engine oil INFINITI QX56 2009 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2009, Model line: QX56, Model: INFINITI QX56 2009Pages: 4171, PDF Size: 84.65 MB

Page 1890 of 4171

OIL SEALEM-67

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

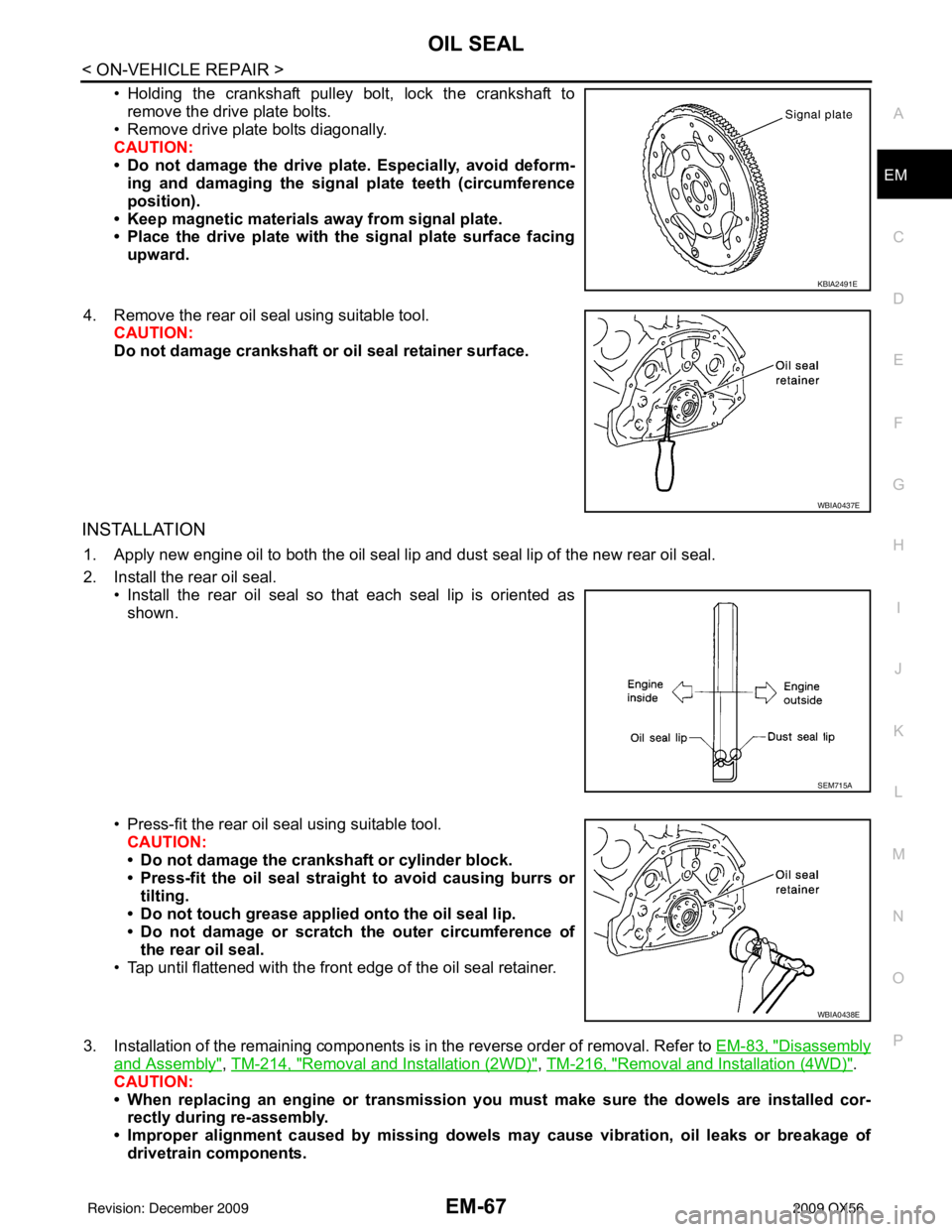

• Holding the crankshaft pulley bolt, lock the crankshaft to

remove the drive plate bolts.

• Remove drive plate bolts diagonally.

CAUTION:

• Do not damage the drive plate. Especially, avoid deform- ing and damaging the signal plate teeth (circumference

position).

• Keep magnetic materials away from signal plate.

• Place the drive plate with th e signal plate surface facing

upward.

