mileage INFINITI QX56 2009 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 348 of 4171

![INFINITI QX56 2009 Factory Service Manual AV-162

< SYMPTOM DIAGNOSIS >[AUDIO SYSTEM]

NORMAL OPERATING CONDITION

PlaceIn a parking lot

When driving in a parking lot, or other loca-

tion where there are no roads on the map,

matching may place INFINITI QX56 2009 Factory Service Manual AV-162

< SYMPTOM DIAGNOSIS >[AUDIO SYSTEM]

NORMAL OPERATING CONDITION

PlaceIn a parking lot

When driving in a parking lot, or other loca-

tion where there are no roads on the map,

matching may place](/img/42/57031/w960_57031-347.png)

AV-162

< SYMPTOM DIAGNOSIS >[AUDIO SYSTEM]

NORMAL OPERATING CONDITION

PlaceIn a parking lot

When driving in a parking lot, or other loca-

tion where there are no roads on the map,

matching may place the vehicle mark on a

nearby road. When the vehicle returns to

the road, the vehicle mark may have devi-

ated from the correct location.

When driving in circle or turning the steer-

ing wheel repeatedly, direction errors accu-

mulate, and the vehicle mark may deviate

from the correct location.

If after travelling about 10 km (6

miles) the correct location has

not been restored, perform lo-

cation correction and, if neces-

sary, direction correction.

Turntable

When the ignition switch is OFF, the navi-

gation system cannot get the signal from

the gyroscope (angular speed sensor).

Therefore, the displayed direction may be

wrong and the correct road may not be eas-

ily returned to after rotating the vehicle on a

turntable with the ignition OFF.

Slippery roads On snow, wet roads, gravel, or other roads

where tires may slip easily, accumulated

mileage errors may cause the vehicle mark

to deviate from the correct road.

Slopes When parking in sloped garages, when

travelling on banked roads, or in other cas-

es where the vehicle turns when tilted, an

error in the turning angle will occur, and the

vehicle mark may deviate from the road.

Map data Road not displayed on the map screen

When driving on new roads or other roads

not displayed on the map screen, map

matching does not function correctly and

matches the location to a nearby road.

When the vehicle returns to a road which is

on the map, the vehicle mark may deviate

from the correct road.

Different road pattern

(Changed due to repair) If the road pattern stored in the map data

and the actual road pattern are different,

map matching does not function correctly

and matches the location to a nearby road.

The vehicle mark may deviate from the cor-

rect road.

Vehicle Use of tire chains When tire chains are used, the mileage is

not correctly detected, and the vehicle mark

may deviate from the correct road.Drive the vehicle for a while. If

the distance still deviates, ad-

just it by using the distance ad-

justment function. (If the tire

chain is removed, recover the

original value.)

Cause (condition) –: While driving ooo: Display

Driving conditionRemarks (correction, etc.)

SEL709V

SEL710V

SEL699V

ELK0201D

Revision: December 20092009 QX56

Page 434 of 4171

BR-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of a ll control units using CONSULT-III.

Precaution for Brake SystemINFOID:0000000003772409

• Always use recommended brake fluid. Refer to MA-12, "Fluids and Lubricants".

• Do not reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas.

• To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use clean brake fluid.

• Do not use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

• Use flare nut wrench when removing and installing brake tube.

• Always check tightening torque when installing brake lines.

• Before working, turn ignition switch to OFF and disconnect con- nectors for ABS actuator and electric unit (control unit) or battery

terminals.

• Burnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage. Refer to BR-30, "

Brake Burnishing

Procedure".

WARNING:

• Clean brake pads and shoes wi th a waste cloth, then wipe

with a dust collector.

