ECU INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3260 of 4171

SE-28

< ECU DIAGNOSIS >

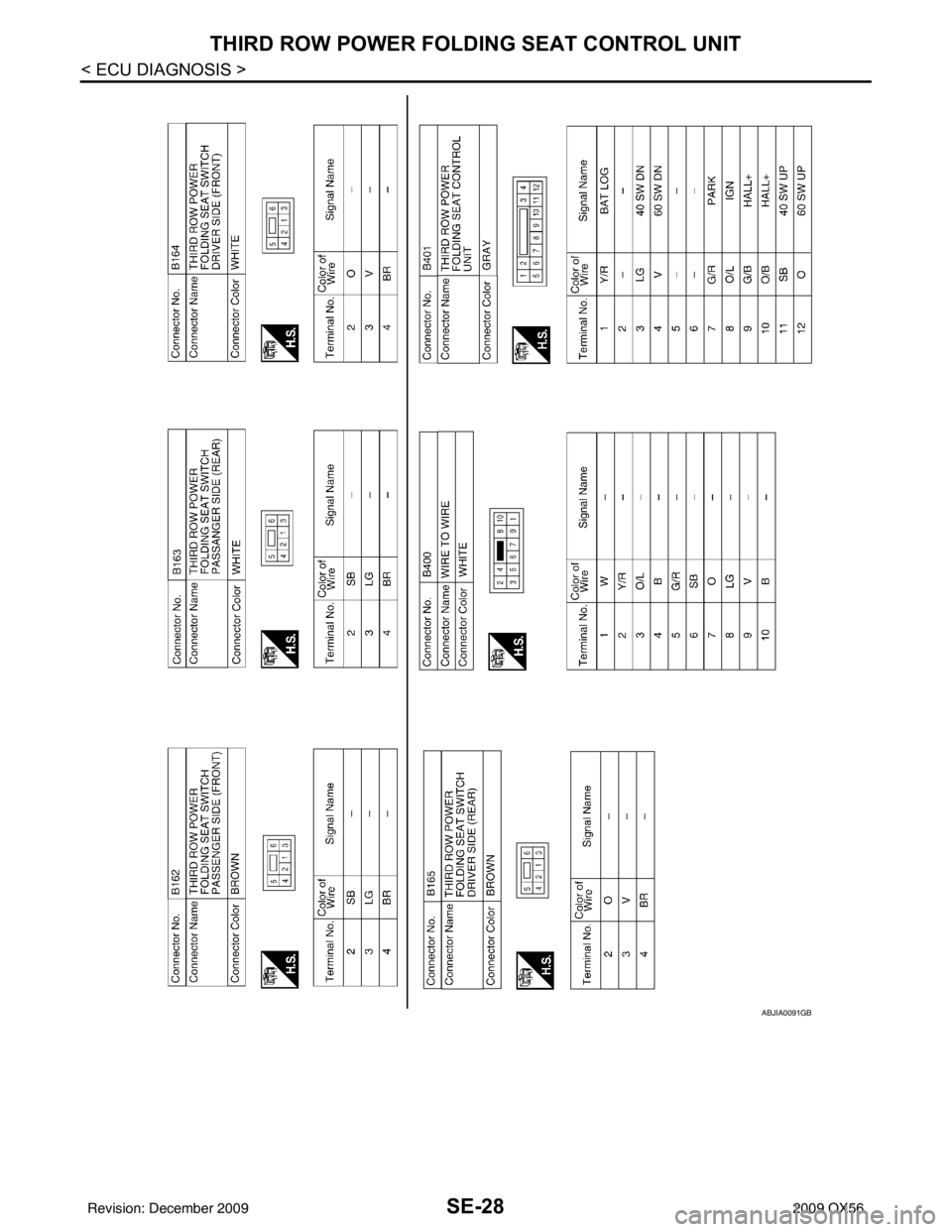

THIRD ROW POWER FOLDING SEAT CONTROL UNIT

ABJIA0091GB

Revision: December 20092009 QX56

Page 3261 of 4171

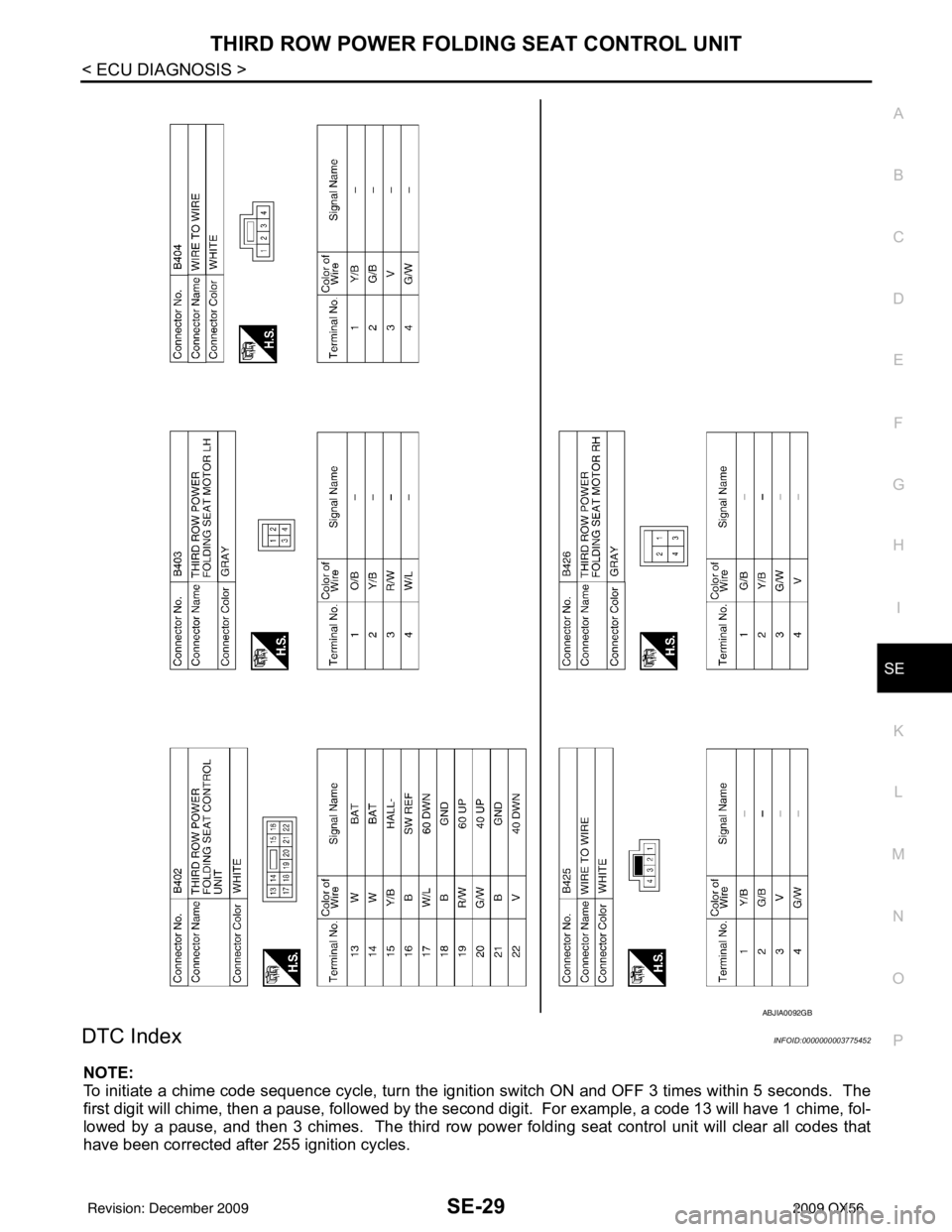

THIRD ROW POWER FOLDING SEAT CONTROL UNITSE-29

< ECU DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

DTC IndexINFOID:0000000003775452

NOTE:

To initiate a chime code sequence cycle, turn the ignition switch ON and OFF 3 times within 5 seconds. The

first digit will chime, then a pause, followed by the sec ond digit. For example, a code 13 will have 1 chime, fol-

lowed by a pause, and then 3 chimes. The third row pow er folding seat control unit will clear all codes that

have been corrected after 255 ignition cycles.