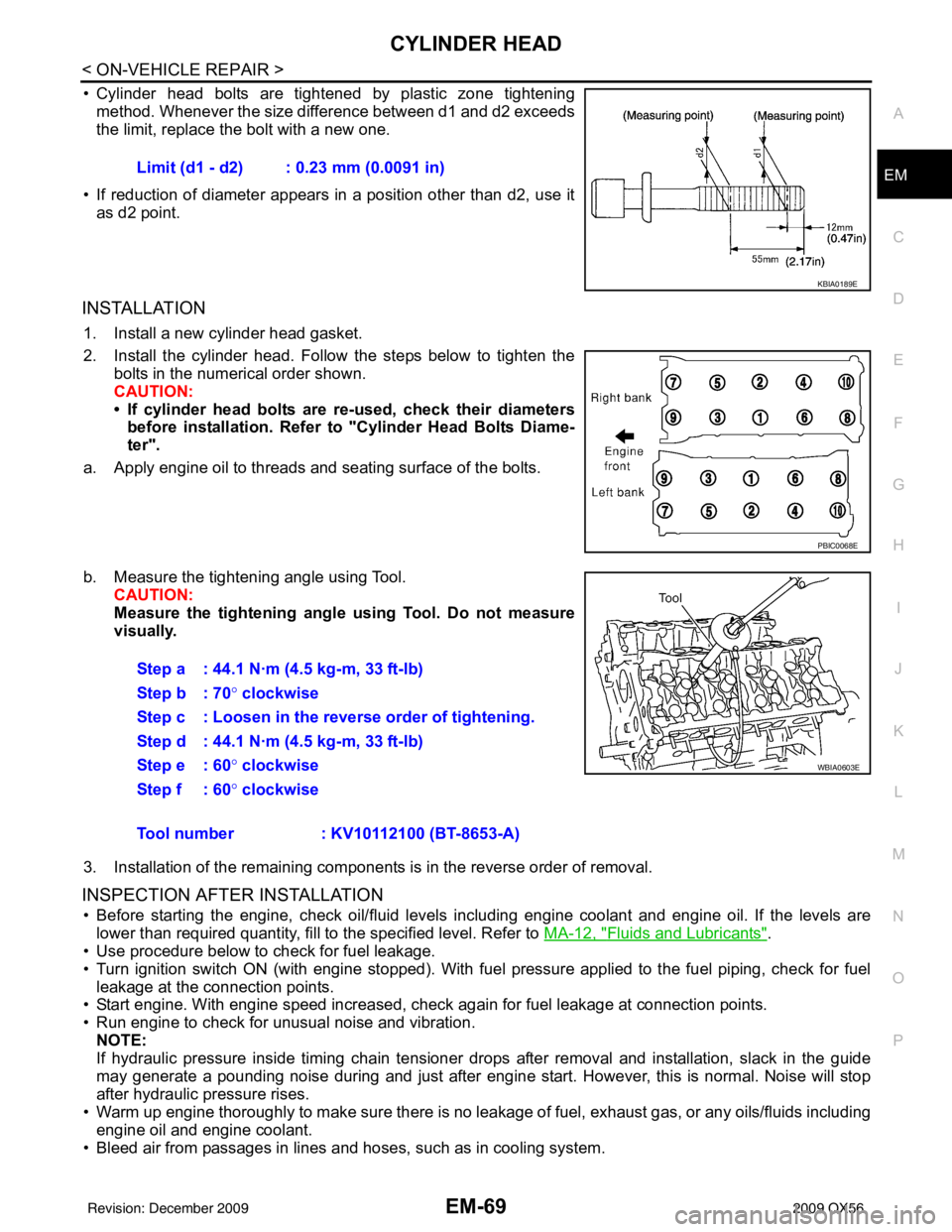

4. Remove the rear oil seal using suitable tool. CAUTION:

Do not damage crankshaft or oil seal retainer surface.

INSTALLATION

1. Apply new engine oil to both the oil seal lip and dust seal lip of the new rear oil seal.

2. Install the rear oil seal.

• Install the rear oil seal so that each seal lip is oriented asshown.

• Press-fit the rear oil seal using suitable tool. CAUTION:

• Do not damage the crankshaft or cylinder block.

• Press-fit the oil seal straight to avoid causing burrs or

tilting.

• Do not touch grease applied onto the oil seal lip.

• Do not damage or scratch the outer circumference of

the rear oil seal.

• Tap until flattened with the front edge of the oil seal retainer.

3. Installation of the remaining components is in the reverse order of removal. Refer to EM-83, "

Disassembly

and Assembly", TM-214, "Removal and Installation (2WD)", TM-216, "Removal and Installation (4WD)".

CAUTION:

• When replacing an engine or transmission you must make sure the dowels are installed cor-

rectly during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of

drivetrain components.

KBIA2491E

WBIA0437E

SEM715A

WBIA0438E

Revision: December 20092009 QX56

Page 1891 of 4171

EM-68

< ON-VEHICLE REPAIR >

CYLINDER HEAD

CYLINDER HEAD

Exploded ViewINFOID:0000000005885894

Removal and InstallationINFOID:0000000005885895

REMOVAL

1. Remove the engine assembly from the vehicle. Refer to EM-78, "Removal and Installation".

2. Remove the following components and related parts: • Drive belt auto tensioner and idler pulley. Refer to EM-14, "

Drive Belt Auto Tensioner and Idler Pulley".

• Generator assembly and bracket. Refer to CHG-20, "

Removal and Installation".

• Thermostat housing and hose. Refer to CO-22, "

Removal and Installation".

• Oil pan and oil strainer. Refer to EM-33, "

Removal and Installation".

• Fuel tube and fuel injector assembly. Refer to EM-40, "

Removal and Installation".

• Intake manifold. Refer to EM-26, "

Removal and Installation".

• Rocker cover. Refer to EM-38, "

Removal and Installation".

3. Remove the crankshaft pulley, front cover, oil pump, and timing chain. Refer to EM-45, "

Removal and

Installation".

4. Remove the camshaft sprockets and camshafts. Refer to EM-53, "

Removal and Installation".

