lock INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 3863 of 4171

TRANSMISSION ASSEMBLYTM-215

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

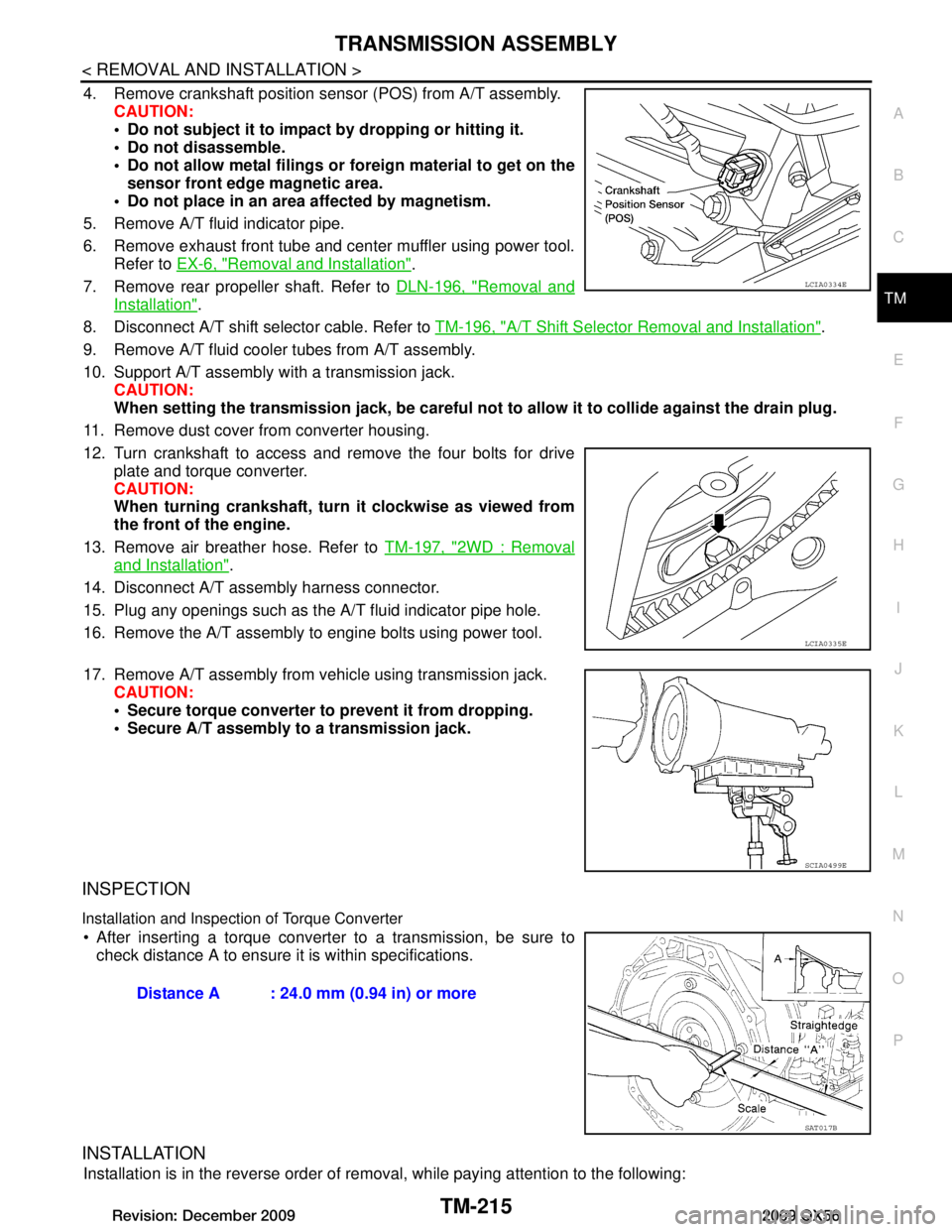

4. Remove crankshaft position sensor (POS) from A/T assembly. CAUTION:

Do not subject it to impact by dropping or hitting it.

Do not disassemble.

Do not allow metal filings or foreign material to get on the

sensor front edge magnetic area.

Do not place in an area affected by magnetism.

5. Remove A/T fluid indicator pipe.

6. Remove exhaust front tube and center muffler using power tool. Refer to EX-6, "Removal and Installation"

.

