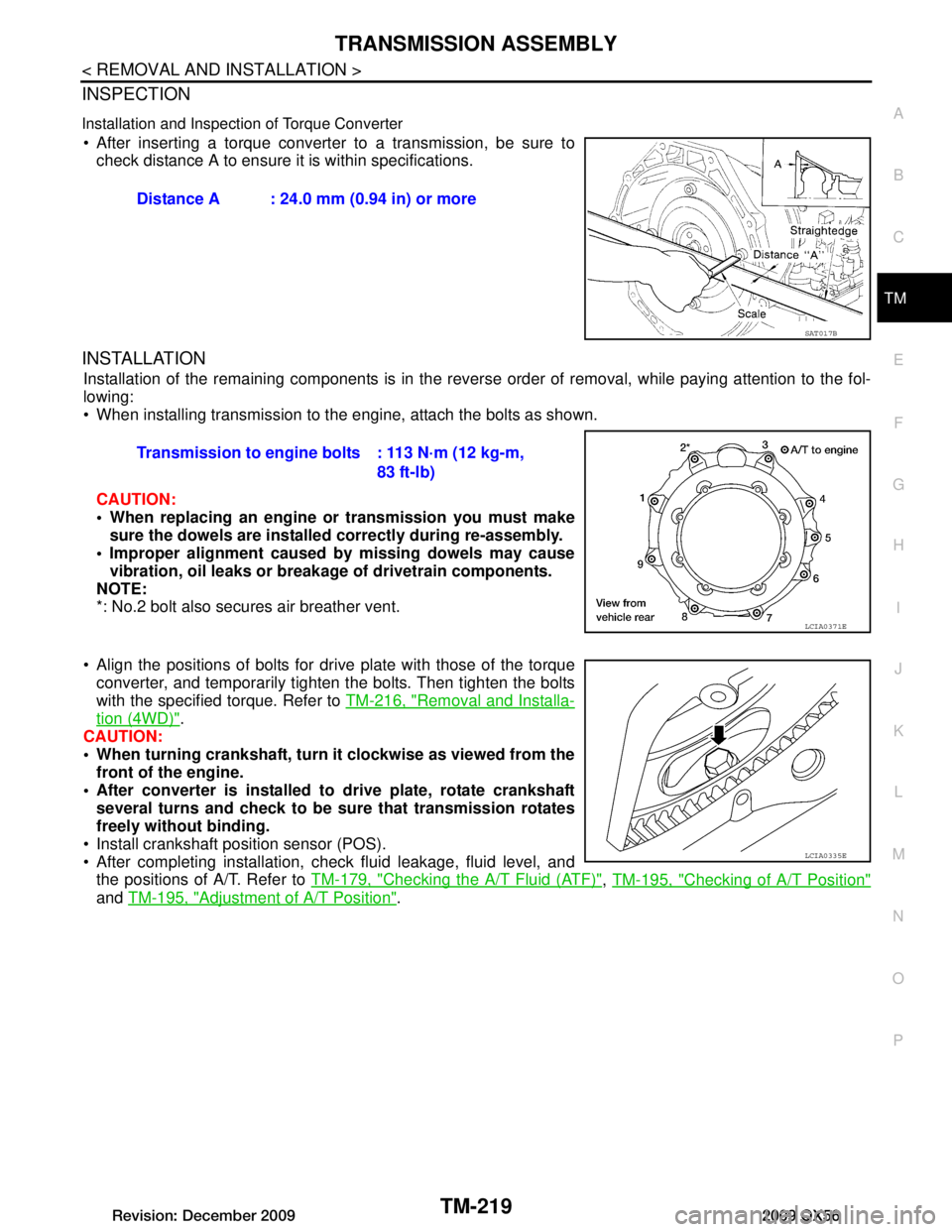

Installation and Inspection of Torque Converter

After inserting a torque converter to a transmission, be sure to check distance A to ensure it is within specifications.

INSTALLATION

Installation of the remaining components is in the revers e order of removal, while paying attention to the fol-

lowing:

When installing transmission to the engine, attach the bolts as shown.

CAUTION:

When replacing an engine or transmission you must make sure the dowels are installed correctly during re-assembly.

Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drivetrain components.

NOTE:

*: No.2 bolt also secures air breather vent.

Align the positions of bolts for dr ive plate with those of the torque

converter, and temporarily tighten the bolts. Then tighten the bolts

with the specified torque. Refer to TM-216, "Removal and Installa-

tion (4WD)".

CAUTION:

When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

After converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission rotates

freely without binding.

Install crankshaft position sensor (POS).

After completing installation, check fluid leakage, fluid level, and the positions of A/T. Refer to TM-179, "Checking the A/T Fluid (ATF)"

, TM-195, "Checking of A/T Position"

and TM-195, "Adjustment of A/T Position".

Distance A : 24.0 mm (0.94 in) or more

SAT017B

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

Revision: December 20092009 QX56

Page 3872 of 4171

TM-224

< DISASSEMBLY AND ASSEMBLY >

OVERHAUL

4WD

16. Bearing race 17. Needle bearing 18. Manual plate

19. Parking rod 20. Manual shaft oil seal 21. Manual shaft

22. O-ring 23. Band servo anchor end pin 24. Detent spring

25. Spacer 26. Seal ring 27. Snap ring

28. Return spring 29. O-ring 30. Servo assembly

31. Snap ring 32. Sub-harness 33. Control valve with TCM

34. Bracket 35. A/T fluid temperature sensor 2 36. A/T assemblt harness connector

37. O-ring 38. Retaining pin 39. Transmission case

*: Apply Genuine Anaerobic Liquid Gasket or equivalent.