ABJIA0092GB

Revision: December 20092009 QX56

Page 3262 of 4171

SE-30

< ECU DIAGNOSIS >

THIRD ROW POWER FOLDING SEAT CONTROL UNIT

Fail Safe

INFOID:0000000003775453

The third row power folding seat will not operate under the following conditions:

• Power supply to the third row power folding seat control unit falls below 9.0V

• One of the third row power foldi ng seat switches is stuck closed

• The A/T selector lever is not in PARK position and the ignition switch is ON

DTCMalfunction Service Procedure

11 LH seat has traveled past normal fold

down position 1. Perform Preliminary Check. Refer to

SE-5, "

Preliminary

Check".

2. Check third row power folding seat motor LH Hall signal and ground circuits. Refer to SE-36, "

Third Row Power

Folding Seat Stops Short of it's Fully Up or Down Posi-

tion".

3. Replace third row power folding seat motor LH. Refer to SE-56, "

Exploded View".

12

LH seat has traveled past normal fold up

position

13 LH seat actuation cycle has taken too

long and timed out 1. Perform Preliminary Check. Refer to

SE-5, "

Preliminary

Check".

2. Check third row power folding seat motor LH motor cir- cuits. Refer to SE-33, "

Only One Third Row Power Fold-

ing Seat Will Operate".

3. Replace third row power folding seat motor LH. Refer to SE-56, "

Exploded View".

14 Third row power folding seat control unit

NVRAM data for LH seat position has

been corrupted Replace third row power folding seat control unit. Refer to

SE-

59, "Power seat cross beam".

15 Power supply to thir

d row power folding

seat control unit has been interrupted

during LH seat fold up/down cycle 1. Perform Preliminary Check. Refer to

SE-5, "

Preliminary

Check".

2. Replace third row power folding seat control unit. Refer to SE-59, "

Power seat cross beam".

21 RH seat has traveled past normal fold

down position 1. Perform Preliminary Check. Refer to

SE-5, "

Preliminary

Check".

2. Check third row power folding seat motor RH Hall signal and ground circuits. Refer to SE-36, "

Third Row Power

Folding Seat Stops Short of it's Fully Up or Down Posi-

tion".

3. Replace third row power folding seat motor RH. Refer to SE-56, "

Exploded View".

22

RH seat has traveled past normal fold up

position

23 RH seat actuation cycle has taken too

long and timed out 1. Perform Preliminary Check. Refer to

SE-5, "

Preliminary

Check".

2. Check third row power folding seat motor RH motor cir- cuits. Refer to SE-33, "

Only One Third Row Power Fold-

ing Seat Will Operate".

3. Replace third row power folding seat motor RH. Refer to SE-56, "

Exploded View".

24 Third row power folding seat control unit

NVRAM data for RH seat position has

been corrupted Replace third row power folding seat control unit. Refer to

SE-

59, "Power seat cross beam".

25 Power supply to thir

d row power folding

seat control unit has been interrupted

during RH seat fold up/down cycle 1. Perform Preliminary Check. Refer to

SE-5, "

Preliminary

Check".

2. Replace third row power folding seat control unit. Refer

to SE-59, "

Power seat cross beam".

33 System normal or END of chime codes —

Revision: December 20092009 QX56

Page 3271 of 4171

SQUEAK AND RATTLE TROUBLE DIAGNOSESSE-39

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half- clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool (Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from. Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks. Refer to SE-40, "

Generic Squeak and Rattle Troubleshooting" .

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loos ening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.94 ×5.31 in)/76884-71L01: 60 ×85 mm (2.36× 3.35 in)/76884-71L02: 15× 25

mm (0.59 ×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50× 50 mm (1.97×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50× 50 mm (1.97 ×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30 ×50 mm (1.18 ×1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occu r. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

Revision: December 20092009 QX56

Page 3273 of 4171

SQUEAK AND RATTLE TROUBLE DIAGNOSESSE-41

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: December 20092009 QX56

Page 3277 of 4171

PRECAUTIONSSE-45

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

SE

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for WorkINFOID:0000000003775464

• When removing or disassembling each component, be ca reful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and keep them.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After re-installation is completed, be sure to check that each part works normally.