7. Remove rear propeller shaft. Refer to DLN-196, "Removal and

Installation".

8. Disconnect A/T shift selector cable. Refer to TM-196, "A/T Shift Selector Removal and Installation"

.

9. Remove A/T fluid cooler tubes from A/T assembly.

10. Support A/T assembly with a transmission jack. CAUTION:

When setting the transmission jack, be careful not to allow it to collide against the drain plug.

11. Remove dust cover from converter housing.

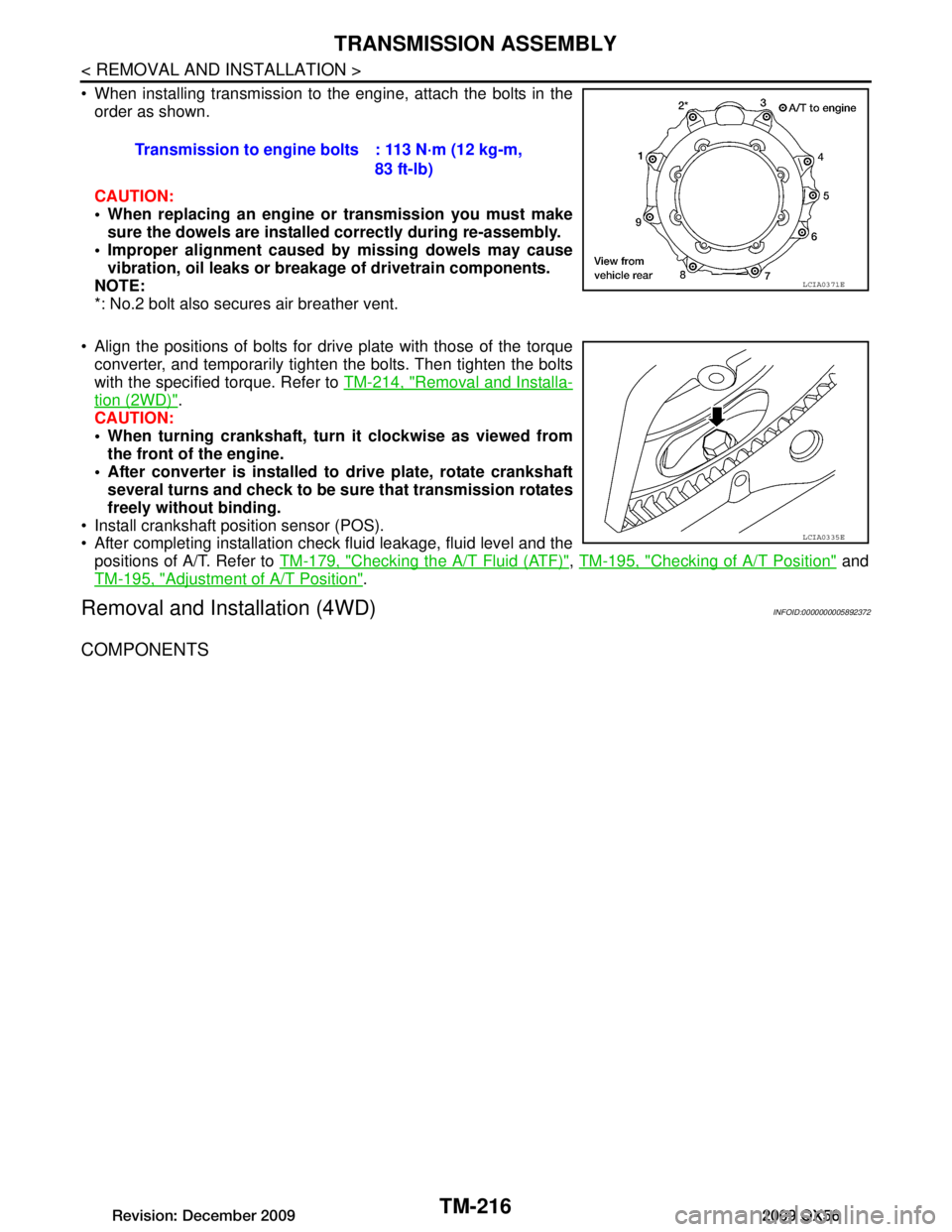

12. Turn crankshaft to access and remove the four bolts for drive plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

13. Remove air breather hose. Refer to TM-197, "2WD : Removal

and Installation".