5. Remove the cylinder head bolts in reverse of order shown.

6. Remove the cylinder heads.

INSPECTION AFTER REMOVAL

Cylinder Head Bolts Diameter

1. Harness bracket 2. Engine coolant temperature sensor 3. Washer

4. Cylinder head gasket (LH) 5. Cylinder head (RH) 6. Cylinder head bolt

7. Cylinder head gasket (RH) 8. Cylinder head (LH)

KBIA2528E

PBIC0068E

Revision: December 20092009 QX56

Page 1892 of 4171

CYLINDER HEADEM-69

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

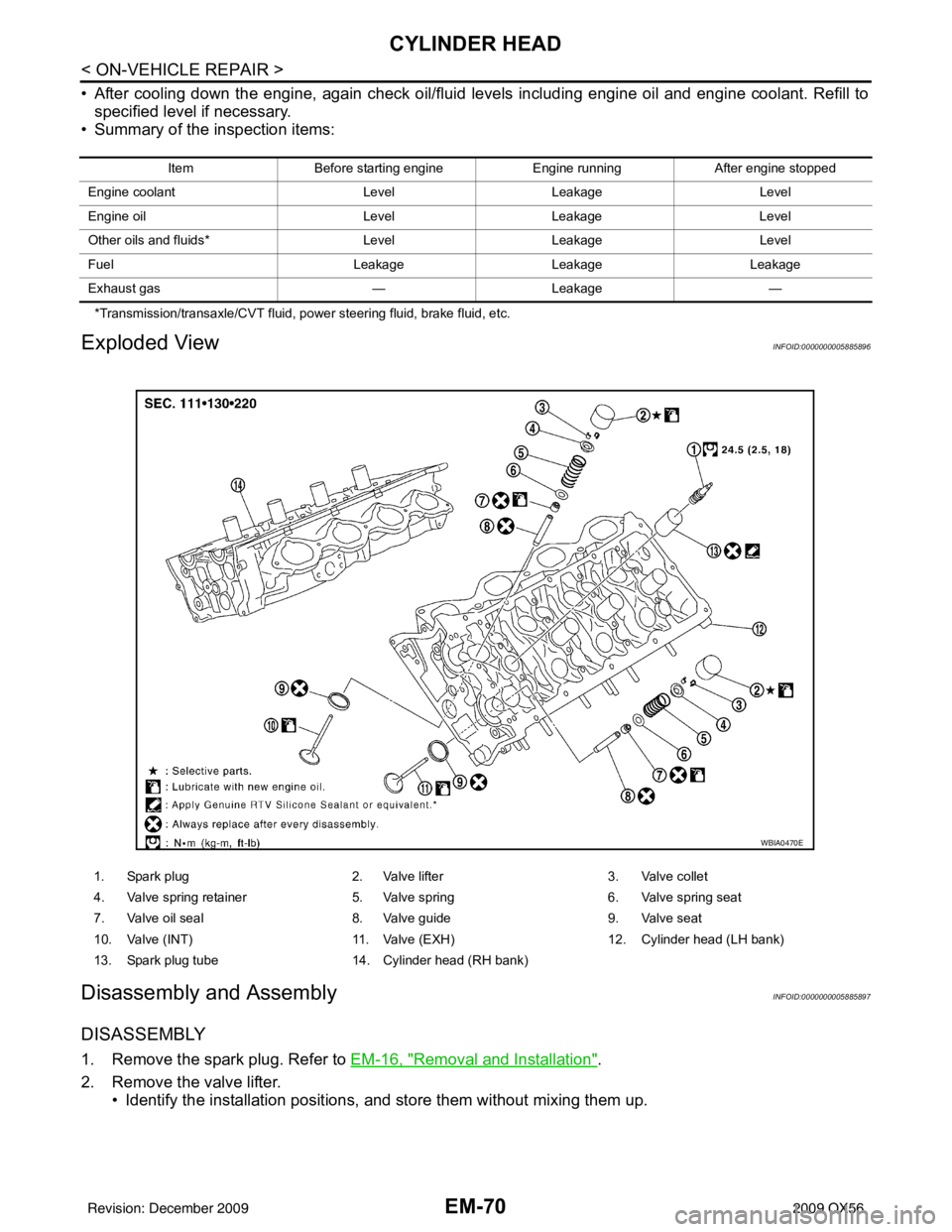

• Cylinder head bolts are tightened by plastic zone tightening

method. Whenever the size difference between d1 and d2 exceeds

the limit, replace the bolt with a new one.

• If reduction of diameter appears in a position other than d2, use it as d2 point.

INSTALLATION

1. Install a new cylinder head gasket.

2. Install the cylinder head. Follow the steps below to tighten the bolts in the numerical order shown.

CAUTION:

• If cylinder head bolts are re-used, check their diameters

before installation. Refer to "Cylinder Head Bolts Diame-

ter".

a. Apply engine oil to threads and seating surface of the bolts.

b. Measure the tightening angle using Tool. CAUTION:

Measure the tightening angl e using Tool. Do not measure

visually.

3. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

• Before starting the engine, check oil/fluid levels including engine coolant and engine oil. If the levels are lower than required quantity, fill to the specified level. Refer to MA-12, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to the fuel piping, check for fuel

leakage at the connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system. Limit (d1 - d2) : 0.23 mm (0.0091 in)

KBIA0189E

PBIC0068E

Step a : 44.1 N·m (4.5 kg-m, 33 ft-lb)

Step b : 70°

clockwise

Step c : Loosen in the reverse order of tightening.