Revision: December 20092009 QX56

Page 3874 of 4171

TM-226

< DISASSEMBLY AND ASSEMBLY >

OVERHAUL

19. Parking rod 20. Manual shaft oil seal 21. Manual shaft

22. O-ring 23. Band servo anchor end pin 24. Detent spring

25. Spacer 26. Seal rings 27. Return spring

28. O-ring 29. Servo assembly 30. Snap ring

31. Snap ring 32. Sub-harness 33. Control valve with TCM

34. Bracket 35. A/T fluid temperature sensor 2 36. Oil pan

37. Magnets 38. Drain plug 39. Drain plug gasket

40. Oil pan bolt 41. Oil pan gasket 42. A/T assembly harness connector

43. O-ring 44. Retaining pin 45. Transmission case

Revision: December 20092009 QX56

Page 3881 of 4171

DISASSEMBLYTM-233

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

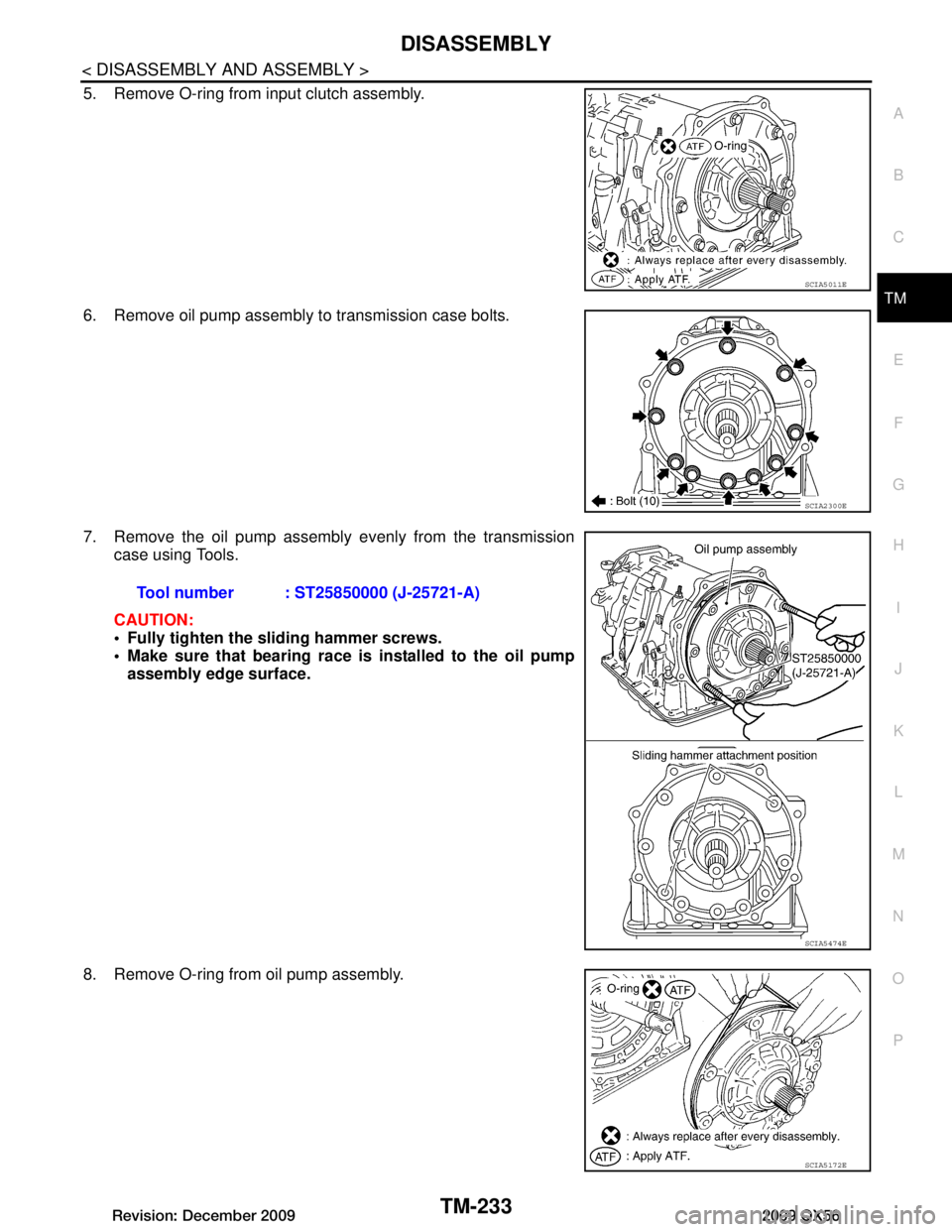

5. Remove O-ring from input clutch assembly.

6. Remove oil pump assembly to transmission case bolts.

7. Remove the oil pump assembly evenly from the transmission case using Tools.

CAUTION:

Fully tighten the sliding hammer screws.

Make sure that bearing race is installed to the oil pump

assembly edge surface.

8. Remove O-ring from oil pump assembly.

SCIA5011E

SCIA2300E

Tool number : ST25850000 (J-25721-A)

SCIA5474E

SCIA5172E

Revision: December 20092009 QX56

Page 3891 of 4171

DISASSEMBLYTM-243

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

47. Remove seal rings from output shaft.

48. Remove needle bearing from transmission case.

49. Remove output speed sensor from transmission case. CAUTION:

Do not subject it to impact by dropping or hitting it.

Do not disassemble.

Do not allow metal filings or any foreign material to get on

the sensor's front edge magnetic area.

Do not place in an area affected by magnetism.

50. Remove reverse brake snap ring using two flat-bladed screw- drivers.

NOTE:

Press out snap ring from the transmission case oil pan side gap

using a flat-bladed screwdriver, and remove it using a another

screwdriver.

51. Remove reverse brake retaining plate from transmission case. Check facing for burns, cracks or damage. If necessary,replace the plate.