• Follow the steps below to clean components.

- Water soluble foul: Dip a soft cloth into lukewarm water, and wring the water out of the cloth to wipe the fouled area.

Then rub with a soft and dry cloth.

- Oily foul: Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%), and wipe the fouled area.

Then dip a cloth into fresh water, and wring the water out of the cloth to wipe the detergent off. Then rub with

a soft and dry cloth.

• Do not use organic solvent such as thinner, benzene, alcohol, or gasoline.

• For genuine leather seats, use a genuine leather seat cleaner.

Revision: December 20092009 QX56

Page 3311 of 4171

SEC-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION SEC

A

B

SEC

N

O P

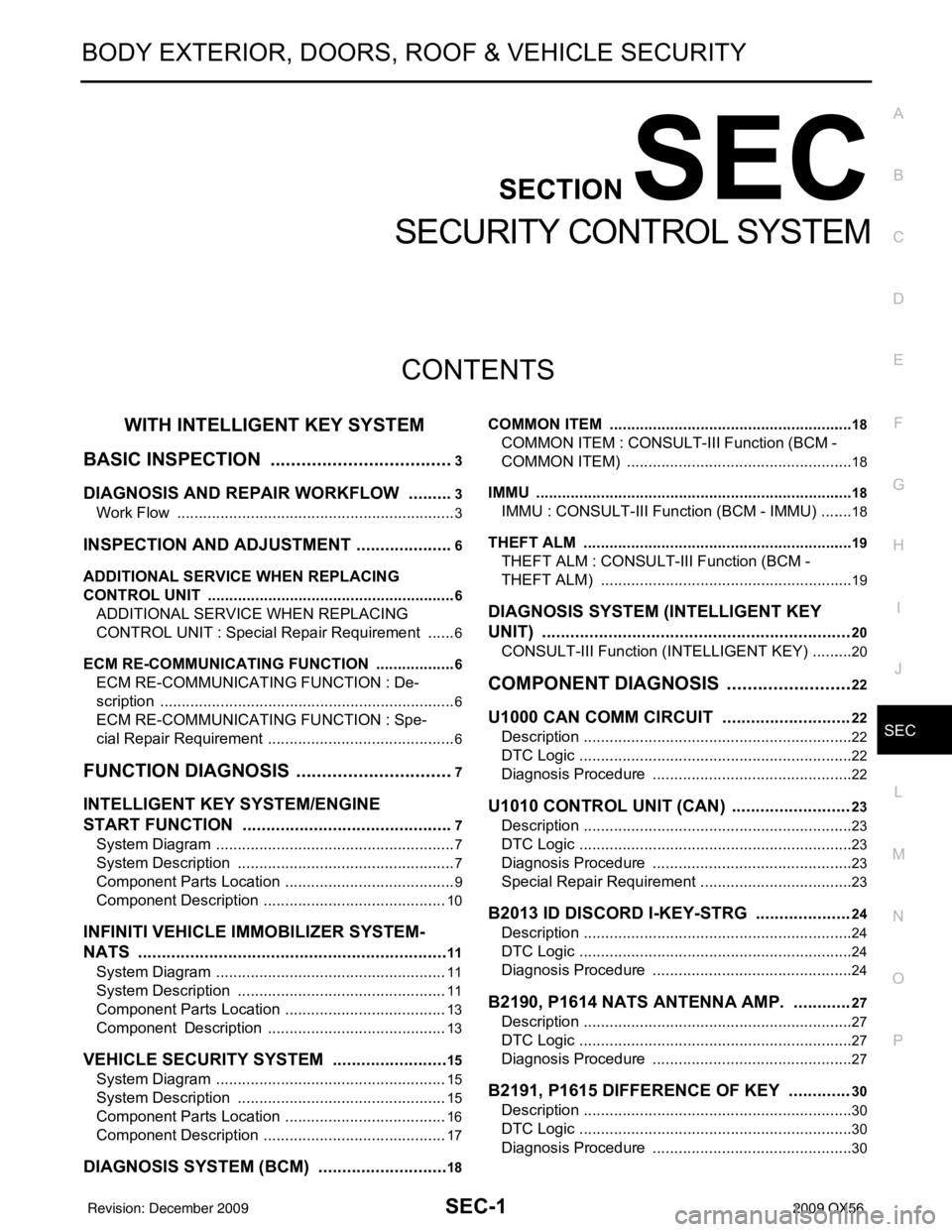

CONTENTS

SECURITY CONTROL SYSTEM

WITH INTELLIGENT KEY SYSTEM

BASIC INSPECTION ....... .............................