Step d : 44.1 N·m (4.5 kg-m, 33 ft-lb)

Step e : 60 ° clockwise

Step f : 60° clockwise

Tool number : KV10112100 (BT-8653-A)

WBIA0603E

Revision: December 20092009 QX56

Page 1893 of 4171

EM-70

< ON-VEHICLE REPAIR >

CYLINDER HEAD

• After cooling down the engine, again check oil/fluid levels including engine oil and engine coolant. Refill tospecified level if necessary.

• Summary of the inspection items:

*Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

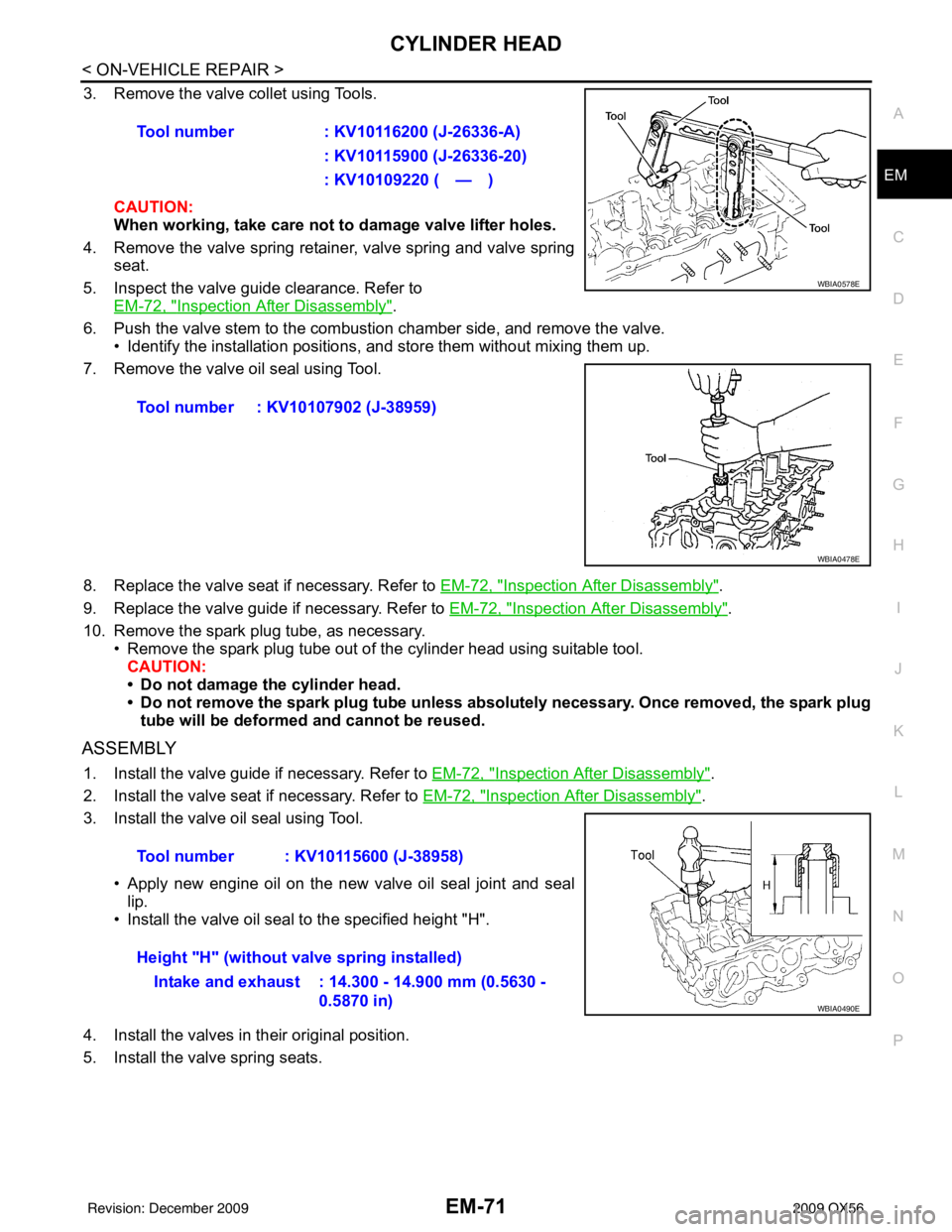

Exploded ViewINFOID:0000000005885896

Disassembly and AssemblyINFOID:0000000005885897

DISASSEMBLY

1. Remove the spark plug. Refer to EM-16, "Removal and Installation".

2. Remove the valve lifter. • Identify the installation positions, and store them without mixing them up.

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gas —Leakage —

1. Spark plug 2. Valve lifter3. Valve collet

4. Valve spring retainer 5. Valve spring6. Valve spring seat

7. Valve oil seal 8. Valve guide9. Valve seat

10. Valve (INT) 11. Valve (EXH)12. Cylinder head (LH bank)

13. Spark plug tube 14. Cylinder head (RH bank)

WBIA0470E

Revision: December 20092009 QX56

Page 1894 of 4171

CYLINDER HEADEM-71

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

3. Remove the valve collet using Tools.

CAUTION:

When working, take care not to damage valve lifter holes.