14. Disconnect A/T assembly harness connector.

15. Plug any openings such as the A/T fluid indicator pipe hole.

16. Remove the A/T assembly to engine bolts using power tool.

17. Remove A/T assembly from vehicle using transmission jack. CAUTION:

Secure torque converter to prevent it from dropping.

Secure A/T assembly to a transmission jack.

INSPECTION

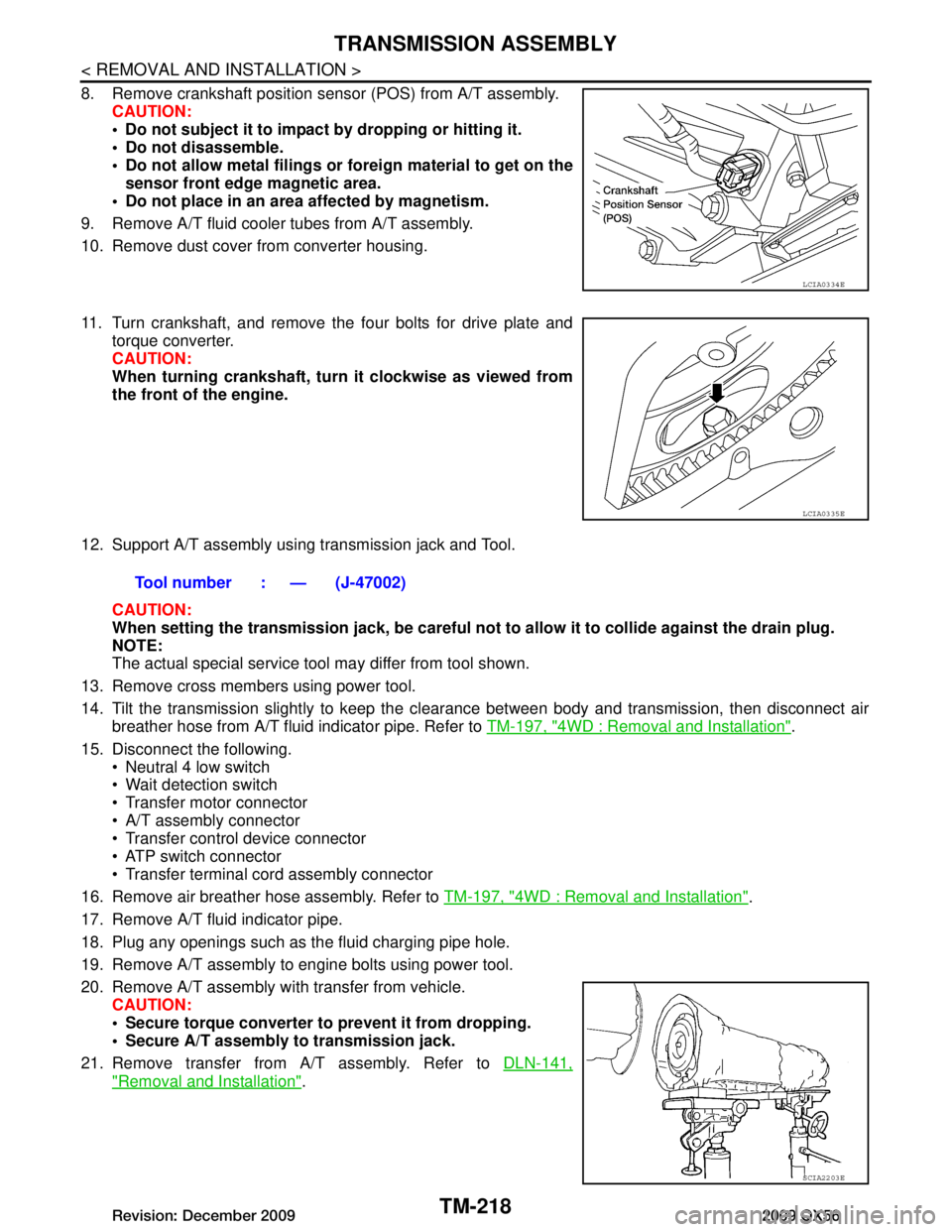

Installation and Inspection of Torque Converter

After inserting a torque converter to a transmission, be sure to check distance A to ensure it is within specifications.