52. Remove N-spring from transmission case.

SCIA5209E

SCIA5031E

SCIA2320E

SCIA5032E

SCIA5214E

Revision: December 20092009 QX56

Page 3893 of 4171

DISASSEMBLYTM-245

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

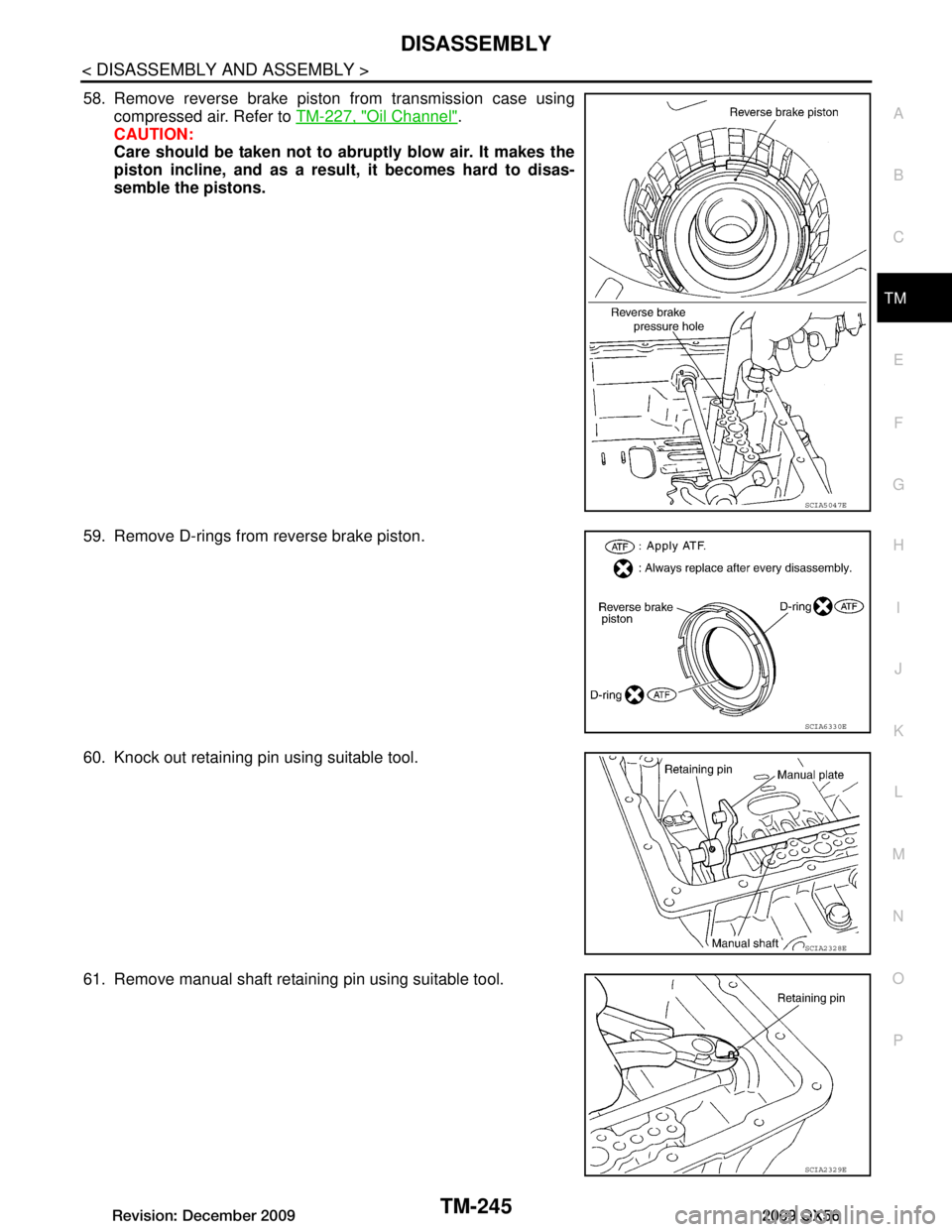

58. Remove reverse brake piston from transmission case using compressed air. Refer to TM-227, "Oil Channel"

.

CAUTION:

Care should be taken not to abruptly blow air. It makes the

piston incline, and as a result , it becomes hard to disas-

semble the pistons.