4. Remove the valve spring retainer, valve spring and valve spring seat.

5. Inspect the valve guide clearance. Refer to EM-72, "

Inspection After Disassembly".

6. Push the valve stem to the combustion chamber side, and remove the valve. • Identify the installation positions, and store them without mixing them up.

7. Remove the valve oil seal using Tool.

8. Replace the valve seat if necessary. Refer to EM-72, "

Inspection After Disassembly".

9. Replace the valve guide if necessary. Refer to EM-72, "

Inspection After Disassembly".

10. Remove the spark plug tube, as necessary. • Remove the spark plug tube out of the cylinder head using suitable tool.

CAUTION:

• Do not damage the cylinder head.

• Do not remove the spark plug tube unless absolutely necessary. Once removed, the spark plug tube will be deformed and cannot be reused.

ASSEMBLY

1. Install the valve guide if necessary. Refer to EM-72, "Inspection After Disassembly".

2. Install the valve seat if necessary. Refer to EM-72, "

Inspection After Disassembly".

3. Install the valve oil seal using Tool.

• Apply new engine oil on the new valve oil seal joint and seallip.

• Install the valve oil seal to the specified height "H".

4. Install the valves in their original position.

5. Install the valve spring seats. Tool number

: KV10116200 (J-26336-A)

: KV10115900 (J-26336-20)

: KV10109220 ( — )

Tool number : KV10107902 (J-38959)

WBIA0578E

WBIA0478E

Tool number : KV10115600 (J-38958)

Height "H" (without valve spring installed) Intake and exhaust : 14.300 - 14.900 mm (0.5630 - 0.5870 in)

WBIA0490E

Revision: December 20092009 QX56

Page 1902 of 4171

ENGINE ASSEMBLYEM-79

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

1. Release the fuel pressure. Refer to

EC-487, "Fuel Pressure Check".

2. Drain the engine coolant. Refer to CO-11, "

Changing Engine Coolant".

3. Drain the engine oil. Refer to LU-9, "

Changing Engine Oil".

4. Disconnect the battery negative and positive terminal. Refer to PG-76, "

Removal and Installation".

5. Remove the engine hood. Refer to DLK-230, "

Removal and Installation of Hood Assembly".

6. Remove the cowl extension. Refer to EXT-18, "

Removal and Installation".

7. Remove the air duct and air cleaner case assembly. Refer to EM-25, "

Removal and Installation".

8. Remove the radiator assembly and hoses. Refer to CO-15, "

Removal and Installation".

NOTE:

To prevent possible A/T fluid drain from transmissi on opening, use appropriate cap to close off transmis-

sion opening during operation.

9. Remove the drive belt. Refer to EM-13, "

Removal and Installation".

10. Remove the fan blade. Refer to CO-18, "

Removal and Installation (Crankshaft Driven Type)".

11. Disconnect the engine room harness from the fuse box and set it aside.

12. Disconnect the ECM.

13. Disconnect the engine room harness from the engine side and set it aside.

14. Disconnect the engine harness grounds.

15. Disconnect the power steering reservoir t ank from the engine and move it aside.

16. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or rope. Refer to ST-26, "

Removal and Installation"

17. Remove the A/C compressor bolts and set the compressor aside. Refer to HA-31, "Removal and Installa-

tion for Compressor" (ATC).

18. Disconnect the brake booster vacuum hose.

19. Disconnect the EVAP line.

20. Disconnect the fuel hose at the engine side connection. Refer to EM-40, "

Removal and Installation".

21. Disconnect the heater hoses at the cowl, and in stall plugs to avoid leakage of engine coolant.

22. Remove the A/T oil level indicator and indicator tube upper bolts.

23. Remove the front final drive assembly (4WD only). Refer to DLN-215, "

Removal and Installation".

24. Remove the exhaust manifolds. Refer to EM-30, "

Removal and Installation".