SBR686C

Revision: December 20092009 QX56

Page 459 of 4171

FRONT DISC BRAKEBR-29

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

FRONT DISC BRAKE

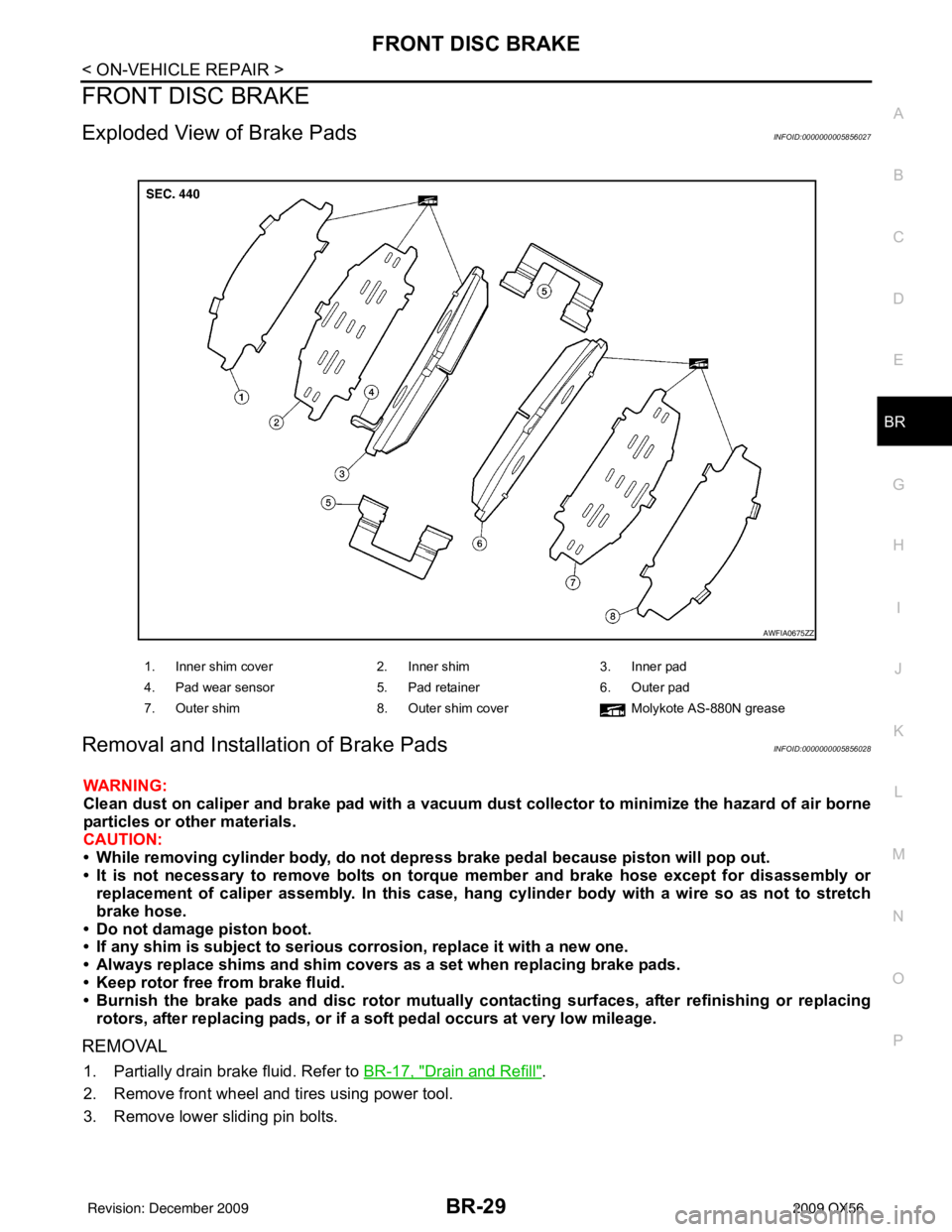

Exploded View of Brake PadsINFOID:0000000005856027

Removal and Installation of Brake PadsINFOID:0000000005856028

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder bod y, do not depress brake pedal because piston will pop out.

• It is not necessary to remove bolts on torque member and brake hose except for disassembly or replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shims and shim covers as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing rotors, after replacing pads, or if a so ft pedal occurs at very low mileage.