59. Remove D-rings from reverse brake piston.

60. Knock out retaining pin using suitable tool.

61. Remove manual shaft retaining pin using suitable tool.

SCIA5047E

SCIA6330E

SCIA2328E

SCIA2329E

Revision: December 20092009 QX56

Page 3894 of 4171

TM-246

< DISASSEMBLY AND ASSEMBLY >

DISASSEMBLY

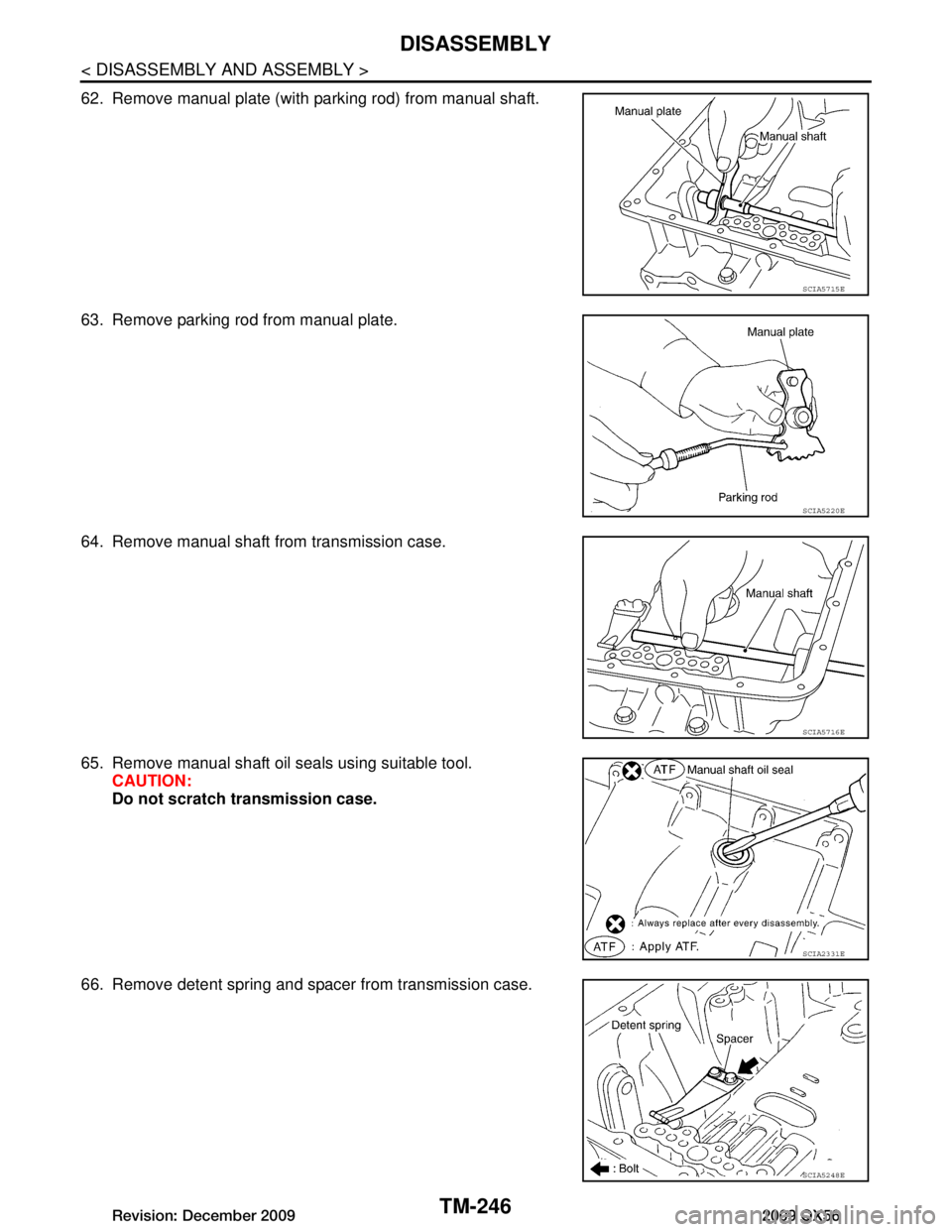

62. Remove manual plate (with parking rod) from manual shaft.

63. Remove parking rod from manual plate.

64. Remove manual shaft from transmission case.

65. Remove manual shaft oil seals using suitable tool.CAUTION:

Do not scratch transmission case.