INSTALLATION

Installation is in the reverse order of removal, while paying attention to the following:

LCIA0334E

LCIA0335E

SCIA0499E

Distance A : 24.0 mm (0.94 in) or more

SAT017B

Revision: December 20092009 QX56

Page 3864 of 4171

TM-216

< REMOVAL AND INSTALLATION >

TRANSMISSION ASSEMBLY

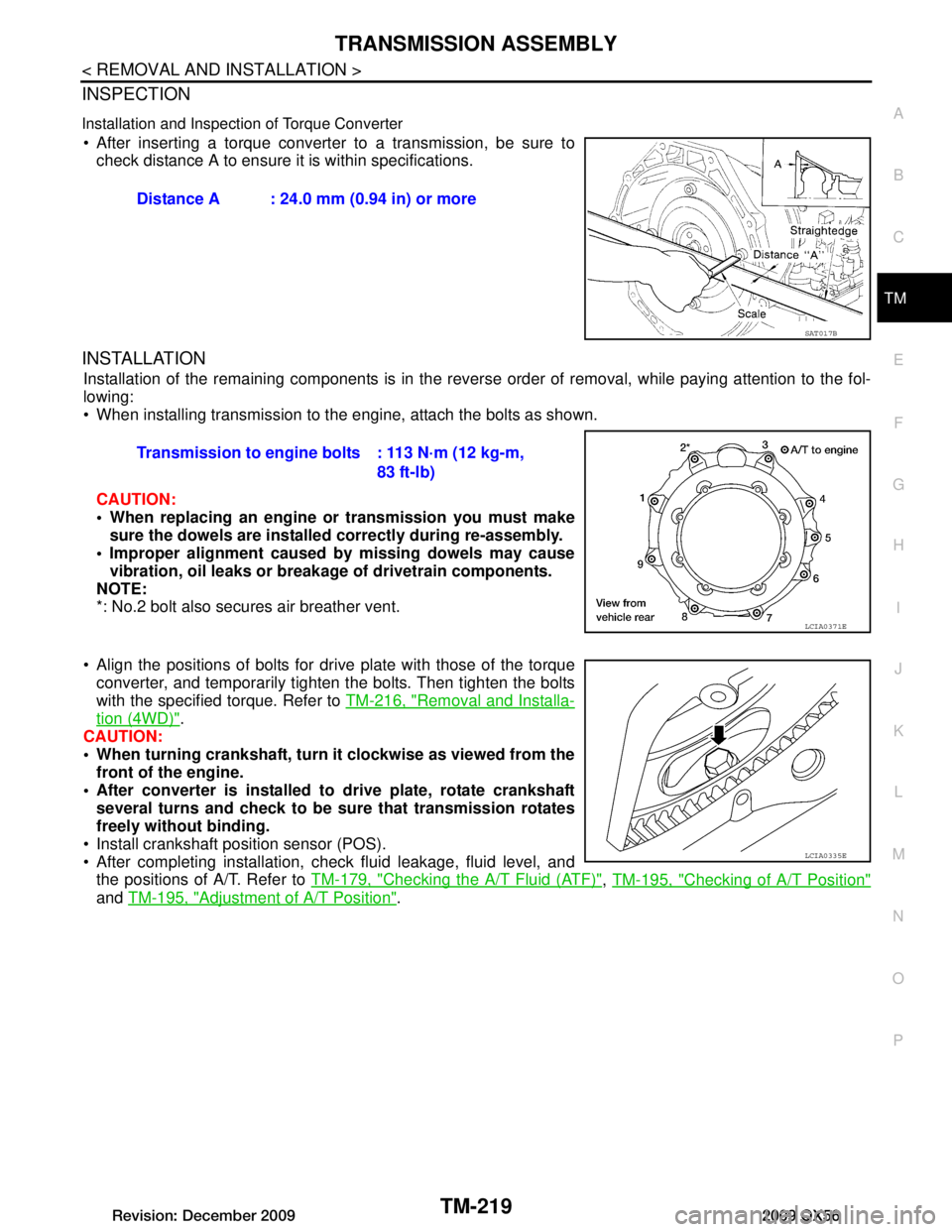

When installing transmission to the engine, attach the bolts in theorder as shown.