REMOVAL

1. Partially drain brake fluid. Refer to BR-17, "Drain and Refill".

2. Remove front wheel and tires using power tool.

3. Remove lower sliding pin bolts.

1. Inner shim cover 2. Inner shim3. Inner pad

4. Pad wear sensor 5. Pad retainer6. Outer pad

7. Outer shim 8. Outer shim cover Molykote AS-880N grease

AWFIA0675ZZ

Revision: December 20092009 QX56

Page 460 of 4171

BR-30

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

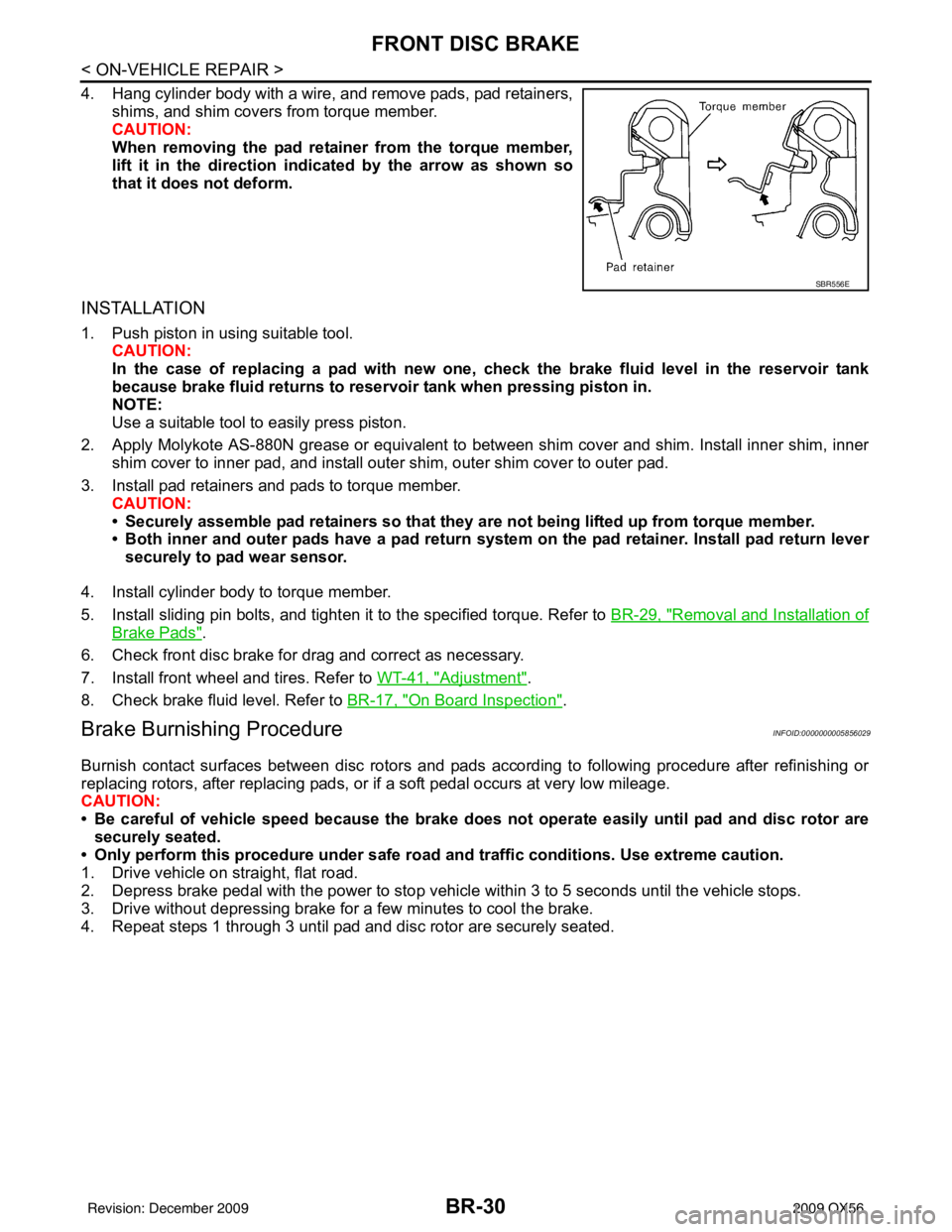

4. Hang cylinder body with a wire, and remove pads, pad retainers,shims, and shim covers from torque member.

CAUTION:

When removing the pad retainer from the torque member,

lift it in the direction indi cated by the arrow as shown so

that it does not deform.