3

DIAGNOSIS AND REPAIR WORKFLOW ..... .....3

Work Flow ........................................................... ......3

INSPECTION AND ADJUSTMENT .....................6

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT .................................................... ......

6

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT : Special Repair Requirement .......

6

ECM RE-COMMUNICATING FUNCTION ............. ......6

ECM RE-COMMUNICATING FUNCTION : De-

scription .....................................................................

6

ECM RE-COMMUNICATING FUNCTION : Spe-

cial Repair Requirement ............................................

6

FUNCTION DIAGNOSIS ...............................7

INTELLIGENT KEY SYSTEM/ENGINE

START FUNCTIO N ........................................ .....

7

System Diagram .................................................. ......7

System Description ...................................................7

Component Parts Location ........................................9

Component Description ...........................................10

INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS ..................................................................

11

System Diagram .................................................. ....11

System Description .................................................11

Component Parts Location ......................................13

Component Description ..........................................13

VEHICLE SECURITY SYSTEM .........................15

System Diagram .................................................. ....15

System Description .................................................15

Component Parts Location ......................................16

Component Description ...........................................17

DIAGNOSIS SYSTEM (BCM) ............................18

COMMON ITEM ..................................................... ....18

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

18

IMMU ...................................................................... ....18

IMMU : CONSULT-III Function (BCM - IMMU) ........18

THEFT ALM ........................................................... ....19

THEFT ALM : CONSULT-III Function (BCM -

THEFT ALM) ....................................................... ....

19

DIAGNOSIS SYSTEM (INTELLIGENT KEY

UNIT) .................................................................