CAUTION:

When replacing an engine or transmission you must make

sure the dowels are installe d correctly during re-assembly.

Improper alignment caused by missing dowels may cause

vibration, oil leaks or breakage of drivetrain components.

NOTE:

*: No.2 bolt also secures air breather vent.

Align the positions of bolts for drive plate with those of the torque converter, and temporarily tight en the bolts. Then tighten the bolts

with the specified torque. Refer to TM-214, "Removal and Installa-

tion (2WD)".

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

After converter is installed to drive plate, rotate crankshaft several turns and check to be su re that transmission rotates

freely without binding.

Install crankshaft position sensor (POS).

After completing installation check fluid leakage, fluid level and the positions of A/T. Refer to TM-179, "Checking the A/T Fluid (ATF)"

, TM-195, "Checking of A/T Position" and

TM-195, "Adjustment of A/T Position"

.

Removal and Installation (4WD)INFOID:0000000005892372

COMPONENTS

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

Revision: December 20092009 QX56

Page 3866 of 4171

TM-218

< REMOVAL AND INSTALLATION >

TRANSMISSION ASSEMBLY

8. Remove crankshaft position sensor (POS) from A/T assembly.CAUTION:

Do not subject it to impact by dropping or hitting it.

Do not disassemble.

Do not allow metal filings or fo reign material to get on the

sensor front edge magnetic area.

Do not place in an area affected by magnetism.

9. Remove A/T fluid cooler tubes from A/T assembly.

10. Remove dust cover from converter housing.

11. Turn crankshaft, and remove the four bolts for drive plate and torque converter.

CAUTION:

When turning crankshaft, turn it clockwise as viewed from

the front of the engine.

12. Support A/T assembly using transmission jack and Tool. CAUTION:

When setting the transmission jack, be careful not to allow it to collide against the drain plug.

NOTE:

The actual special service tool may differ from tool shown.

13. Remove cross members using power tool.

14. Tilt the transmission slightly to keep the cl earance between body and transmission, then disconnect air

breather hose from A/T fluid indicator pipe. Refer to TM-197, "4WD : Removal and Installation"

.

15. Disconnect the following. Neutral 4 low switch

Wait detection switch

Transfer motor connector

A/T assembly connector

Transfer control device connector

ATP switch connector

Transfer terminal cord assembly connector

16. Remove air breather hose assembly. Refer to TM-197, "4WD : Removal and Installation"

.

17. Remove A/T fluid indicator pipe.

18. Plug any openings such as the fluid charging pipe hole.

19. Remove A/T assembly to engine bolts using power tool.

20. Remove A/T assembly with transfer from vehicle. CAUTION:

Secure torque converter to prevent it from dropping.

Secure A/T assembly to transmission jack.

21. Remove transfer from A/T assembly. Refer to DLN-141,

"Removal and Installation".

LCIA0334E

LCIA0335E

Tool number : — (J-47002)

SCIA2203E

Revision: December 20092009 QX56

Page 3867 of 4171

TRANSMISSION ASSEMBLYTM-219

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

TM

N

O P

INSPECTION

Installation and Inspection of Torque Converter

After inserting a torque converter to a transmission, be sure to check distance A to ensure it is within specifications.

INSTALLATION

Installation of the remaining components is in the revers e order of removal, while paying attention to the fol-

lowing:

When installing transmission to the engine, attach the bolts as shown.

CAUTION:

When replacing an engine or transmission you must make sure the dowels are installed correctly during re-assembly.

Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drivetrain components.

NOTE:

*: No.2 bolt also secures air breather vent.

Align the positions of bolts for dr ive plate with those of the torque

converter, and temporarily tighten the bolts. Then tighten the bolts

with the specified torque. Refer to TM-216, "Removal and Installa-

tion (4WD)".

CAUTION:

When turning crankshaft, turn it clockwise as viewed from the

front of the engine.

After converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that transmission rotates

freely without binding.

Install crankshaft position sensor (POS).

After completing installation, check fluid leakage, fluid level, and the positions of A/T. Refer to TM-179, "Checking the A/T Fluid (ATF)"

, TM-195, "Checking of A/T Position"

and TM-195, "Adjustment of A/T Position".