INSTALLATION

1. Push piston in using suitable tool.

CAUTION:

In the case of replacing a pad with new one, ch eck the brake fluid level in the reservoir tank

because brake fluid returns to reservoir tank when pressing piston in.

NOTE:

Use a suitable tool to easily press piston.

2. Apply Molykote AS-880N grease or equivalent to between shim cover and shim. Install inner shim, inner shim cover to inner pad, and install outer shim, outer shim cover to outer pad.

3. Install pad retainers and pads to torque member. CAUTION:

• Securely assemble pad retainers so that they ar e not being lifted up from torque member.

• Both inner and outer pads have a pad return system on the pad retainer. Install pad return lever

securely to pad wear sensor.

4. Install cylinder body to torque member.

5. Install sliding pin bolts, and tighten it to the specified torque. Refer to BR-29, "

Removal and Installation of

Brake Pads".

6. Check front disc brake for drag and correct as necessary.

7. Install front wheel and tires. Refer to WT-41, "

Adjustment".

8. Check brake fluid level. Refer to BR-17, "

On Board Inspection".

Brake Burnishing ProcedureINFOID:0000000005856029

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

SBR556E

Revision: December 20092009 QX56

Page 461 of 4171

FRONT DISC BRAKEBR-31

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

Exploded View of Brake CaliperINFOID:0000000005856030

Removal and Installation of Brake Caliper and RotorINFOID:0000000005856031

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder bod y, do not depress brake pedal because piston will pop out.

• It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shim and shim cover as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing rotors, after replacing pads, or if a so ft pedal occurs at very low mileage.

REMOVAL

1. Remove front wheel and tires using power tool.

2. Fasten disc rotor using wheel nut.

3. Drain brake fluid. Refer to CO-11, "

Changing Engine Coolant".

4. Remove union bolt, and then disconnect brake hose from caliper assembly.

1. Sliding pin bolt 2. Bleed valve 3. Cap

4. Union bolt 5. Brake hose 6. Copper washer

7. Torque member bolt 8. Sliding pin boot 9. Torque member

10. Sliding pin 11. Piston boot 12. Piston

13. Piston seal 14. Cylinder body B: Brake fluid

R: Rubber grease

AWFIA0683GB

Revision: December 20092009 QX56

Page 464 of 4171

BR-34

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

REAR DISC BRAKE

Exploded View of Brake PadsINFOID:0000000004057217

Removal and Installation of Brake PadINFOID:0000000004057218

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder body, do not depress brake pedal because piston will pop out.

• It is not necessary to disconnect brake hose connection except for disassembly or replacement of caliper assembly. In this case, ha ng cylinder body with a wire so as not to stretch brake hose.

• Do not damage piston boot.

• If any shim is subject to serious corrosion, replace it with a new one.

• Always replace shim and shim cover as a set when replacing brake pads.

• Keep rotor free from brake fluid.

• Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

REMOVAL

1. Partially drain brake fluid. Refer to BR-17, "Drain and Refill".

2. Remove rear wheel and tires using power tools. Refer to WT-41, "

Adjustment".

3. Remove the sliding pin bolt from the cylinder body. Refer to BR-35, "

Exploded View of Brake Caliper".

4. Remove the cylinder body secure with wire and remove pads.

INSTALLATION

1. Push piston in using suitable tool. CAUTION:

1. Outer pad 2. Inner pad

AWFIA0676ZZ

Revision: December 20092009 QX56

Page 465 of 4171

REAR DISC BRAKEBR-35

< ON-VEHICLE REPAIR >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

By pushing in piston, br ake fluid returns to master cylinder reservoir tank. Watch the brake fluid

level in the reservoir tank.