20

CONSULT-III Function (INTELLIGENT KEY) ..........20

COMPONENT DIAGNOSIS .........................22

U1000 CAN COMM CIRCUIT ...........................22

Description ........................................................... ....22

DTC Logic ................................................................22

Diagnosis Procedure ...............................................22

U1010 CONTROL UNIT (CAN) .........................23

Description ...............................................................23

DTC Logic ................................................................23

Diagnosis Procedure ...............................................23

Special Repair Requirement ....................................23

B2013 ID DISCORD I-KEY-STRG ....................24

Description ...............................................................24

DTC Logic ................................................................24

Diagnosis Procedure ...............................................24

B2190, P1614 NATS ANTENNA AMP. ............27

Description ...............................................................27

DTC Logic ................................................................27

Diagnosis Procedure ...............................................27

B2191, P1615 DIFFERENCE OF KEY .............30

Description ...............................................................30

DTC Logic ................................................................30

Diagnosis Procedure ...............................................30

Revision: December 20092009 QX56

Page 3312 of 4171

SEC-2

B2192, P1611 ID DISCORD, IMMU-ECM .........31

Description ........................................................... ...31

DTC Logic ...............................................................31

Diagnosis Procedure ..............................................31

B2193, P1612 CHAIN OF ECM-IMMU ..............33

Description ........................................................... ...33

DTC Logic ...............................................................33

Diagnosis Procedure ..............................................33

B2194 ID DISCORD IMMU-I-KEY .....................34

Description ........................................................... ...34

DTC Logic ...............................................................34

Diagnosis Procedure ..............................................34

B2552 INTELLIGENT KEY ................................35

Description ........................................................... ...35

DTC Logic ...............................................................35

Diagnosis Procedure ..............................................35

Special Repair Requirement ...................................35

B2590 ID DISCORD BCM-I-KEY .................... ...36

Description ........................................................... ...36

DTC Logic ...............................................................36

Diagnosis Procedure ..............................................36

P1610 LOCK MODE ..........................................37

Description ........................................................... ...37

DTC Logic ...............................................................37

Diagnosis Procedure ..............................................37

POWER SUPPLY AND GROUND CIRCUIT .....38

INTELLIGENT KEY UNIT ...................................... ...38

INTELLIGENT KEY UNIT : Diagnosis Procedure ...38

BCM ........................................................................ ...38

BCM : Diagnosis Procedure ...................................38

KEY CYLINDER SWITCH .................................40

Description ........................................................... ...40

Component Function Check ...................................40

Diagnosis Procedure ..............................................40

IGNITION KNOB SWITCH .................................42

Ignition Knob Switch Check ................................. ...42

HOOD SWITCH .................................................44

Diagnosis Procedure ..............................................44

HORN FUNCTION .............................................46

Symptom Table ................................................... ...46

VEHICLE SECURITY INDICATOR ....................47

Description ........................................................... ...47

Component Function Check .................................47

Diagnosis Procedure ..............................................47

ECU DIAGNOSIS ..................................... ...49

BCM (BODY CONTROL MODULE) ............... ...49

Reference Value .................................................. ...49

Terminal Layout ......................................................51

Physical Values .......................................................51

Wiring Diagram - VEHICLE SECURITY SYSTEM ...57

Wiring Diagram - IVIS .............................................68

Fail Safe .................................................................76

DTC Inspection Priority Chart ...............................77

DTC Index ..............................................................77

INTELLIGENT KEY UNIT ..................................79

Reference Value - Intelligent Key Unit ................. ...79

Reference Value - Steering Lock Solenoid .............82

Wiring Diagram - INTELLIGENT KEY SYSTEM/

ENGINE START FUNCTION - ................................

83

Fail Safe .................................................................95

DTC Inspection Priority Chart ...............................95

DTC Index ..............................................................95

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

96

Reference Value .................................................. ...96

Terminal Layout ......................................................98

Physical Values .......................................................98

Fail Safe ...............................................................102

DTC Index ............................................................103

SYMPTOM DIAGNOSIS ...........................104

INTELLIGENT KEY SYSTEM/ENGINE

START FUNCTION SYMPTOMS ................... ..

104

Symptom Table .................................................... .104

VEHICLE SECURITY SYSTEM SYMPTOMS ..105

Symptom Table .....................................................105

INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS SYMPTOMS ...........................................

106

Symptom Table .................................................... .106

ON-VEHICLE MAINTENANCE .................107

PRE-INSPECTION FOR DIAGNOSTIC ......... ..107

Basic Inspection ................................................... .107

Vehicle Security Operation Check ........................107

PRECAUTION ...........................................109

PRECAUTIONS .............................................. ..109

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. .

109

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ................................

109

ON-VEHICLE REPAIR ..............................111

VEHICLE SECURITY SYSTEM ...................... ..111

Removal and Installation .......................................111

Revision: December 20092009 QX56

Page 3318 of 4171

![INFINITI QX56 2009 Factory Service Manual SEC-8

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

• Intelligent Key has 2 IDs (for Intelligent Key and for

NATS). It can perform the door lock/u INFINITI QX56 2009 Factory Service Manual SEC-8

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

• Intelligent Key has 2 IDs (for Intelligent Key and for

NATS). It can perform the door lock/u](/img/42/57031/w960_57031-3317.png)

SEC-8

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

• Intelligent Key has 2 IDs (for Intelligent Key and for

NATS). It can perform the door lock/unlock operation and

the engine start operation when the registered Intelligent Key is carried.

• When the Intelligent Key battery is discharged, it can be used as emergency back-up by inserting the

mechanical key set in the Intelligent Key to the ignition key cylinder. At that time, perform the NATS ID verifi-

cation. If it is used when the Intelligent Key is carried, perform the Intelligent Key ID verification.

• If the ID is successfully verified, and when the igniti on knob switch is pressed, steering lock will be released

and initiating the engine will be possible.

• The door lock/unlock operation can be performed when the Intelligent Key battery is discharged, by operat-

ing the driver door key cylinder using the mechanical key set in the Intelligent Key.

• Up to 4 Intelligent Keys can be registered (including the standard Intelligent Key) on request from the owner. NOTE:

• Refer to DLK-21, "

INTELLIGENT KEY : System Description" for any functions other than engine start func-

tion of Intelligent Key system.