Distance A : 24.0 mm (0.94 in) or more

SAT017B

Transmission to engine bolts : 113 N·m (12 kg-m,

83 ft-lb)

LCIA0371E

LCIA0335E

Revision: December 20092009 QX56

Page 3880 of 4171

TM-232

< DISASSEMBLY AND ASSEMBLY >

DISASSEMBLY

DISASSEMBLY

DisassemblyINFOID:0000000004187489

CAUTION:

Do not disassemble parts behind Drum Support. Refer to TM-8, "Cross-Sectional View (2WD models)"

.

1. Drain A/T fluid through drain plug.

2. Remove torque converter by holding it firmly and turing while pulling straight out.

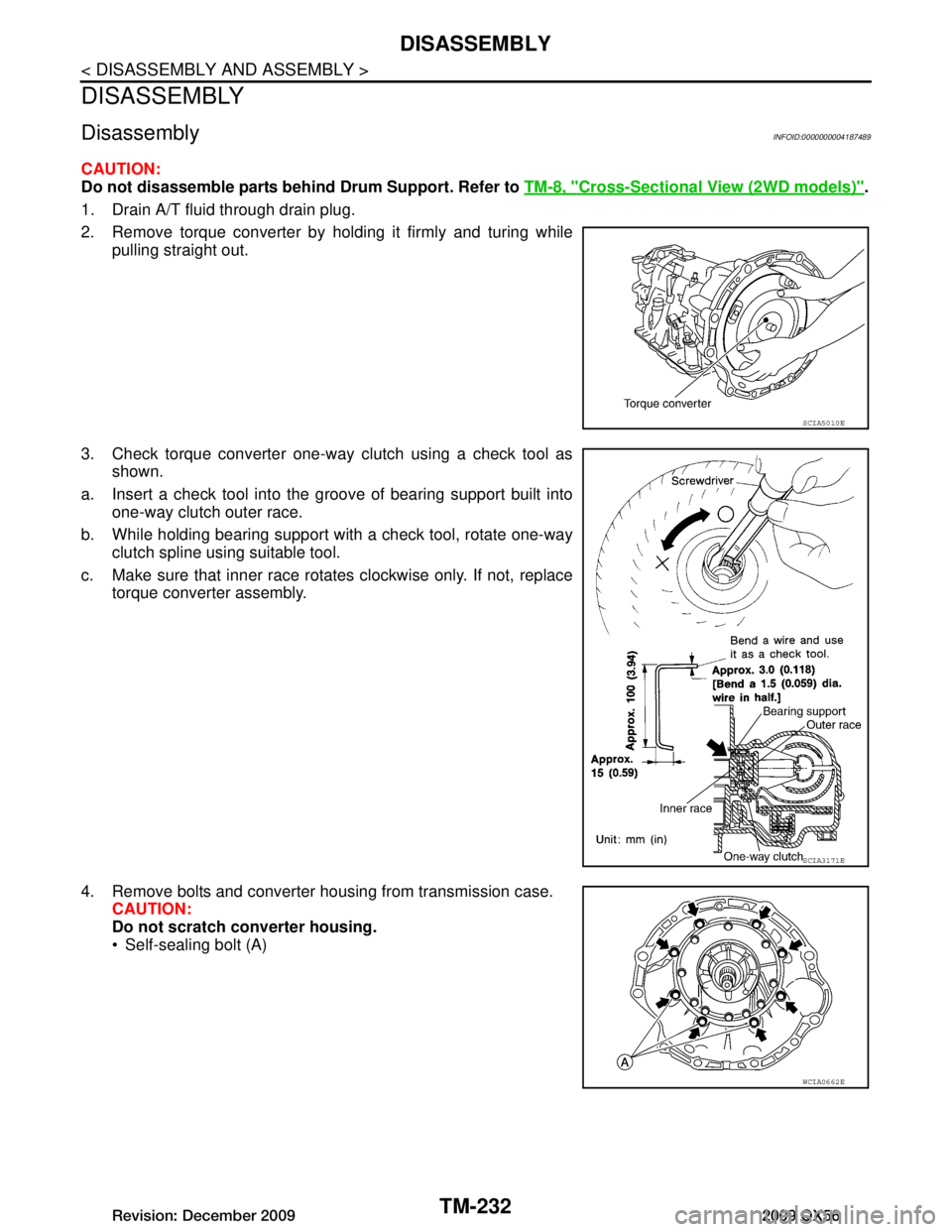

3. Check torque converter one-way clutch using a check tool as shown.

a. Insert a check tool into the groove of bearing support built into one-way clutch outer race.

b. While holding bearing support with a check tool, rotate one-way clutch spline using suitable tool.

c. Make sure that inner race rotates clockwise only. If not, replace torque converter assembly.