NOTE:

Using a suitable tool, makes it easier to push in the piston.

2. Apply Molykote M-77 grease to knuckle slide where brake pad contacts. CAUTION:

Do not get grease on the brake pads or brake rotor friction surfaces.

3. Install pads to cylinder body.

4. Install cylinder body to torque member

5. Install sliding pin bolt and tighten to specification. Refer to BR-35, "

Exploded View of Brake Caliper"

6. Check rear disc brake for drag and correct as necessary.

7. Install rear wheel and tires. Refer to WT-41, "

Adjustment".

8. Check brake fluid level. Refer to BR-17, "

On Board Inspection".

Brake Burnishing ProcedureINFOID:0000000004057219

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

• Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are securely seated.

• Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 through 3 until pad and disc rotor are securely seated.

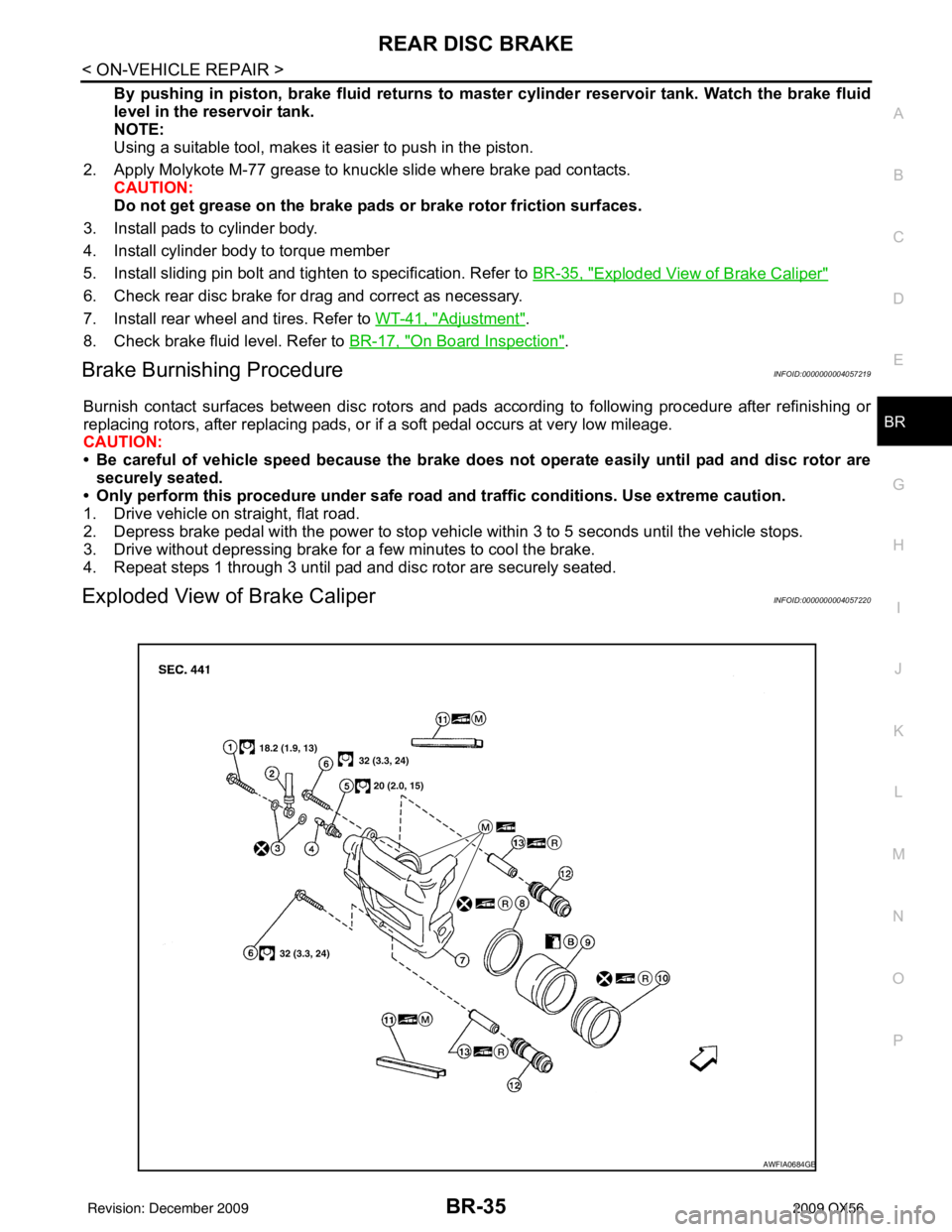

Exploded View of Brake CaliperINFOID:0000000004057220

AWFIA0684GB

Revision: December 20092009 QX56

Page 466 of 4171

BR-36

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Removal and Installation of Brake Caliper and Disc Rotor

INFOID:0000000004057221

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

• While removing cylinder body, do not depress brake pedal because piston will pop out.

• Do not damage piston boot.

• Keep rotor free from brake fluid.

• Refill with new specified brake fluid.

• Burnish brake contact surface after refinishing or re placing rotors, after replacing pads, or it a soft

pedal occurs at very low mileage. Refer to BR-35, "

Brake Burnishing Procedure".

REMOVAL

1. Remove rear wheel and tires using power tools. Refer to WT-41, "Adjustment".

2. Fasten disc rotor using wheel nut.

3. Drain brake fluid as necessary. Refer to BR-17, "

Drain and Refill".

4. Remove union bolt and cylinder body bolts, then remove cylin- der body.

NOTE:

Discard the copper washers, do not reuse.

5. Apply matching marks to disc rotor and wheel hub assembly if the disc rotor is to be reused, then remove disc rotor.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor

if the disc rotor is to be reused.

INSTALLATION

1. If reusing the disc rotor, use the matching marks to align disc rotor on the wheel hub assembly, then install