PRECAUTIONS FOR INTELLIGENT KEY SYSTEM

• For vehicles equipped with the Intelligent Key system , the transponder [the chip for NATS ID verifi-

cation] is integrated into the Inte lligent Key. Therefore, the Intellig ent Key alone is capable of provid-

ing security clearance for the engine to start. Also, when the mechanical key alone is inserted into

the key cylinder, performs the NATS ID verification to allow the engine to start. For vehicles without

Intelligent Key system, the transponder is integrated into the mechanical key which must be inserted

into the key cylinder to perform the NATS ID verification to allow the engine to start.

OPERATION WHEN INTELLIGENT KEY IS CARRIED

1. When the ignition knob switch is ON, the Intelligent Key unit transmits the request signal to the Intelligent

Key.

2. The Intelligent Key receives the request signal and transmits the Intelligent Key ID signal to the Intelligent Key unit.

3. The Intelligent Key unit receives the Intelligent Key ID signal and verifies it with the registered ID.

4. Intelligent Key unit transmits the steering lock/unlock signal to steering lock solenoid if the verification results are OK. For detail of key warning message operation, refer to DLK-38, "

System Description".

5. Release of the steering lock.

6. BCM transmits the starter request signal via CAN communication to IPDM E/R and turns the starter relay in IPDM E/R ON if BCM judges that the engine start condition is satisfied.

7. IPDM E/R turns the starter control relay ON when receiving the starter request signal.

8. When shift position is in P or N position, battery power is supplied through the starter relay and operate the starter motor and to start the cranking.

CAUTION:

If a malfunction is detected in the Intelligent Key system, the “KEY” warning message will be dis-

played in the combination meter. At th at time, the engine cannot be started.

OPERATION RANGE

Engine can be started when Intelligent Key is inside the vehicle. However, sometimes engine might not start

when Intelligent Key is on instrument panel or in glove box.

OPERATION WHEN MECHANICAL KEY IS USED

When the Intelligent Key battery is discharged, performs the NATS ID verification between the integrated tran-

sponder and BCM by inserting the mechanical key into the key cylinder, and then the engine can be started.

For details relating to starting the engine using mechanical key, refer to SEC-11, "

System Description".

STEERING LOCK OPERATION

Steering is locked by steering lock solenoid when ignition switch is in the LOCK position (the ignition knob is

released) and key switch is OFF (key is removed from ignition key cylinder).

Revision: December 20092009 QX56

Page 3320 of 4171

![INFINITI QX56 2009 Factory Service Manual SEC-10

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Component Description

INFOID:0000000003775871

10. Inside key antenna 1 (rear of center con- sole INFINITI QX56 2009 Factory Service Manual SEC-10

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Component Description

INFOID:0000000003775871

10. Inside key antenna 1 (rear of center con- sole](/img/42/57031/w960_57031-3319.png)

SEC-10

< FUNCTION DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

INTELLIGENT KEY SYSTEM/ENGINE START FUNCTION

Component Description

INFOID:0000000003775871

10. Inside key antenna 1 (rear of center con- sole) M209 11. Inside key antenna 4 (overhead console

area) R210

(view with overhead console removed) 12. Inside key antenna 2 (luggage

compartment) B76

(view with rear carpet removed)

13. Intelligent Key warning buzzer E25 14. Combination meter M23, M24 15. Vehicle security indicator lamp

Item Function

Intelligent Key unit Receives lock/unlock signal from remote keyless entry receiver, and then transmits to BCM.

BCM Verifies the received signal from Intelligent Key, then informs ECM whether to allow engine start.

Remote keyless entry receiver Receives lock/unlock signal from th e Intelligent Key, and then transmits to Intelligent Key unit.

Intelligent Key Transmits button operation to remote keyless entry receiver.

Steering lock solenoid Locks the steering wheel when the ignition key is off and the Intelligent Key is outside the vehicle.

Inside key antenna Detects if Intelligent Key is inside the vehicle.

Intelligent Key warning buzzer Warns the user of the lock/unlock condition and inappropriate operations with the buzzer sound.

A/T shift selector (park position

switch) Detects whether the shift lever is in park.

Revision: December 20092009 QX56