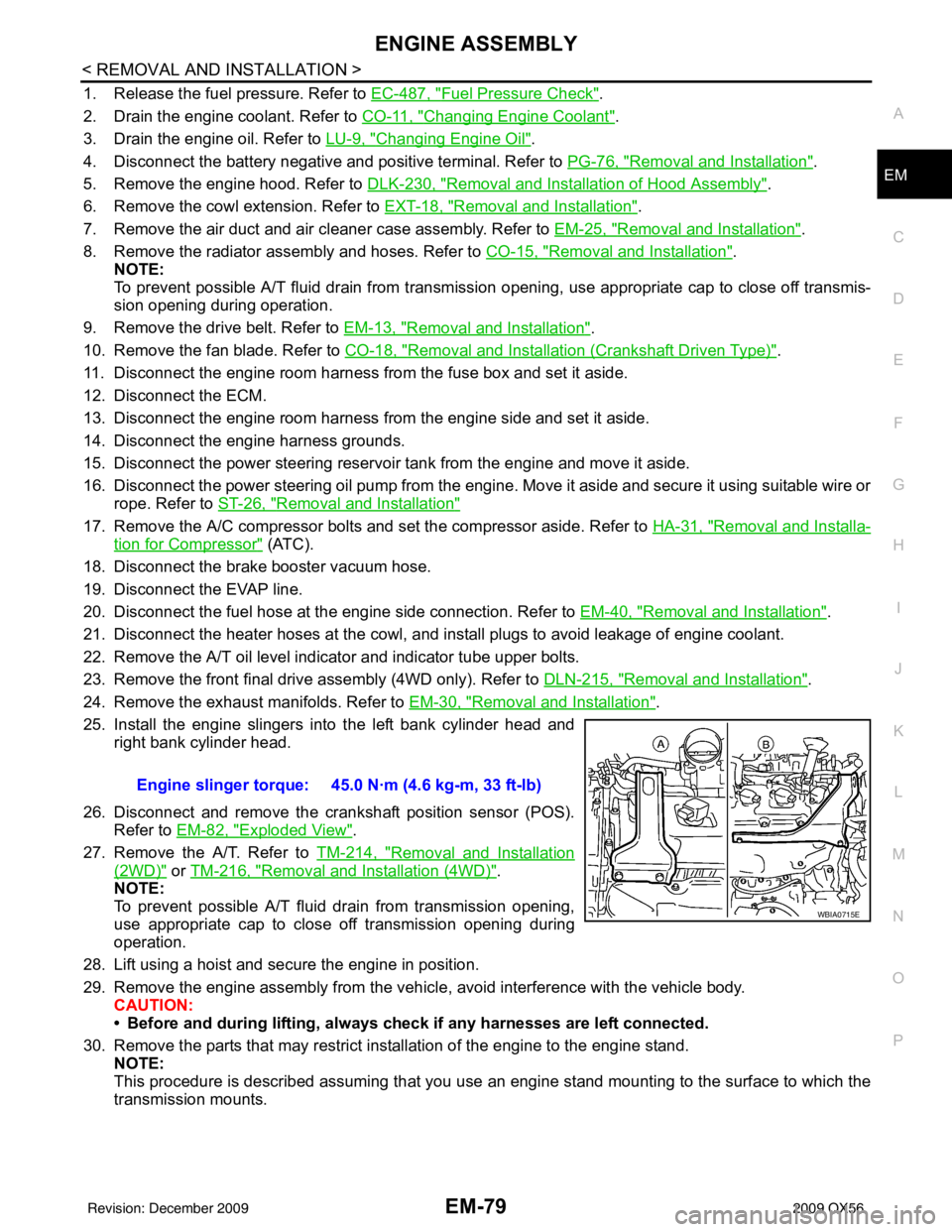

25. Install the engine slingers into the left bank cylinder head and right bank cylinder head.

26. Disconnect and remove the crankshaft position sensor (POS). Refer to EM-82, "

Exploded View".

27. Remove the A/T. Refer to TM-214, "

Removal and Installation

(2WD)" or TM-216, "Removal and Installation (4WD)".

NOTE:

To prevent possible A/T fluid drain from transmission opening,

use appropriate cap to close off transmission opening during

operation.

28. Lift using a hoist and secure the engine in position.

29. Remove the engine assembly from the vehicl e, avoid interference with the vehicle body.

CAUTION:

• Before and during lifting, always check if any harnesses are left connected.

30. Remove the parts that may restrict installation of the engine to the engine stand. NOTE:

This procedure is described assuming that you use an engine stand mounting to the surface to which the

transmission mounts. Engine slinger torque: 45.0 N·m (4.6 kg-m, 33 ft-lb)