4. Remove bolts and converter housing from transmission case. CAUTION:

Do not scratch converter housing.

Self-sealing bolt (A)

SCIA5010E

SCIA3171E

WCIA0662E

Revision: December 20092009 QX56

Page 3883 of 4171

DISASSEMBLYTM-235

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

14. Loosen lock nut and remove band servo anchor end pin from transmission case.

15. Remove brake band from transmission case.

CAUTION:

To prevent brake linings from cracking or peeling, do not

stretch the flexible band unnecessarily. When removing

the brake band, always secure it with a clip as shown.

Check brake band facing for damage, cracks, wear or

burns.

16. Remove mid carrier assembly and rear carrier assembly as a unit.

SCIA6512E

SCIA2580E

SAT655

SCIA5017E

Revision: December 20092009 QX56

Page 3901 of 4171

REPAIR FOR COMPONENT PARTSTM-253

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

2. Install snap ring in front sun gear using suitable tool.

3. Check operation of 3rd one-way clutch.

a. Hold oil pump assembly and turn front sun gear.

b. Check 3rd one-way clutch for correct locking and unlocking directions.

CAUTION:

If not as shown, check installati on direction of 3rd one-way

clutch.

Front Carrier, Input Clut ch, Rear Internal GearINFOID:0000000004187492

COMPONENTS

SCIA3110E

SCIA3131E

Revision: December 20092009 QX56

Page 3911 of 4171

REPAIR FOR COMPONENT PARTSTM-263

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

6. Install high and low reverse clutch hub to mid sun gear assem- bly.

7. Install snap ring to mid sun gear assembly using suitable tool. CAUTION:

Do not expand snap ring excessively.

8. Check operation of 1st one-way clutch.

a. Hold mid sun gear and turn rear sun gear.

b. Check 1st one-way clutch for correct locking and unlocking directions.

CAUTION:

If not as shown, check installa tion direction of 1st one-way

clutch.

9. Install needle bearing and bearing races to high and low reverse clutch hub.

CAUTION:

Apply petroleum jelly to needle bearing and bearingraces.

Take care with order of bearing races.

High and Low Reverse ClutchINFOID:0000000004187494

COMPONENTS

SCIA2856E

SCIA2855E

SCIA3132E

SCIA5238E

Revision: December 20092009 QX56

Page 3928 of 4171

TM-280

< DISASSEMBLY AND ASSEMBLY >

ASSEMBLY

48. Install band servo anchor end pin and lock nut in transmissioncase.

CAUTION:

Do not reuse band servo anchor end pin.

49. Install brake band in transmission case. CAUTION:

Install it so that the identificat ion to avoid incorrect installa-

tion faces the servo side.

50. Install front sun gear to front carrier assembly. CAUTION:

Apply ATF to front sun gear bearing and 3rd one-way clutch

end bearing.

51. Install needle bearing to front sun gear. CAUTION:

Apply petroleum jelly to needle bearing.