disc rotor using a wheel nut to hold it in place.

CAUTION:

Use matching marks on wheel hub assembly and di sc rotor if the disc rotor is to be reused.

2. Install cylinder body and tighten cylinder body bolts to specification. CAUTION:

Before installing cylinder body to the vehic le, wipe off mating surface of cylinder body.

3. Install brake hose to cylinder body with new copper washers and tighten union bolt to specification.

CAUTION:

• Do not reuse copper washers.

• Securely attach brake hose to projection on cylinderbody.

4. Refill with new brake fluid and bleed. Refer to BR-17, "

Bleeding

Brake System".

5. Check rear disc brake for drag and correct as necessary.

6. Install rear wheel and tires. Refer to WT-41, "

Adjustment".

1. Union bolt2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Knuckle slide 12. Sliding sleeve boot

13. Sliding sleeve B: Brake fluidR: Rubber grease

M: Molykote 7439 grease Front

LFIA0211E

SFIA1137E

Revision: December 20092009 QX56

Page 588 of 4171

![INFINITI QX56 2009 Factory Service Manual PRECAUTIONSBRC-111

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the ba INFINITI QX56 2009 Factory Service Manual PRECAUTIONSBRC-111

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the ba](/img/42/57031/w960_57031-587.png)

PRECAUTIONSBRC-111

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Brake SystemINFOID:0000000003772632

CAUTION:

• Always use recommended brake fluid. Refer to MA-12, "

Fluids and Lubricants".

• Never reuse drained brake fluid.

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

• To clean or wash all parts of master cylin der and disc brake caliper, use clean brake fluid.

• Never use mineral oils such as gasoline or kerosen e. They will ruin rubber parts of the hydraulic sys-

tem.

• Use flare nut wrench when removing and installing brake

tube.

• If a brake fluid leak is found, the part must be disassembled

without fail. Then it has to be replaced with a new one if a

defect exists.

• Turn the ignition switch OFF and remove the connector of the ABS actuator and electric unit (con trol unit) or the battery ter-

minal before performing the work.

• Always torque brake lines when installing.

• Burnish the brake contact surf aces after refinishing or replac-

ing rotors, after replacing pads, or if a soft pedal occurs at

very low mileage.