WBIA0715E

Revision: December 20092009 QX56

Page 1903 of 4171

EM-80

< REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

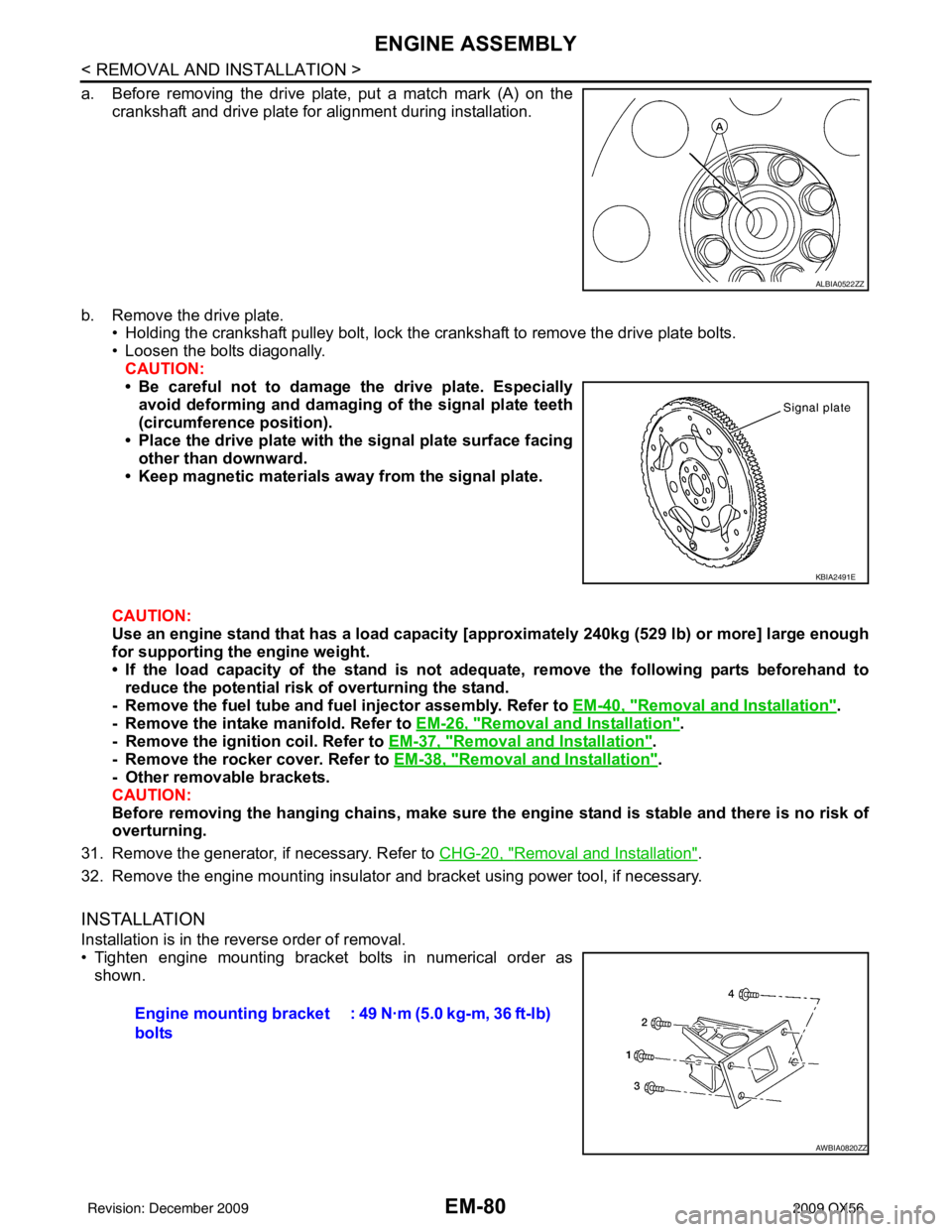

a. Before removing the drive plate, put a match mark (A) on thecrankshaft and drive plate for alignment during installation.

b. Remove the drive plate. • Holding the crankshaft pulley bolt, lock the crankshaft to remove the drive plate bolts.

• Loosen the bolts diagonally.

CAUTION:

• Be careful not to damage the drive plate. Especiallyavoid deforming and damaging of the signal plate teeth

(circumference position).

• Place the drive plate with th e signal plate surface facing

other than downward.

• Keep magnetic materials away from the signal plate.

CAUTION:

Use an engine stand that has a load capacity [a pproximately 240kg (529 lb) or more] large enough

for supporting the engine weight.

• If the load capacity of the stand is not adeq uate, remove the following parts beforehand to

reduce the potential risk of overturning the stand.

- Remove the fuel tube and fuel injector assembly. Refer to EM-40, "

Removal and Installation".

- Remove the intake manifold. Refer to EM-26, "

Removal and Installation".

- Remove the ignition coil. Refer to EM-37, "

Removal and Installation".

- Remove the rocker cover. Refer to EM-38, "

Removal and Installation".

- Other removable brackets.

CAUTION:

Before removing the hanging chains, make sure th e engine stand is stable and there is no risk of

overturning.

31. Remove the generator, if necessary. Refer to CHG-20, "

Removal and Installation".