52. Adjust brake band tilting using a clip so that brake band contacts front sun gear drum evenly.

SCIA6512E

SCIA5498E

SCIA5014E

SCIA2808E

SCIA5033E

Revision: December 20092009 QX56

Page 3929 of 4171

ASSEMBLYTM-281

< DISASSEMBLY AND ASSEMBLY >

CEF

G H

I

J

K L

M A

B

TM

N

O P

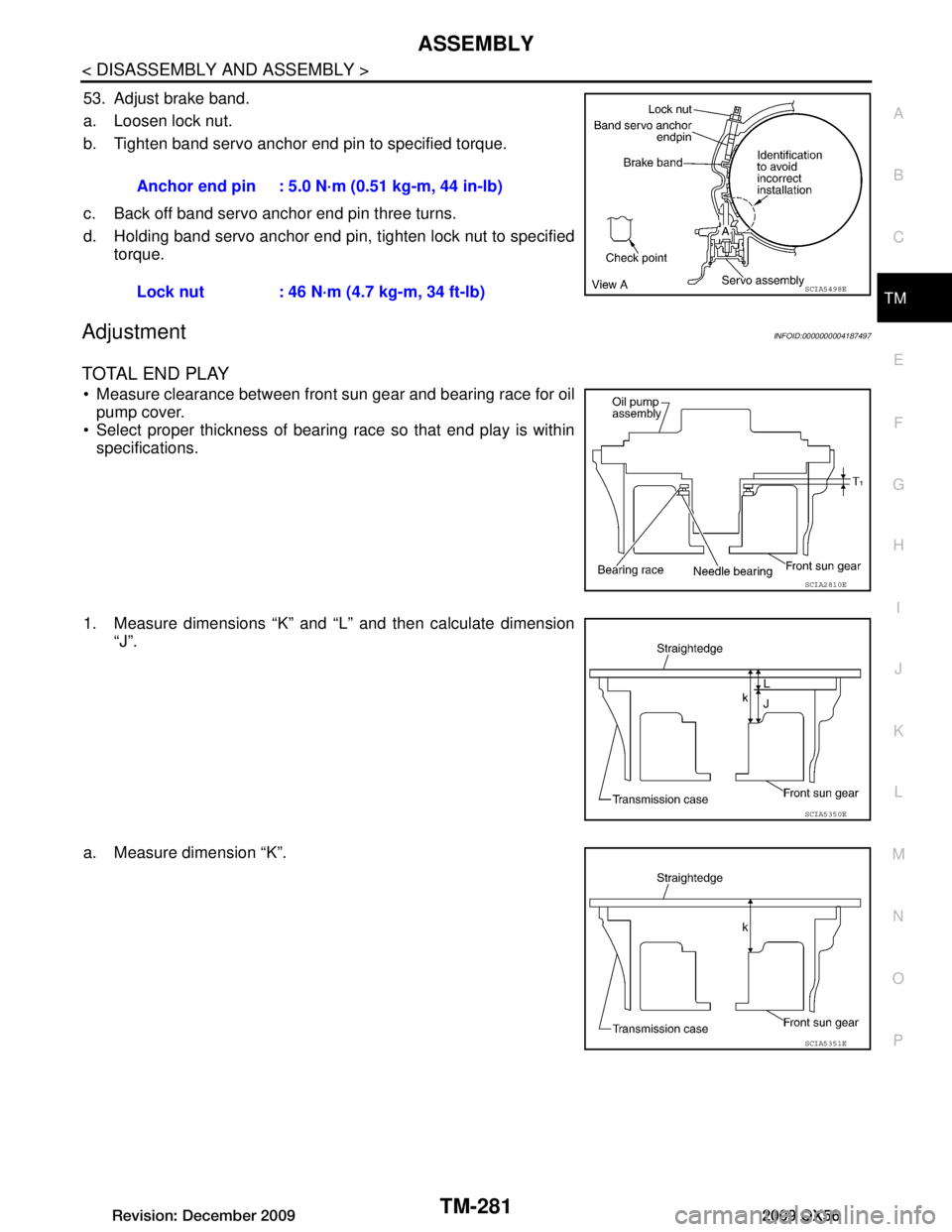

53. Adjust brake band.

a. Loosen lock nut.

b. Tighten band servo anchor end pin to specified torque.

c. Back off band servo anchor end pin three turns.

d. Holding band servo anchor end pin, tighten lock nut to specified torque.

AdjustmentINFOID:0000000004187497

TOTAL END PLAY

Measure clearance between front sun gear and bearing race for oilpump cover.

Select proper thickness of bearing race so that end play is within specifications.

1. Measure dimensions “K” and “L” and then calculate dimension “J”.

a. Measure dimension “K”. Anchor end pin : 5.0 N·m (0.51 kg-m, 44 in-lb)

Lock nut : 46 N·m (4.7 kg-m, 34 ft-lb)

SCIA5498E

SCIA2810E

SCIA5350E

SCIA5351E

Revision: December 20092009 QX56