Refer to BR-30, "

Brake Burnishing Procedure" (front disc brake) or BR-35, "Brake Burnishing Proce-

dure" (rear disc brake).

WARNING:

• Clean brake pads and shoes with a waste cl oth, then wipe with a dust collector.

Precaution for Brake ControlINFOID:0000000003772633

• During ABS operation, the brake pedal may vibrate lightly and a mechanical noise may be heard. This is

normal.

• Just after starting vehicle, the brake pedal may vibrate or a motor operating noise may be heard from engine

compartment. This is a normal status of operation check.

• Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or snow-covered (fresh, deep snow) roads.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer (what symptoms are present under what conditions) and check for simple causes before starting diagnosis.

Besides electrical system inspection, check boos ter operation, brake fluid level, and fluid leaks.

• If incorrect tire sizes or types are installed on the vehicle or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• If there is a radio, antenna or related wiring near control module, ABS function may have a malfunction or

error.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness pinches, open circuits or improper wiring.

• If the following components are replaced with non-genuine components or modified, the VDC OFF indicator lamp and SLIP indicator lamp may turn on or the VDC system may not operate properly. Components

related to suspension (shock absorbers, struts, springs , bushings, etc.), tires, wheels (exclude specified

size), components related to brake system (pads, roto rs, calipers, etc.), components related to engine (muf-

fler, ECM, etc.), components related to body reinforcement (roll bar, tower bar, etc.).

• Driving with broken or excessively worn suspensi on components, tires or brake system components may

cause the VDC OFF indicator lamp and the SLIP indicator lamp to turn on, and the VDC system may not

operate properly.

• When the TCS or VDC is activated by sudden acceleration or sudden turn, some noise may occur. The noise is a result of the normal operation of the TCS and VDC.

• When driving on roads which have extreme slopes (such as mountainous roads) or high banks (such as sharp curves on a freeway), the VDC may not operate no rmally, or the VDC warning lamp and the SLIP indi-

cator lamp may turn on. This is not a problem if normal operation can be resumed after restarting the engine.

SBR686C

Revision: December 20092009 QX56

Page 2681 of 4171

MA-8

< ON-VEHICLE MAINTENANCE >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000003776980

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage or ti me intervals, whichever comes first.

Maintenance for Off-road Driving (4WD only)INFOID:0000000003776981

After driving the vehicle off-road through sand, mud, or water; more frequent maintenance may be required for

the following items:

Brake pads and rotors

Brake lines and hoses

Rear final drive oil, transmission fluid, and transfer fluid

Steering linkage

Drive shafts

Engine air cleaner filter

In-cabin microfilters

Schedule 1INFOID:0000000003776982

EMISSION CONTROL SYSTEM MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or r eplace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if your driving habits frequently includes

one or more of the following driving conditions:

• Repeated short trips of less than 5 miles (8 km).

• Repeated short trips of less than 10 miles (16 km) with outside temperatures re-

maining below freezing.

• Operating in hot weather in stop-and-go “rush hour” traffic.

• Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

• Driving in dusty conditions.

• Driving on rough, muddy, or salt spread roads.

• Towing a trailer or using a car-top carrier. Emission Control Sys-

tem Maintenance

MA-8

Chassis and Body

Maintenance

MA-8

Schedule 2Follow Periodic Maintenance Schedule 2 if none of the driving conditions shown

in Schedule 1 apply to the driving habits.

Emission Control Sys-

tem MaintenanceMA-10Chassis and Body

Maintenance

MA-10

MAINTENANCE OPERATION

MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.50

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Drive belts NOTE (1) MA-14

Air cleaner filterNOTE (2) [R]MA-17

EVAP vapor lines I*MA-20

Fuel lines I*MA-17

Fuel filter NOTE (3) —

Engine coolant NOTE (4) MA-14

Engine oilR R R R R R R R MA-18

Engine oil filterR R R R R R R R MA-18

Spark plugs (Iridium-tipped type)Replace every 105,000 miles (169,000 km).MA-19

Intake and exhaust valve clear-

ance*NOTE (5)

EM-18

Revision: December 20092009 QX56