32. Remove the engine mounting insulator and bracket using power tool, if necessary.

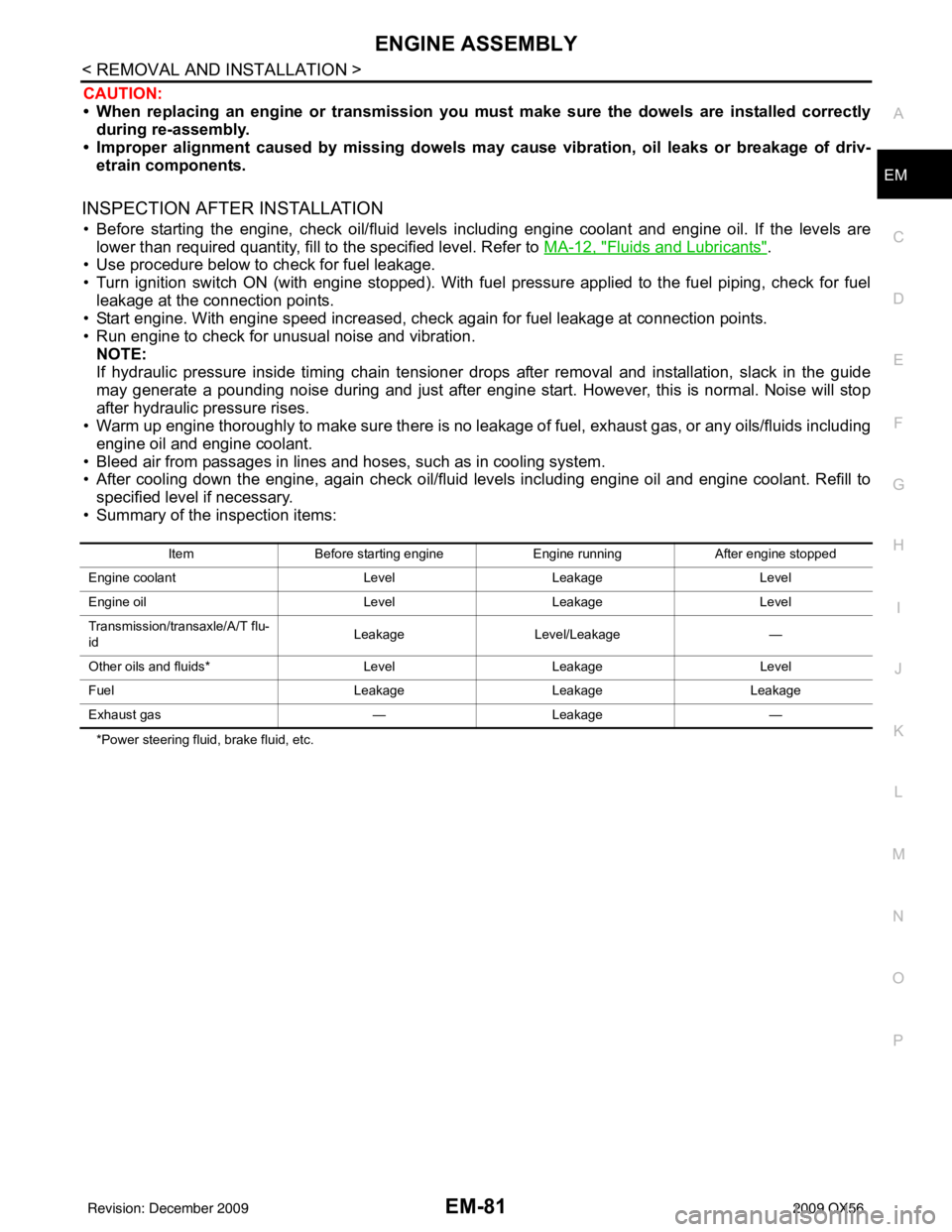

INSTALLATION

Installation is in the reverse order of removal.

• Tighten engine mounting bracket bolts in numerical order as shown.

ALBIA0522ZZ

KBIA2491E

Engine mounting bracket

bolts : 49 N·m (5.0 kg-m, 36 ft-lb)

AWBIA0820ZZ

Revision: December 20092009 QX56

Page 1904 of 4171

ENGINE ASSEMBLYEM-81

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

CAUTION:

• When replacing an engine or tr

ansmission you must make sure the dowels are installed correctly

during re-assembly.

• Improper alignment caused by missing dowels m ay cause vibration, oil leaks or breakage of driv-

etrain components.

INSPECTION AFTER INSTALLATION

• Before starting the engine, check oil/fluid levels including engine coolant and engine oil. If the levels are lower than required quantity, fill to the specified level. Refer to MA-12, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to the fuel piping, check for fuel leakage at the connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down the engine, again check oil/fluid levels including engine oil and engine coolant. Refill to specified level if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/transaxle/A/T flu-

id Leakage

Level/Leakage —

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakage Leakage

Exhaust gas —Leakage —

Revision: December 20092009 QX56

Page 1905 of 4171

EM-82

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

DISASSEMBLY AND ASSEMBLY

ENGINE UNIT

Exploded ViewINFOID:0000000005885901

1. Knock sensor sub-harness 2. Knock sensor3. Cylinder block

4. Main bearing upper 5. Top ring6. Second ring

7. Oil ring 8. Crankshaft key9. Piston

10. Connecting rod 11. Snap ring12. Piston pin

13. Connecting rod bearing 14. Connecting rod bearing cap 15. Main bearing cap

WBIA0471E

Revision: December 20092009 QX56

Page 1906 of 4171

ENGINE UNITEM-83

< DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Disassembly and AssemblyINFOID:0000000005885902

DISASSEMBLY

NOTE:

Explained here is how to disassemble with engine stand supporting transmission surface. When using differ-

ent type of engine stand, some steps may be different.

1. Remove engine assembly and mount to engine stand. Refer to

EM-78, "

Removal and Installation".

CAUTION:

Before removing the hanging chains, make sure engi ne stand is stable and there is no risk of over-

turning.

2. Drain engine coolant by removing the cylinder block drain plugs “A”, “B”, “C” and “D” as shown.

3. Remove the following components and associated parts (the parts referred to in step 1 are not included here).

• Oil pan (upper and lower) and oil strainer. Refer to EM-33, "

Removal and Installation".

• Crankshaft pulley, front cover and timing chain. Refer to EM-45, "

Removal and Installation".

• Camshaft. Refer to EM-53, "

Removal and Installation".

• Cylinder head. Refer to EM-68, "

Removal and Installation".

4. Remove knock sensor and sub harness. CAUTION:

Carefully handle sensor, avoiding shocks.

5. Check connecting rod side clearance. Refer to EM-90, "

Inspection After Disassembly".

6. Remove piston and connecting rod assembly as follows.

a. Position the crankshaft pin corresponding to the connecting rod to be removed onto bottom dead center.

b. Remove connecting rod cap.

16. Thrust bearing lower 17. Main bearing lower18. Crankshaft

19. Pilot converter 20. Thrust bearing upper21. Side bolt

22. Drive plate 23. Reinforcement plate24. Rear oil seal retainer

25. Rear oil seal 26. Transmission27. O-ring

28. Crankshaft position sensor (POS) 29. Gasket 30. Cylinder block heater

31. Connector cap

WBIA0419E

KBIA2549E

Revision: December 20092009 QX56