66. Remove detent spring and spacer from transmission case.

SCIA5715E

SCIA5220E

SCIA5716E

SCIA2331E

SCIA5248E

Revision: December 20092009 QX56

Page 3916 of 4171

TM-268

< DISASSEMBLY AND ASSEMBLY >

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000004187496

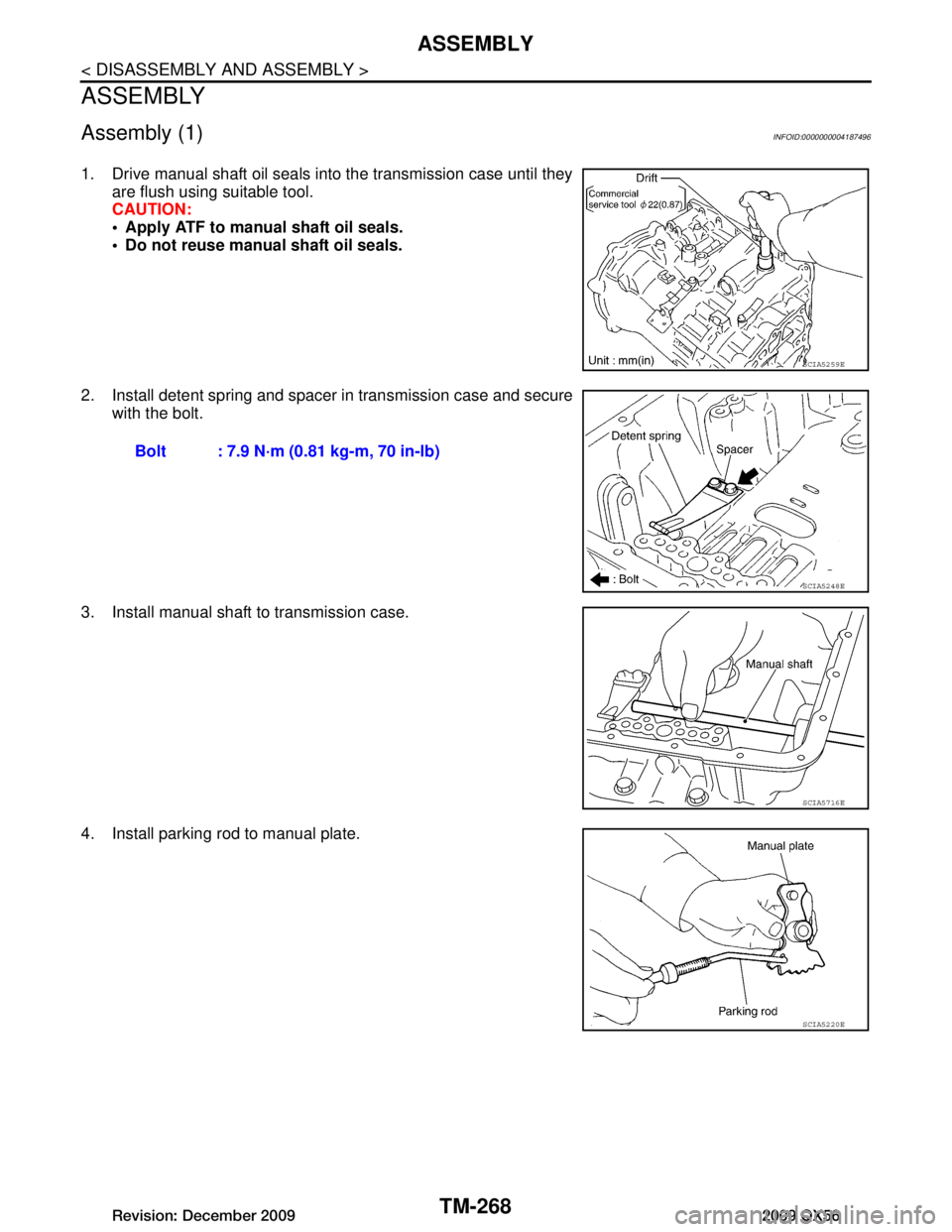

1. Drive manual shaft oil seals into the transmission case until theyare flush using suitable tool.

CAUTION:

Apply ATF to manual shaft oil seals.

Do not reuse manual shaft oil seals.

2. Install detent spring and spacer in transmission case and secure with the bolt.

3. Install manual shaft to transmission case.

4. Install parking rod to manual plate.

SCIA5259E

Bolt : 7.9 N·m (0.81 kg-m, 70 in-lb)

SCIA5248E

SCIA5716E

SCIA5220E

Revision: December 20092009 QX56